Handling clamp for handling hollow bodies and method for producing same

A manufacturing method, hollow body technology, applied in additive processing, conveyor objects, transportation and packaging, etc., can solve problems such as production decline, clamps cannot be replaced, shutdowns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The term "hollow body" is used hereinafter to denote preforms and final containers which have undergone at least one blow molding operation or stretch blow molding operation.

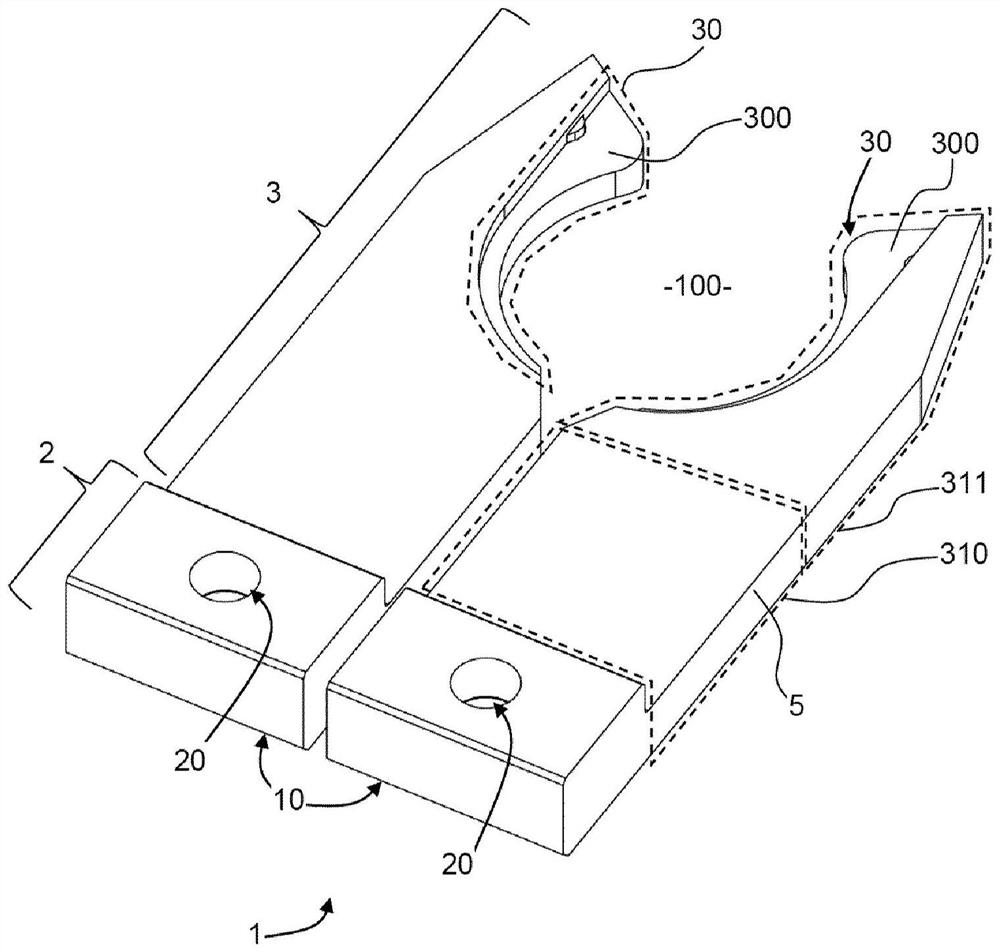

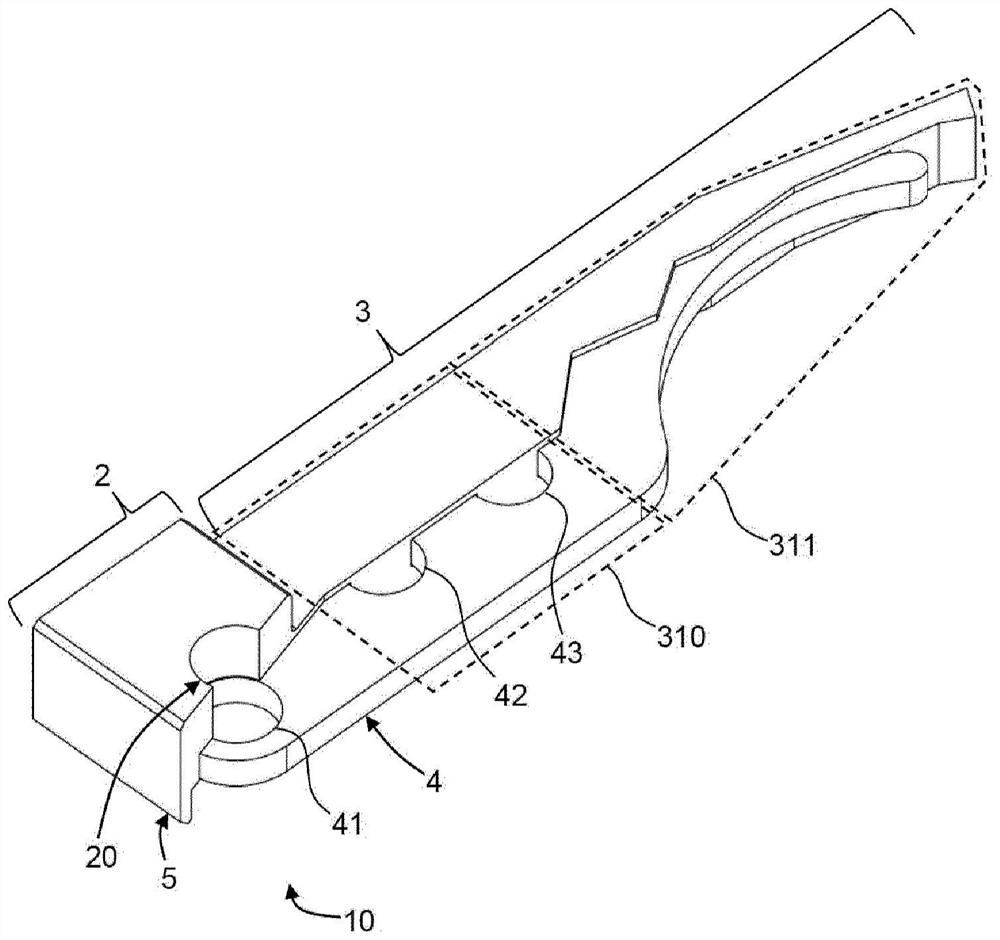

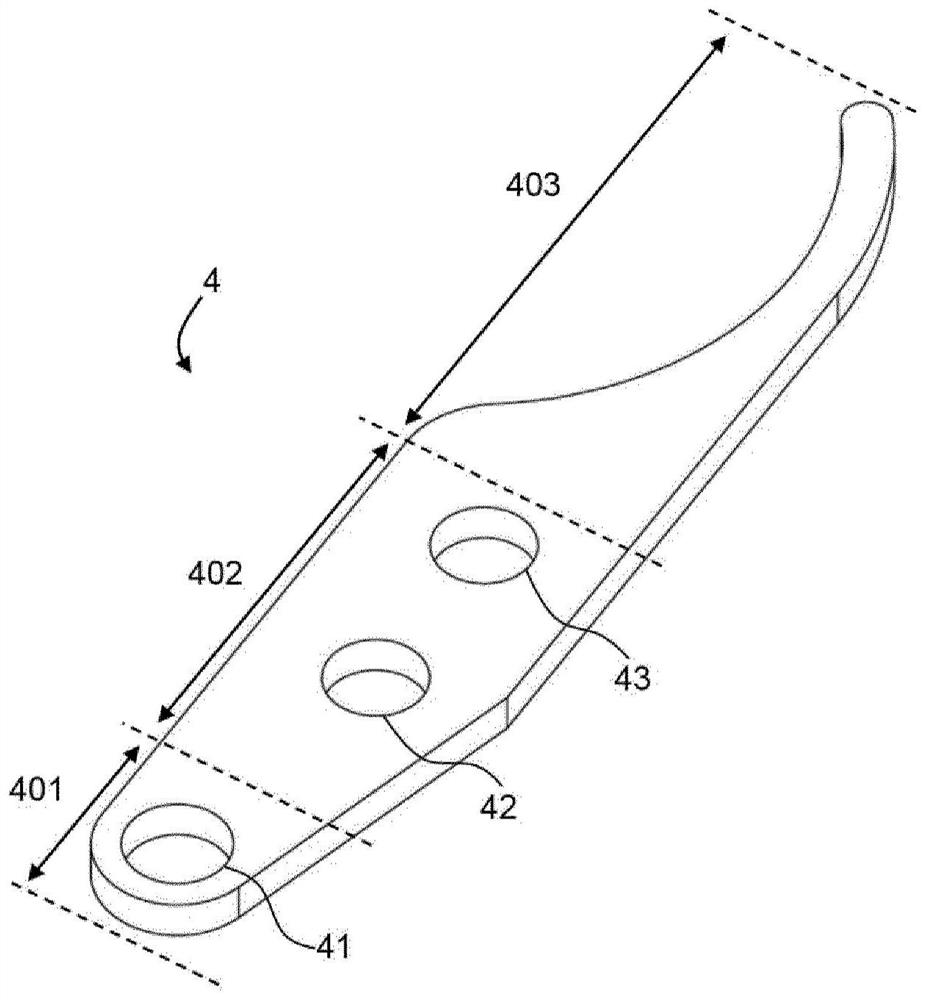

[0091] refer to figure 1 , shows the operating tongs 1 for operating the hollow body. Such a handling gripper 1 is used in a manufacturing cell of plastic containers comprising the following machines: blow molding machines, filling machines, labeling machines and the like.

[0092] The operating tongs 1 comprise two arms 10 .

[0093] The two arms 10 are designed to be held by holding members (not shown) of the manufacturing unit. For this purpose, each arm 10 comprises cooperating means 20 for cooperating with the retaining member to establish the coupling of the arm 10 with the retaining member.

[0094] The arm 10 serves to grip the hollow body by its neck. These two arms 10 together define a receiving space 100 for receiving the hollow body when it is gripped.

[0095] The hollow body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com