Patents

Literature

30results about How to "Suitable for replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

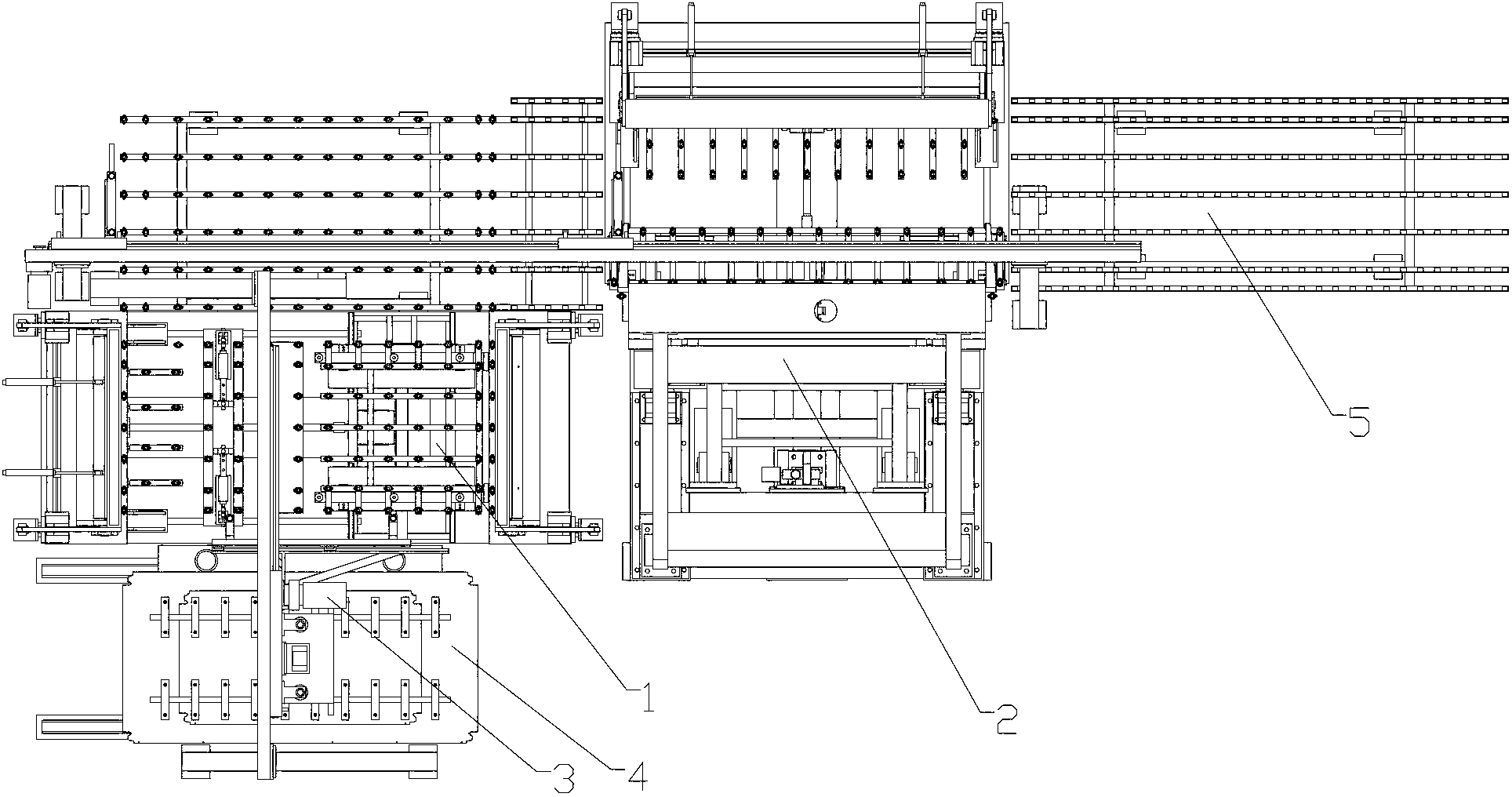

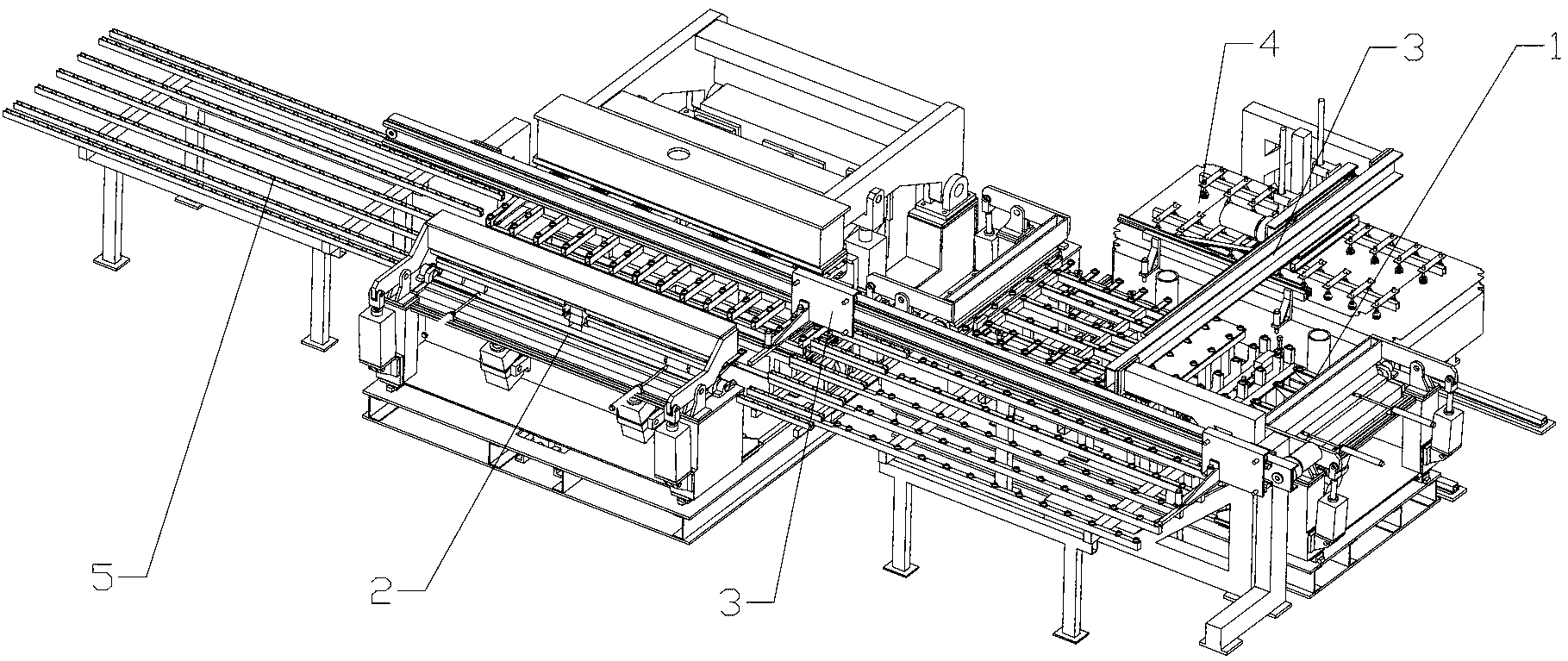

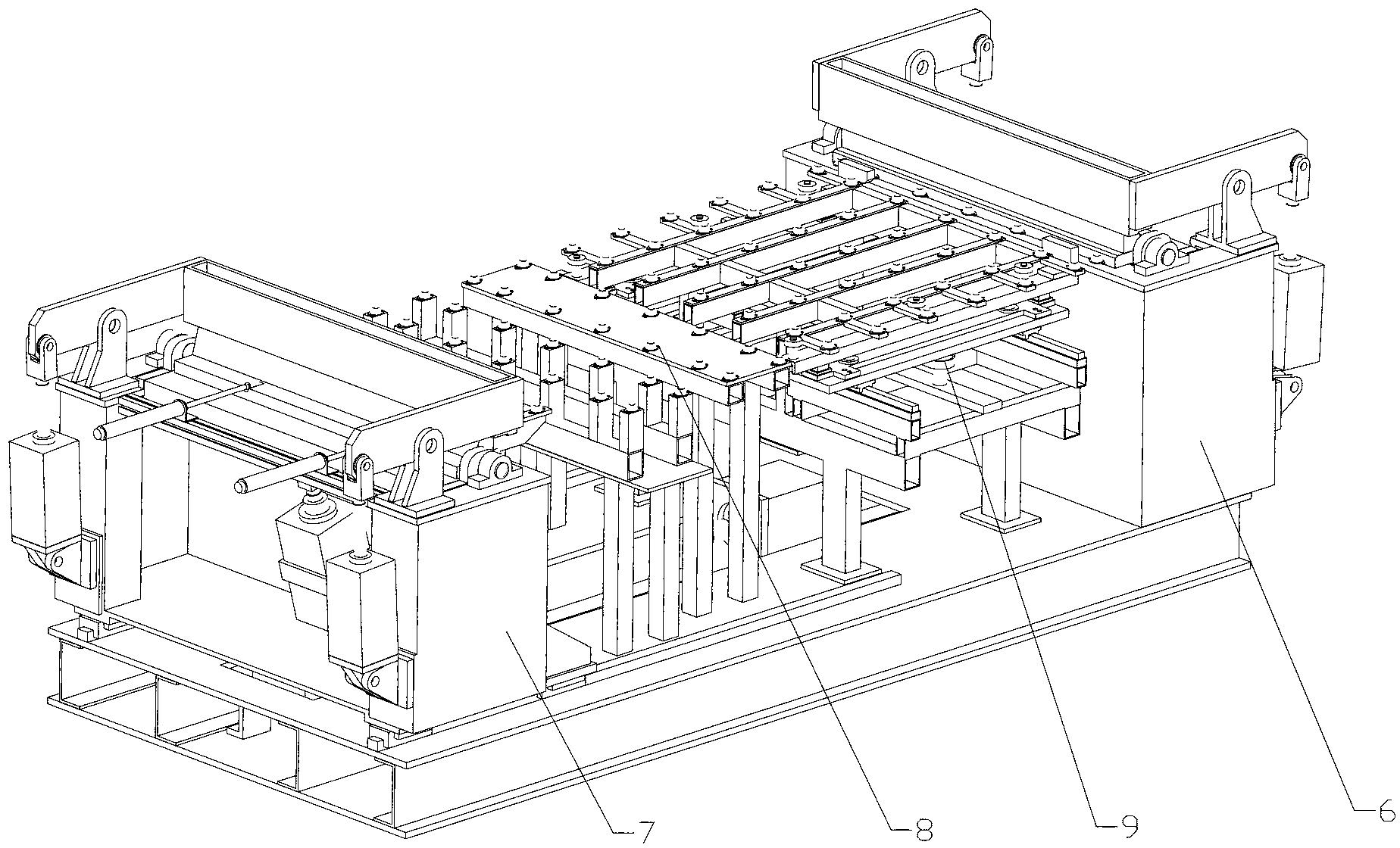

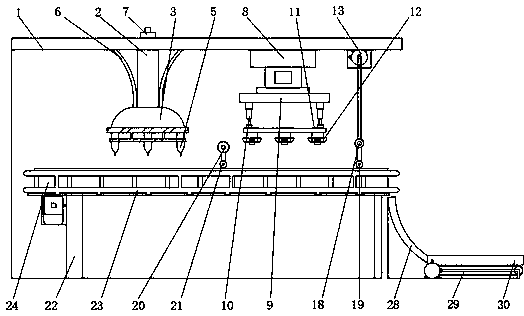

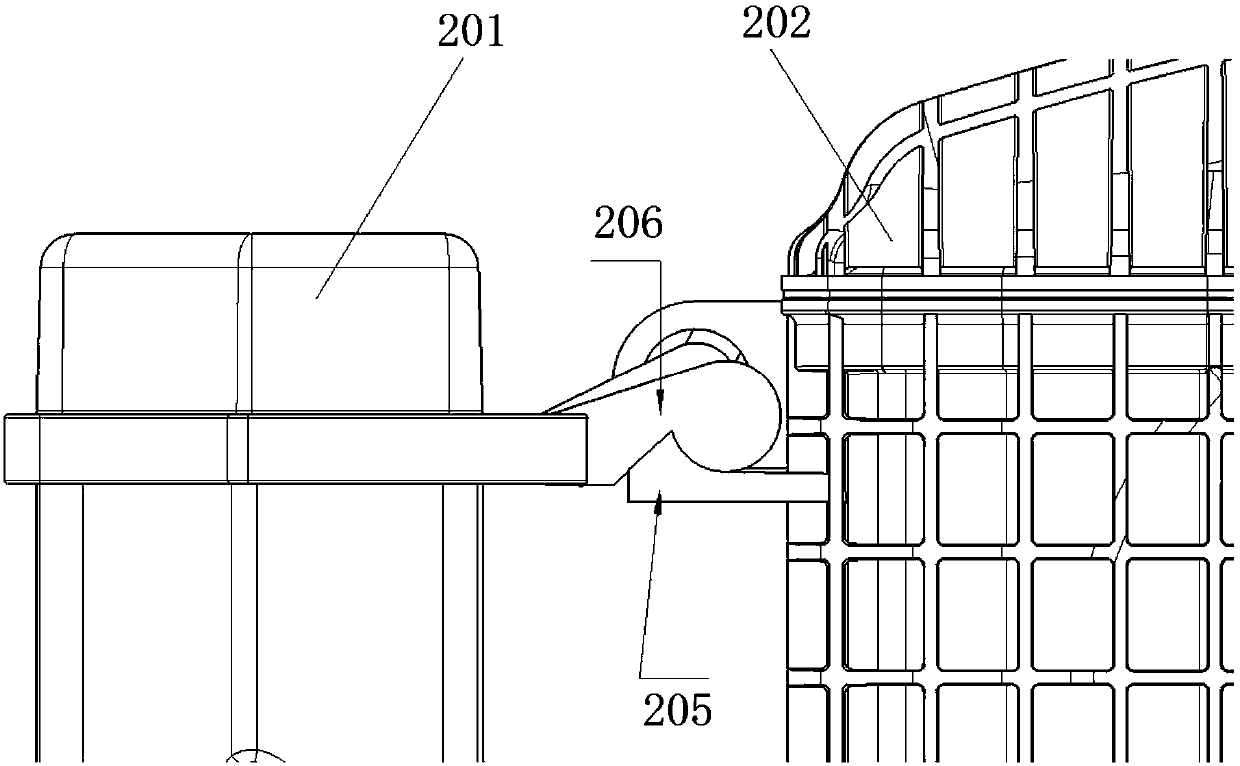

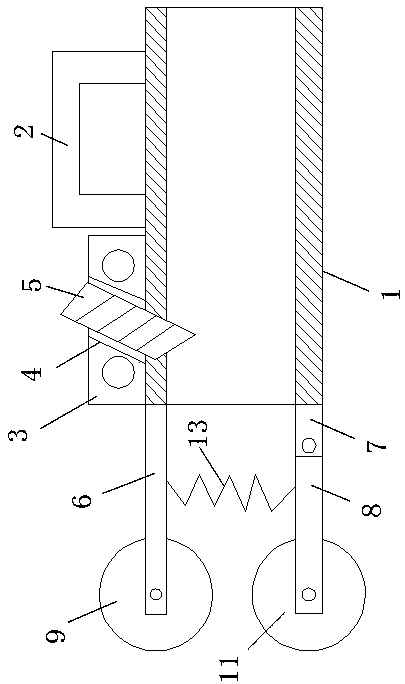

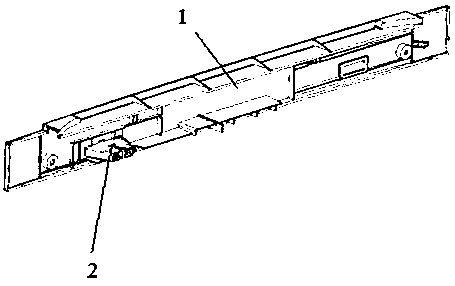

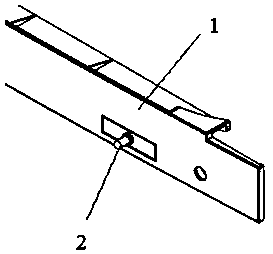

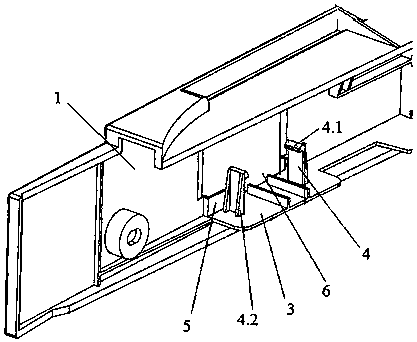

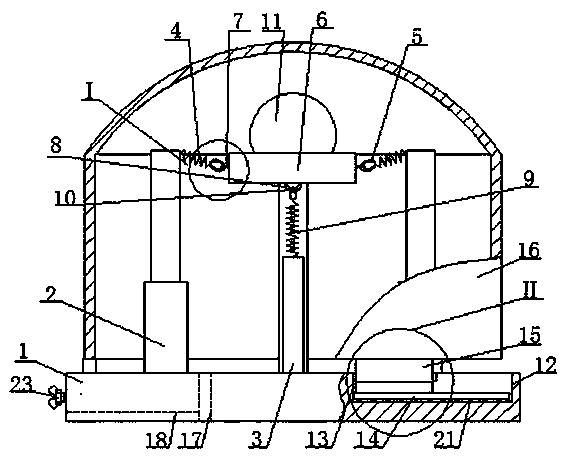

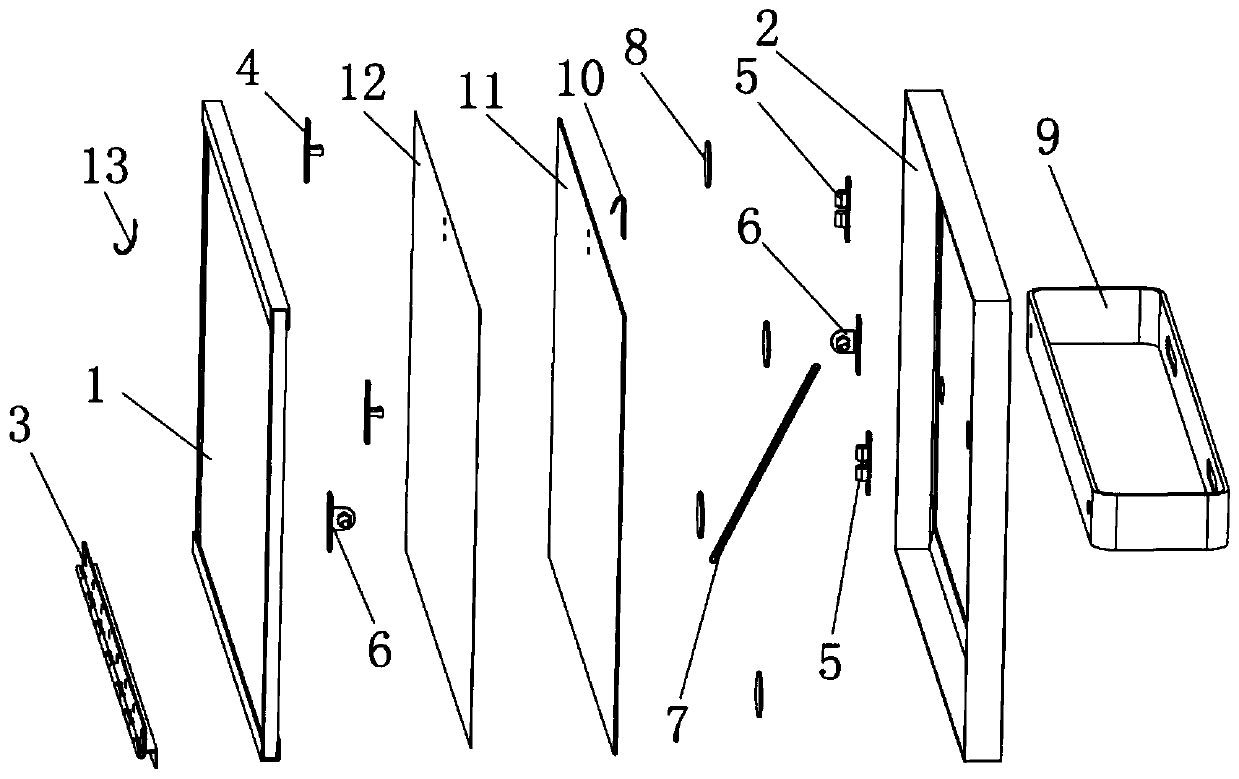

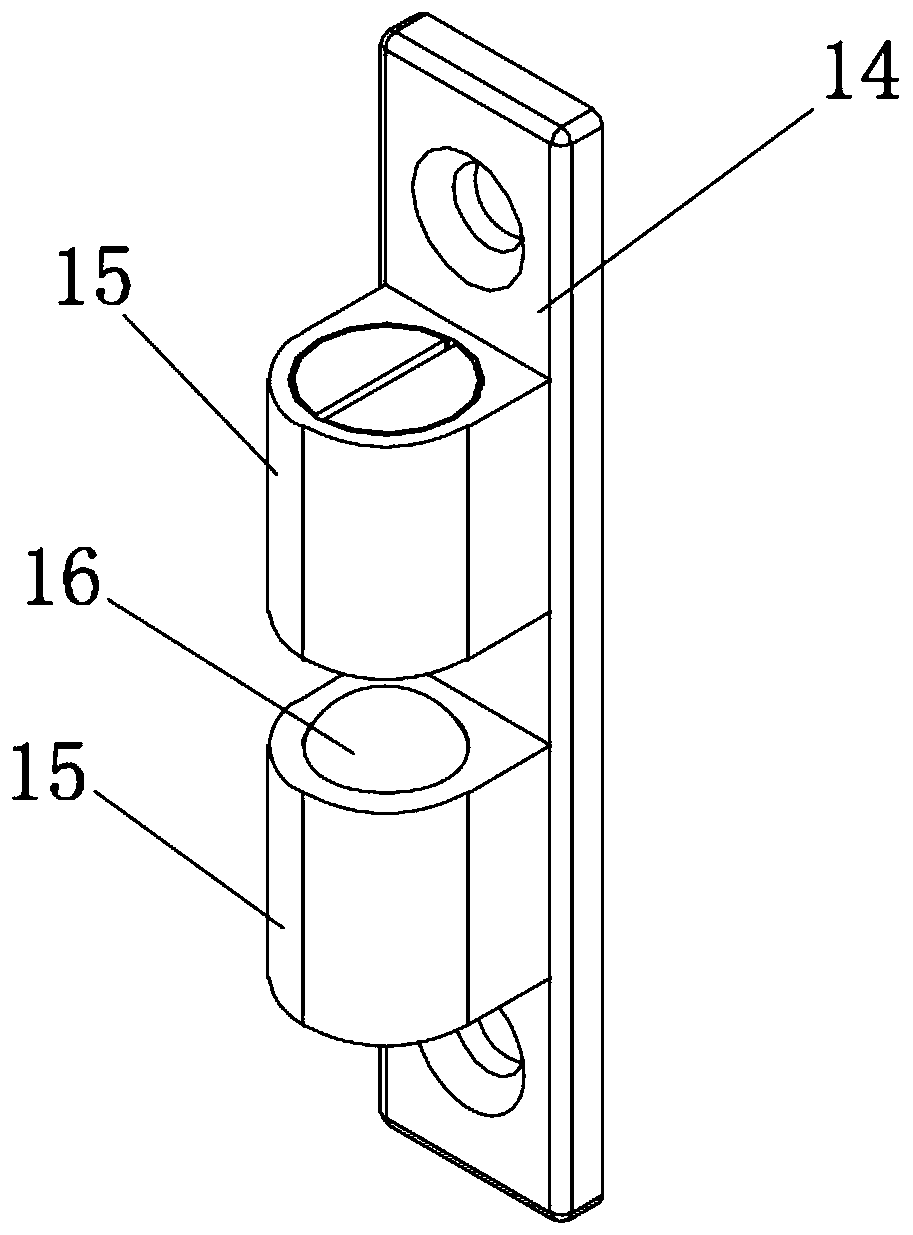

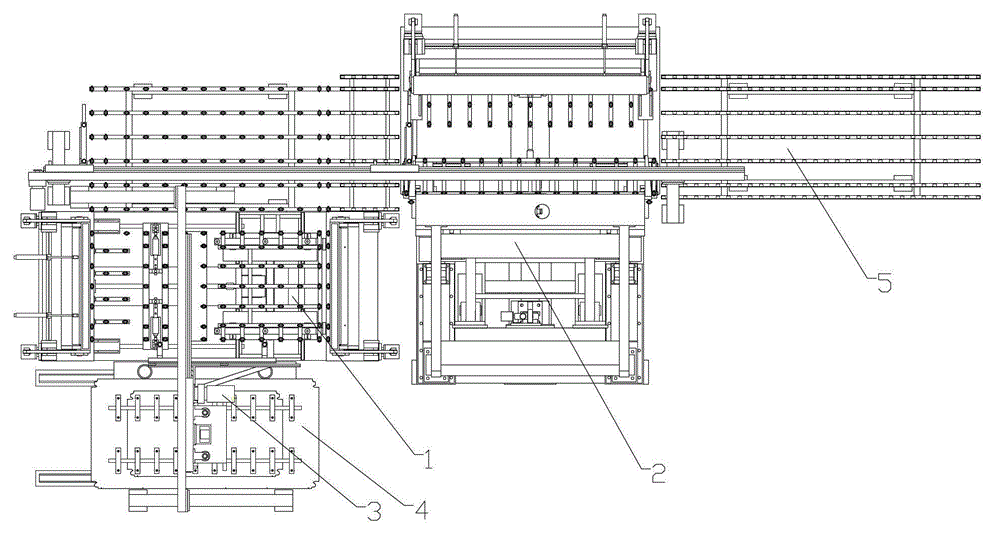

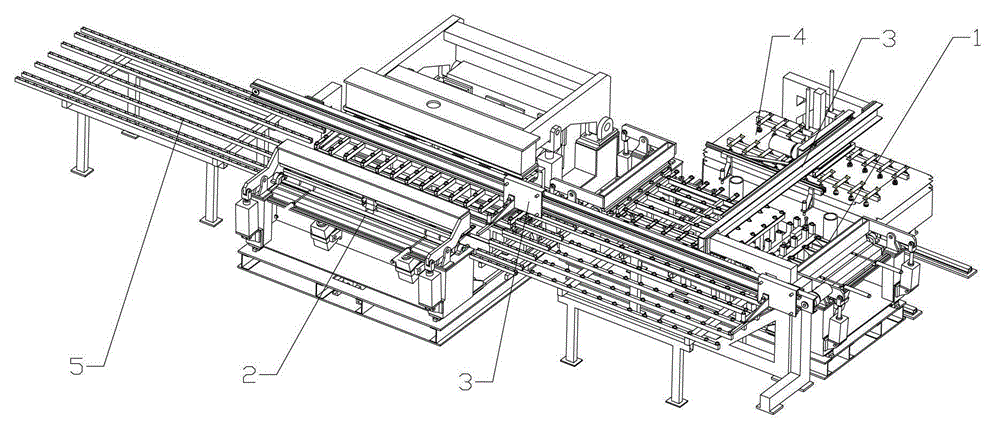

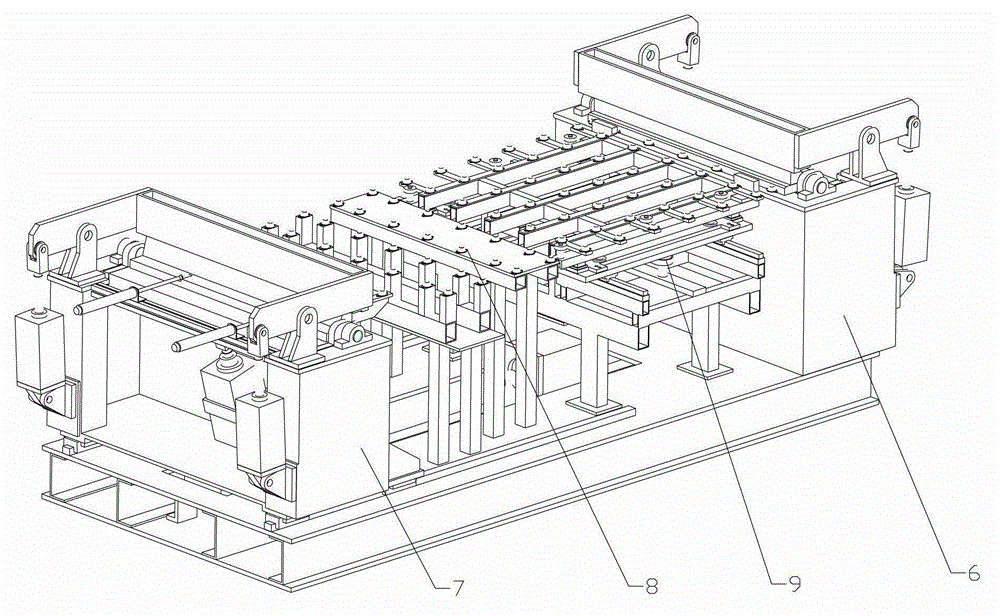

Four-side bending system

ActiveCN102909244AImprove combination efficiencyEasy to arrange for productionMaterial transferPress brake

The invention relates to a four-side bending system comprising a first bending unit, a second bending unit and a material transferring device, wherein the first bending unit is used for completing the bending work of a group of opposite sides of a material to be bent; the second bending unit is used for completing the bending work of the other group of opposite sides of the material to be bent; and the material transferring device is used for shifting the material according to the process. The first bending unit comprises a first static bending machine, a first movable bending machine, a first working table and a first positioning part, wherein the first static bending machine and the first movable bending machine are oppositely placed on a main frame; and the working table and the positioning part are placed between the first static bending machine and the first movable bending machine. The second bending unit comprises a second static bending machine, a second movable bending machine, a second working table and a second positioning part, wherein the second static bending machine and the second movable bending machine are oppositely placed on the main frame; and the second working table and the second positioning part are placed between the second static bending machine and the second movable bending machine. The four-side bending system is relatively high in production efficiency, relatively low in manufacture cost and simple to maintain and is suitable for various productions.

Owner:YINDU KITCHEN EQUIP

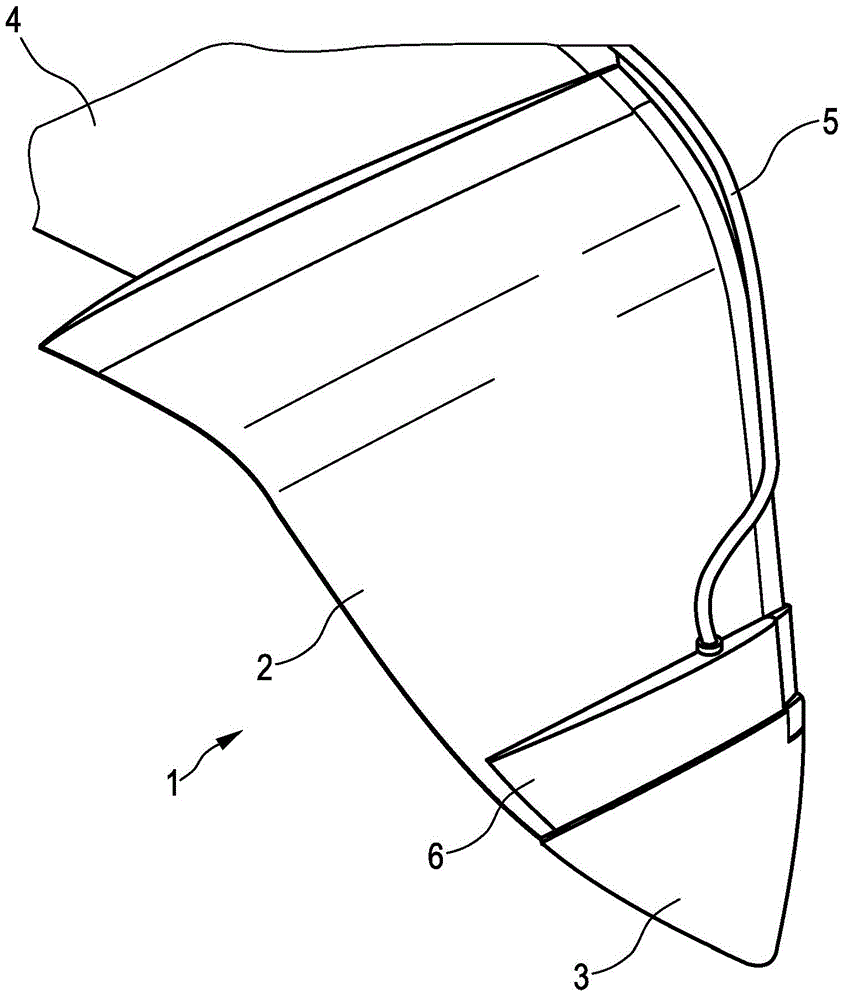

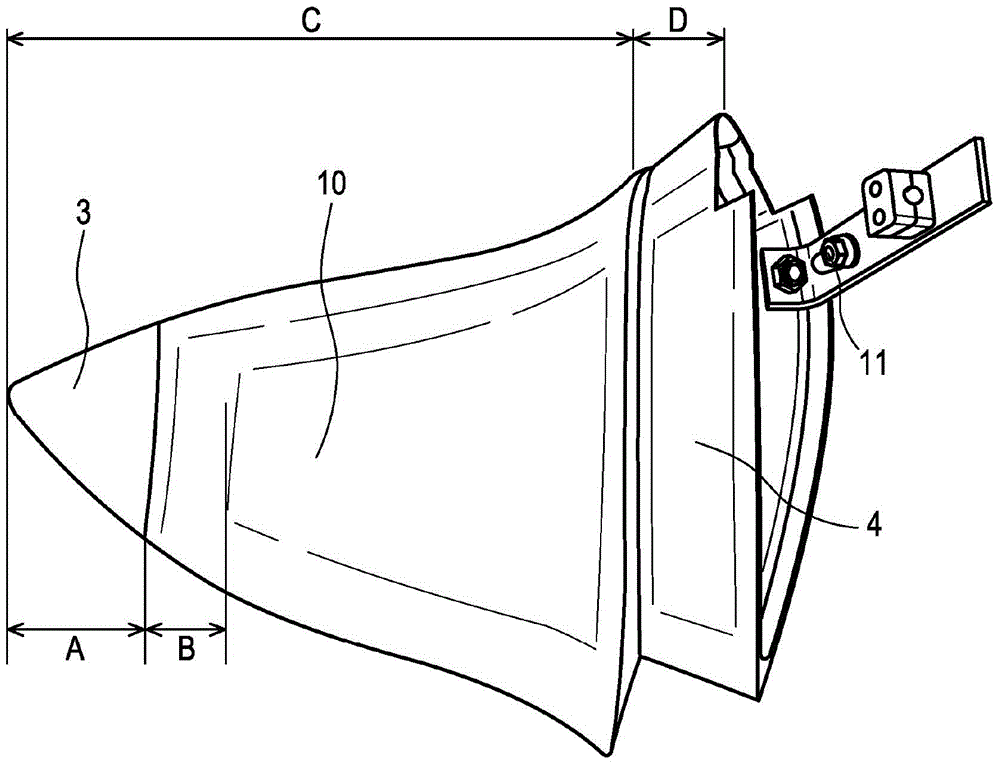

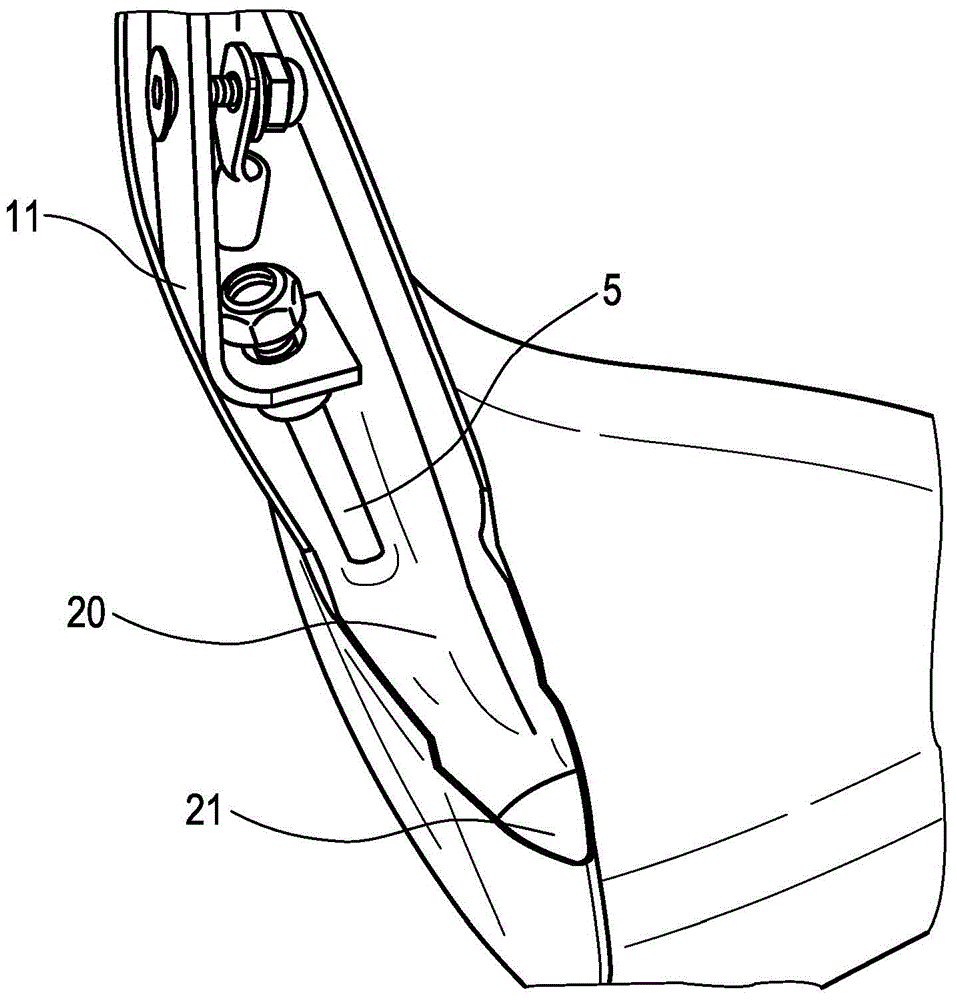

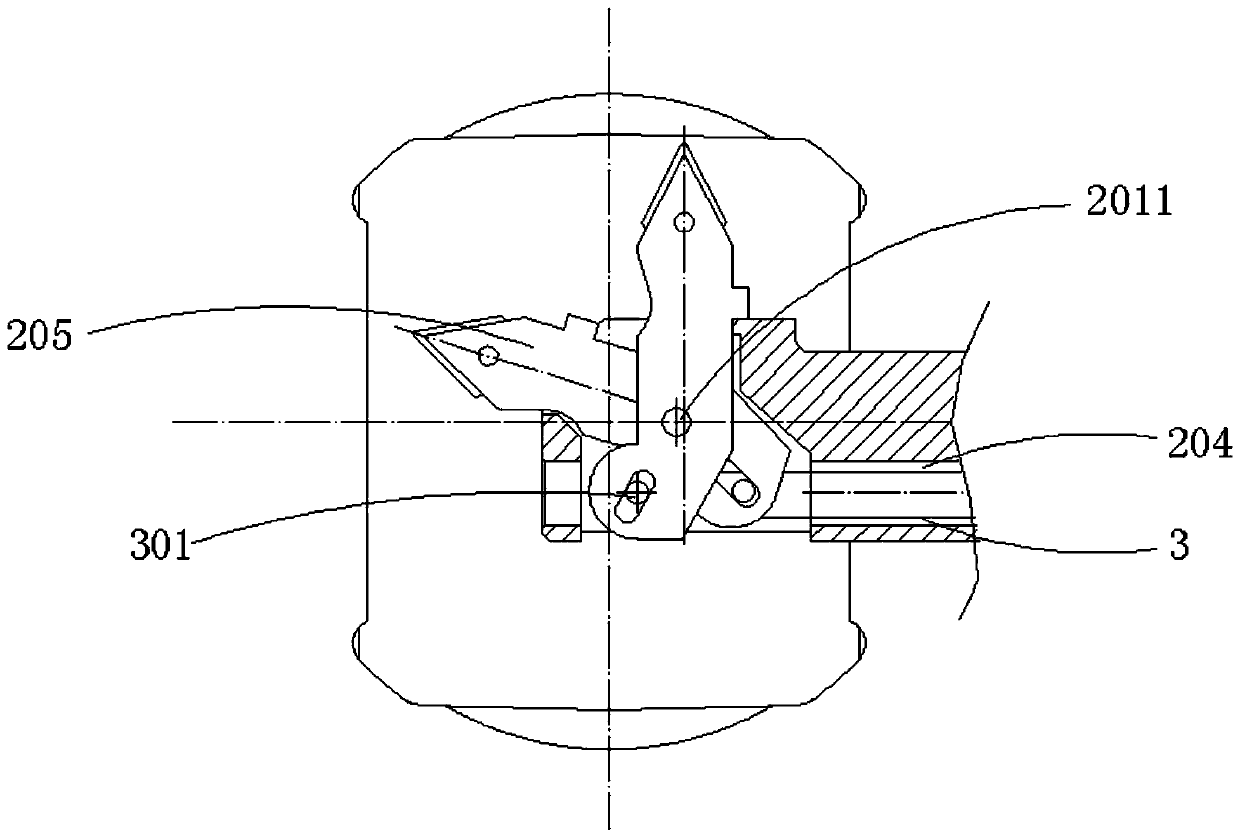

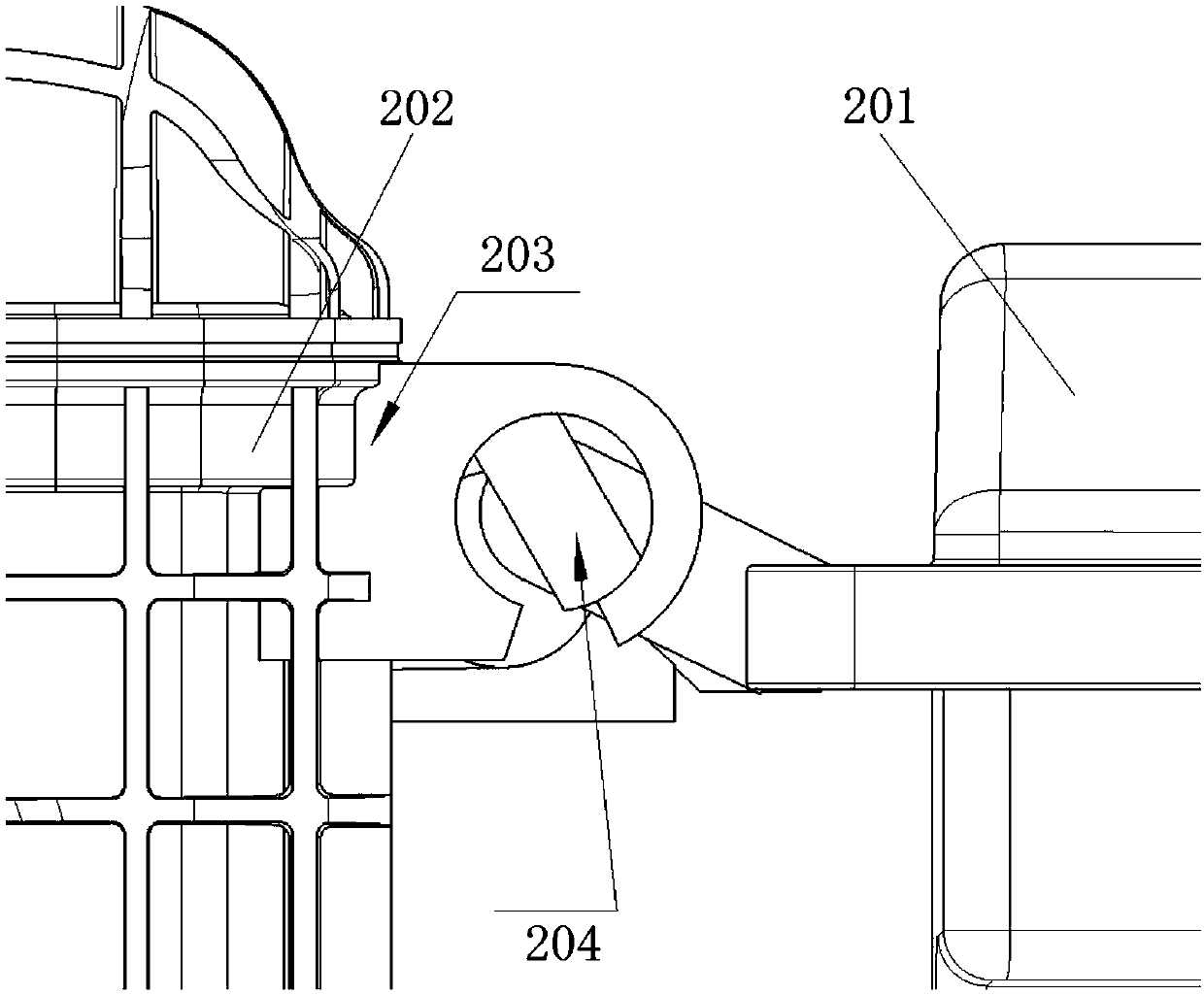

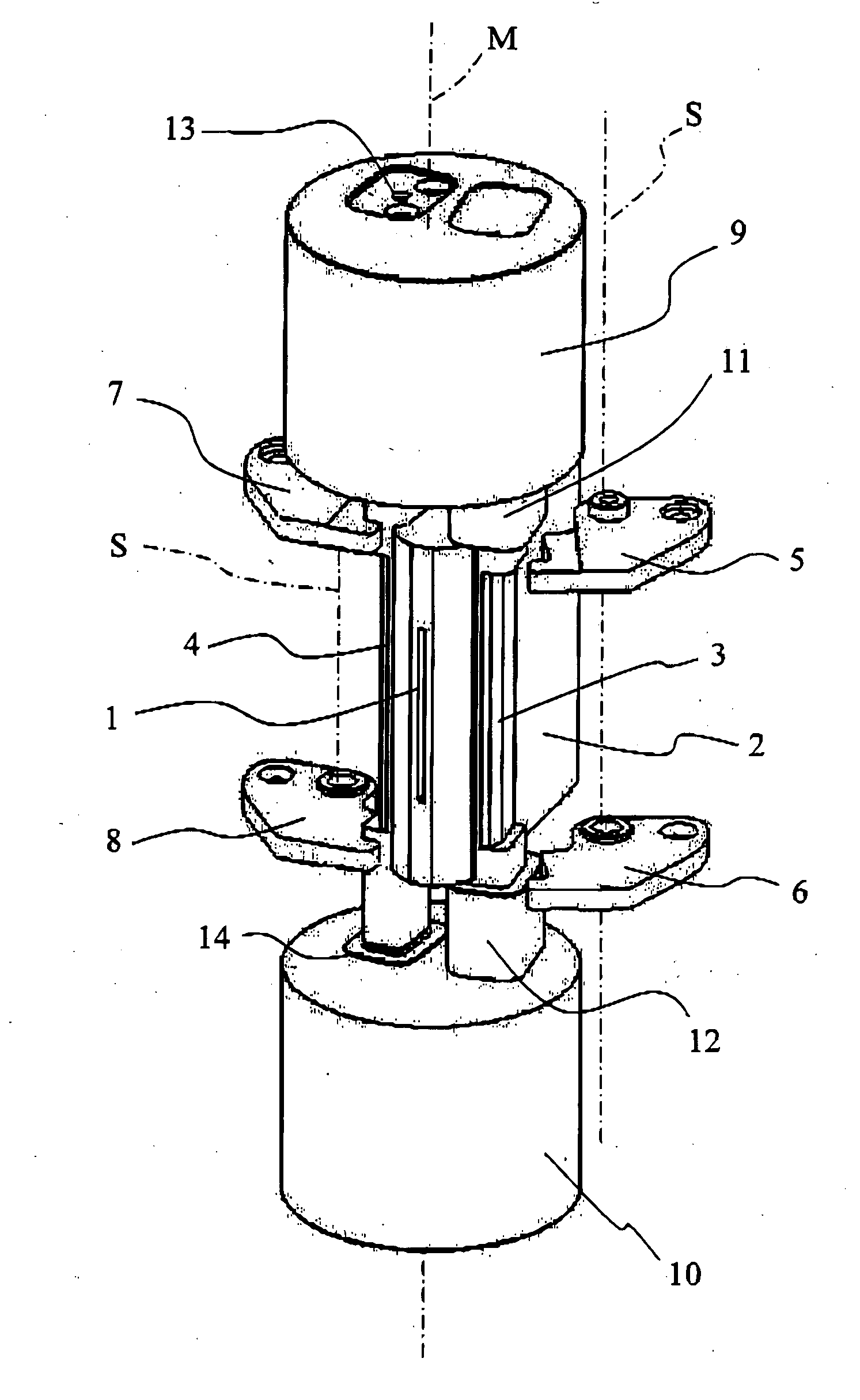

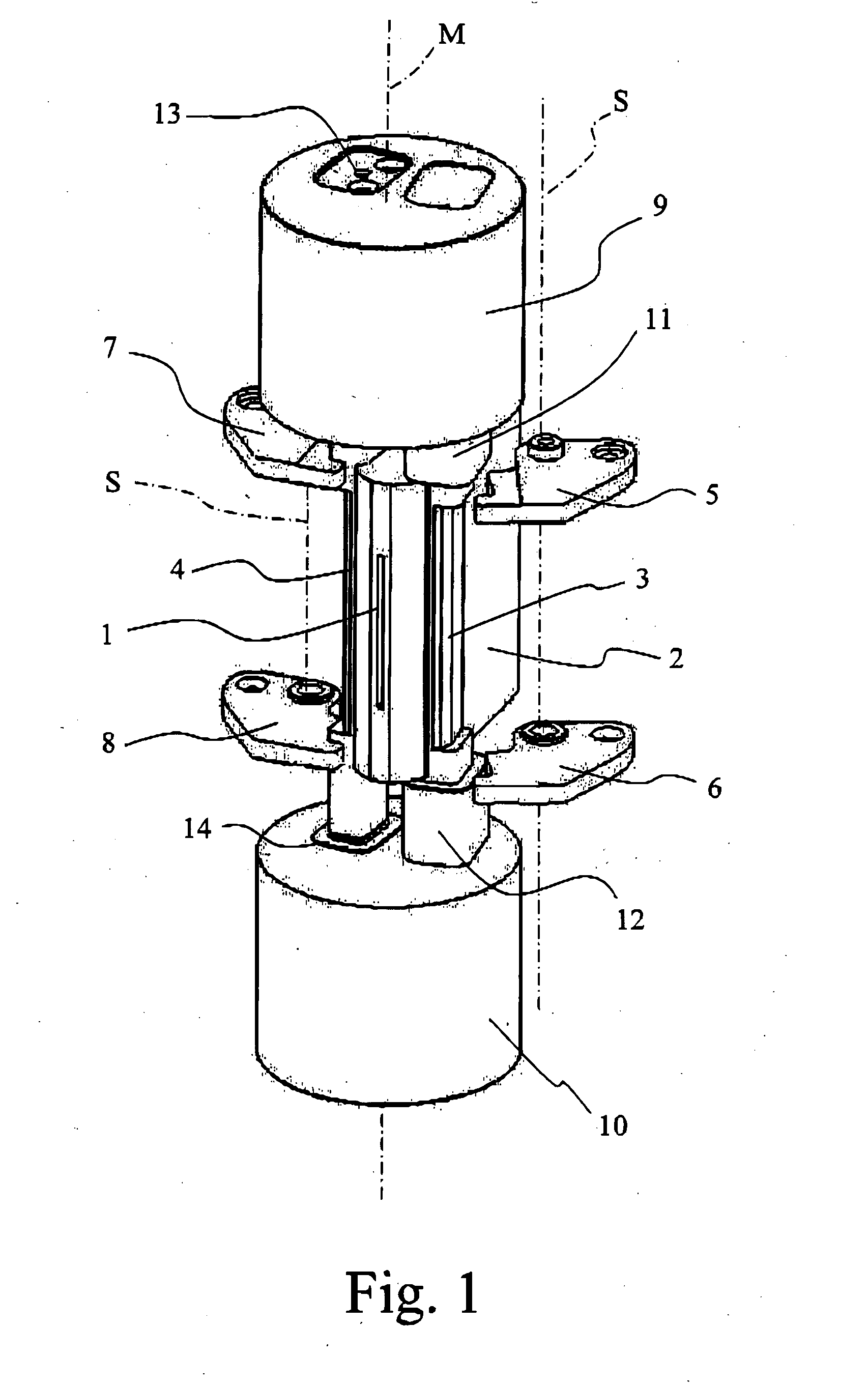

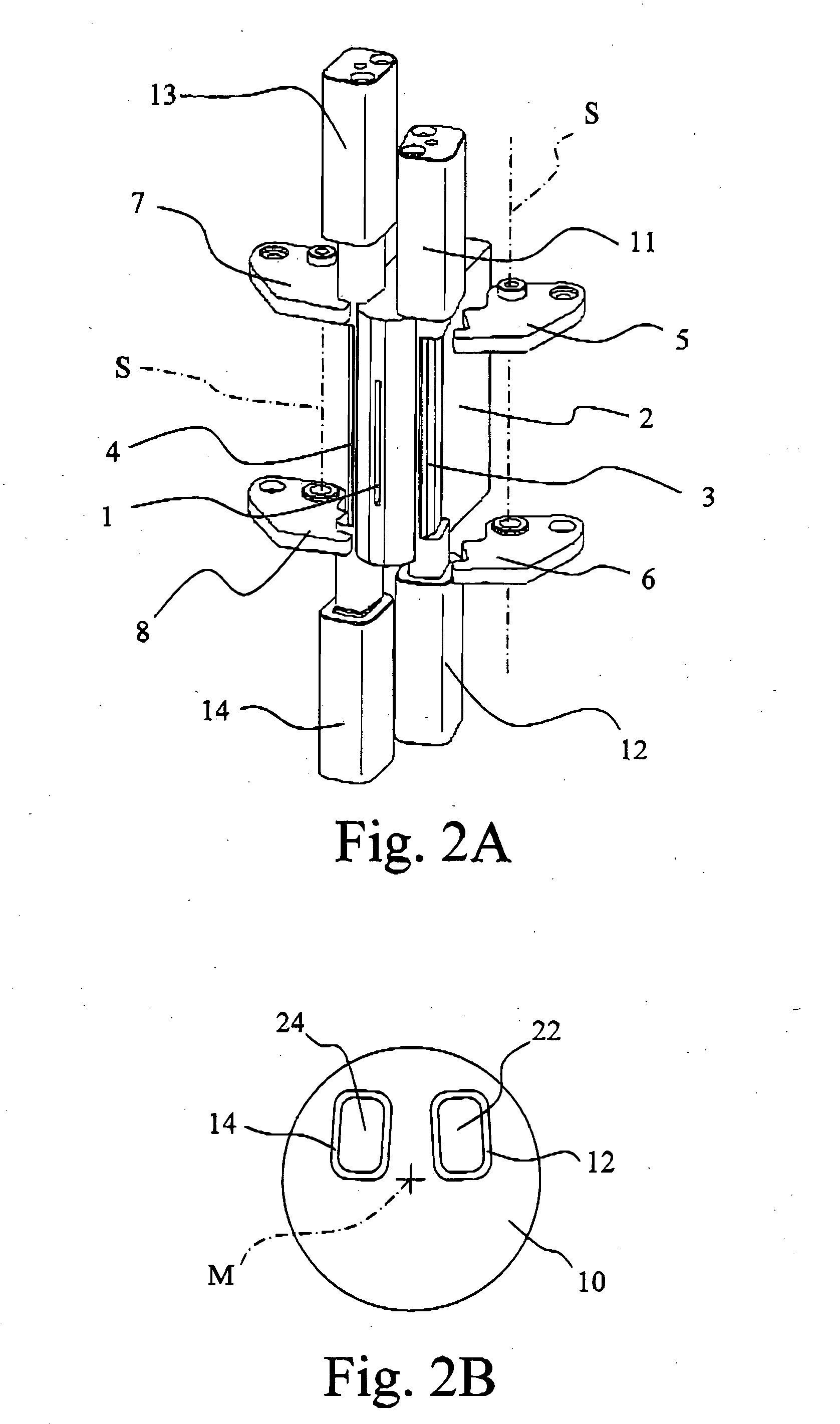

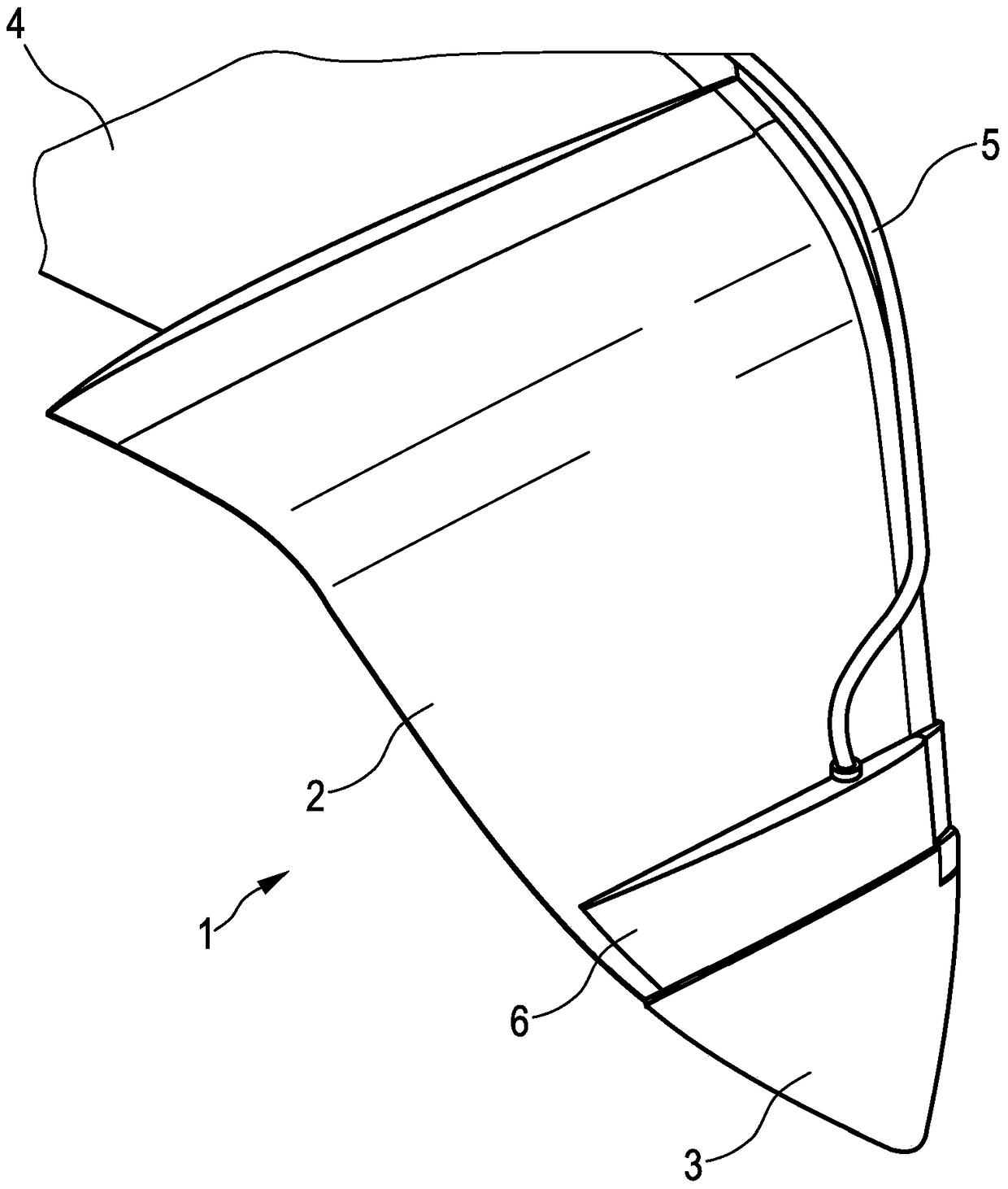

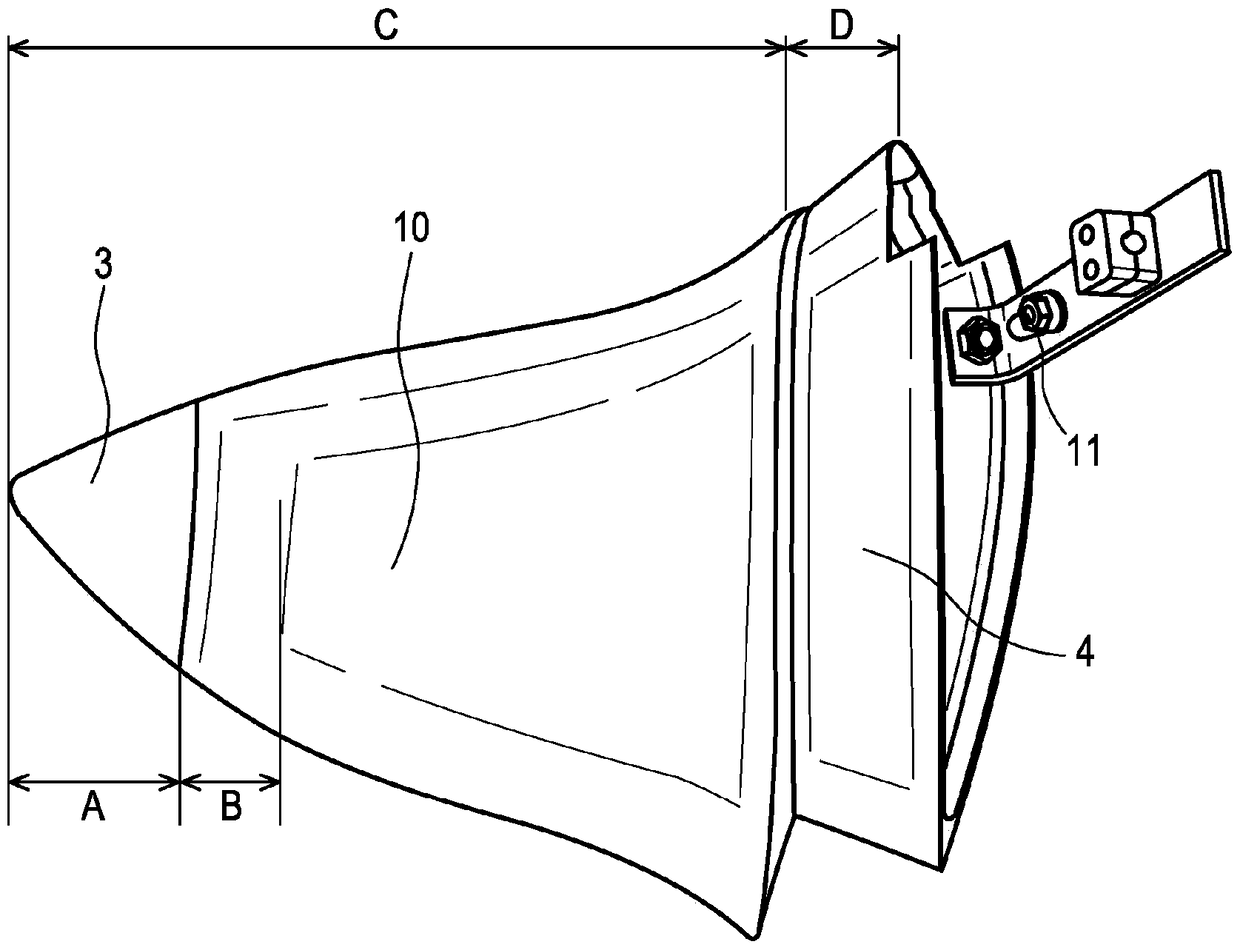

Rotor blade tip

InactiveCN104797815AAvoid damageEasy to manufactureEngine manufactureFinal product manufactureEngineeringTurbine

The invention relates to a rotor blade (30) of a wind turbine (100), comprising a main blade part and a blade tip (260), the blade tip (260) being detachably fastened to the main part by means of a connecting device (202). The connecting device (202) comprises a tip section (206) fastened to the blade tip (260) and a base section (204) for receiving the tip section (206), said base section being fastened to the main blade part. The tip section (206) comprises at least one securing means (242) for securing the tip section (206) to the base section (204), said securing means extending at least to the base section (204). The securing means (242) can be actuated through an opening (286) in the surface (282) of the blade tip (260) to secure the tip section.

Owner:WOBBEN PROPERTIES GMBH

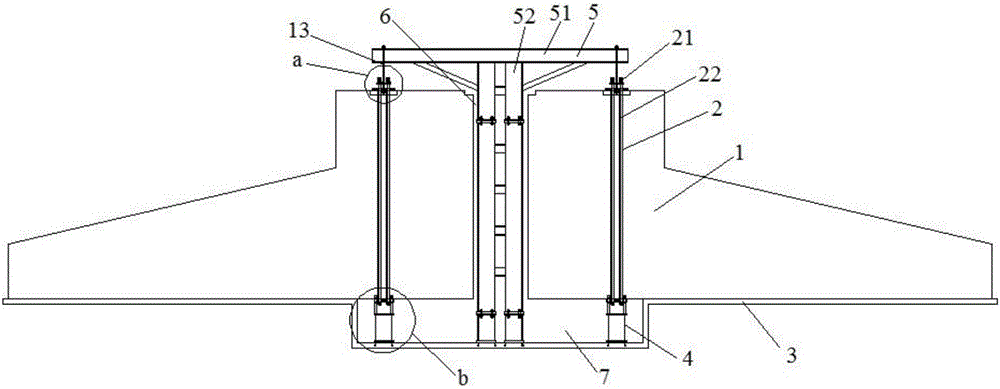

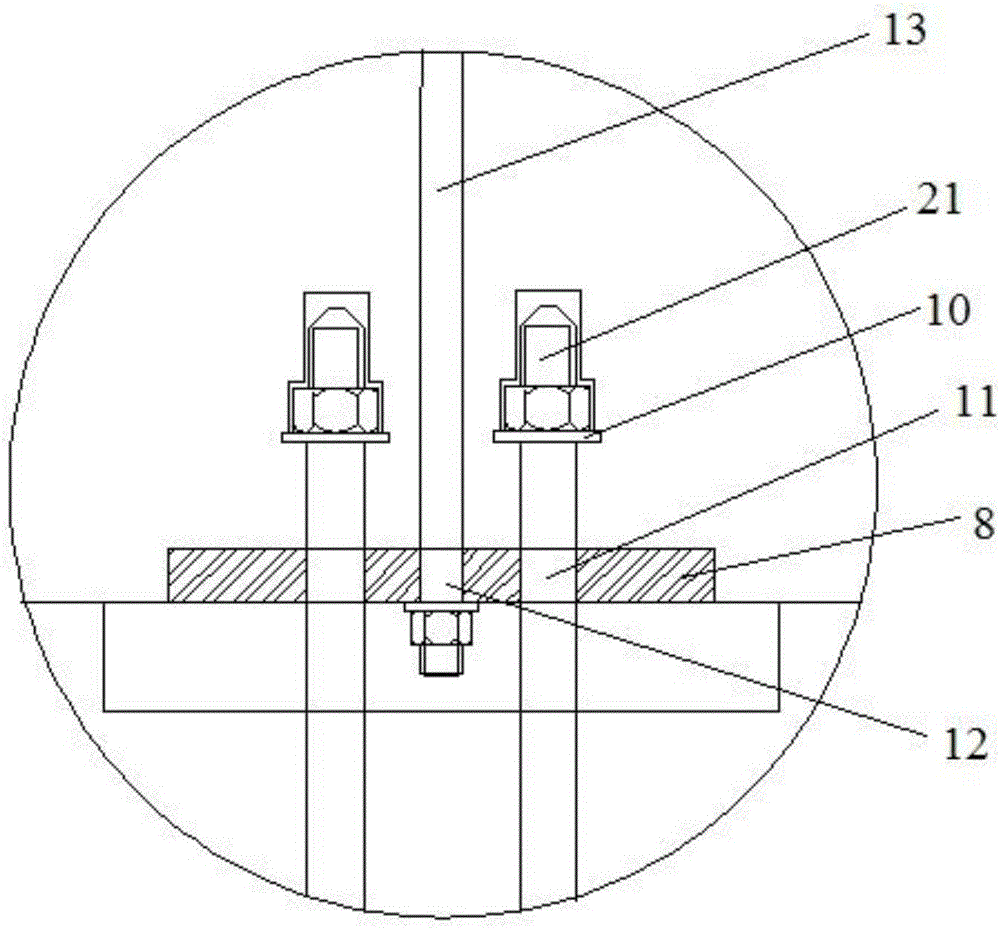

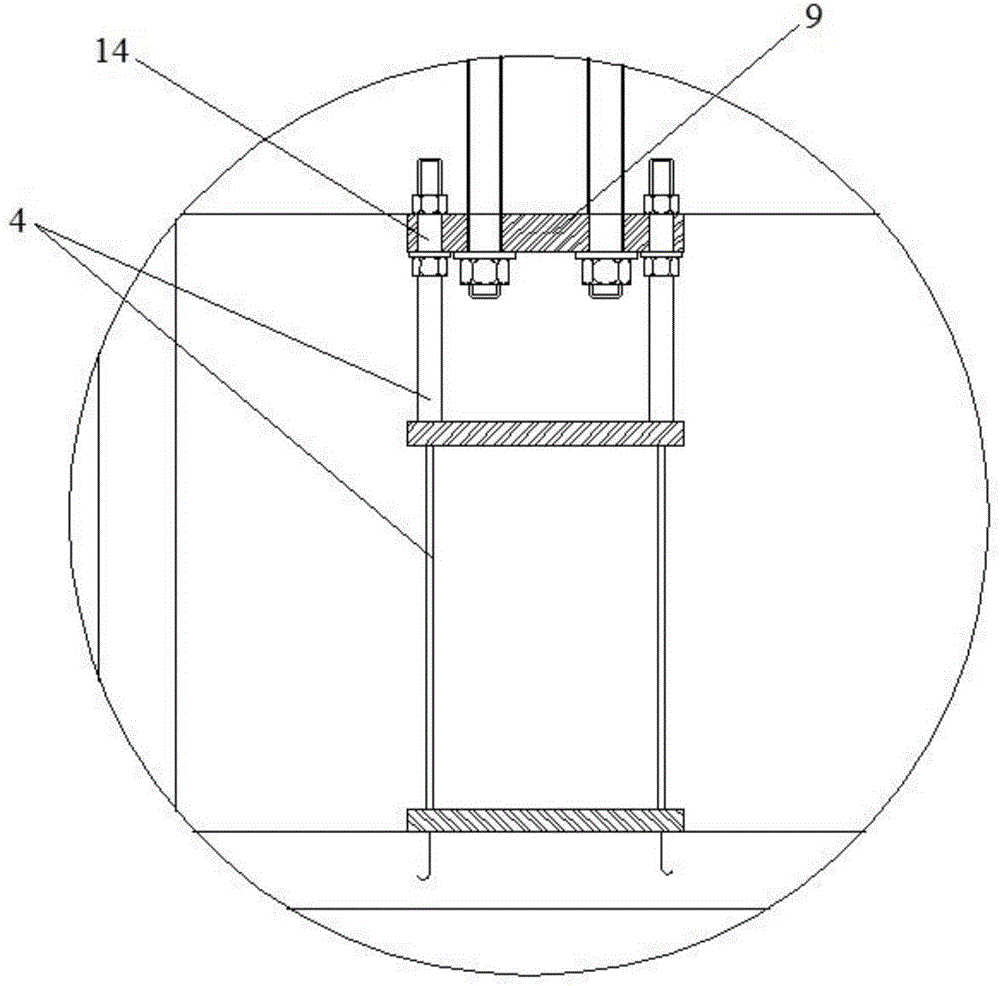

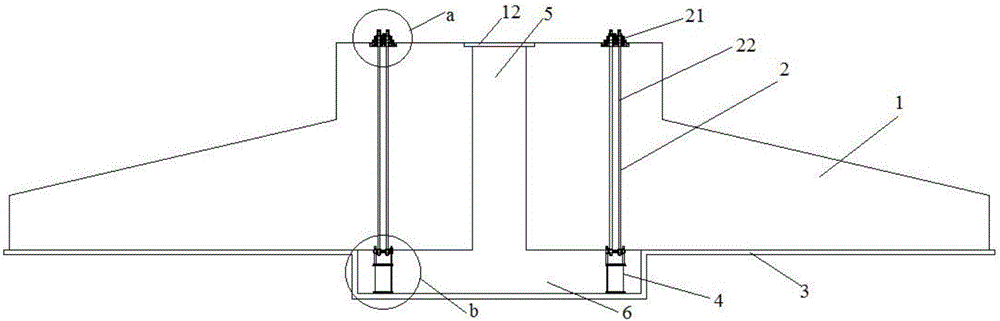

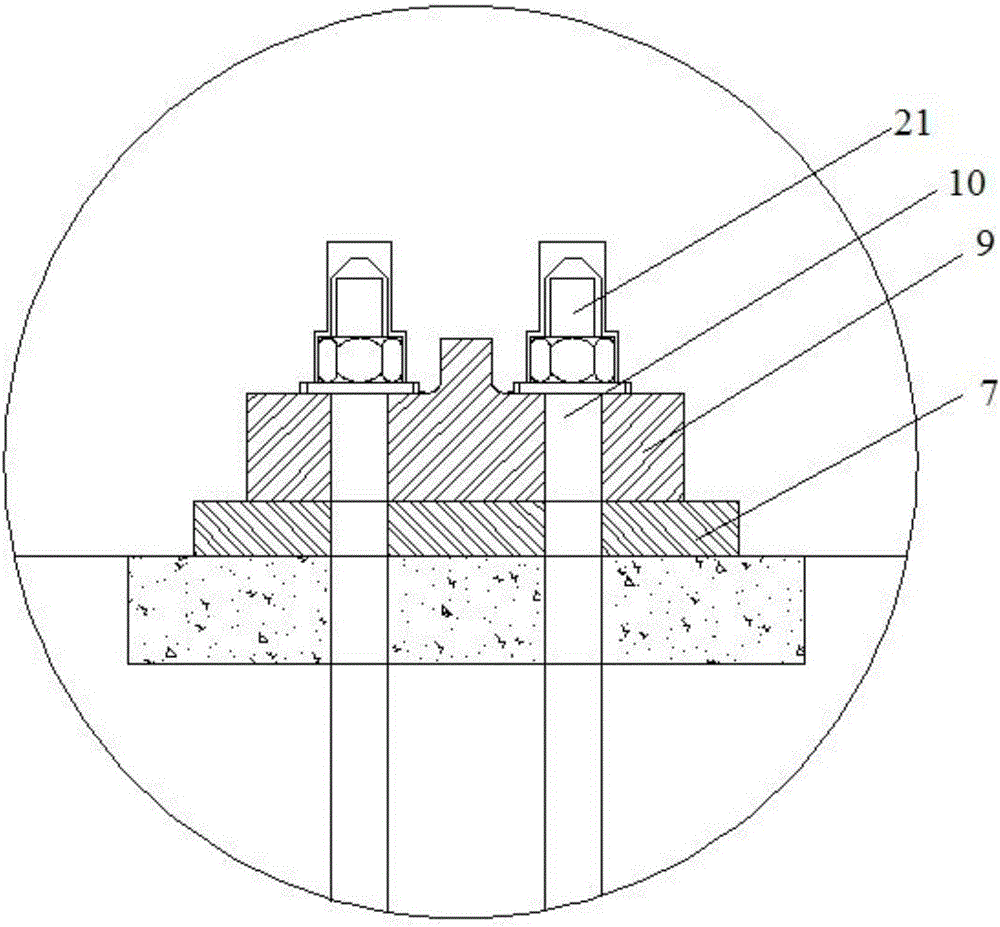

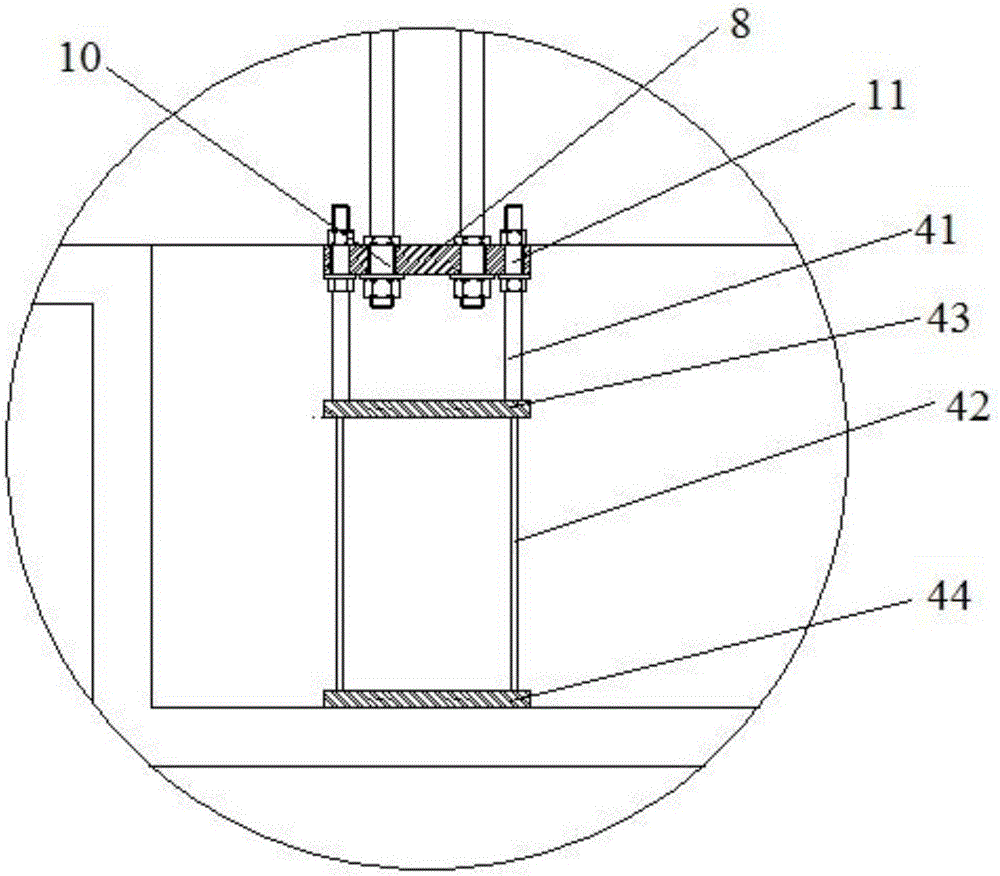

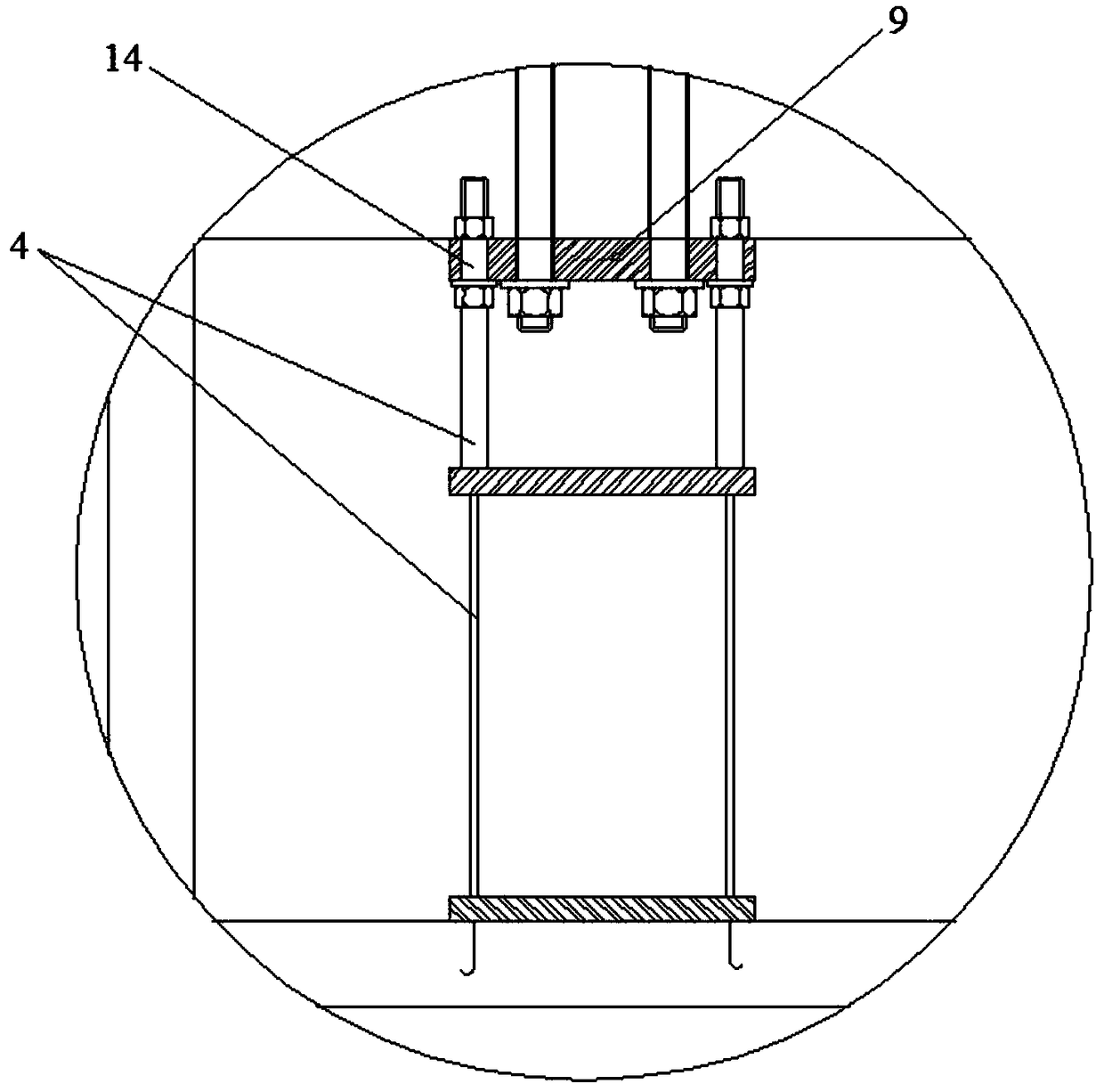

Wind power tower foundation with support and construction technology of foundation

The invention relates to a wind power tower foundation with a support and a construction technology of the foundation. The foundation comprises a wind power tower foundation body, a ground anchor cage, a cushion layer, a ground anchor cage supporting column and the support. The ground anchor cage is vertically embedded in the wind power tower foundation body, the cushion layer is arranged below the ground anchor cage and the wind power tower foundation body, a hollow cavity is formed in the wind power tower foundation body, the cushion layer is arranged in the center of the lower surface of the wind power tower foundation body and downwards indented to form a concave cavity, the support used for fixing the ground anchor cage is arranged in the hollow cavity, the upper end of the support extends out of the upper portion of the hollow cavity and is fixedly connected with the ground anchor cage and the wind power tower foundation body, and the lower end of the support is fixedly connected with the cushion layer. The invention further provides a corresponding construction technological method. Installation is firm and reliable, and the support can be repeatedly used. The wind power tower foundation with the support and the construction technology of the foundation have the advantages that damaged anchor bolts can be replaced, and the support can be repeatedly used.

Owner:瑞风能源(武汉)工程技术有限公司

Process for preparing fermorite-doped biological active bone cement

InactiveCN101444639ASuitable for repairSuitable for replacementImpression capsDentistry preparationsManufacturing technologyO-Phosphoric Acid

The invention discloses a process for preparing strontium-doped calcium polyphosphate biological active bone cement. The cement solid phase adopted by the process is a mixture comprising tracalcium phosphate and Alpha-calcium phosphate which are distributed in a certain grain fineness and prepared according to a certain molar ratio, wherein, the Alpha-calcium phosphate strontium salt powder is a mixture comprises Alpha-SrxCa3-x(PO4)2 or Alpha-Sr3(PO4)2 and Alpha-Ca3(PO4)2 powder which are mixed by a certain molar ratio; the aqueous phase is a water deionized dilute phosphoric acid solution or a dilute phosphoric acid solution with the concentration being lower than 2 mol / l; the solid-to-liquid mass ratio is 1.0 to 4.0; and the final product under the physiological environment is strontium-doped calcium polyphosphate hydroxylapatite. The cement has the advantages that the strontium doping content and the calcium strontium / phosphorus ratio are adjustable; the manufacturing technology is simpler; and the like. Compared with calcium phosphate bone cement of other types, the biological active bone cement has wider application prospect.

Owner:XI AN JIAOTONG UNIV

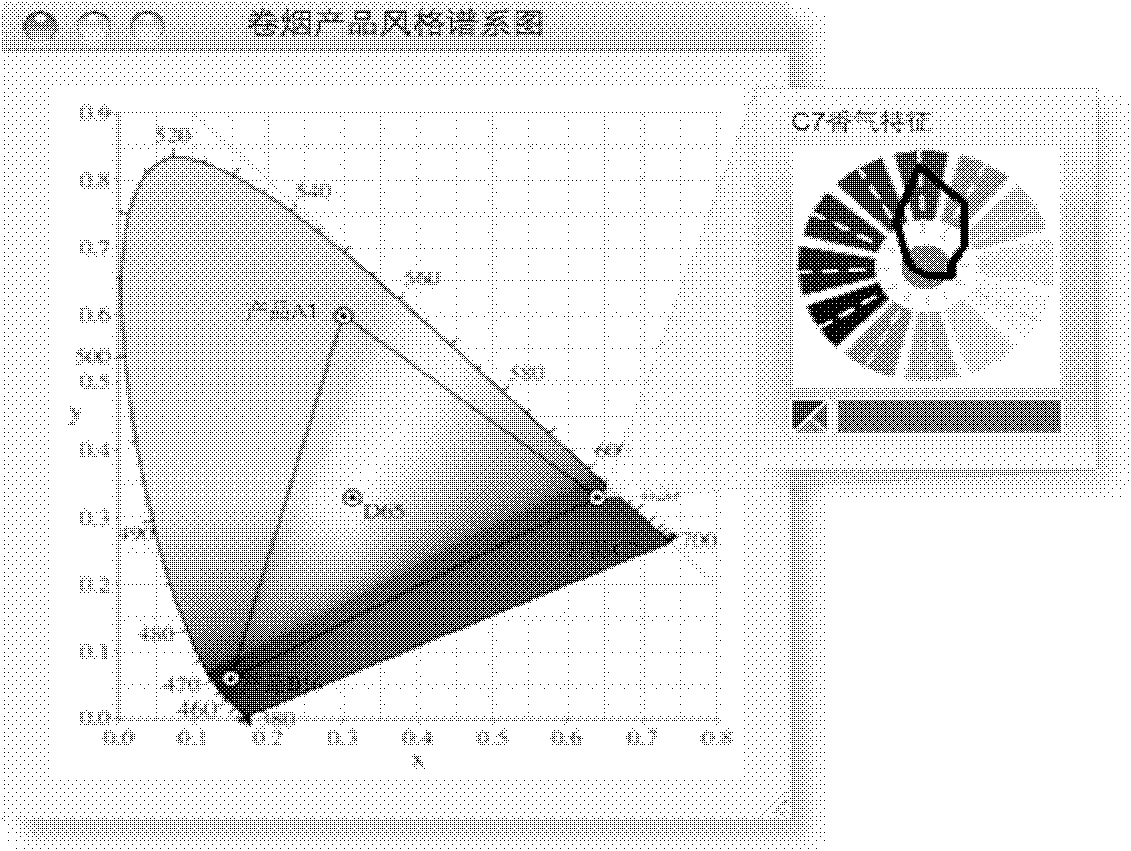

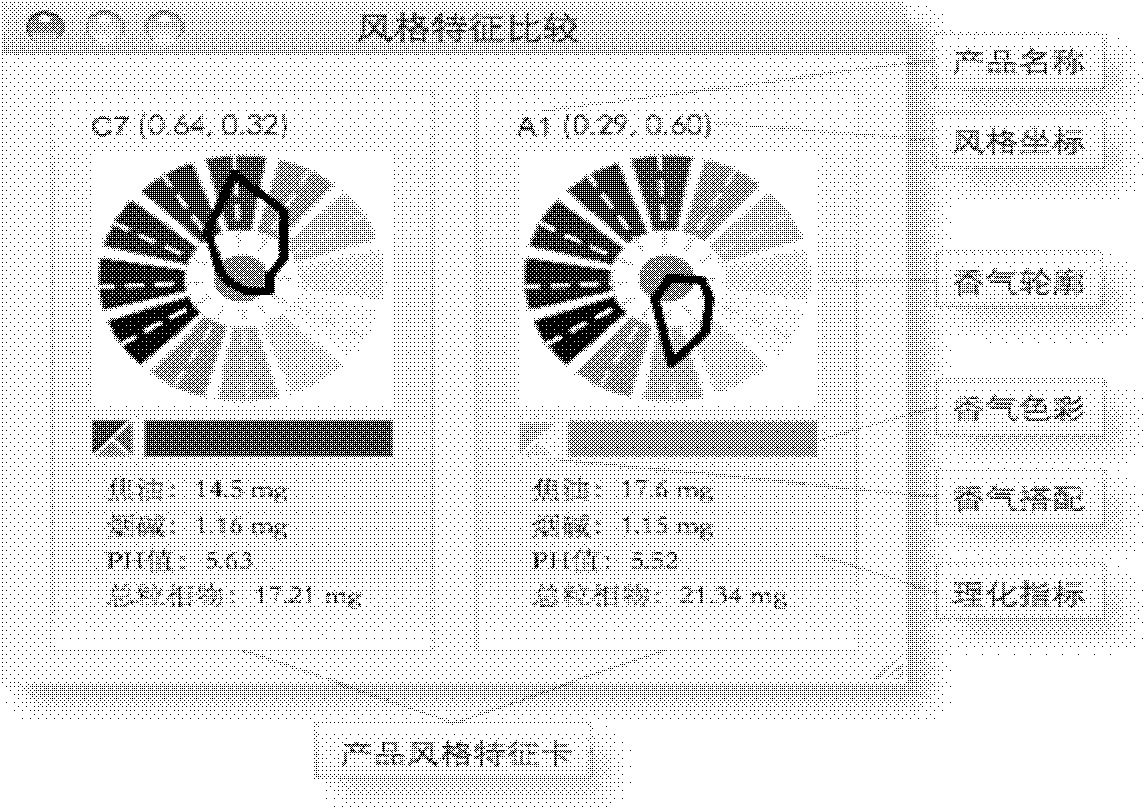

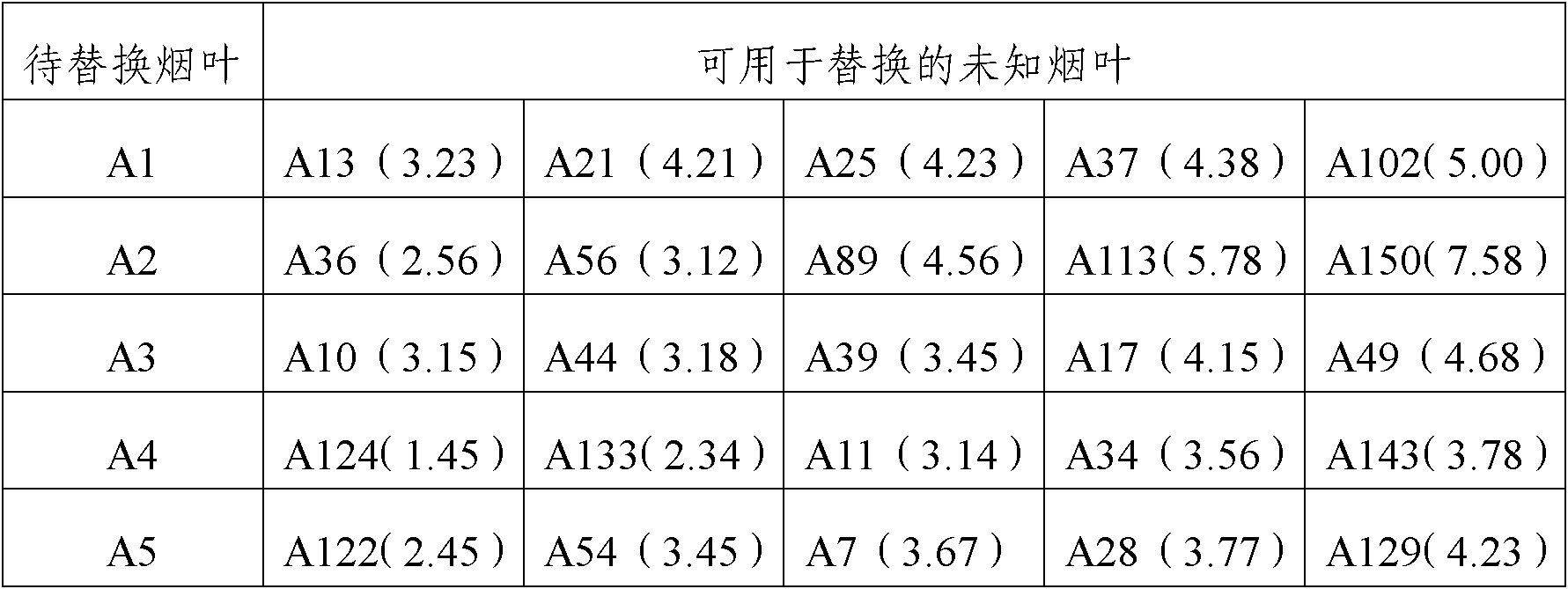

Tobacco replacement method based on visualized style graphs

InactiveCN102608268ARealize visualizationSuitable for replacementWithdrawing sample devicesPreparing sample for investigationReplacement methodComputer science

The invention discloses a tobacco replacement method based on visualized style graphs, which includes the steps: firstly, performing sensory smoke panel test for different unblended cigarettes; then, inputting smoke panel test values into a style graph software MDS1.0 to obtain a style hierarchical graph of each unblended cigarette; and finally, judging similarities according to the style hierarchical graphs, and comparing by combining style characteristics of the unblended cigarettes prior to tobacco replacement. By setting the style characteristics of the unblended cigarettes as a starting point, based on MDA (multidimensional analysis) technology and by applying the style graph software MDS1.0, the tobacco replacement method realizes visualization of sensory quality, and provides a novel tobacco replacement mode as tobacco replacement is performed by comparing the similarities of the style graphs of the unblended cigarettes. The tobacco replacement method is simple in treatment process and suitable for replacement of all tobaccos for cigarette blending.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

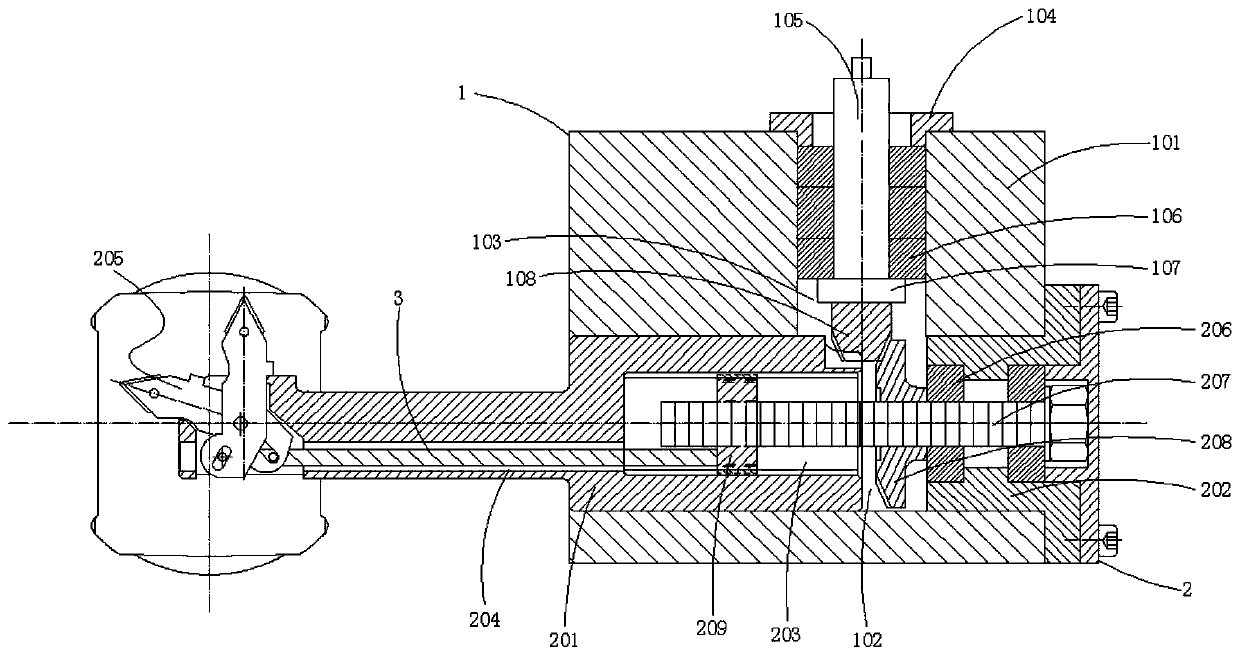

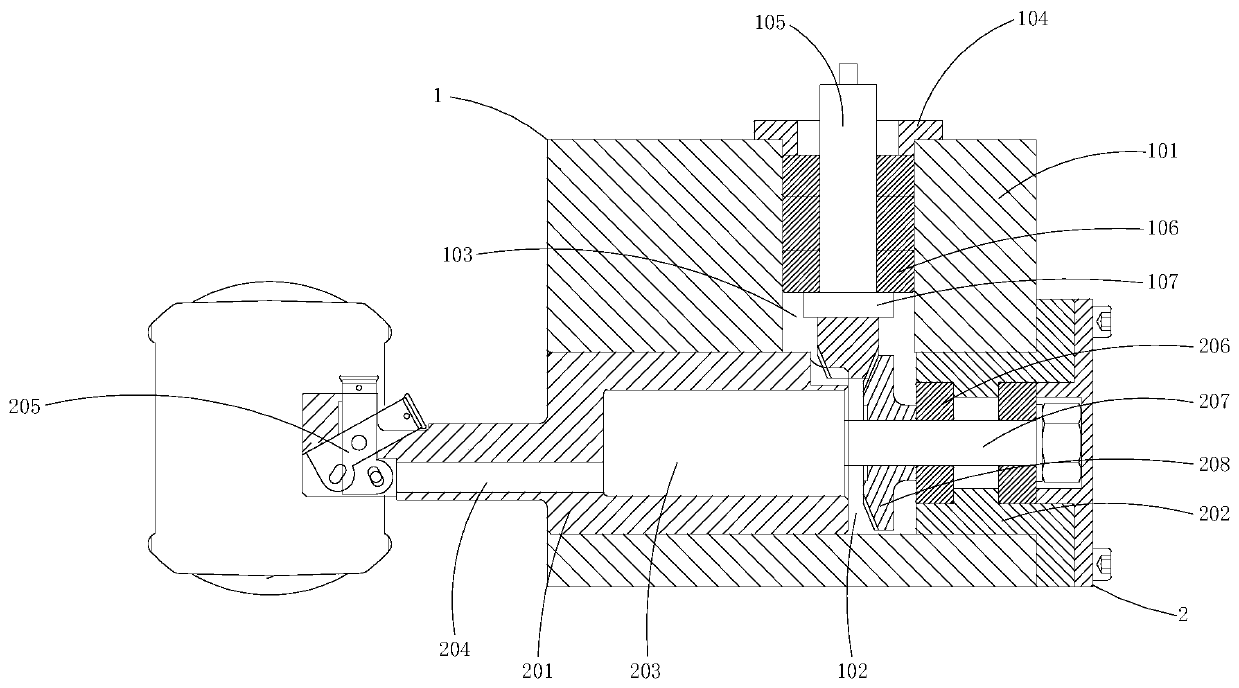

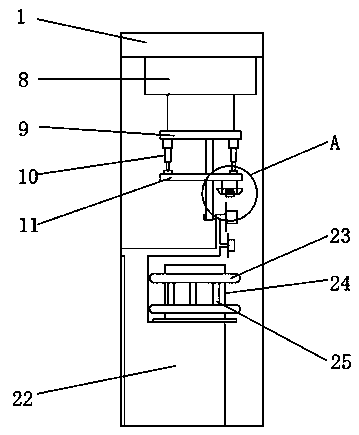

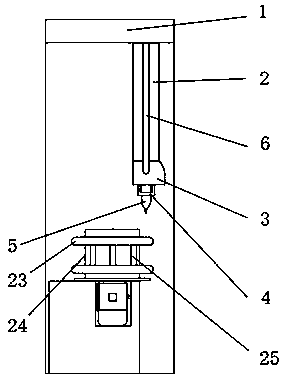

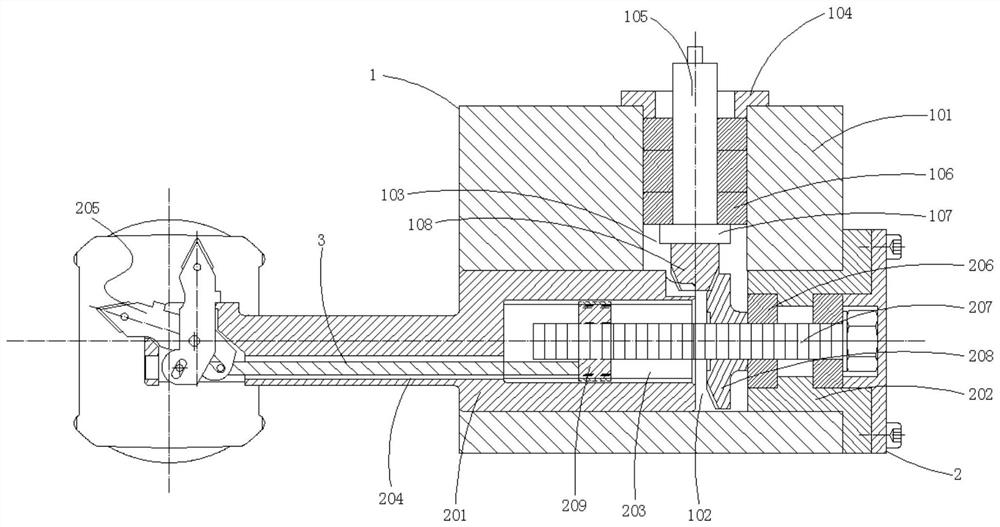

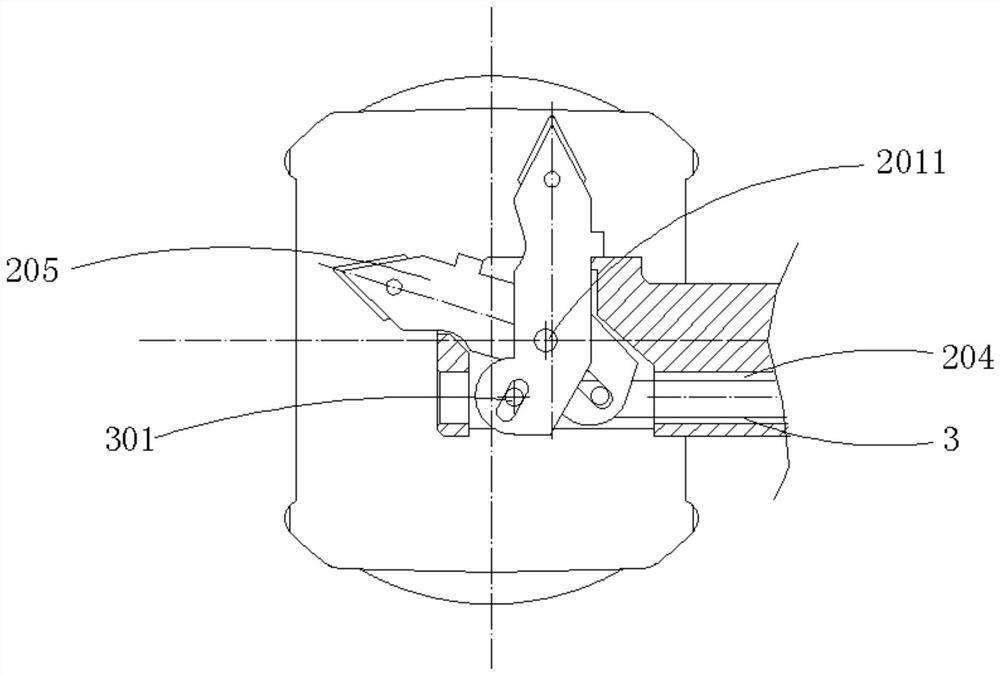

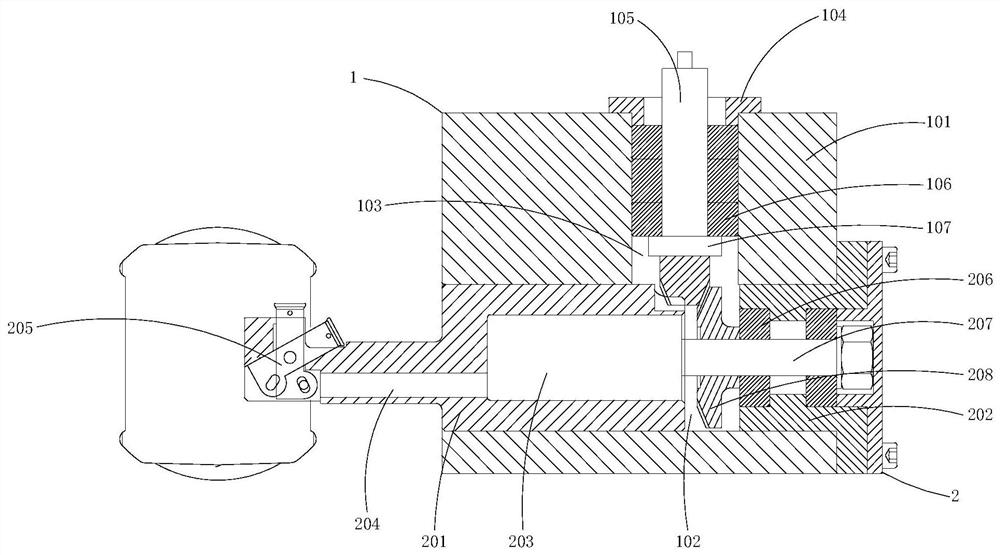

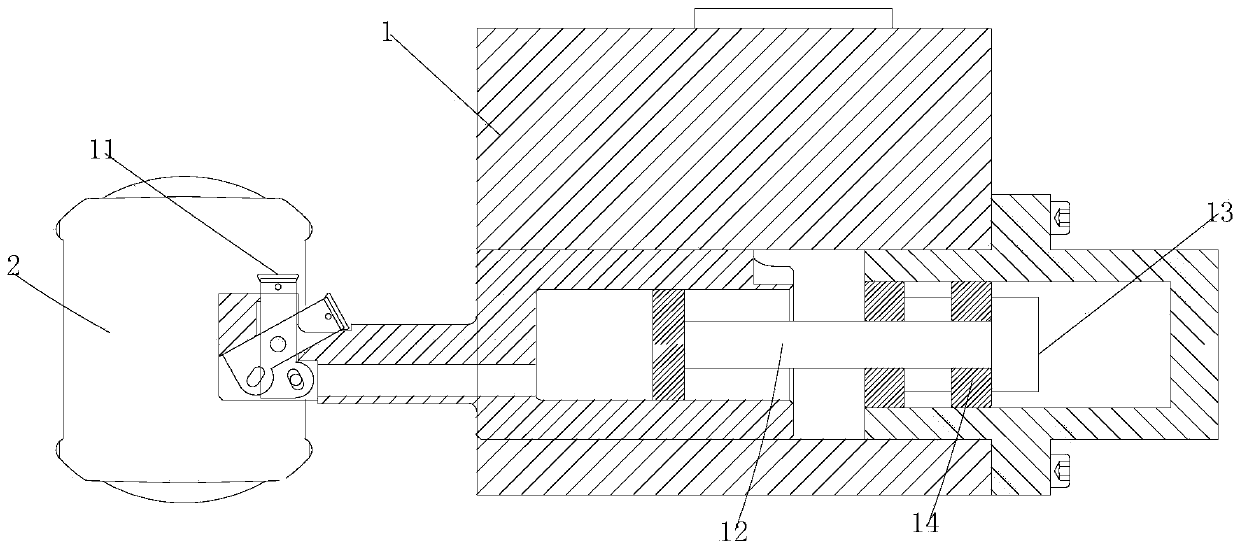

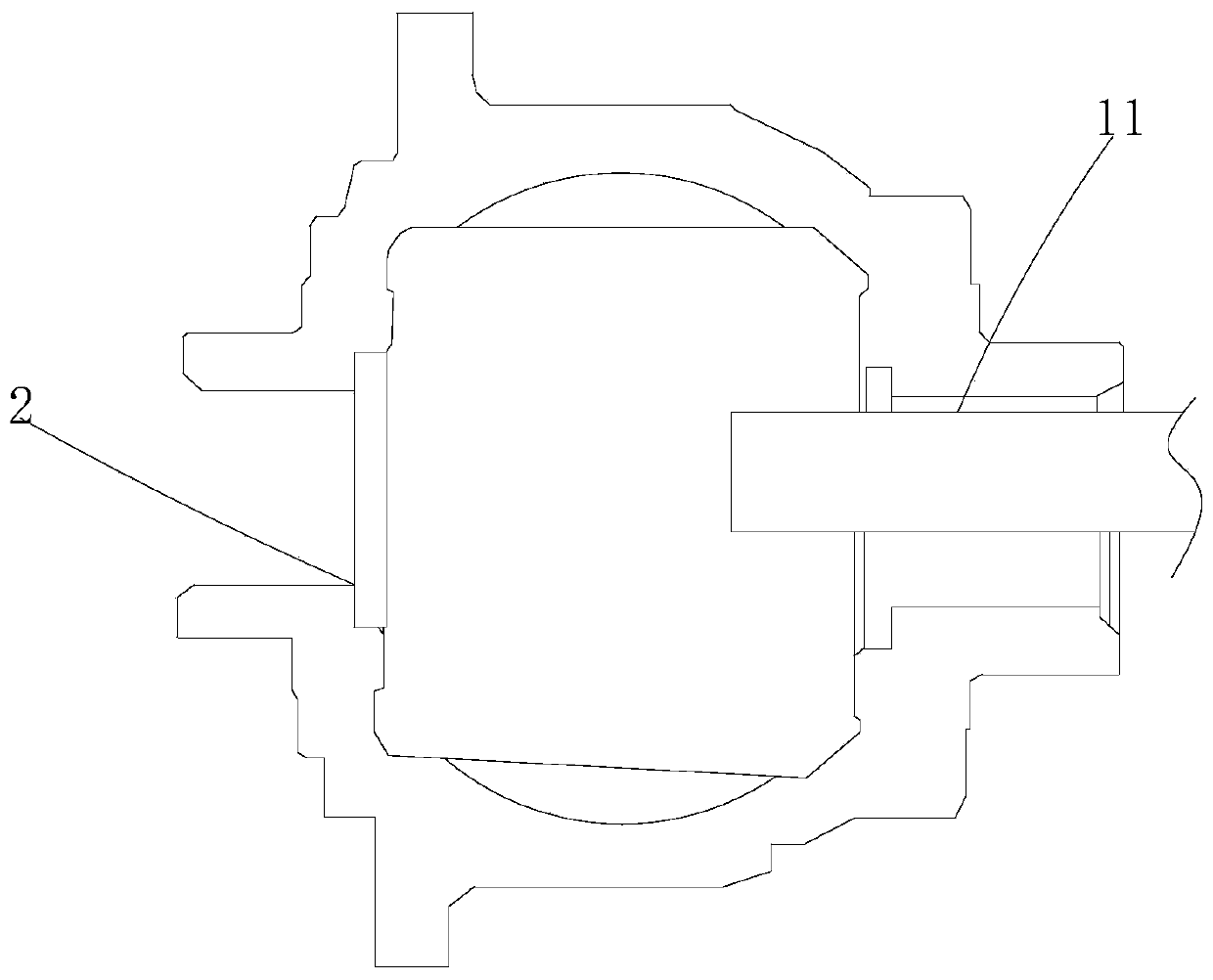

Machine tool driving type retractable cutter and method for machining differential mechanism shell by using same

ActiveCN111266656AReduce investment riskLow investment costLarge fixed membersPositioning apparatusStructural engineeringMachine tool

The invention discloses a machine tool driving type retractable cutter. The machine tool driving type retractable cutter comprises a power cutter tower and a power cutter seat, and is characterized inthat the inner part of the power cutter tower is connected with the outer part of the power cutter seat. The machine tool driving type retractable cutter is suitable for machining a mechanical part with an inner cavity being in a lantern shape, such as an automobile differential mechanism shell, wherein the size of the middle part of an inner cavity of the differential mechanism shell is about 70-110 mm, the size of hole parts at the two ends is about 24-32 mm, the cutter enters the inner cavity in a retracted state, and machines the inner cavity of the middle part after being automatically stretched, the key characteristic size items are completed in one process, the deviation caused by repeated clamping is reduced, and the size accuracy and the form and position tolerance accuracy are effectively guaranteed.

Owner:山东沪金精工科技股份有限公司

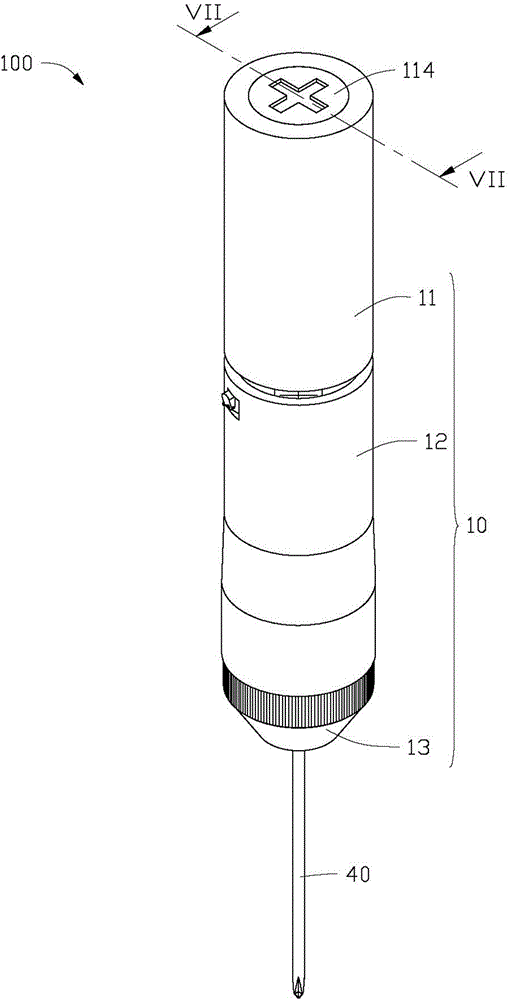

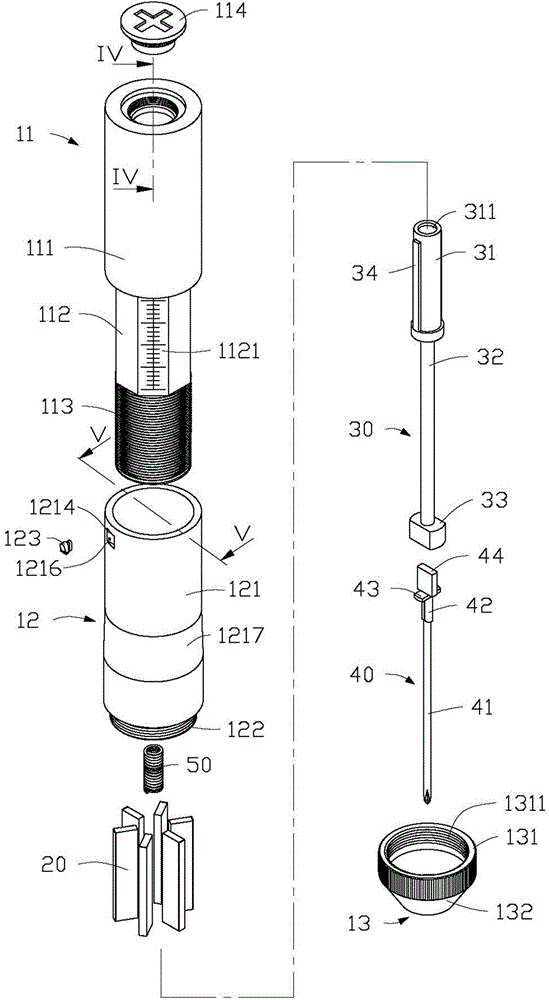

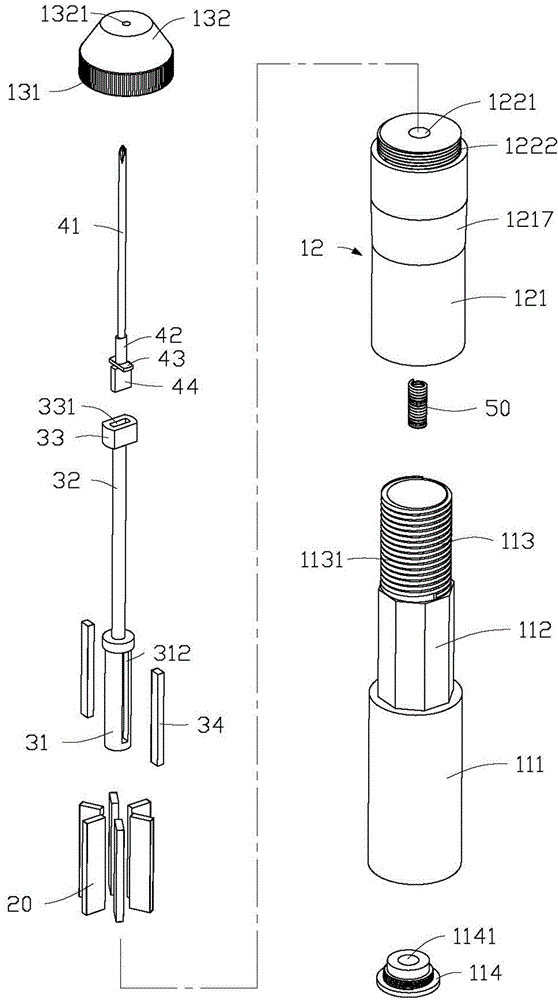

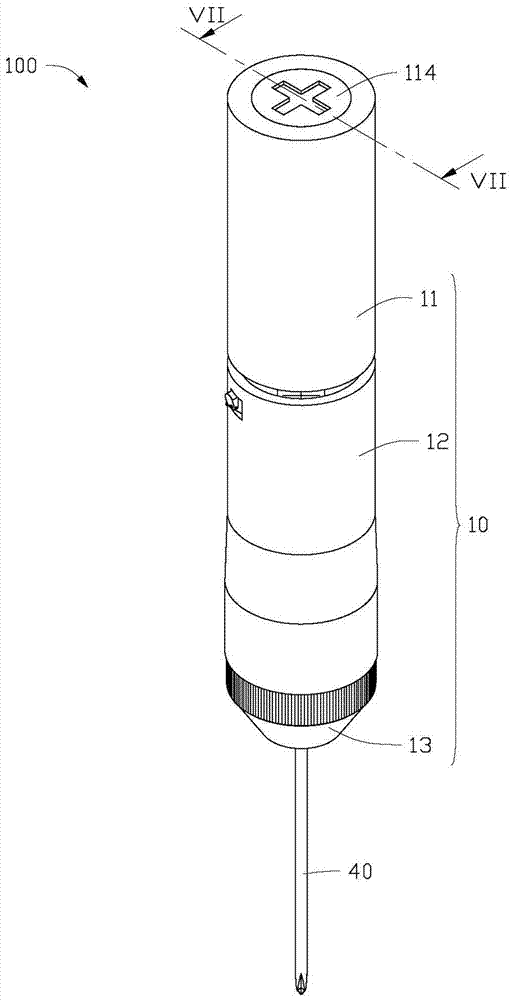

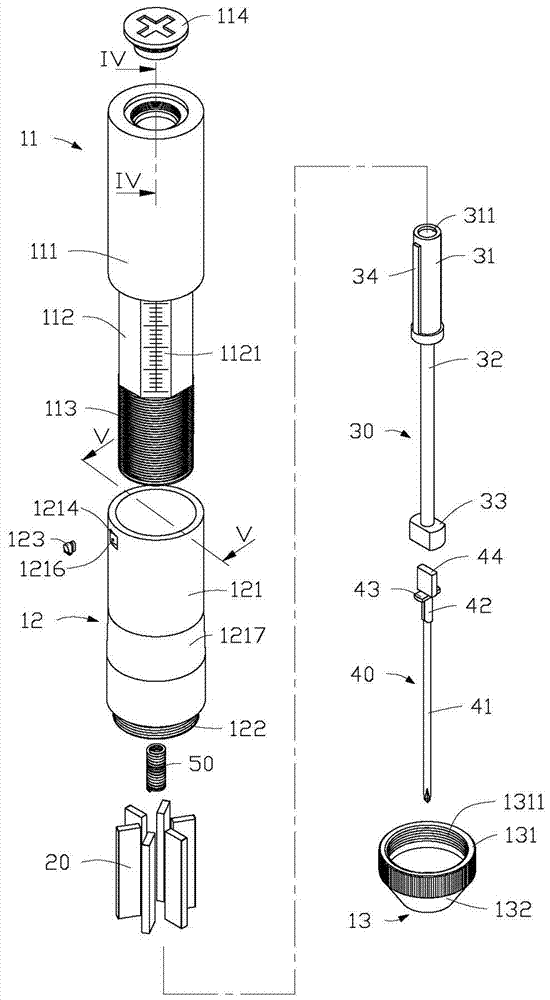

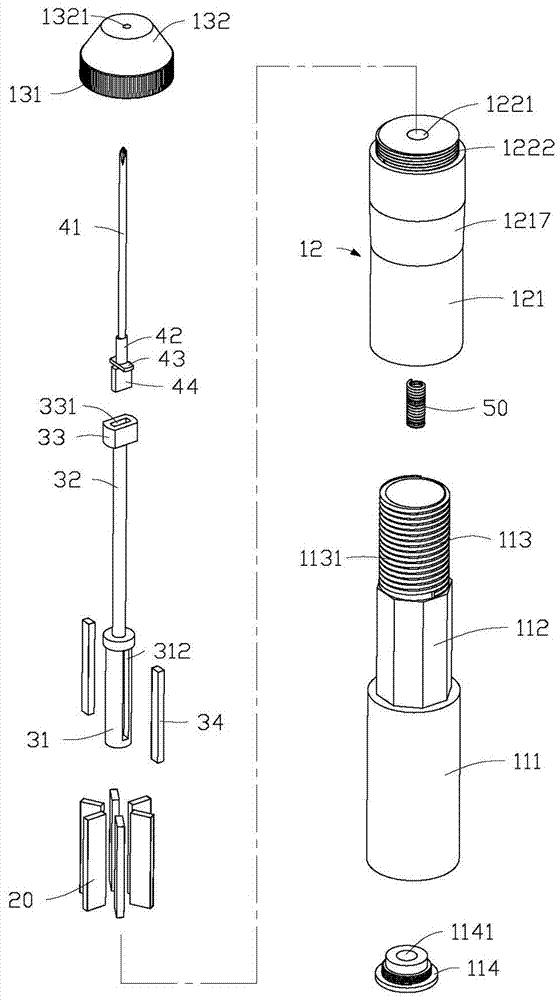

Torsion-adjustable screw driver

A torsion-adjustable screw driver comprises a length-adjustable sleeve and a screw driver head with one end accommodated in the sleeve. The torsion-adjustable screw driver is characterized in that the torsion-adjustable screw driver further comprises resistance parts and a rotating shaft making contact with the resistance parts; the resistance parts and the rotating shaft are both accommodated in the sleeve, the resistance parts are fixedly connected to the sleeve, and the resistance parts and one end of the rotating shaft interact with each other to provide resistance for preventing the rotating shaft from rotating relative to the sleeve; the other end of the rotating shaft is fixedly connected with one end of the screw driver head; the magnitude of the resistance for preventing the rotating shaft from rotating relative to the sleeve is in direct proportion to the contact area of the rotating shaft and the resistance parts; by controlling the contact area of the rotating shaft and the resistance parts, the resistance for preventing the rotating shaft from rotating relative to the sleeve is determined, and therefore the maximum torsion for rotating the rotating shaft is determined, and the maximum screwing torsion of the screw driver head is determined. According to the torsion-adjustable screw driver, bidirectional torsion adjustment can be achieved through the resistance between the resistance parts and the rotating shaft, a good examination effect in engineering examination is achieved, the structure is simple, and the screw driver head can be replaced by various screw driver heads.

Owner:苏州卫优知识产权运营有限公司

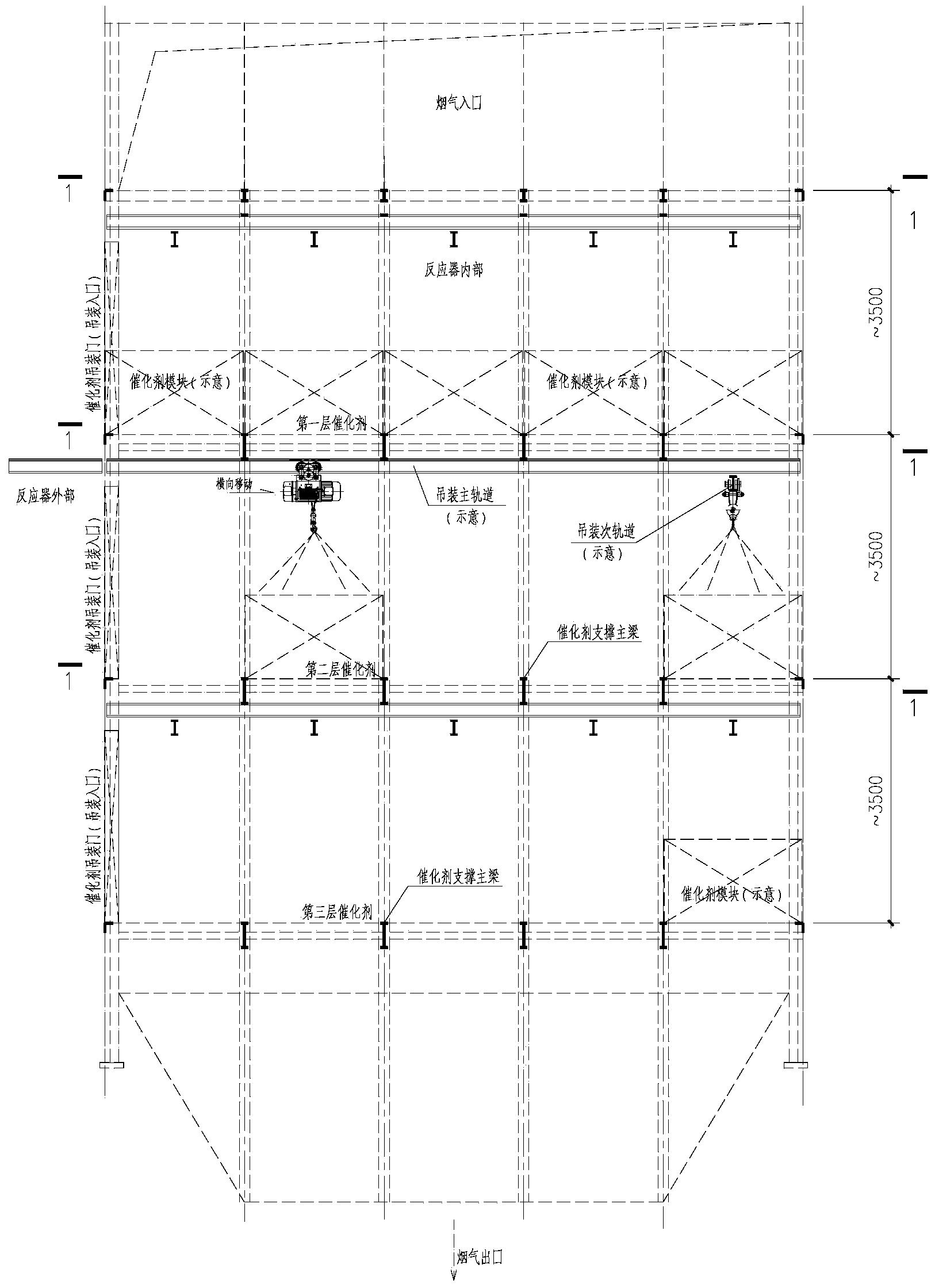

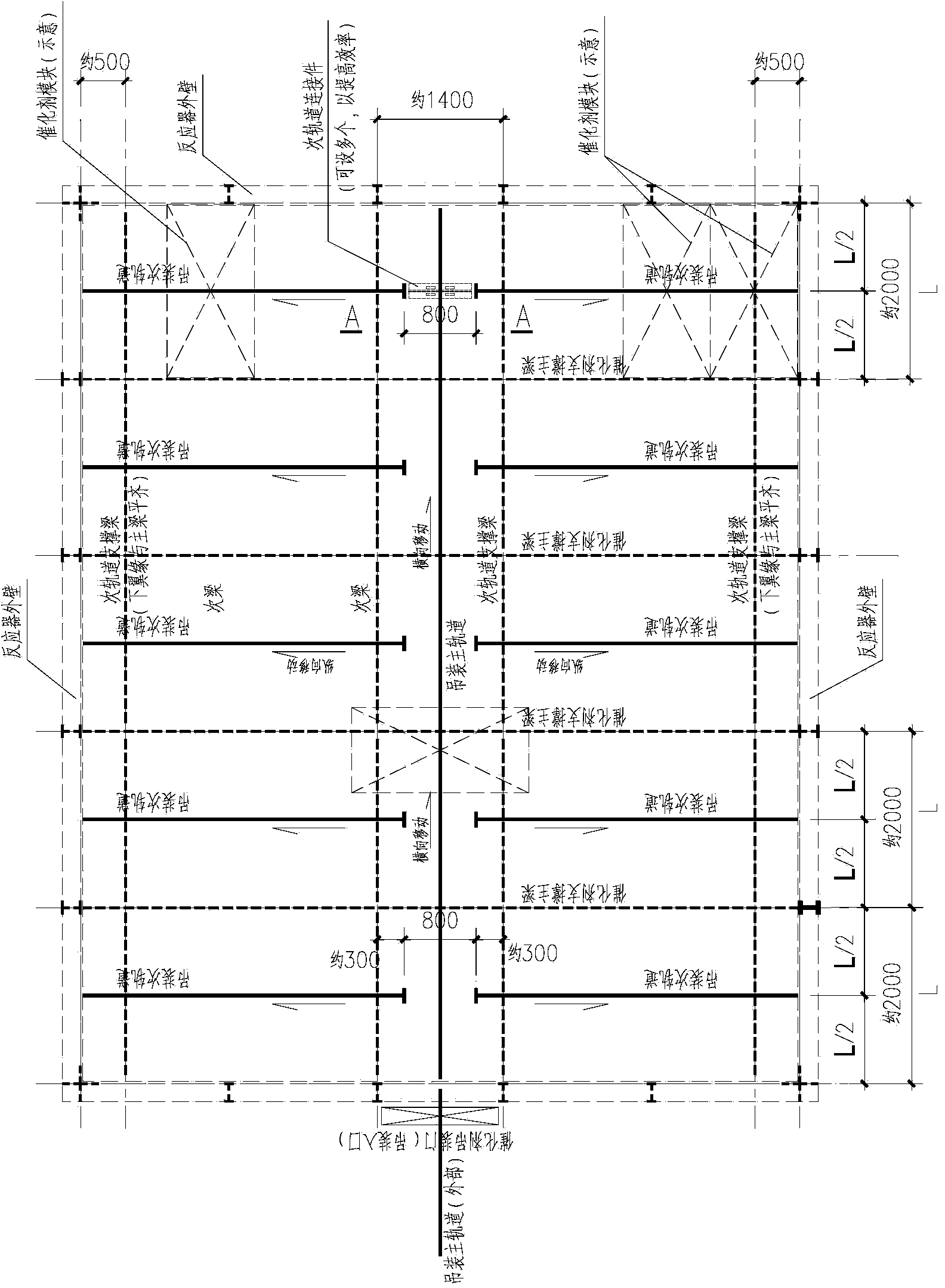

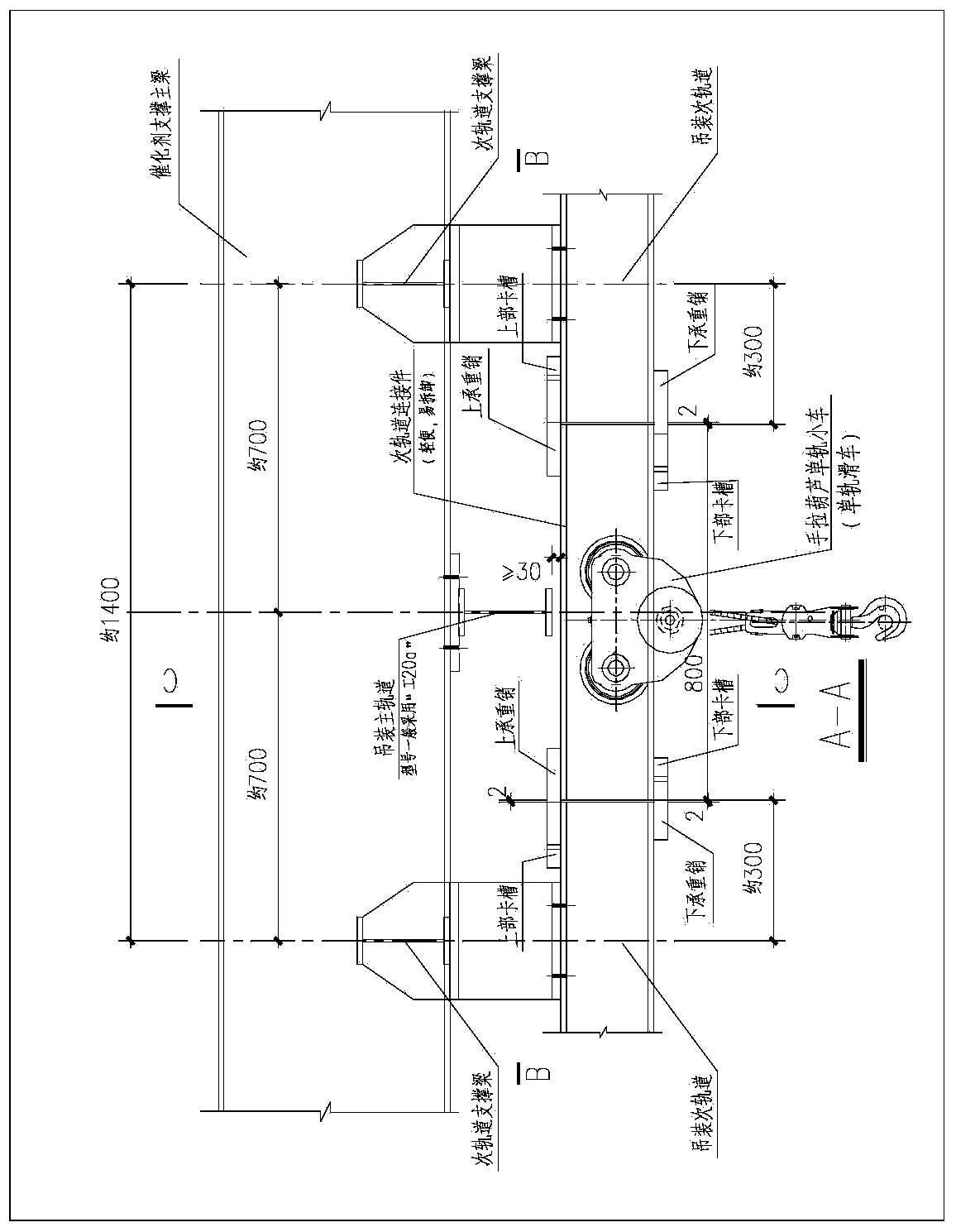

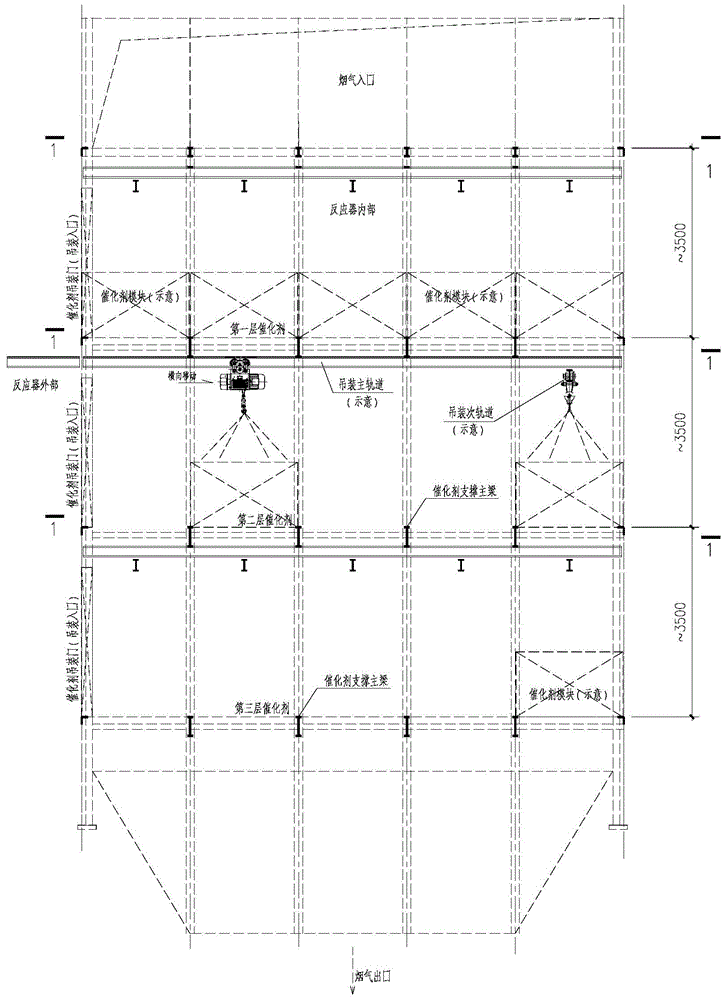

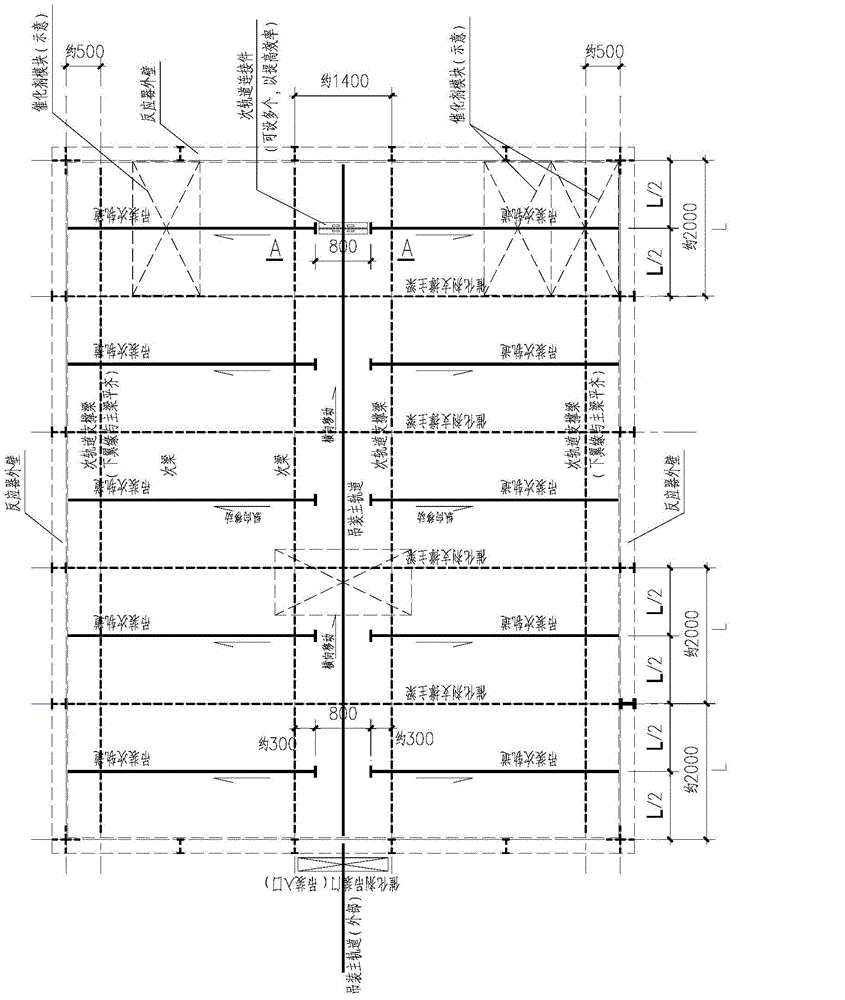

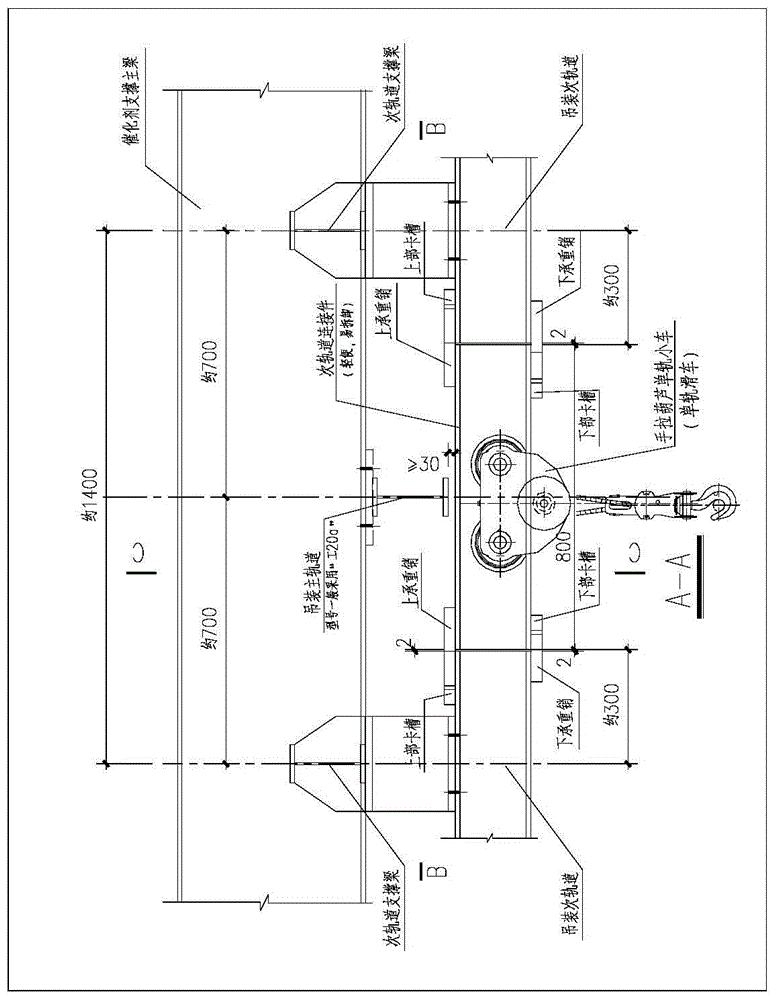

Assembly method for catalyst modules in novel SCR (Selective Catalytic Reduction) denitration reactor

InactiveCN103831014ASimple designReasonable designDispersed particle separationMonorailPetroleum engineering

The invention discloses an assembly method for catalyst modules in a novel SCR (Selective Catalytic Reduction) denitration reactor. The method comprises the following four steps: step one, arranging a transverse hoisting main rail and a vertical hoisting secondary rail on a monorail hoist which is located on the bottom of a top steel beam of a layer when assembling the catalyst modules of the layer, and enabling the catalyst modules to enter a reactor along with transverse movement of a manual hoist or an electric hoist which is arranged on the hoisting main rail; step two, putting the catalyst modules down near the hoisting secondary rail after reaching main units through the hoisting main rail, then withdrawing from the electric hoist or manual hoist of the main rail; step three, manually assembling a secondary rail connection part, vertically moving the secondary rail connection part and a manual hoist to hoist the catalyst modules in determined positions; and step four, taking the secondary rail connection part down after a whole line of catalyst modules is assembled for each time and applying the secondary rail connection part to assembly of other lines or other layers. The assembly method for the catalyst modules in the novel SCR denitration reactor is a catalyst module assembling technique which is simple, reliable, easy to operate and convenient to assembly in site.

Owner:BEIJING BREEZEWIND ENVIRONMENTAL PROTECTION TECH

Canning apparatus capable of conveniently sealing bottled cosmetics

The invention discloses a canning apparatus capable of conveniently sealing bottled cosmetics. The canning apparatus comprises a housing, wherein a first fixing frame is arranged on the upper end of the left side of the housing, a connector is arranged on the lower portion of the first fixing frame, a syringe fixing frame is arranged on the lower portion of the connector, and is provided with a syringe, the syringe is connected to the connector, the lower end of a water pipe penetrates through the connector and is connected to the syringe, the upper end of the water pipe penetrates through thehousing and is connected to a water inlet, the upper end of the middle portion of the housing is provided with a hydraulic device, a second fixing frame is arranged below the hydraulic device, a stretching connection rod is connected below the second fixing frame, a sealing device bracket is connected to the lower end of the stretching connection rod, and a sealing device is arranged on the lowerend of the sealing device bracket. According to the present invention, the canning apparatus is provided with the first conveying device, the syringe and the sealing device, the mode is simple, and the sealing can be performed immediately after the cosmetic filling, such that the use is convenient.

Owner:安徽润仕佳化妆品有限公司

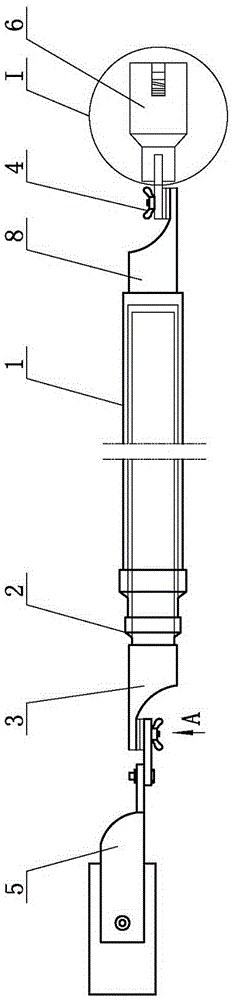

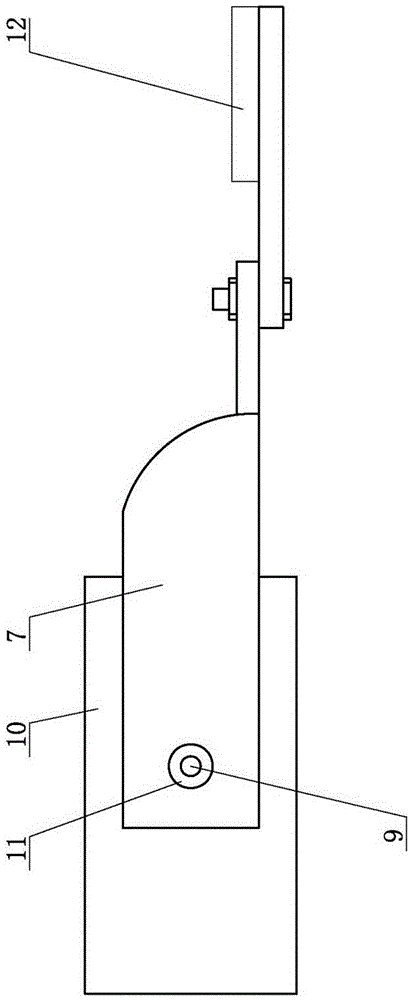

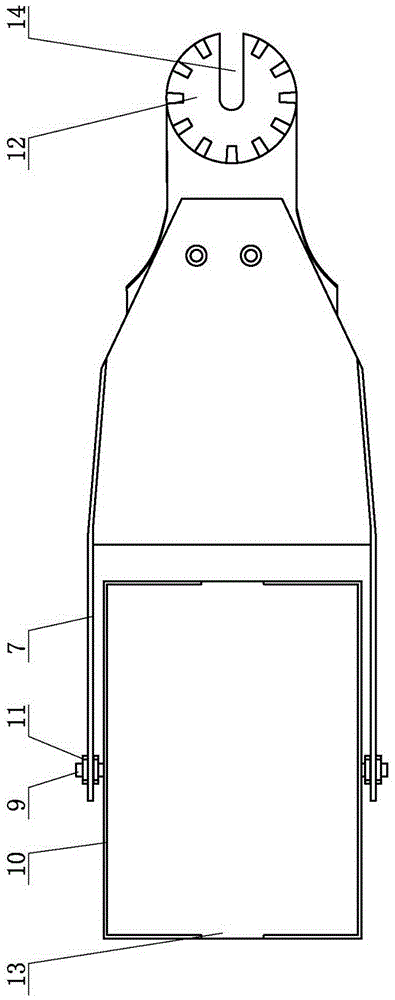

Stretchable type general local discharge detection sensor mounting tool

PendingCN106645821ALightweight replacementReplacing different types of placement with lightweightTesting dielectric strengthCoatingsControl theoryUltrahigh frequency

The invention relates to a stretchable type general local discharge detection sensor mounting tool which comprises an expansion link, wherein a fixing base is arranged at one end of the expansion link; a first steering head is arranged on the fixing base; an ultrahigh frequency type placement base is arranged on the first steering head; a second steering head is arranged at the other end of the expansion link; steering head end-toothed discs are respectively arranged on the first steering head and the second steering head; and a through hole is formed at the center of each steering head end-toothed disc. Through the replacement for different kinds of placement bases, the mounting tool can adapt to both of an ultrasonic local discharge detection method and an ultrahigh frequency local discharge detection method; the structure design is smart, so that the placement bases can be easily replaced; a stretchable operation rod is adopted by the mounting tool, so that the length of the operation rod can be accurately adjusted according to the height of the onsite to-be-detected equipment; and the stretchable structure design is space-saving, so that a local discharge tester can conveniently carry the mounting tool.

Owner:STATE GRID CORP OF CHINA +1

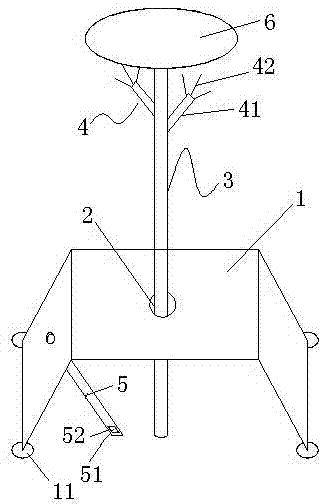

Multifunctional coat tree

InactiveCN105433723AIncrease useThe overall structure is simpleApparel holdersAcute angleClothes hanger

The invention discloses a multifunctional coat tree which comprises a base capable of being used as a stool. A through hole is formed in the base, and a vertical rod is vertically arranged on the base and is inserted in the through hole in a penetrating mode. A plurality of hanging racks are arranged on the vertical rod, acute angles are formed between the hanging racks and the vertical rod, a sleeve used for containing umbrellas is arranged on the side face of the base, and an acute angle is formed between the sleeve and the side face of the base. The bottom face of the sleeve and the bottom end of the side face of the base are in same horizontal face. Sliding wheels capable of being locked are arranged on the bottom face of the base. Each hanging rack comprises a main rod and a branch rod, a detachable dust shading plate is arranged at the top end of the vertical rod, and the straight line distance from the outer edge of the dust shading plate to the center of the vertical rod is larger than or equal to that from the upper end of each branch rod to the center of the vertical rod. The multifunctional coat tree integrates functions of the stool, functions of a clothes hanger and the umbrella hanging function, and is convenient to use and suitable for many families to use.

Owner:叶梦婷

Hollow wind power generation tower foundation

The invention relates to a hollow wind power generation tower foundation. The hollow wind power generation tower foundation comprises a wind power generation tower foundation main body, a ground anchor cage, a bed course and ground anchor cage brackets, wherein the ground anchor cage is vertically embedded into the wind power generation tower foundation main body which is formed by pouring concrete, the bed course is arranged under the ground anchor cage and the wind power generation tower foundation main body, a hollow cavity penetrates through the wind power generation tower foundation main body up and down, the bed course is concave downwards in the center of the lower surface of the wind power generation tower foundation main body, so as to form a concave cavity where operation can be conveniently carried out by a person or a tool, the hollow cavity communicates with the concave cavity, the lower end of the ground anchor cage extends into the concave cavity, and the ground anchor cage brackets which are used for supporting the ground anchor cage are arranged in the concave cavity. The hollow wind power generation tower foundation has the beneficial effects that the hollow cavity and the concave cavity are formed in the wind power generation tower foundation main body, so that the person or the tool can conveniently enter the wind power generation tower foundation main body to replace damaged anchor bolts, and the ground anchor cage can be well fixedly supported.

Owner:瑞风能源(武汉)工程技术有限公司

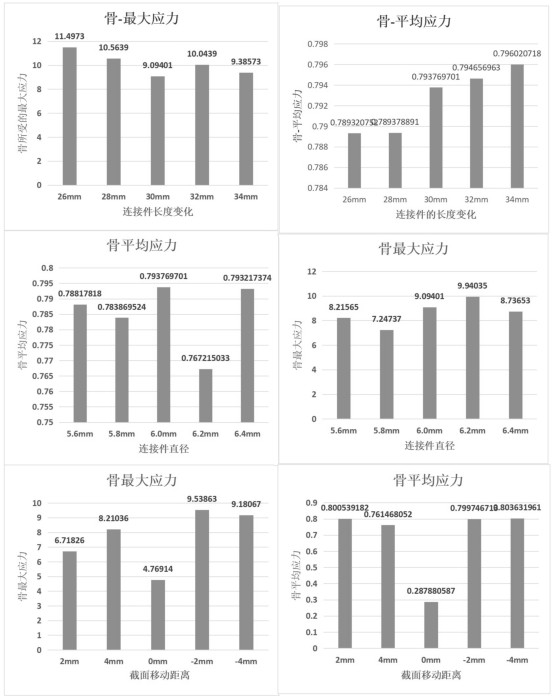

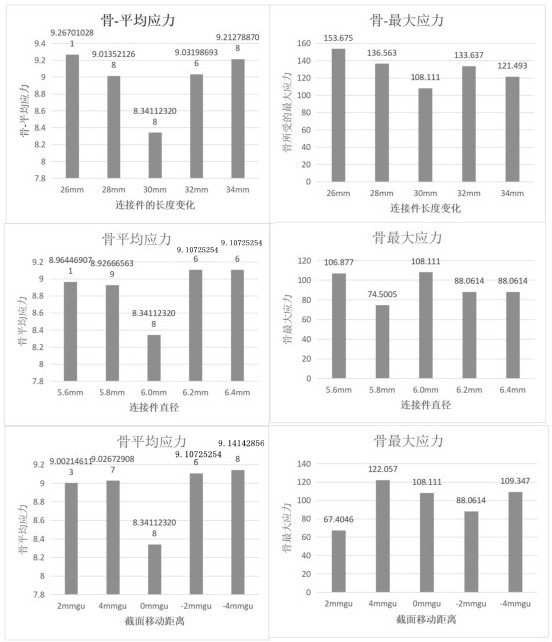

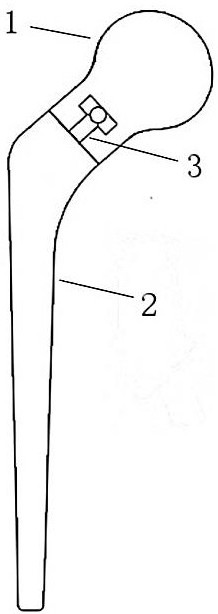

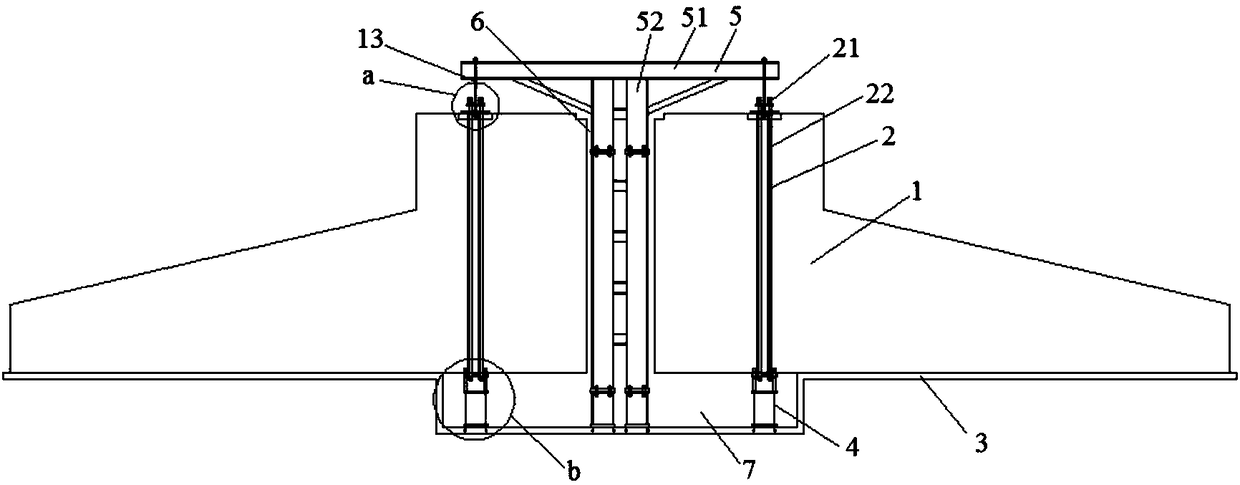

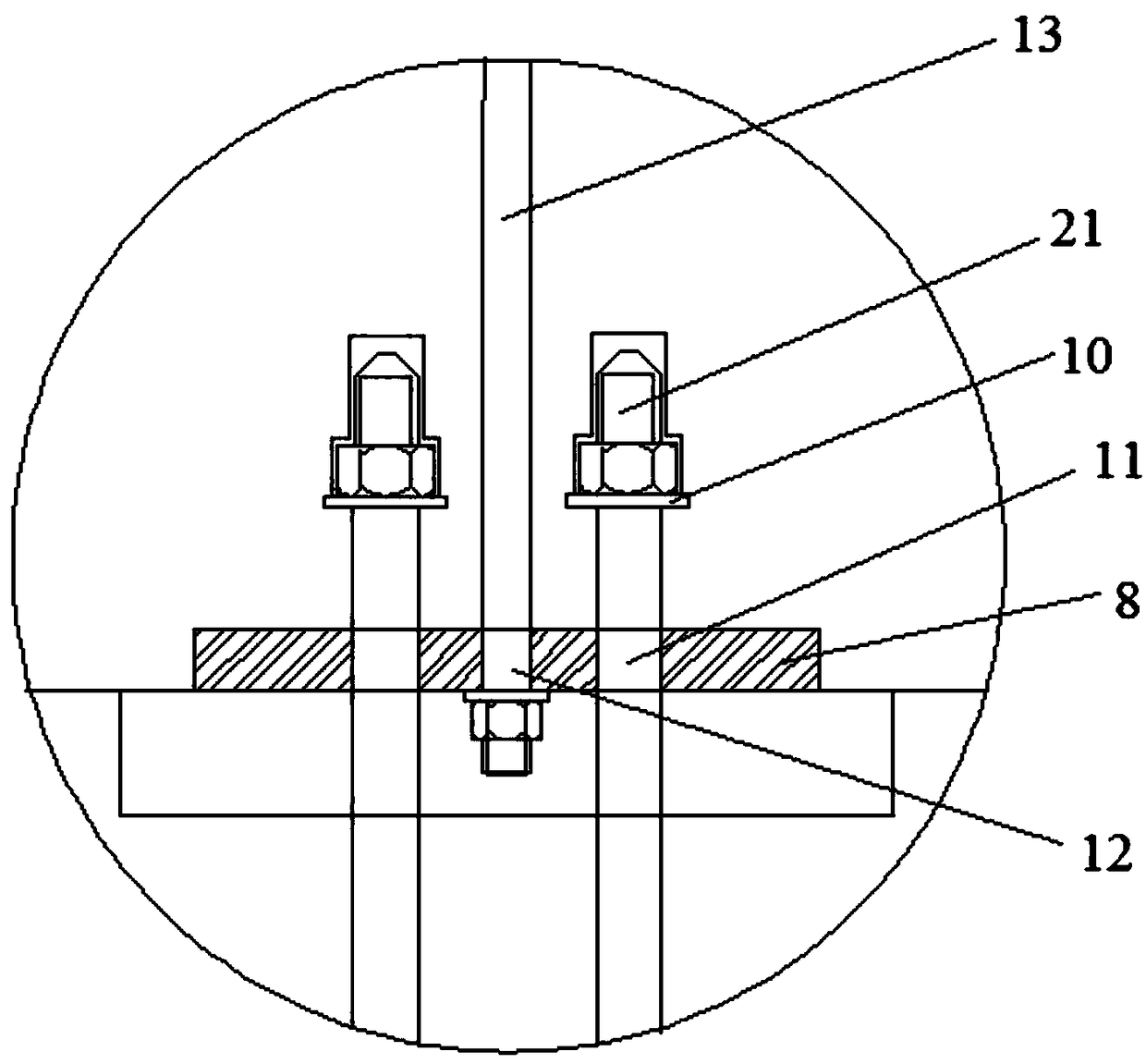

Manufacturing method of composite structural femoral prosthesis

PendingCN113367853AImprove tensile propertiesAccelerated corrosionMedical simulationJoint implantsBiomechanicsElement analysis

The invention discloses a manufacturing method of a composite structural femoral prosthesis. The method is characterized by comprising the following steps in sequence of three-dimensional reconstruction of a femoral prosthesis, establishment of a mathematical model of the femoral prosthesis and a connecting piece, grid division of the femoral prosthesis, finite element analysis under different biomechanical environments, determination of evaluation indexes and optimization selection, and manufacturing of the femoral prosthesis by using a 3D printing technology. The composite structural femoral prosthesis prepared by the method has relatively high tensile property and corrosion resistance, and is very close to the real bone in physical property.

Owner:DALIAN MEDICAL UNIVERSITY

A wind power generation tower foundation with support and its construction technology

The invention relates to a wind power tower foundation with a support and a construction technology of the foundation. The foundation comprises a wind power tower foundation body, a ground anchor cage, a cushion layer, a ground anchor cage supporting column and the support. The ground anchor cage is vertically embedded in the wind power tower foundation body, the cushion layer is arranged below the ground anchor cage and the wind power tower foundation body, a hollow cavity is formed in the wind power tower foundation body, the cushion layer is arranged in the center of the lower surface of the wind power tower foundation body and downwards indented to form a concave cavity, the support used for fixing the ground anchor cage is arranged in the hollow cavity, the upper end of the support extends out of the upper portion of the hollow cavity and is fixedly connected with the ground anchor cage and the wind power tower foundation body, and the lower end of the support is fixedly connected with the cushion layer. The invention further provides a corresponding construction technological method. Installation is firm and reliable, and the support can be repeatedly used. The wind power tower foundation with the support and the construction technology of the foundation have the advantages that damaged anchor bolts can be replaced, and the support can be repeatedly used.

Owner:瑞风能源(武汉)工程技术有限公司

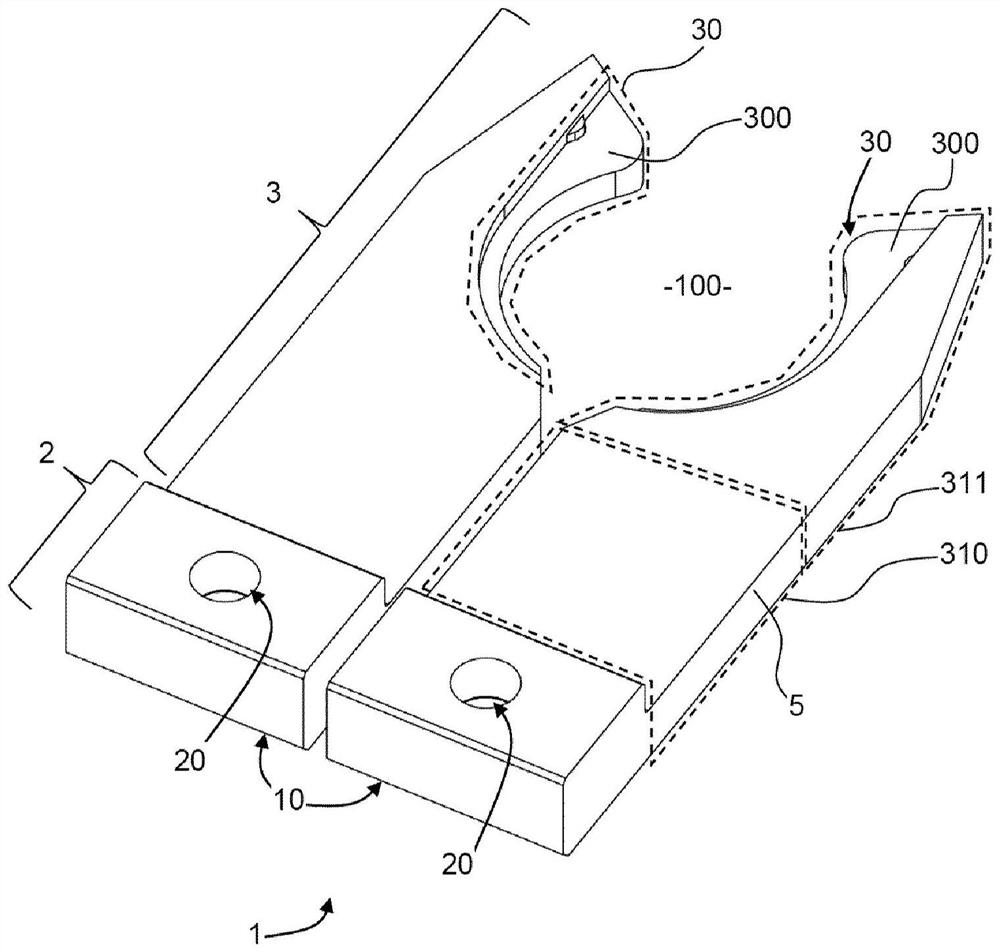

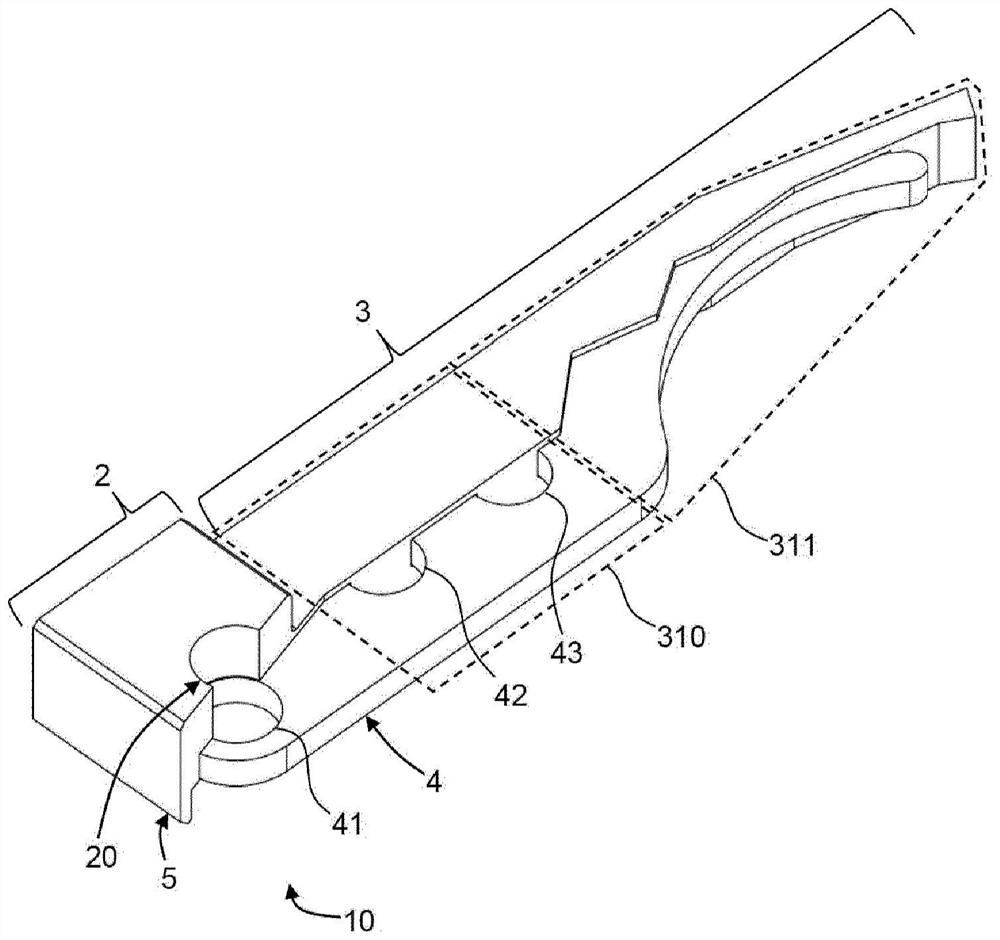

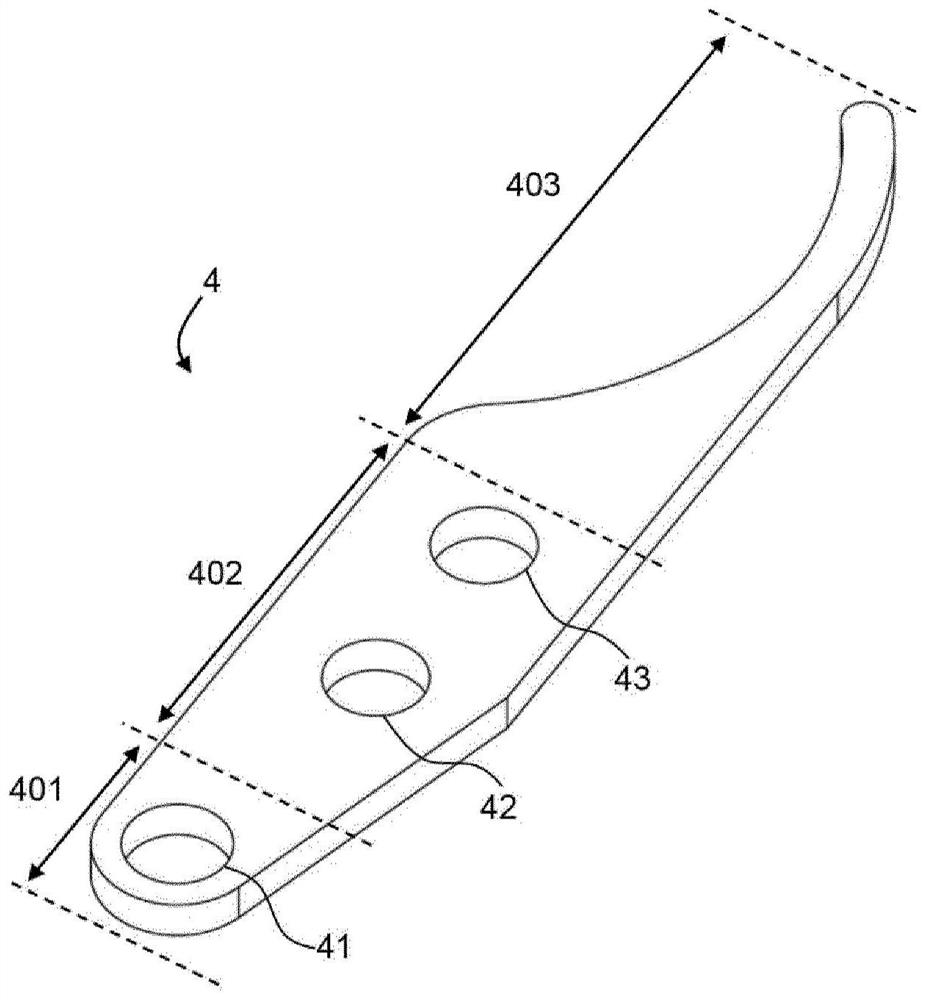

Handling clamp for handling hollow bodies and method for producing same

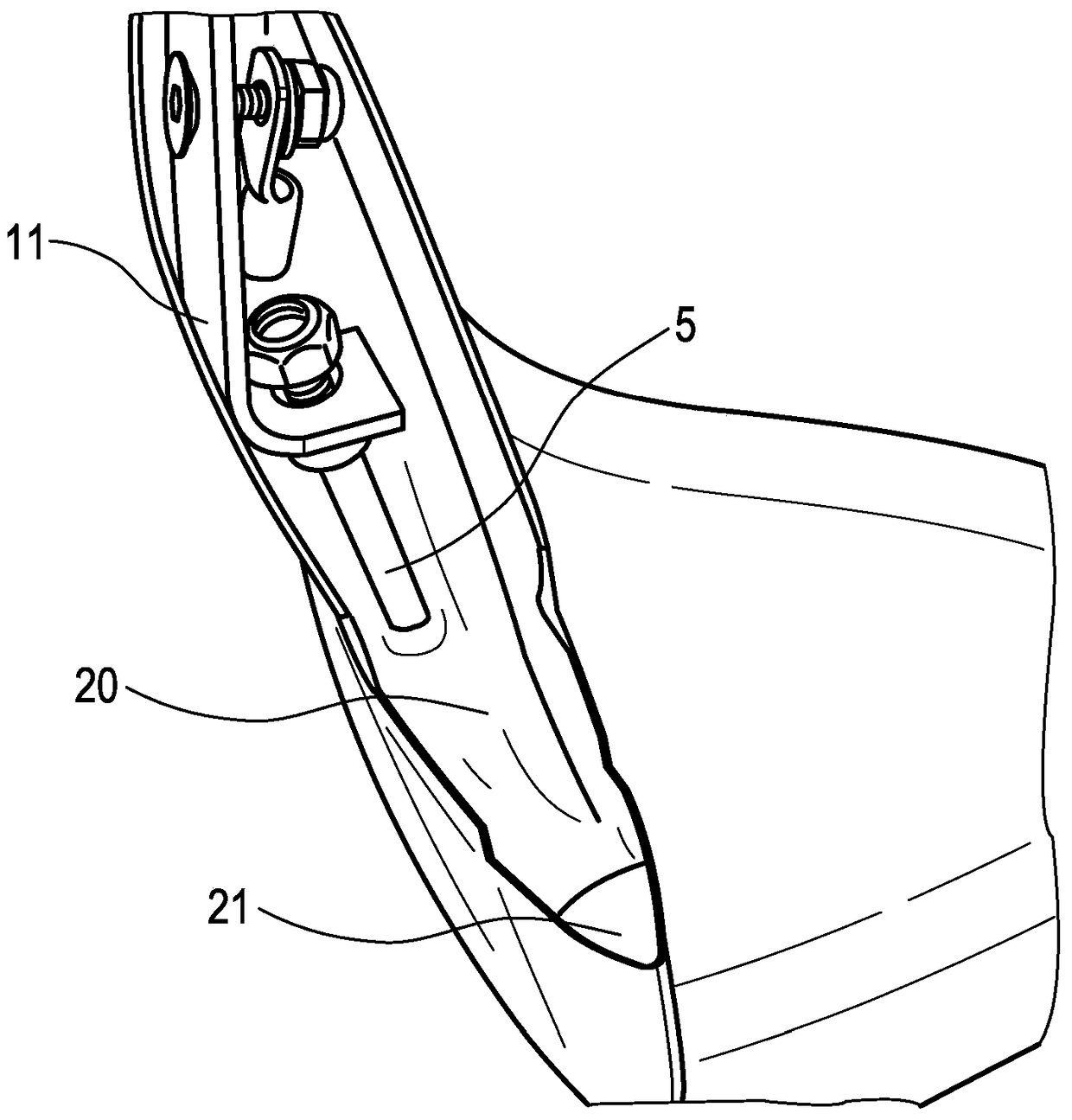

PendingCN114502346ASuitable for replacementLow costAdditive manufacturing apparatusConveyorsFront edgeManufacturing engineering

The invention relates to an arm (10) of a handling clamp (1) for handling hollow bodies in a unit for manufacturing plastic containers, comprising two arms (10) for being held by a holding member and for gripping hollow bodies, each arm (10) comprising a base (2) having a leading edge (30) for contacting a hollow body, and a jaw (3) extending from the base (2), the arm (10) is formed by: a metal core (4) extending in the jaw (3) after the leading edge (30); -a plastic complement (5) at least partially covering the metal core (4), the plastic complement (5) forming at least the leading edge (30) and being fixed to the metal core (4).

Owner:SIDEL PARTICIPATIONS SAS

Machine tool-driven retractable cutter and method for processing differential case using the cutter

ActiveCN111266656BReduce investment riskLow investment costLarge fixed membersPositioning apparatusEngineeringMachine

The invention discloses a machine tool driving type retractable cutter. The machine tool driving type retractable cutter comprises a power cutter tower and a power cutter seat, and is characterized inthat the inner part of the power cutter tower is connected with the outer part of the power cutter seat. The machine tool driving type retractable cutter is suitable for machining a mechanical part with an inner cavity being in a lantern shape, such as an automobile differential mechanism shell, wherein the size of the middle part of an inner cavity of the differential mechanism shell is about 70-110 mm, the size of hole parts at the two ends is about 24-32 mm, the cutter enters the inner cavity in a retracted state, and machines the inner cavity of the middle part after being automatically stretched, the key characteristic size items are completed in one process, the deviation caused by repeated clamping is reduced, and the size accuracy and the form and position tolerance accuracy are effectively guaranteed.

Owner:山东沪金精工科技股份有限公司

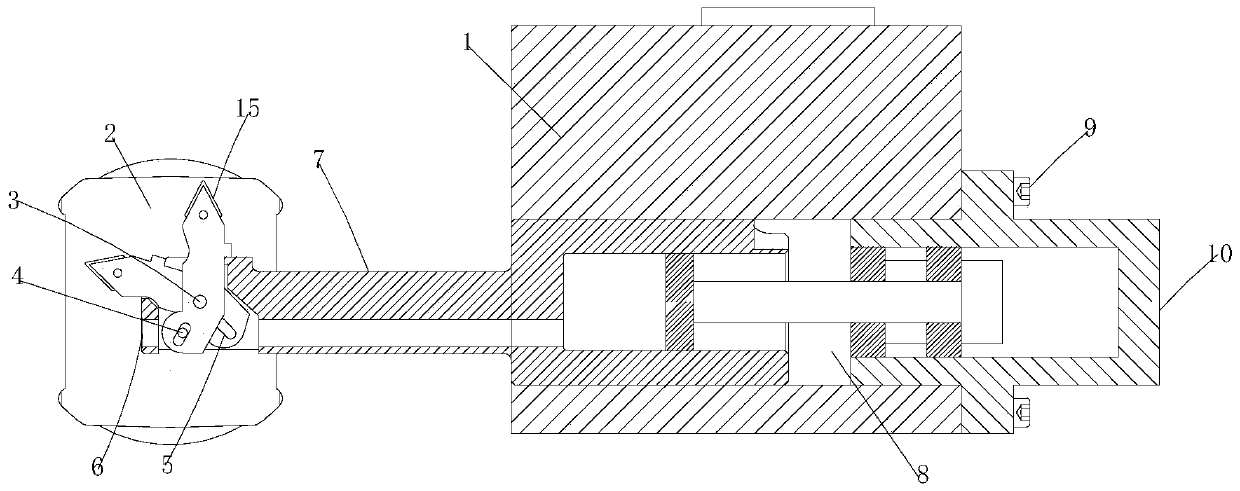

Hydraulic telescopic cutter and differential mechanism shell machining method applying the same

InactiveCN111014830AReduce investment riskLow investment costFeeding apparatusPositioning apparatusHydraulic cylinderStructural engineering

The invention relates to the technical field of machining and discloses a hydraulic telescopic cutter. The tool comprises a tool turret, a differential mechanism shell, a hinge shaft, a connecting rod, a cutter bar, a fixing sleeve, a working cavity, an end face automatic tool, a tool telescopic control connecting rod, a tool telescopic hydraulic cylinder, a gasket and a ball cage tool, wherein aninner wall of the tool turret is connected with an outer wall of the working cavity, an outer wall of the fixing sleeve is connected with an outer wall of the working cavity, an output end of the cutter telescopic hydraulic cylinder is connected with a right side surface of the cutter telescopic control connecting rod, an outer surface of the cutter telescopic control connecting rod is connectedwith an inner wall of the gasket, a left side face of the cutter telescopic control connecting rod is connected with a right side face of the cutter bar, an outer surface of the cutter bar is connected with an inner wall of the fixing sleeve, a head of the cutter bar is connected with an outer surface of the hinge shaft, and the end, away from the cutter bar, of the hinge shaft is connected with the end face automatic cutter. The cutter solves problems that machining difficulty of an inner spherical surface of the differential mechanism shell is large, the requirement is high, and machining cost of the inner spherical surface of the differential mechanism shell is high.

Owner:山东沪金精工科技股份有限公司

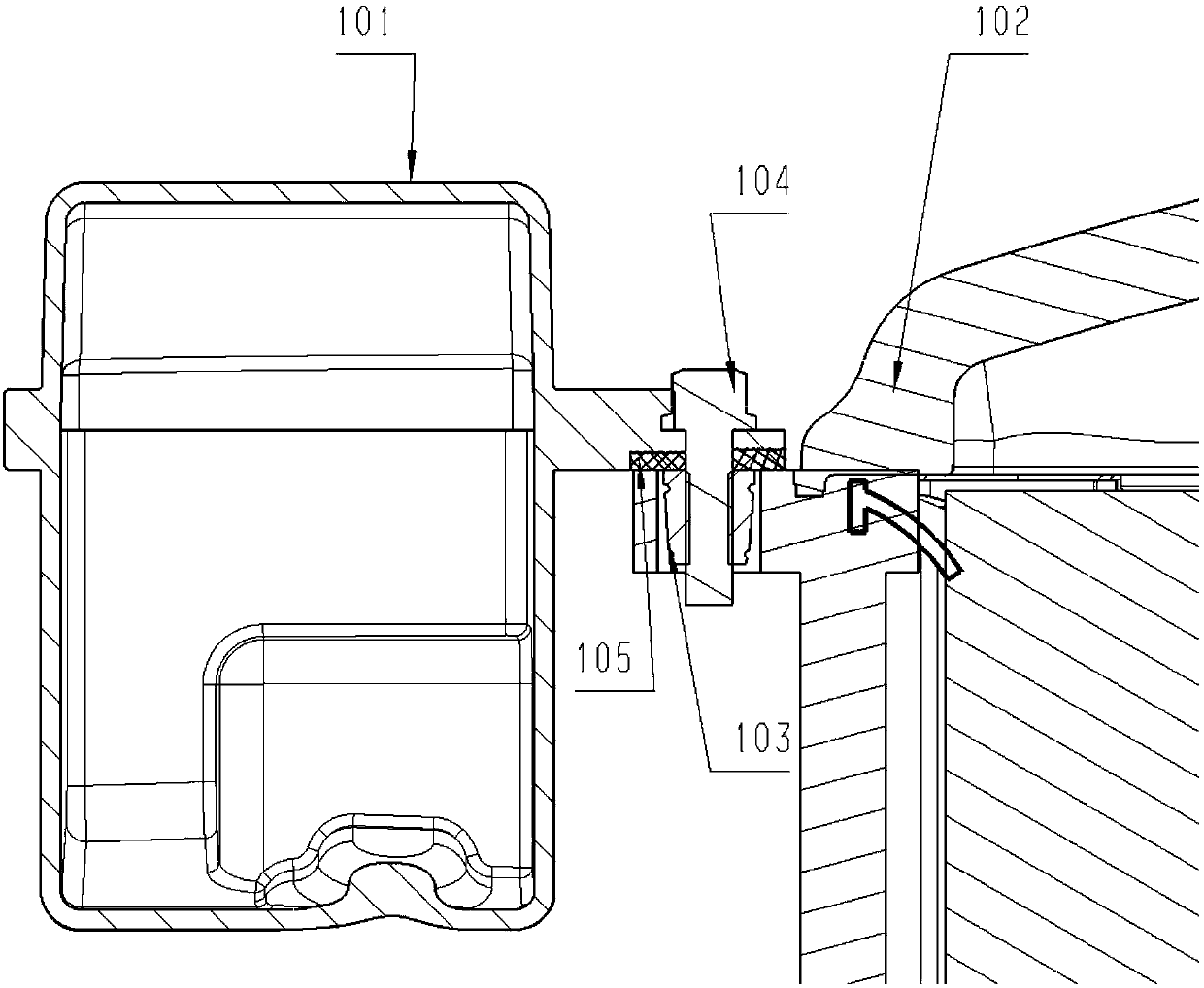

Buckle structure for connecting integrated parts

PendingCN109899187AAchieve reliabilityAvoid damage from broken connectionsAir intakes for fuelEngineeringMechanical engineering

The invention relates to a buckle structure for connecting integrated parts. An air inlet manifold shell and a vacuum cavity shell are connected through the buckle structure. The buckle structure comprises a first clamping groove, a second clamping groove, a first resisting buckle and a second resisting buckle. The first clamping groove and the second clamping groove are formed in the two sides ofthe air inlet manifold shell, and the first resisting buckle and the second resisting buckle are arranged on the two sides of the vacuum cavity shell. The first clamping groove and the first resisting buckle are correspondingly arranged, and the second resisting buckle and the second clamping groove are correspondingly arranged. The first resisting buckle is inserted into the first clamping groove, and the second resisting buckle and the second clamping groove are connected with each other in a clamped mode. Compared with the prior art, the buckle structure has the advantages that the firmness of the connection between the air inlet manifold shell and the vacuum cavity shell is effectively achieved, and the phenomenon that when an engine runs, the connection breakage damage is caused by the stress concentration which is generated due to the vibration is avoided. By the adoption of the buckle structure, the concentrated stress generated by the hard connection of bolts, thermal plugs and the like can be well avoided, a certain buffering protection effect on the connection between the two parts exists, and the strength and the reliability of the connection between the two parts are improved.

Owner:MANNHUMMEL FILTER SHANGHAI

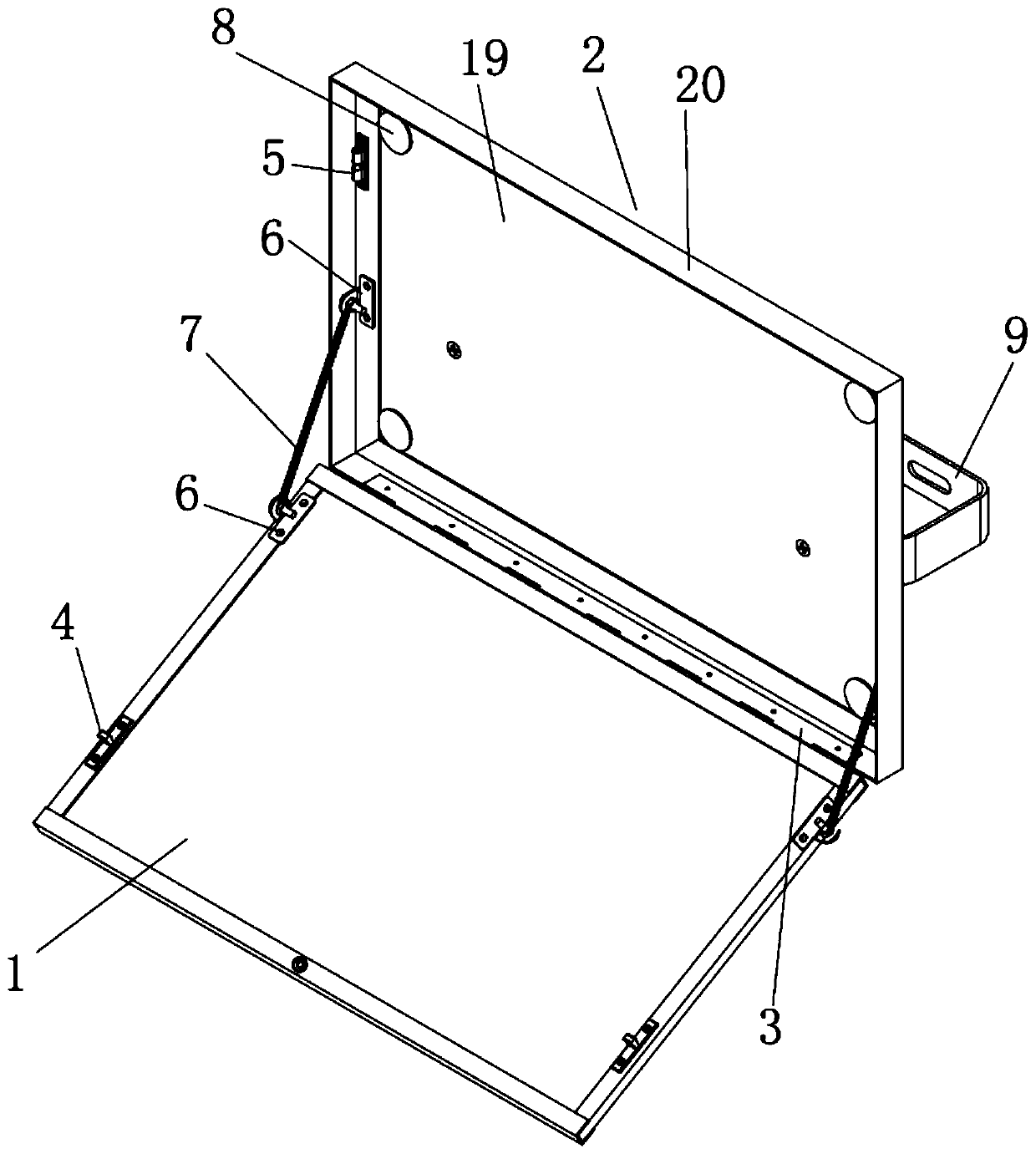

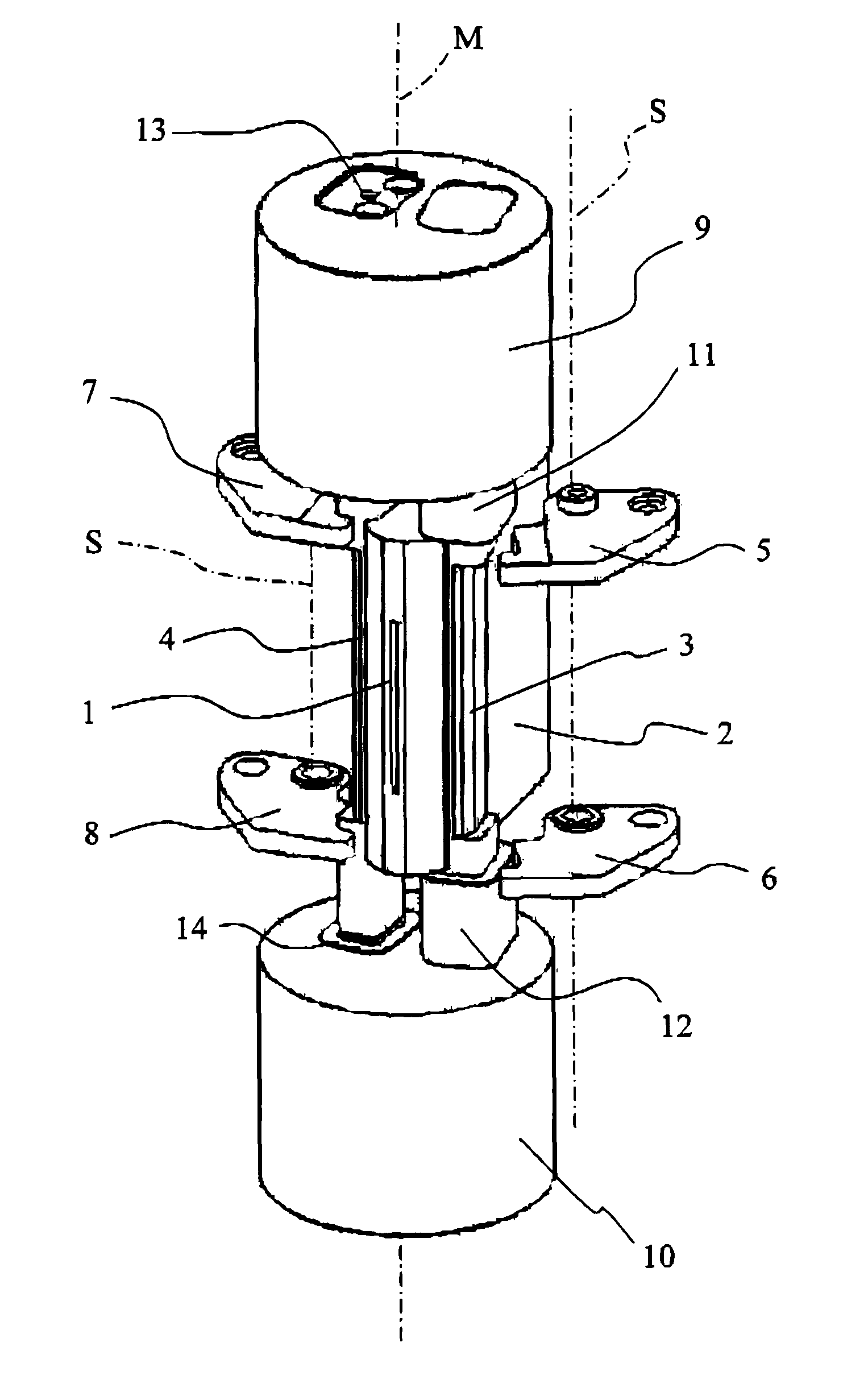

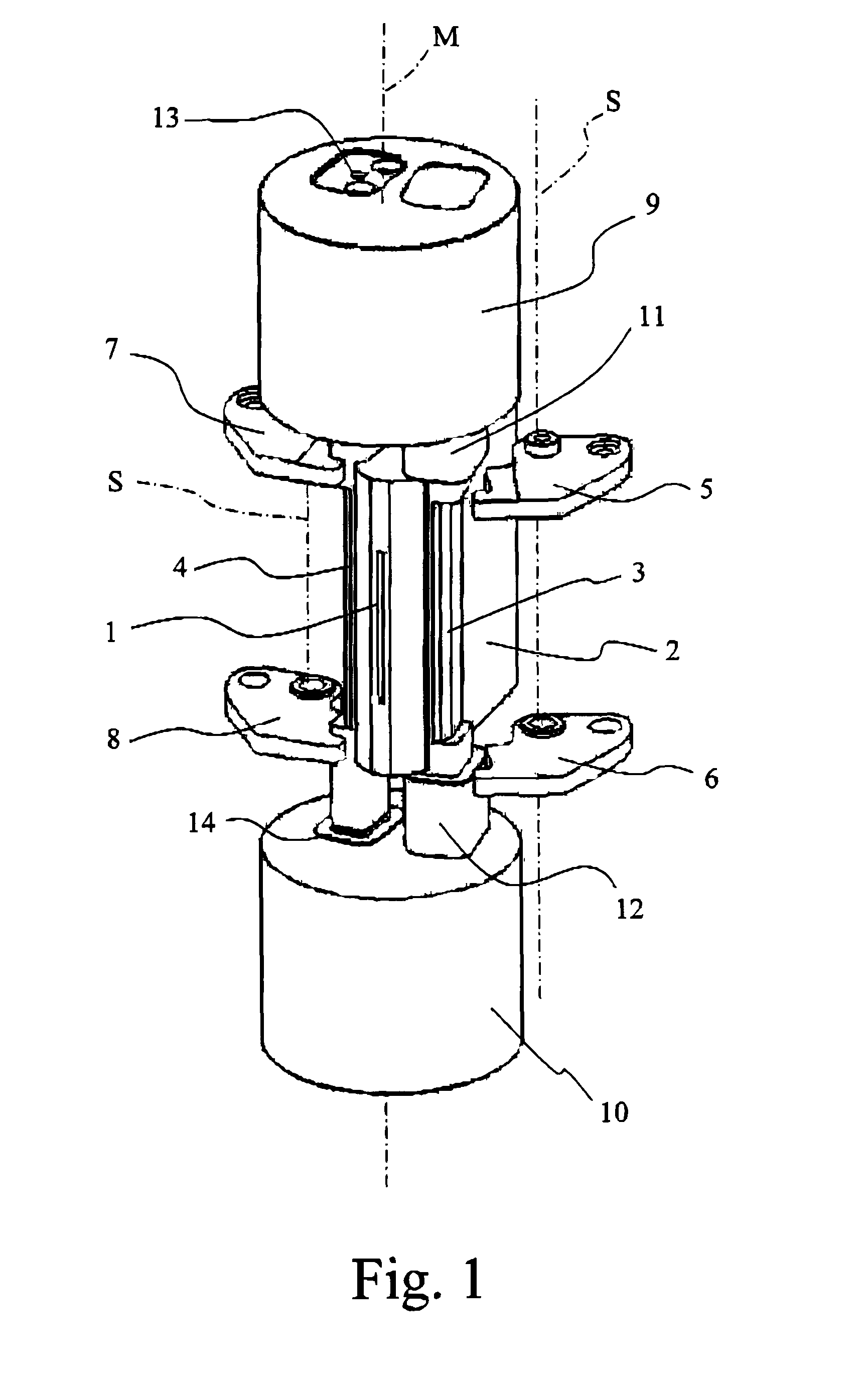

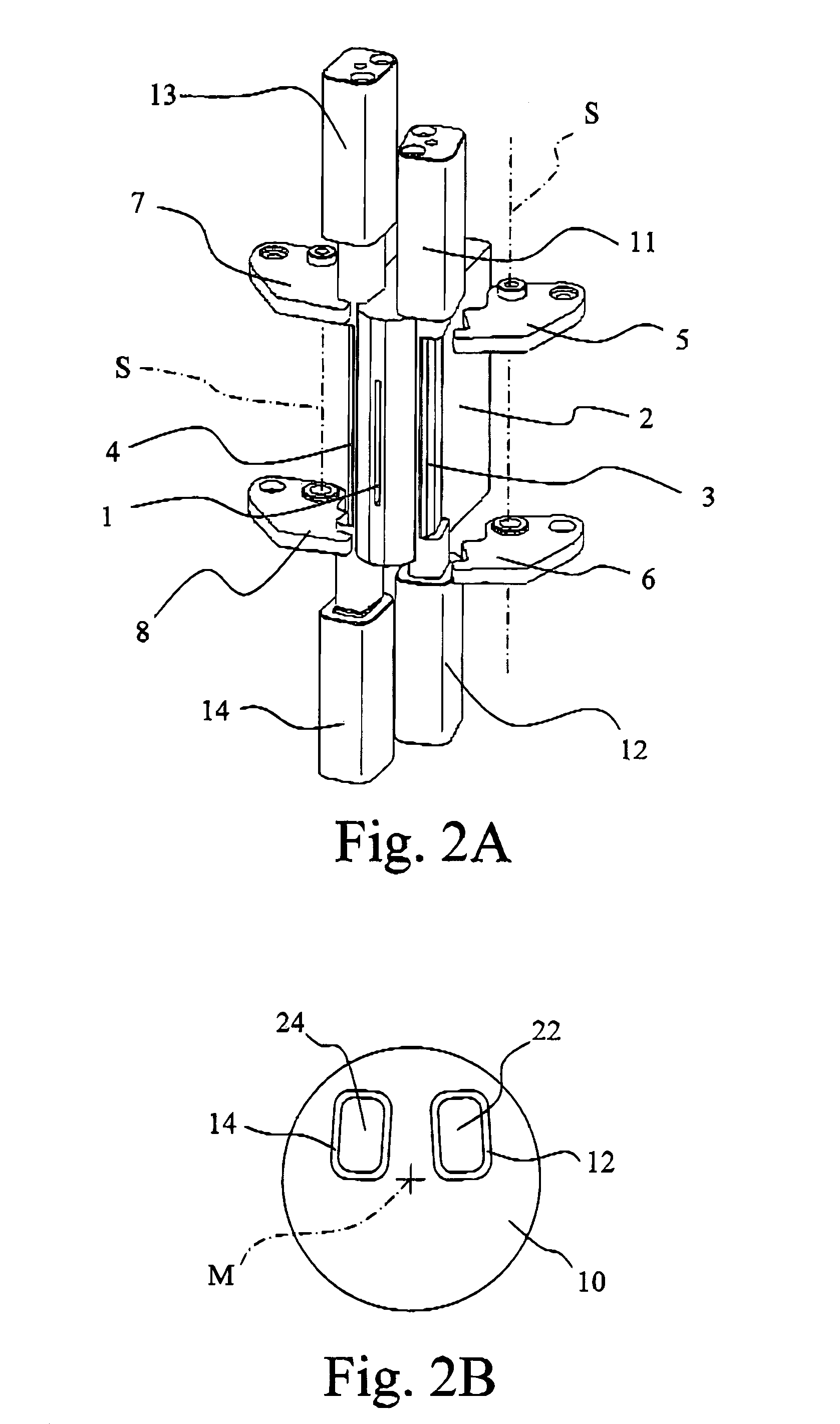

System for bending a metallic strip

ActiveUS20110107809A1Easy to produceSuitable for replacementShaping toolsMetal-working feeding devicesElectrical and Electronics engineeringMetal strips

Owner:PROFORM

adjustable torque driver

ActiveCN105437125BSuitable for replacementGood verification effectSpannersWrenchesEngineeringResistance force

A torsion-adjustable screw driver comprises a length-adjustable sleeve and a screw driver head with one end accommodated in the sleeve. The torsion-adjustable screw driver is characterized in that the torsion-adjustable screw driver further comprises resistance parts and a rotating shaft making contact with the resistance parts; the resistance parts and the rotating shaft are both accommodated in the sleeve, the resistance parts are fixedly connected to the sleeve, and the resistance parts and one end of the rotating shaft interact with each other to provide resistance for preventing the rotating shaft from rotating relative to the sleeve; the other end of the rotating shaft is fixedly connected with one end of the screw driver head; the magnitude of the resistance for preventing the rotating shaft from rotating relative to the sleeve is in direct proportion to the contact area of the rotating shaft and the resistance parts; by controlling the contact area of the rotating shaft and the resistance parts, the resistance for preventing the rotating shaft from rotating relative to the sleeve is determined, and therefore the maximum torsion for rotating the rotating shaft is determined, and the maximum screwing torsion of the screw driver head is determined. According to the torsion-adjustable screw driver, bidirectional torsion adjustment can be achieved through the resistance between the resistance parts and the rotating shaft, a good examination effect in engineering examination is achieved, the structure is simple, and the screw driver head can be replaced by various screw driver heads.

Owner:苏州卫优知识产权运营有限公司

Portable electric cable peeling tool

InactiveCN107658801AEasy to carrySuitable for carryingApparatus for removing/armouring cablesElectric driveEngineering

The invention discloses a portable electric cable peeling tool, and the tool comprises a cylindrical body. The cylindrical body is provided with a cable conveying device, and the interior of the bodyis through in a length direction. The upper side of the front part of the body is provided with a handle, and the body at the rear side of the handle is provided with a clamping knife rest. The central part of the clamping knife rest is provided with a knife slot, and the knife slot is communicated with the interior of the body in an inward manner. The interior of the knife slot is provided with ablade, and the blade and the axis of the body are located in the same plane. The tip of the blade is disposed in the body. The tool provided by the invention is simple and light in structure, is portable, and is used for the peeling of waste cables through electric drive.

Owner:STATE GRID CORP OF CHINA +2

A kind of installation method of catalyst module in scr denitrification reactor

InactiveCN103831014BSimple designReasonable designDispersed particle separationPetroleum engineeringSelective catalytic reduction

The invention discloses an assembly method for catalyst modules in a novel SCR (Selective Catalytic Reduction) denitration reactor. The method comprises the following four steps: step one, arranging a transverse hoisting main rail and a vertical hoisting secondary rail on a monorail hoist which is located on the bottom of a top steel beam of a layer when assembling the catalyst modules of the layer, and enabling the catalyst modules to enter a reactor along with transverse movement of a manual hoist or an electric hoist which is arranged on the hoisting main rail; step two, putting the catalyst modules down near the hoisting secondary rail after reaching main units through the hoisting main rail, then withdrawing from the electric hoist or manual hoist of the main rail; step three, manually assembling a secondary rail connection part, vertically moving the secondary rail connection part and a manual hoist to hoist the catalyst modules in determined positions; and step four, taking the secondary rail connection part down after a whole line of catalyst modules is assembled for each time and applying the secondary rail connection part to assembly of other lines or other layers. The assembly method for the catalyst modules in the novel SCR denitration reactor is a catalyst module assembling technique which is simple, reliable, easy to operate and convenient to assembly in site.

Owner:BEIJING BREEZEWIND ENVIRONMENTAL PROTECTION TECH

a refrigerator door

ActiveCN105716359BImprove stabilityAesthetic issuesDomestic cooling apparatusLighting and heating apparatusRefrigerator carRefrigerated temperature

The invention particularly provides a refrigerator door comprises a door front cover; a fixing device for a magnetic control lamp switch is shaped on the inner side face of the door front cover. According to the refrigerator door provided by the invention, by arranging the fixing device for the magnetic control lamp switch on the inner side face of the door front cover, not only can a problem that aesthetic property of the door is influenced due to the fact that the switch is exposed on the door front cover be avoided, but also the magnetic control lamp switch can be suitable for being installed and can be replaced with any magnetic control lamp switch, and the refrigerator door is simple in structure and convenient to install.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

In-vehicle anti-seismic video monitoring system

An in-vehicle anti-seismic video monitoring system includes a base, wherein the top side of the base is provided with a plurality of fixing holes uniformly distributed; the top side of the base is fixedly connected to the lower ends of three uniformly distributed support rods; the support rods are circumferentially distributed in a circle which is collinear with the centerline of the base; the upper ends of the support rods are fixedly connected to one end of the first spring, and the other end of the first spring is fixedly provided with a first hook; the inner side of the each support rod isprovided with the same fixing plate; the fixing plate is collinear with the centerline of the base, and the outer periphery of the fixing plate is fixedly provided with a first hook ring corresponding to the first hook; the first hook can hook the corresponding first hook ring; and the middle of the top side of the base is fixedly connected with the lower end of the upright column. The in-vehicleanti-seismic video monitoring system has the advantages of simple structure, reasonable design, quick disassembly of the fixing plate and the camera, convenient maintenance and replacement of the camera, meeting the market demand, and being suitable for popularization.

Owner:北斗时空(天津)研究院有限公司

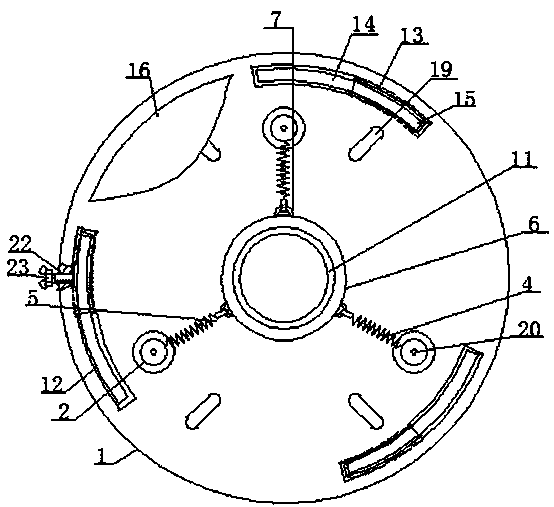

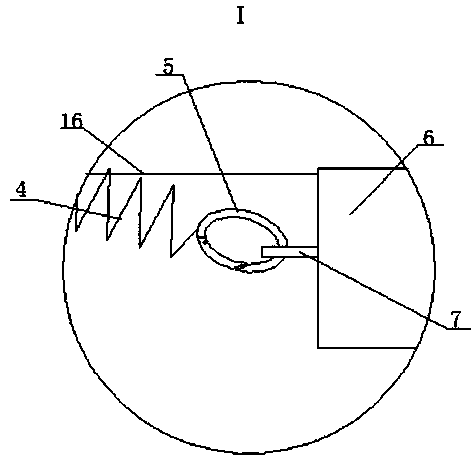

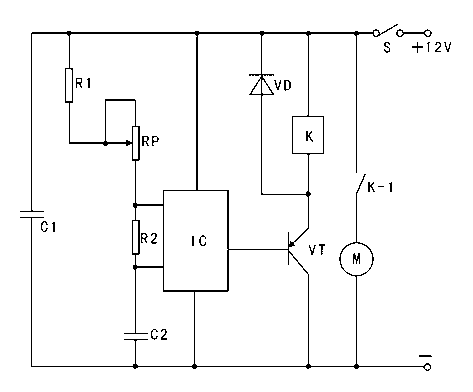

Simple controller of automobile wiper rod

InactiveCN103318137ASuitable for installationSuitable for replacementVehicle cleaningCapacitanceControl theory

The invention discloses a simple controller of an automobile wiper rod. The controller comprises a direct-current power supply, a timing integrated circuit, a relay, a wiper rod motor, a first resistor, a second resistor, a slide rheostat, a first capacitor, a second capacitor, a diode, a triode and a start switch. According to the simple controller of the automobile wiper rod, components of the timing integrated circuit, the start switch and the like together control the on and off of a power supply of the relay, and the on and off of a power supply of the wiper rod is controlled through a normally-opened switch of the relay, so that the work state of the wiper rod is controlled. The simple controller of the automobile wiper rod has the advantages that the structure is simple, the installation is convenient, the control is accurate and the cost is low, and is suitable for being installed or replaced in all vehicles.

Owner:CHENGDU SIMAO TECH

Signboard support

Owner:GUANGDONG POWER GRID CO LTD +1

rotor blade tip

InactiveCN104797815BAvoid damageEasy to manufactureEngine manufactureFinal product manufactureFastenerEnergy plant

Owner:WOBBEN PROPERTIES GMBH

System for bending a metallic strip

ActiveUS8720245B2Suitable for replacementPrecise positioningShaping toolsMetal-working feeding devicesEngineeringMetal

Owner:PROFORM

Four side bending system

ActiveCN102909244BImprove combination efficiencyEasy to arrange for productionEngineeringMaterial transfer

The invention relates to a four-side bending system comprising a first bending unit, a second bending unit and a material transferring device, wherein the first bending unit is used for completing the bending work of a group of opposite sides of a material to be bent; the second bending unit is used for completing the bending work of the other group of opposite sides of the material to be bent; and the material transferring device is used for shifting the material according to the process. The first bending unit comprises a first static bending machine, a first movable bending machine, a first working table and a first positioning part, wherein the first static bending machine and the first movable bending machine are oppositely placed on a main frame; and the working table and the positioning part are placed between the first static bending machine and the first movable bending machine. The second bending unit comprises a second static bending machine, a second movable bending machine, a second working table and a second positioning part, wherein the second static bending machine and the second movable bending machine are oppositely placed on the main frame; and the second working table and the second positioning part are placed between the second static bending machine and the second movable bending machine. The four-side bending system is relatively high in production efficiency, relatively low in manufacture cost and simple to maintain and is suitable for various productions.

Owner:YINDU KITCHEN EQUIP

Process for preparing strontium-doped calcium polyphosphate biological active bone cement

InactiveCN101444639BSuitable for repairSuitable for replacementImpression capsDentistry preparationsManufacturing technologyMass ratio

The invention discloses a process for preparing fermorite-doped biological active bone cement. The cement solid phase adopted by the process is a mixture comprising tracalcium phosphate and Alpha-calcium phosphate which are distributed in a certain grain fineness and prepared according to a certain molar ratio, wherein, the Alpha-calcium phosphate strontium salt powder is a mixture comprises Alpha-SrxCa3-x(PO4)2 or Alpha-Sr3(PO4)2 and Alpha-Ca3(PO4)2 powder which are mixed by a certain molar ratio; the aqueous phase is a water deionized dilute phosphoric acid solution or a dilute phosphoric acid solution with the concentration being lower than 2 mol / l; the solid-to-liquid mass ratio is 1.0 to 4.0; and the final product under the physiological environment is strontium-doped hydroxylapatite. The cement has the advantages that the strontium doping content and the calcium strontium / phosphorus ratio are adjustable; the manufacturing technology is simpler; and the like. Compared with calcium phosphate bone cement of other types, the biological active bone cement has wider application prospect.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com