A kind of installation method of catalyst module in scr denitrification reactor

A catalyst module and denitrification reactor technology, applied in the field of environmental protection, can solve the problems of inability to set up horizontal supports, large steel consumption, unreasonable structure, etc., and achieve the effects of optimizing the body design, saving cost, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

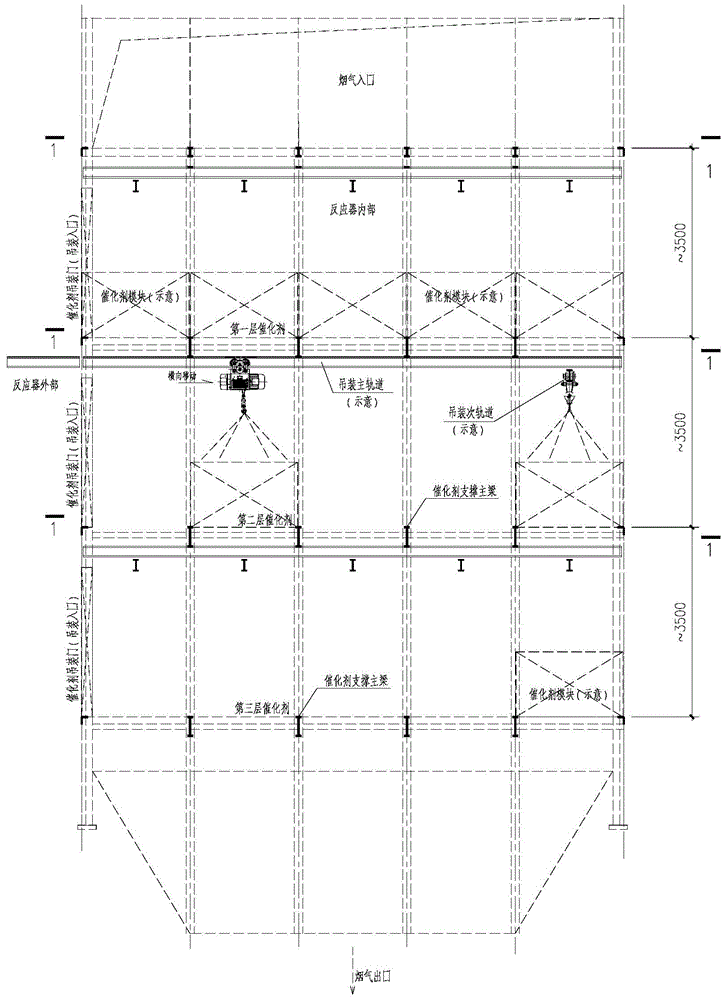

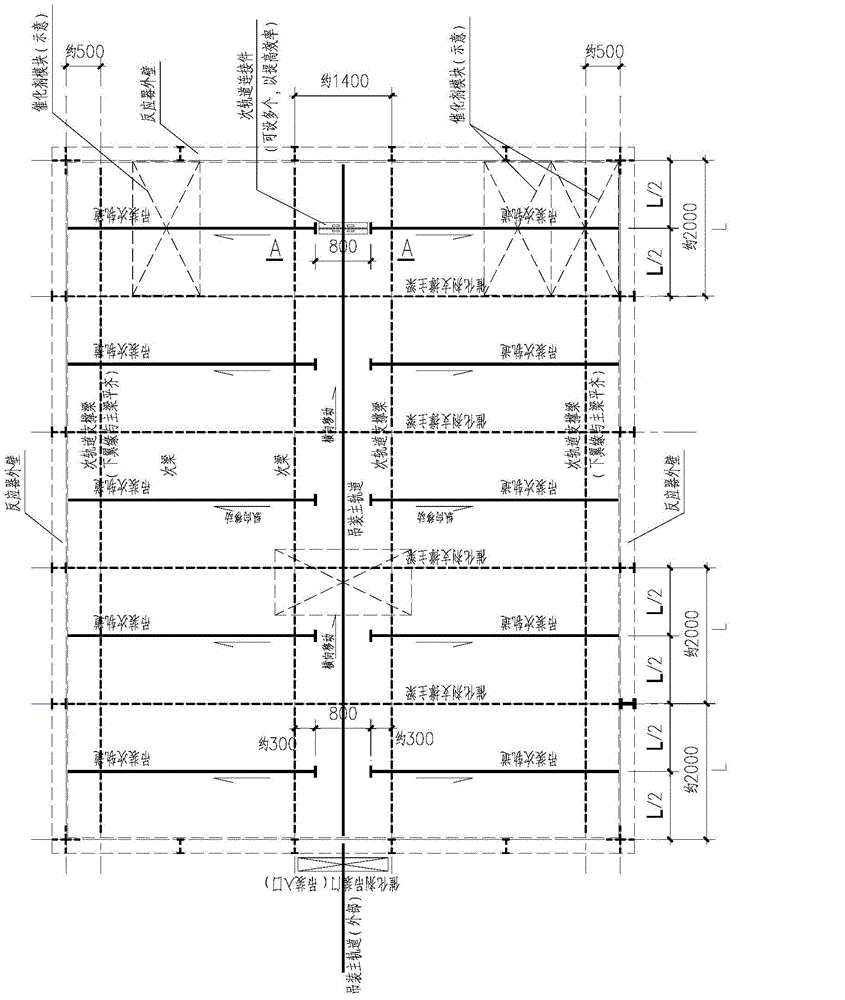

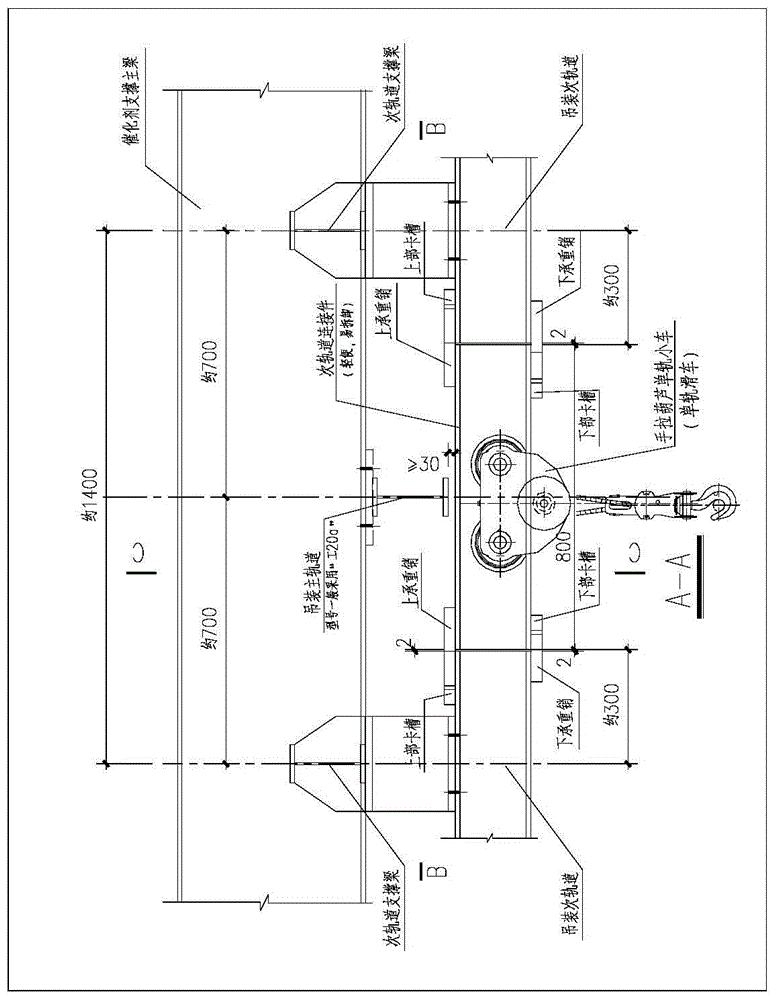

[0023] See figure 1 , figure 2 , Figure 3a , Figure 3b , Figure 3c , the installation method of catalyst module in a kind of SCR denitrification reactor of the present invention, its concrete steps are as follows:

[0024] Step 1, when installing the catalyst module of this layer, set the horizontal "main rail for hoisting" and the vertical "secondary rail for hoisting" at the bottom of the steel beam on the top surface of this layer (that is, the bottom of the steel beam supporting the catalyst module on the previous layer). The catalyst module enters the reactor through "lateral movement" of an electric or manual hoist on the "hoisting main rail". See accompanying drawing of the present invention " figure 1 "--" Schematic diagram of the elevation of the catalyst module in the SCR denitrification reactor." figure 1 " is the installation mode for installing one layer of catalyst. The installation of catalyst modules of other layers shall be carried out according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com