Cast casting machining process

A processing technology and technology for casting castings, which is applied in the field of foundry processing and can solve the problems of mold sand separation, falling, and pits on the surface of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

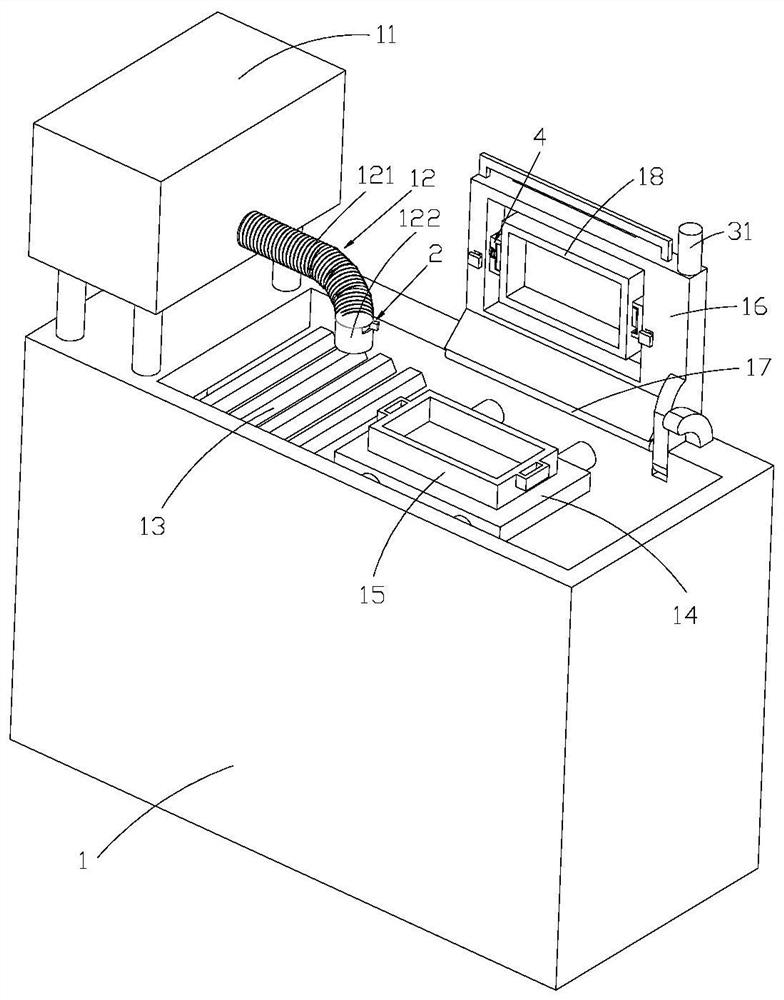

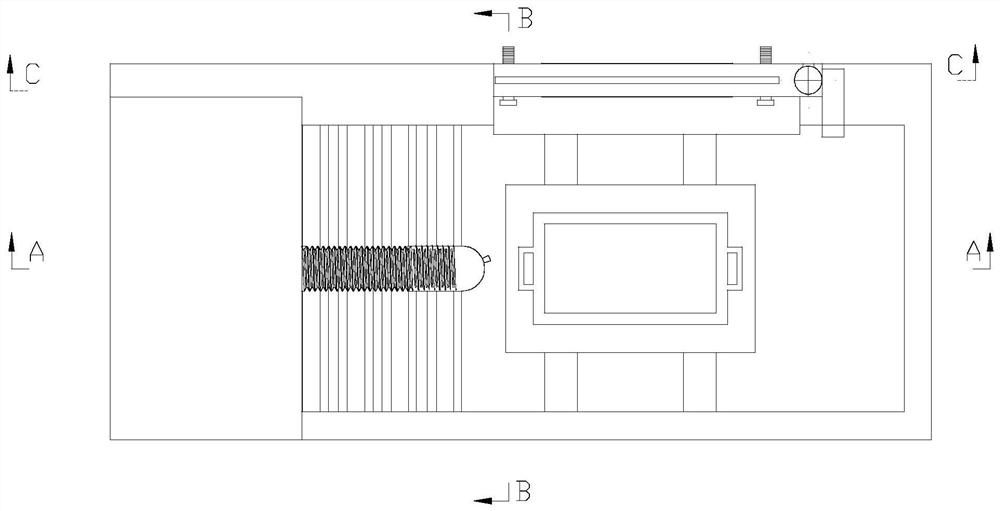

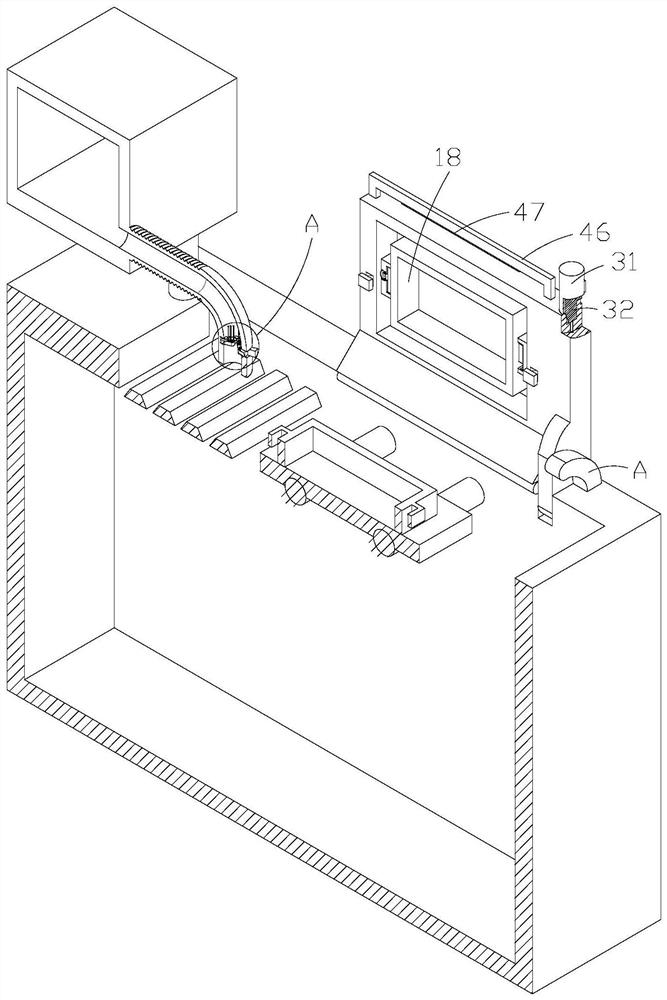

[0027] A casting casting process, characterized in that: comprising the following steps:

[0028] (1) Smelting: Melt the steel in an electric furnace. When the temperature rises to 1600°C, add a refining agent and refine for 15 minutes to obtain molten steel. The sulfur content in the molten steel is less than 0.02%, the phosphorus content is less than 0.02%, and the carbon content is 0.05%, silicon content 0.2%, manganese content 0.35%, nickel content 0.15%;

[0029] (2) Mold preparation: Prepare the casting samples, put the casting samples into the sand mold, process the sand mold through the mold processing table, bake the sand mold at a temperature of 600°C for 10 minutes, and then cool down to 350°C for standby;

[0030] (3) Pouring: pour the molten steel in (1) into the sand mold in (2), the pouring temperature is 1450°C, and the pouring time is 25s. After the pouring is completed, keep it warm for 20 minutes;

[0031] (4) Cooling: After cooling to room temperature, tak...

Embodiment 2

[0040] (1) Smelting: Melt the steel in an electric furnace. When the temperature rises to 1700°C, add a refining agent and refine for 20 minutes to obtain molten steel. The sulfur content in the molten steel is less than 0.02%, the phosphorus content is less than 0.02%, and the carbon content is 0.08%, silicon content 0.25%, manganese content 0.45%, nickel content 0.25%;

[0041] (2) Mold preparation: prepare casting samples, put the casting samples into the molding sand mold, process the sand mold through the mold processing table, bake the sand mold at a temperature of 700°C for 15 minutes, and then cool down to 380°C for standby;

[0042] (3) Pouring: pour the molten steel in (1) into the sand mold in (2), the pouring temperature is 1550°C, and the pouring time is 30s. After the pouring is completed, keep it warm for 25 minutes;

[0043] (4) Cooling: After cooling to room temperature, take out the formed casting, clean the surface, and get the casting after polishing.

[0...

Embodiment 3

[0047] (1) Smelting: Melt the steel in an electric furnace. When the temperature rises to 1650°C, add a refining agent and refine for 17 minutes to obtain molten steel. The sulfur content in the molten steel is less than 0.02%, the phosphorus content is less than 0.02%, and the carbon content is 0.07%, silicon content 0.23%, manganese content 0.40%, nickel content 0.20%;

[0048] (2) Mold preparation: prepare casting samples, put the casting samples into the molding sand mold, process the sand mold through the mold processing table, bake the sand mold at a temperature of 650°C for 13 minutes, and then cool down to 365°C for standby;

[0049] (3) Pouring: pour the molten steel in (1) into the sand mold in (2), the pouring temperature is 1500°C, and the pouring time is 27s. After the pouring is completed, keep it warm for 23 minutes;

[0050] (4) Cooling: After cooling to room temperature, take out the formed casting, clean the surface, and get the casting after polishing.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com