Buckle structure for connecting integrated parts

A technology of snap-fit structure and integrated components, applied in directions such as fuel and air inlets, can solve problems such as increased cost, stress concentration at the vacuum chamber connection, fracture failure at the connection, etc., to facilitate disassembly and installation, avoid stress concentration, improve The effect of strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

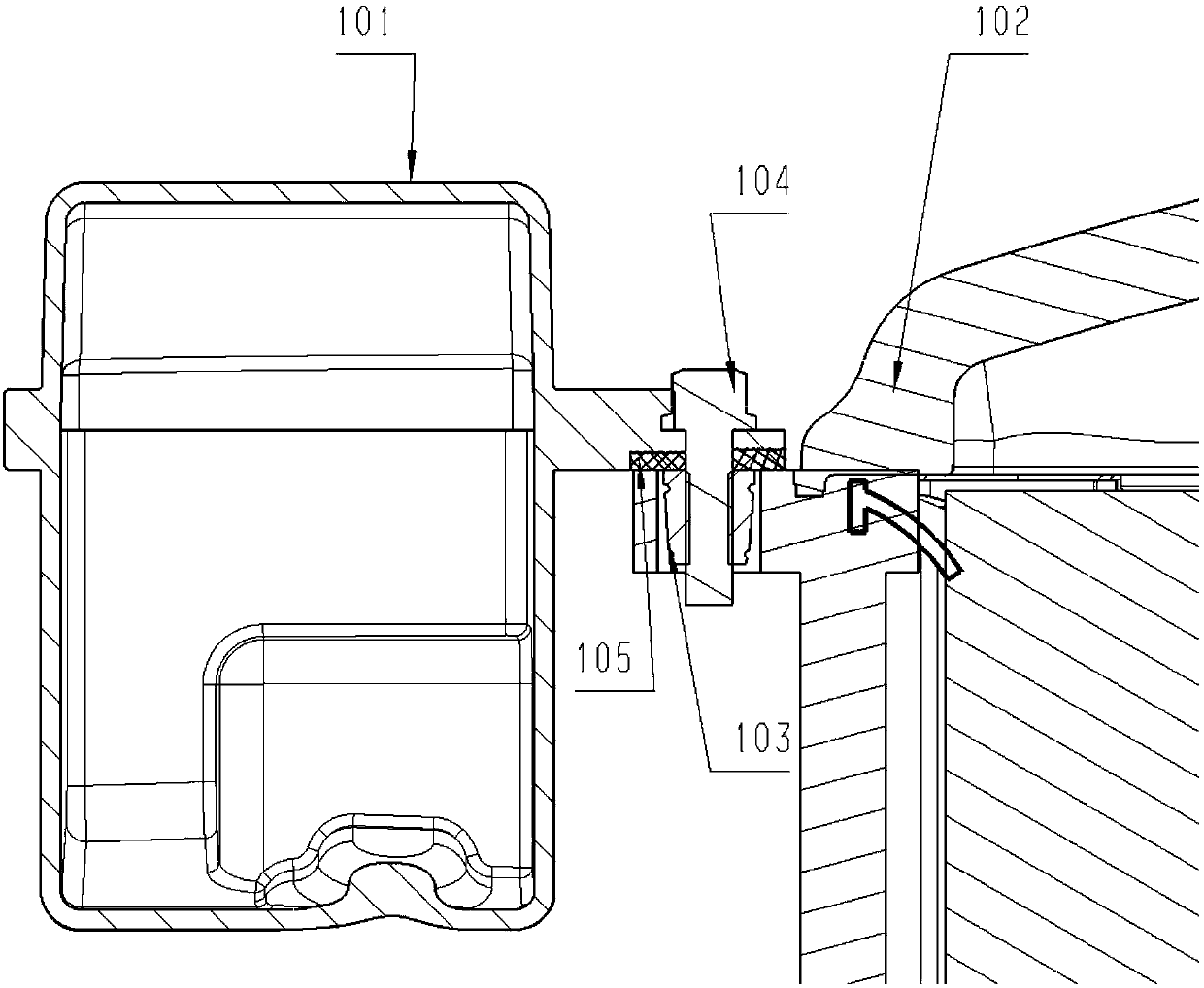

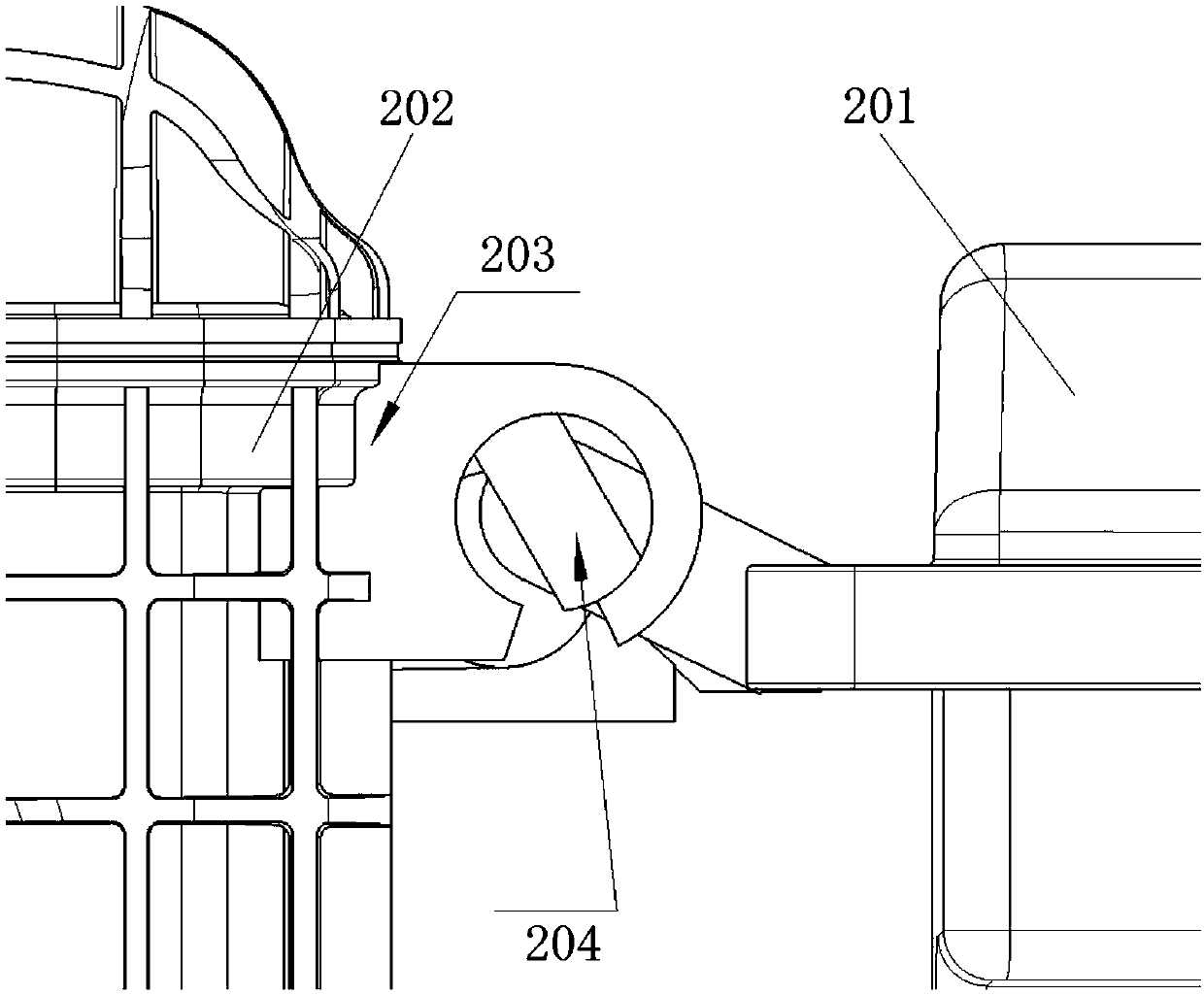

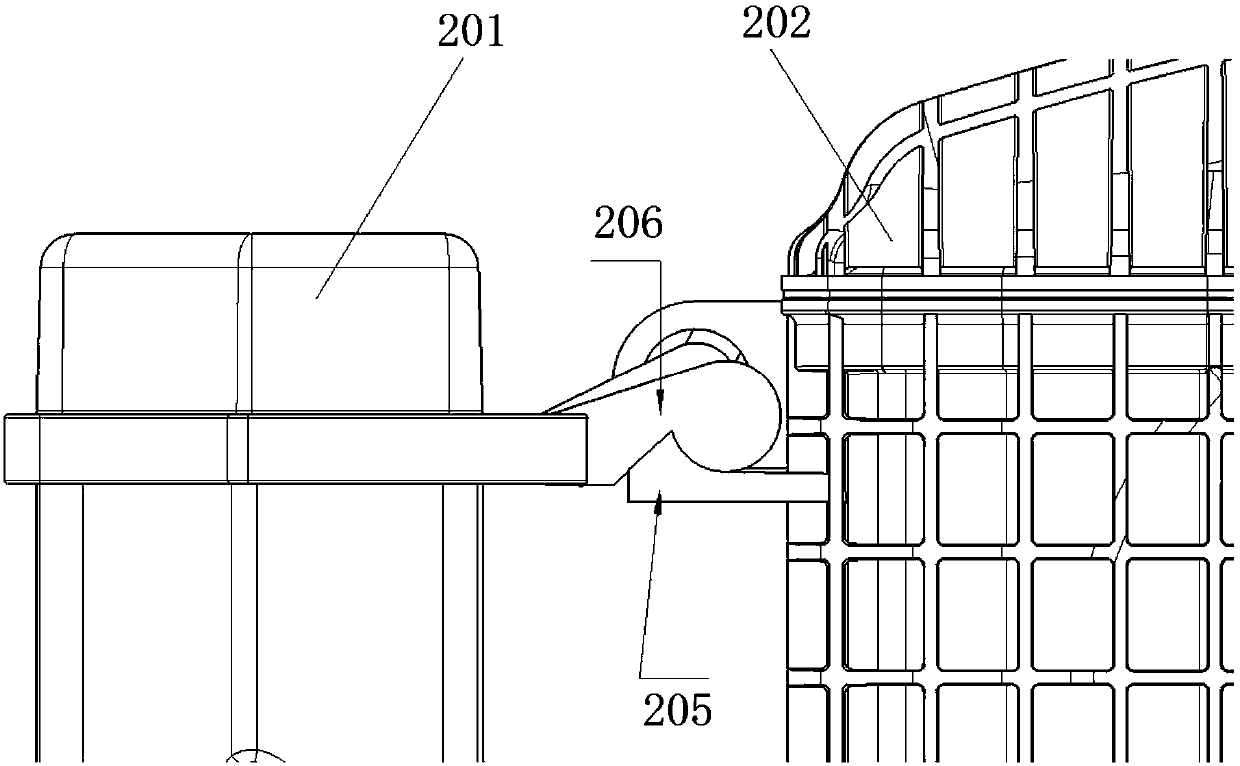

[0023] A snap-fit structure for connecting integrated components such as figure 2 , 3 As shown, it is used to connect the intake manifold housing 202 and the vacuum chamber housing 201, including the first card slot 203 and the second card slot 205 arranged on both sides of the intake manifold housing 202, and the vacuum chamber housing The first gear button 204 and the second gear button 206 on both sides of the body 201, the first card slot 203 is provided correspondingly to the first gear button 204, the second card slot 205 is correspondingly arranged to the second gear button 206, and the first card slot 203 is provided correspondingly. The first gear buckle 204 is inserted, and the second gear buckle 206 is engaged with the second locking slot 205 .

[0024] As a preferred technical solution, the first card slot 203 is a circular c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Opening width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com