Patents

Literature

40results about How to "Increased Strength Reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

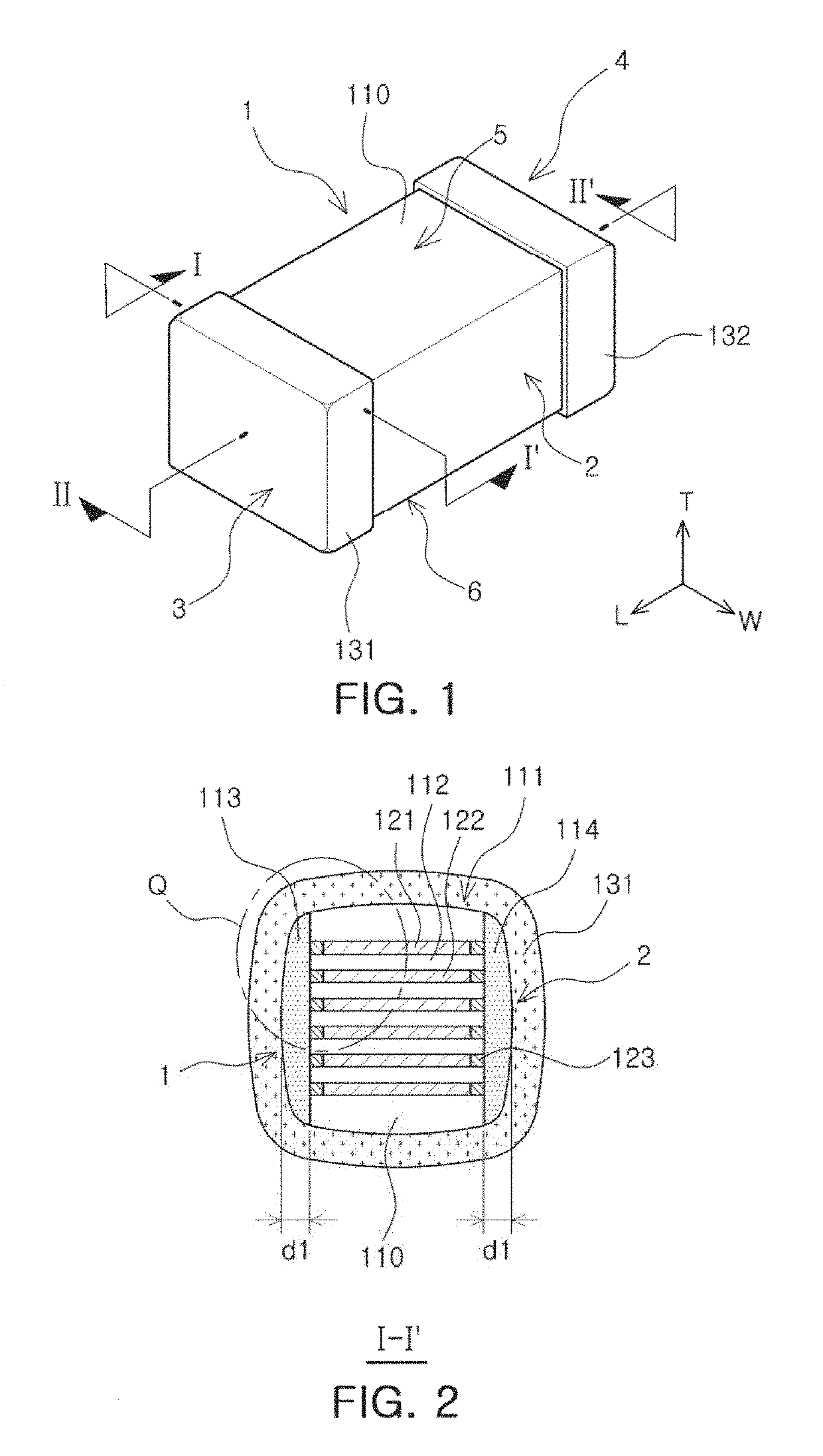

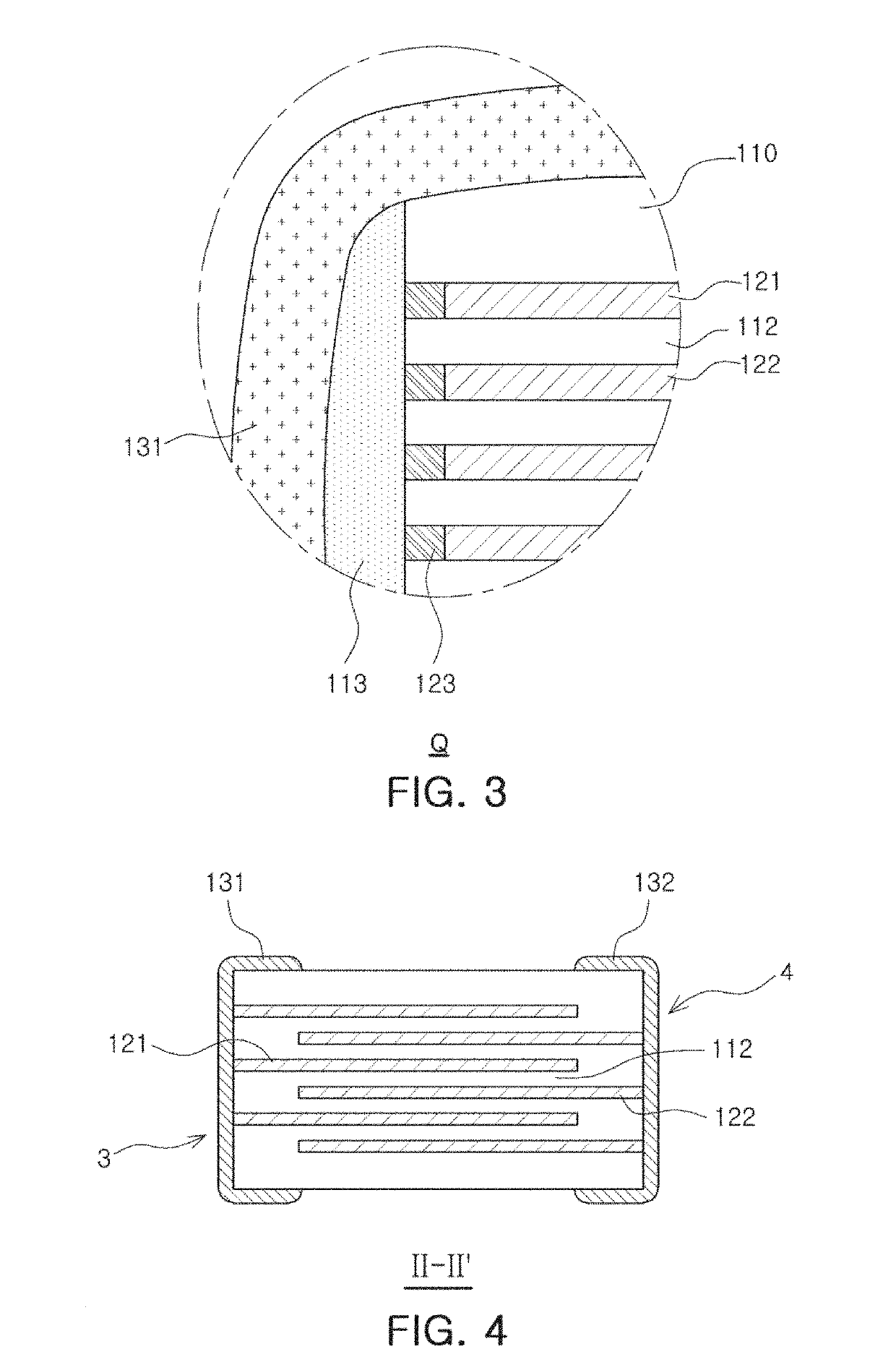

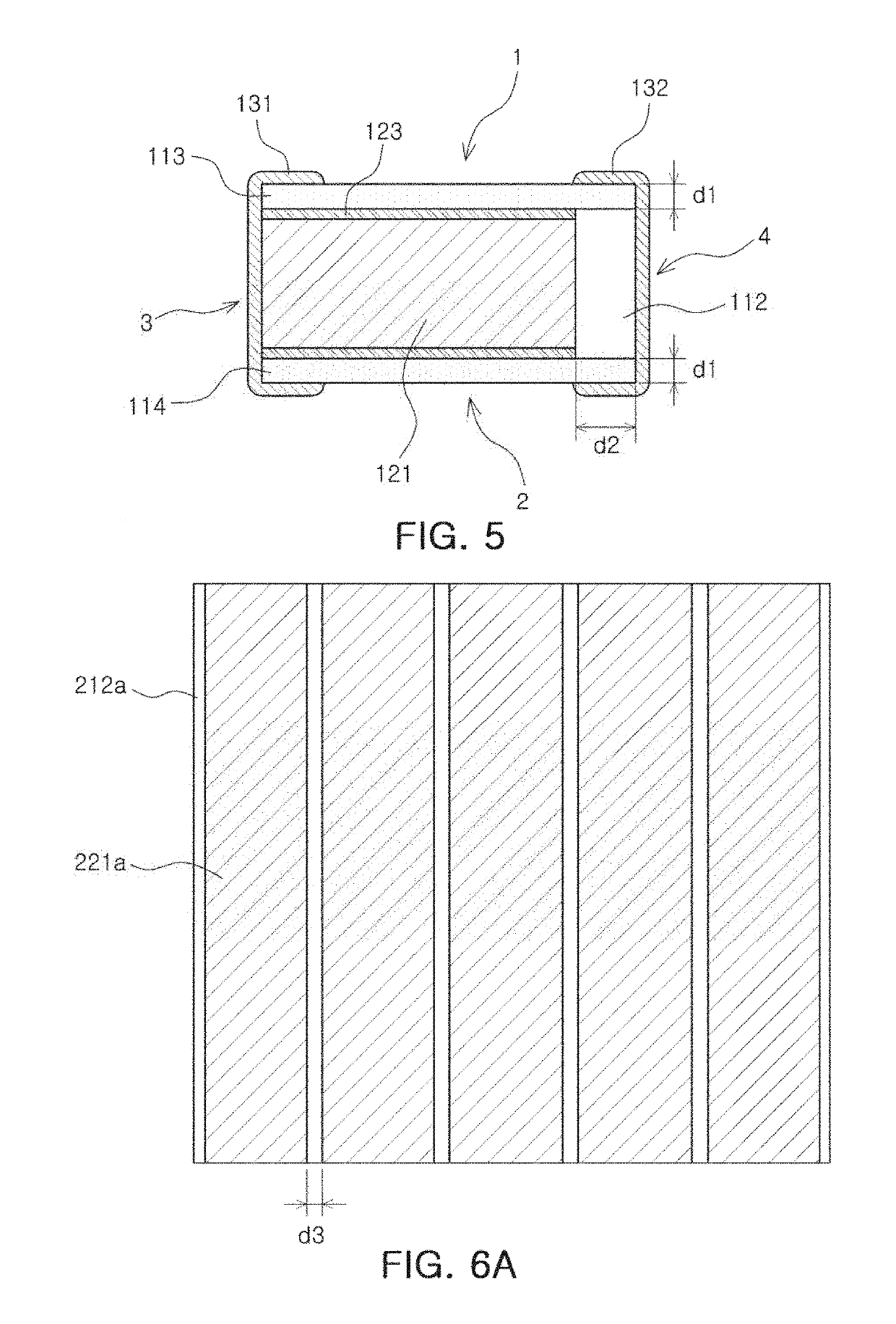

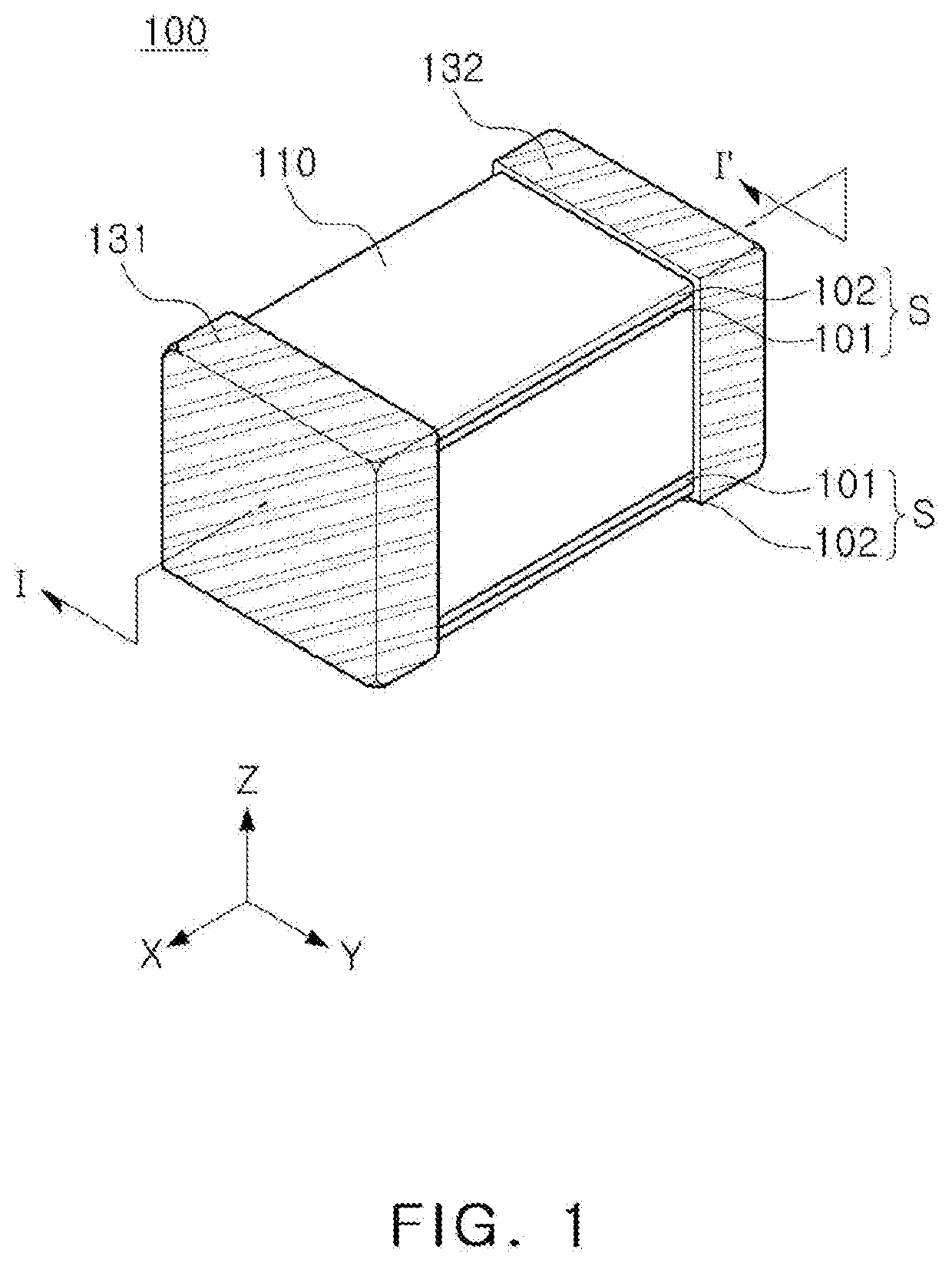

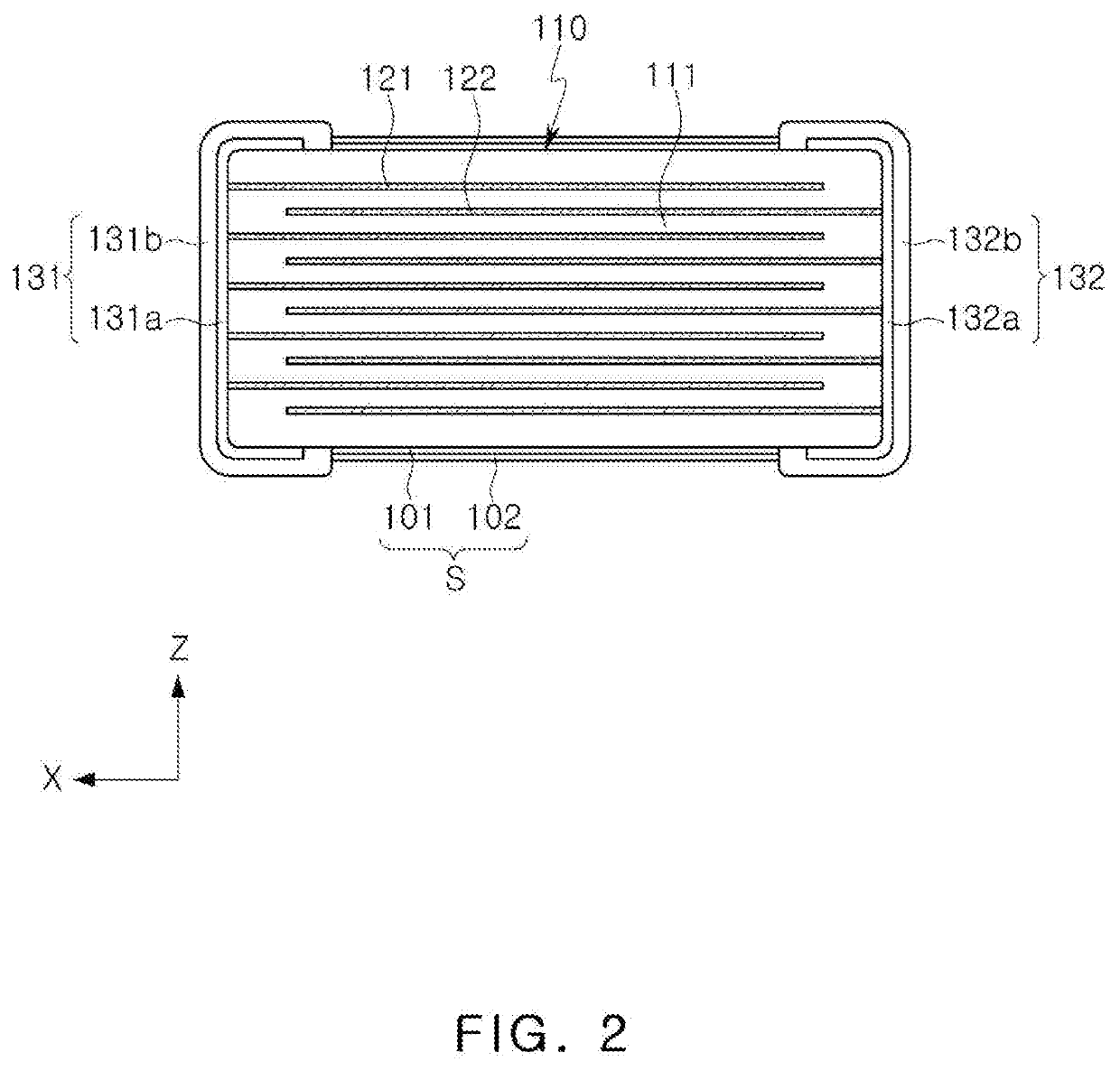

Multilayer ceramic capacitor

ActiveUS20190115153A1Improve high temperature reliabilityHigh mechanical strengthFixed capacitor electrodesFixed capacitor dielectricBarium titanateCeramic capacitor

A multilayer ceramic capacitor includes: a ceramic body having first and second surfaces opposing each other and third and fourth surfaces connecting the first and second surfaces to each other; a plurality of internal electrodes disposed in the ceramic body, exposed to the first and second surfaces, and each having one end exposed to the third or fourth surface; and first and second side margin portions disposed on the first and second surfaces and covering exposed surfaces of the internal electrodes. A dielectric composition contained in the first and second side margin portions is different from a dielectric composition contained in the ceramic body, the first and second side margin portions contain a barium titanate-based base material powder and magnesium (Mg), manganese (Mn), and aluminum (Al) as accessory ingredients, and a content ratio of manganese (Mn) to magnesium (Mg), manganese (Mn), and aluminum (Al) satisfies 0.316≤Mn / (Mn+Mg+Al)≤0.500, based on a molar content of Mn, Mg and Al in the first and second side margin portions.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

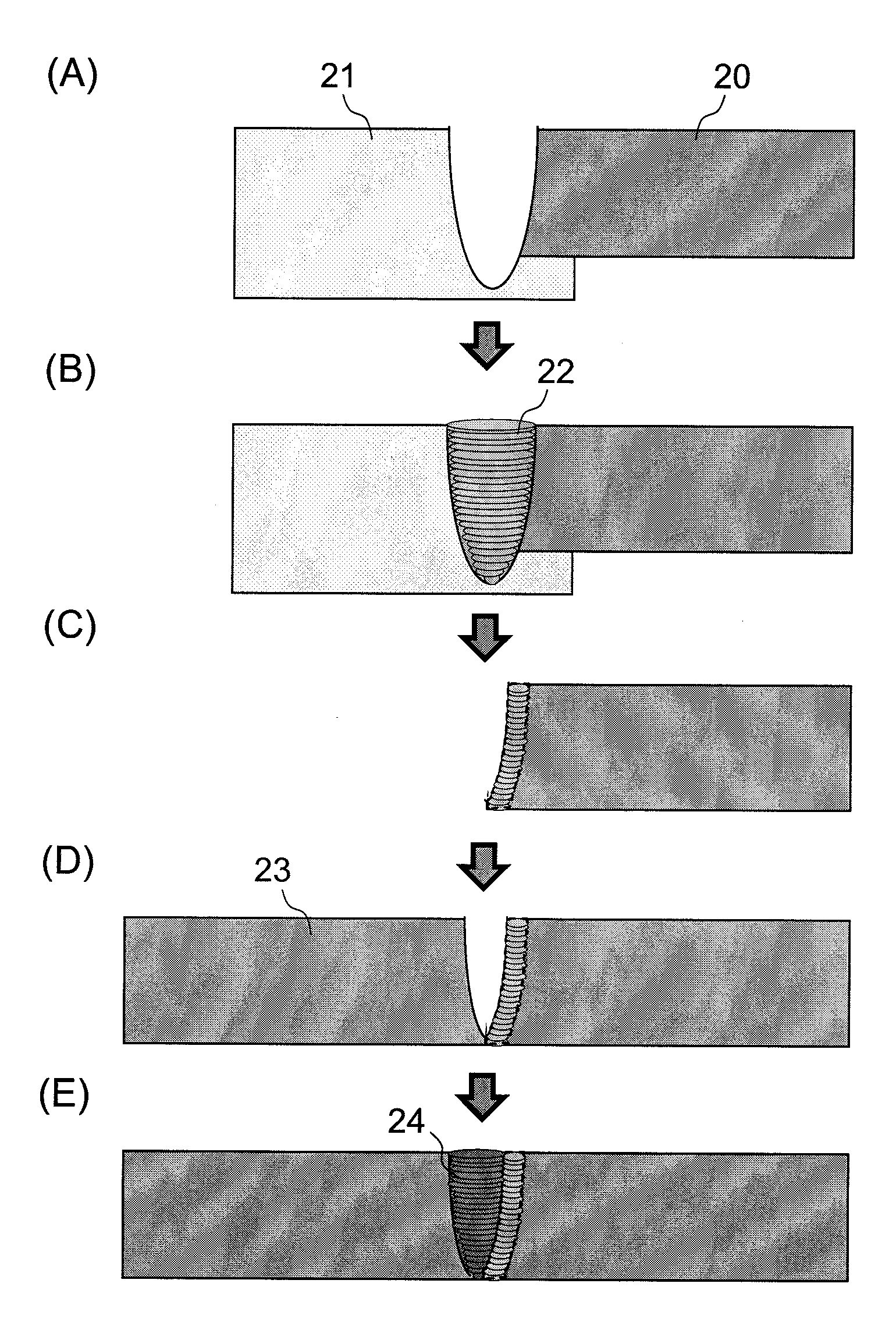

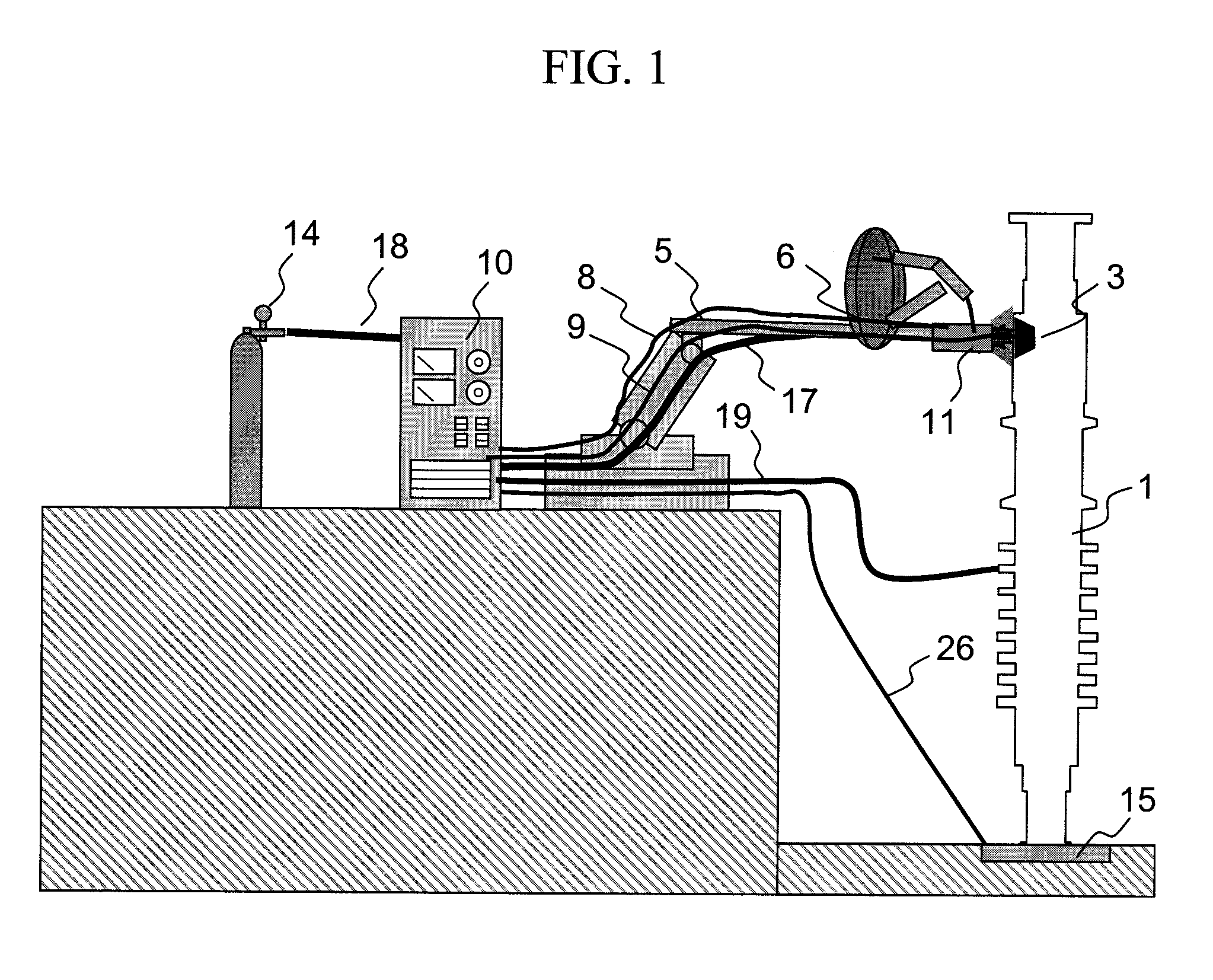

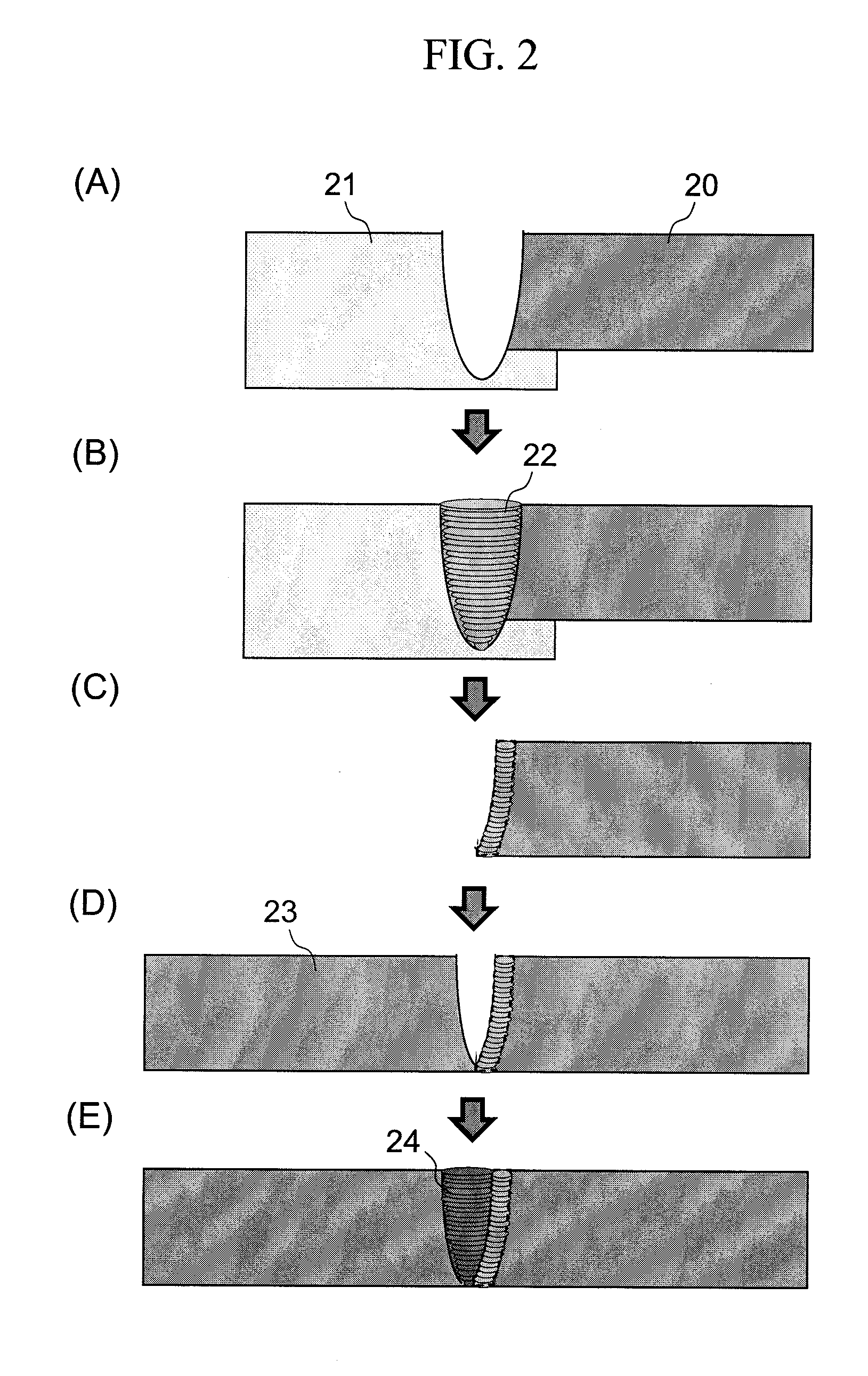

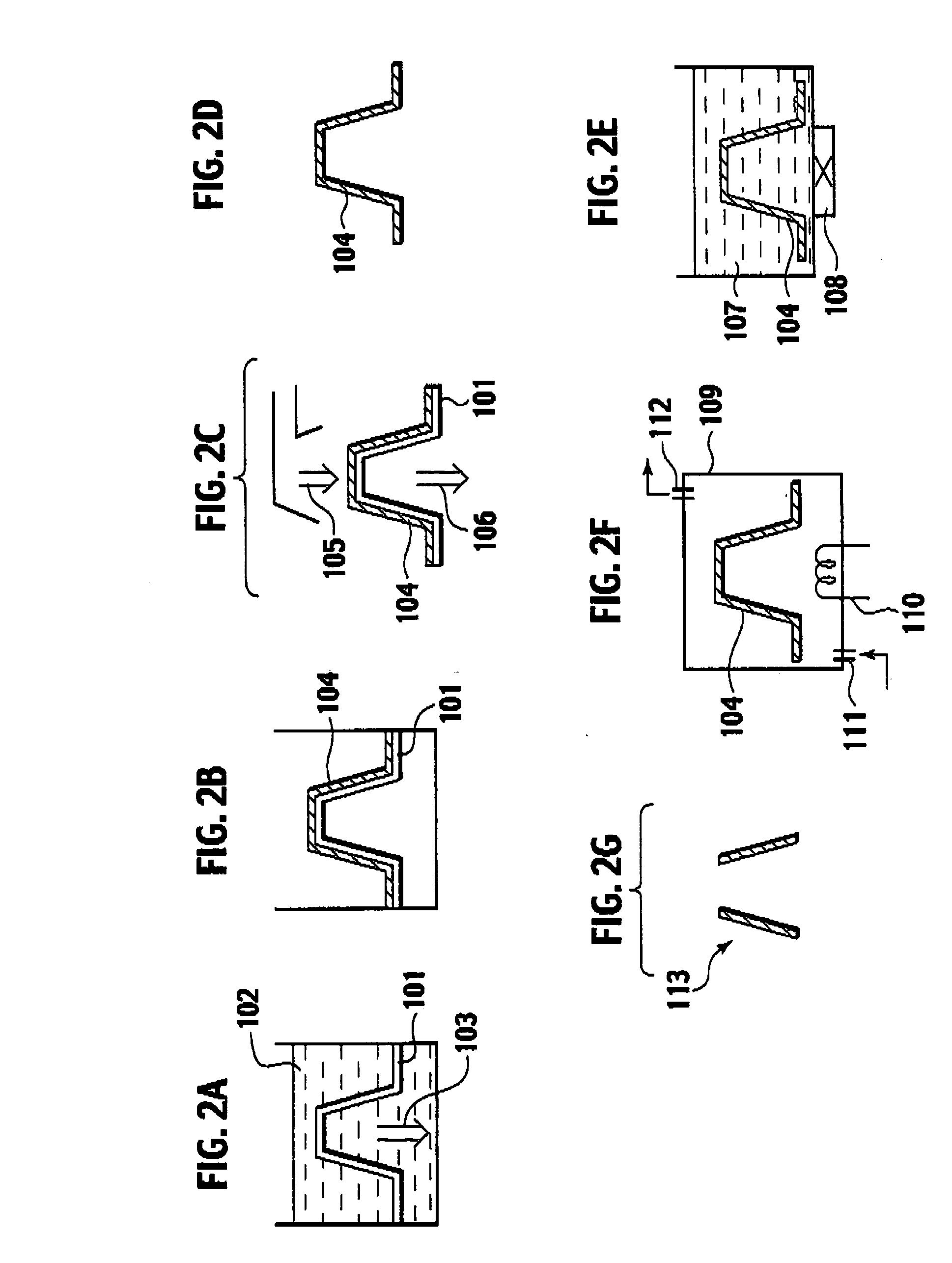

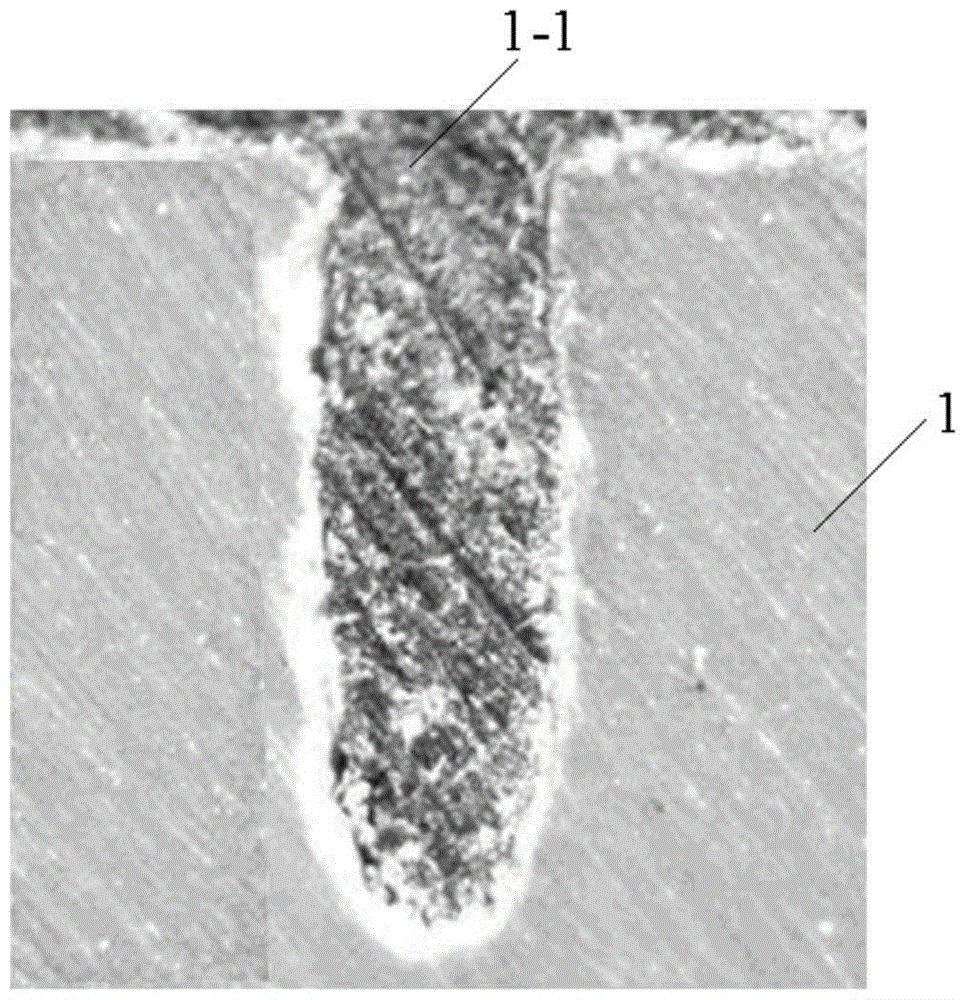

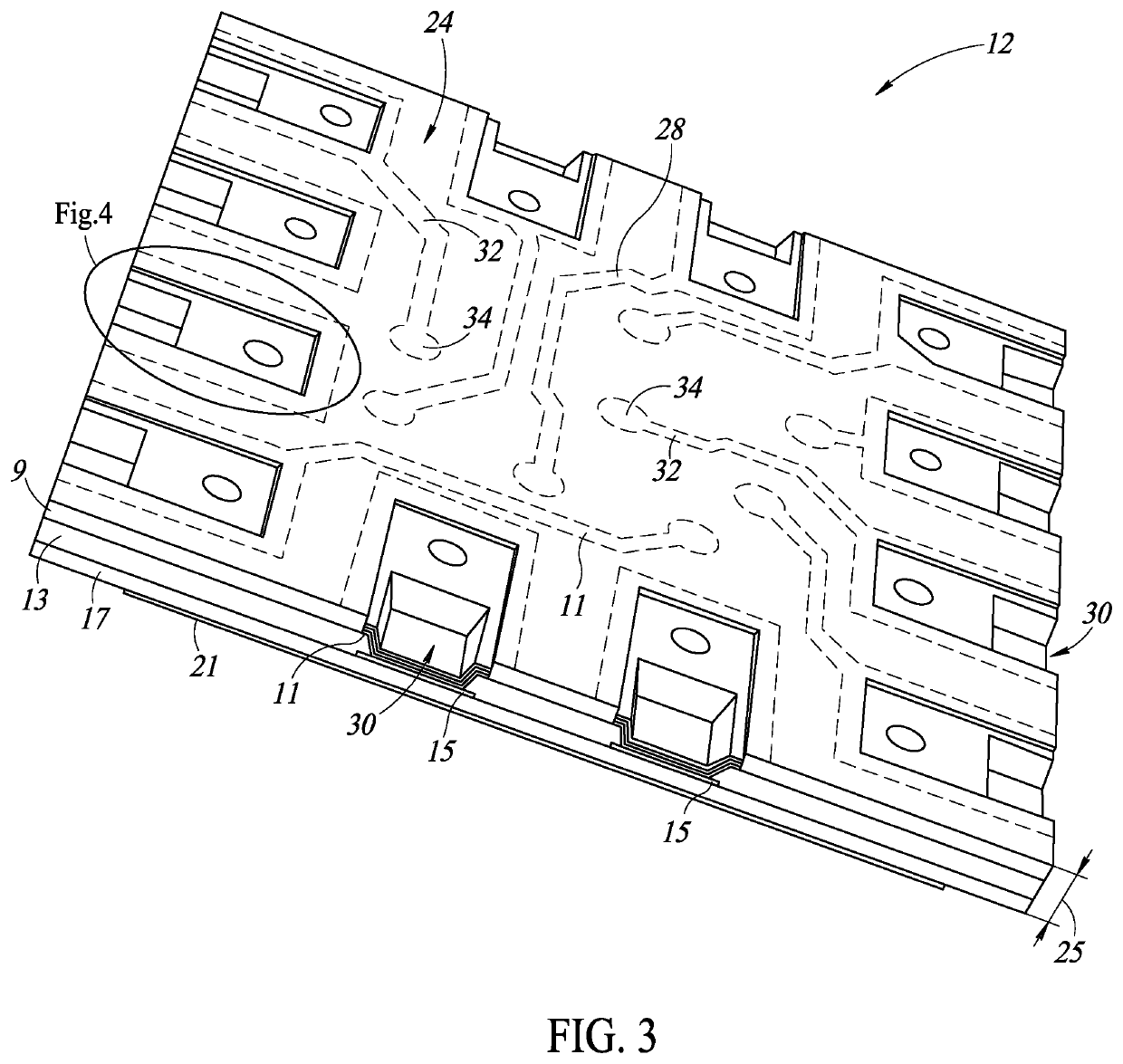

Dissimilar metal welds and its manufacturing method of large welded structures such as the turbine rotor

InactiveUS20120301309A1Preventing deterioration strengthIncreased Strength ReliabilityTurbinesPump componentsButt weldingUltimate tensile strength

Dissimilar metal welds including a buttering portion with a small variation in strength distribution in a plate thickness direction are formed by welding two parent materials having at least one of different compositions and different refining conditions through a buttering for alleviating mismatch between one of the different compositions and the different refining conditions of the two members and through a welded metal for joining one of the parent materials and the buttering. The buttering is formed of welding metals laminated in a plate thickness direction, and a dilution ratio of the buttering with the parent materials is 50% or less. The manufacturing method includes performing butt welding on a dummy material formed by increasing a groove depth by providing a member on a bottom side of a welding groove and on parent materials by using the buttering; and processing a groove within a welding metal formed of the buttering.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

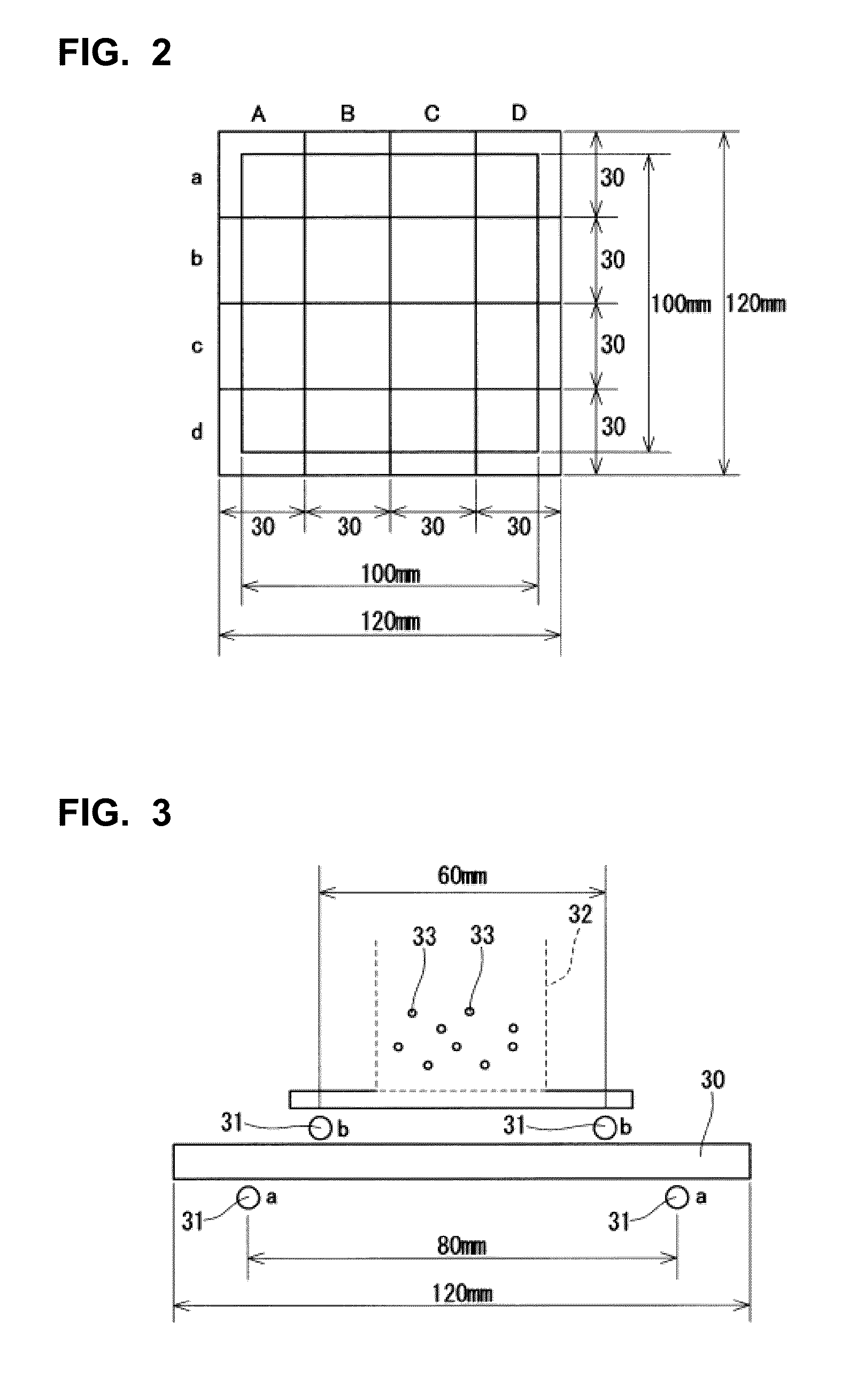

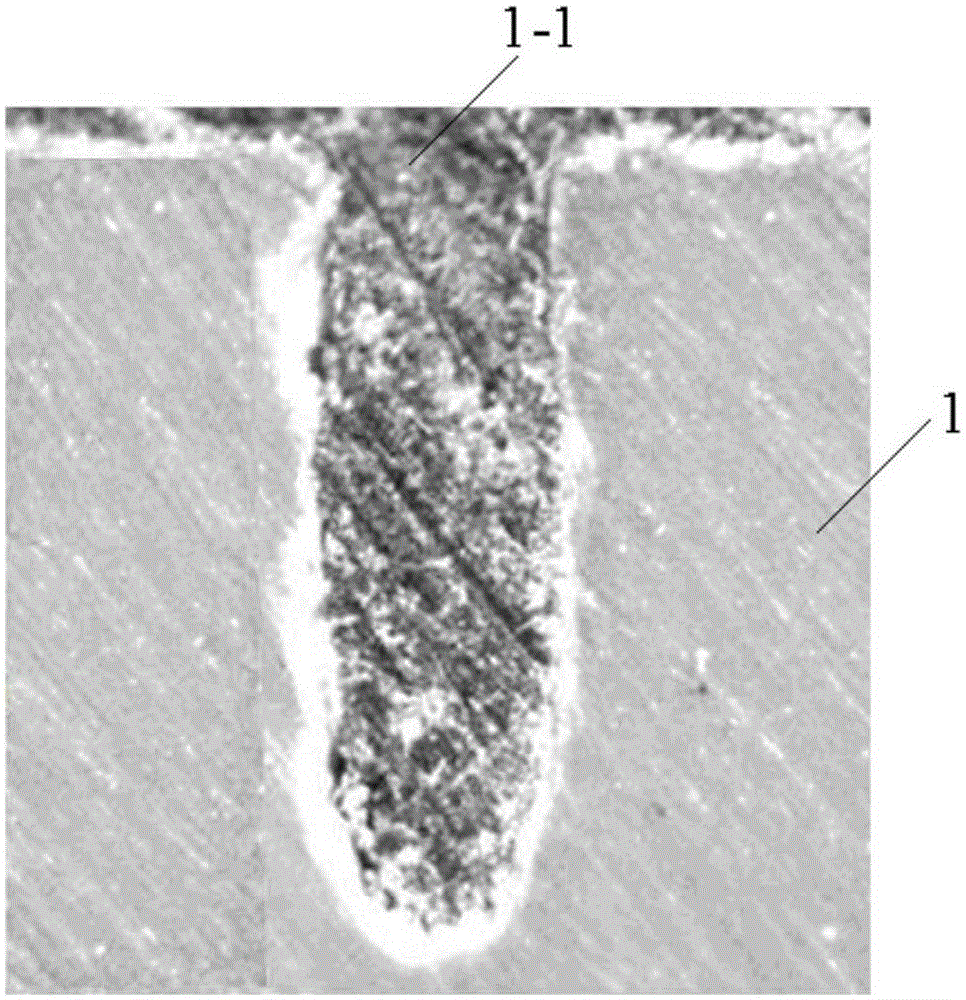

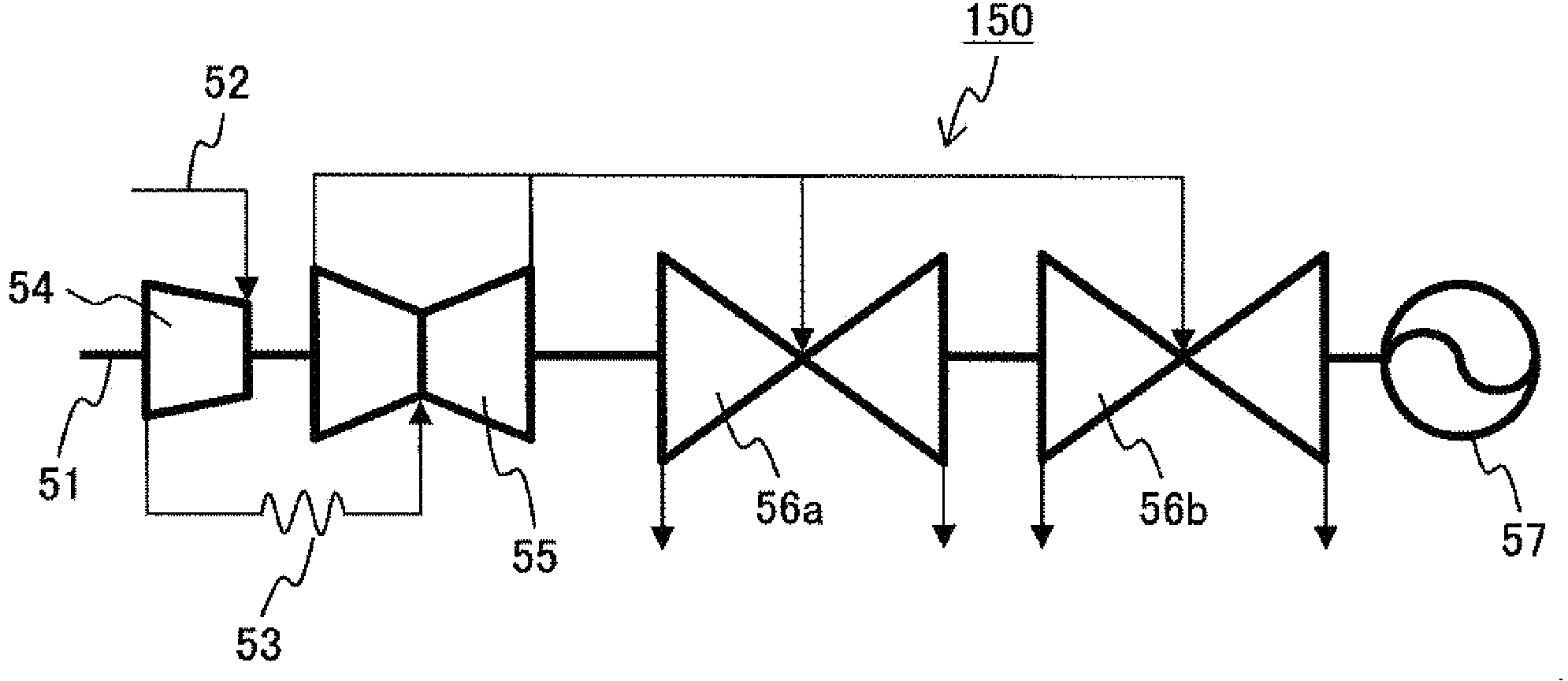

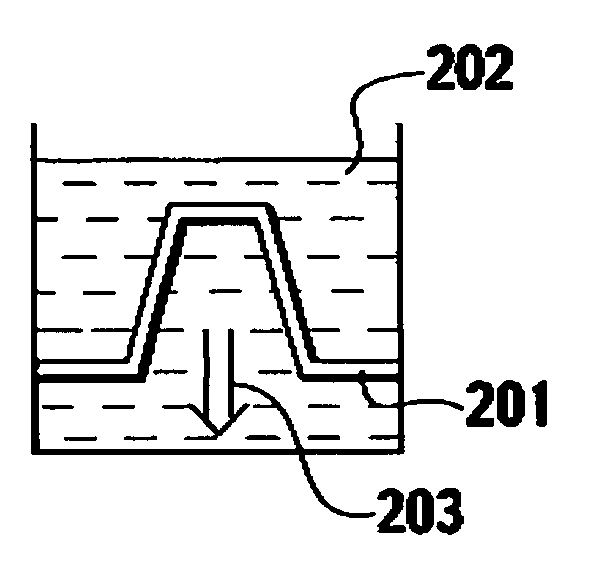

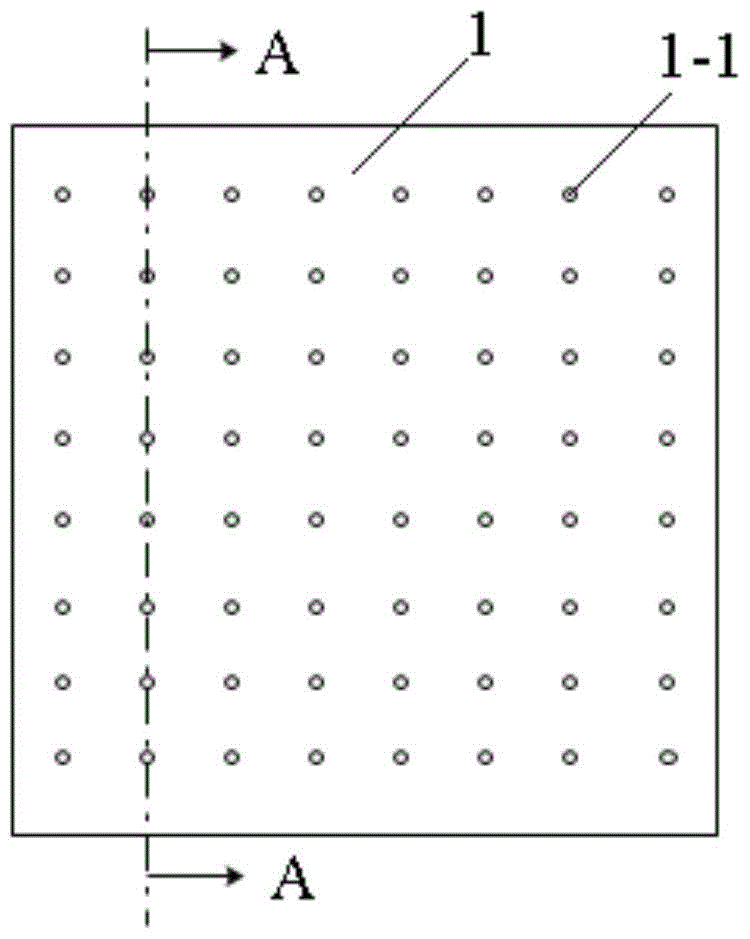

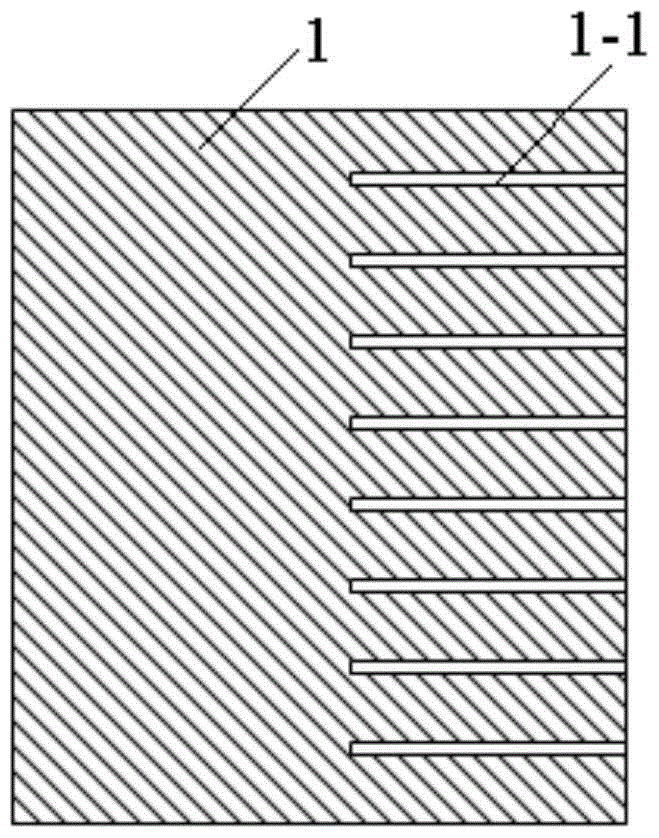

Electrolyte sheet for solid oxide fuel cell, unit cell for solid oxide fuel cell and solid oxide fuel cell equipped with same, method for testing electrolyte sheet for solid oxide fuel cell, and method for manufacturing electrolyte sheet for solid oxide fuel cell

ActiveUS20140017579A1Reduce harmImprove reliabilityFinal product manufactureLuminescent dosimetersFuel cellsFluorescence

In an electrolyte sheet for a solid oxide fuel cell according to the present invention, the number of flaws on at least one of surfaces of the sheet detected by a fluorescent penetrant inspection is 30 points or less in each of sections obtained by dividing the sheet into the sections each measuring 30 mm or less on a side. A unit cell for a solid oxide fuel cell according to the present invention comprises a fuel electrode, an air electrode, and the electrolyte sheet for a solid oxide fuel cell according to the present invention, which is disposed between the fuel electrode and the air electrode. A solid oxide fuel cell of the present invention includes the unit cell for a solid oxide fuel cell according to the present invention.

Owner:NIPPON SHOKUBAI CO LTD

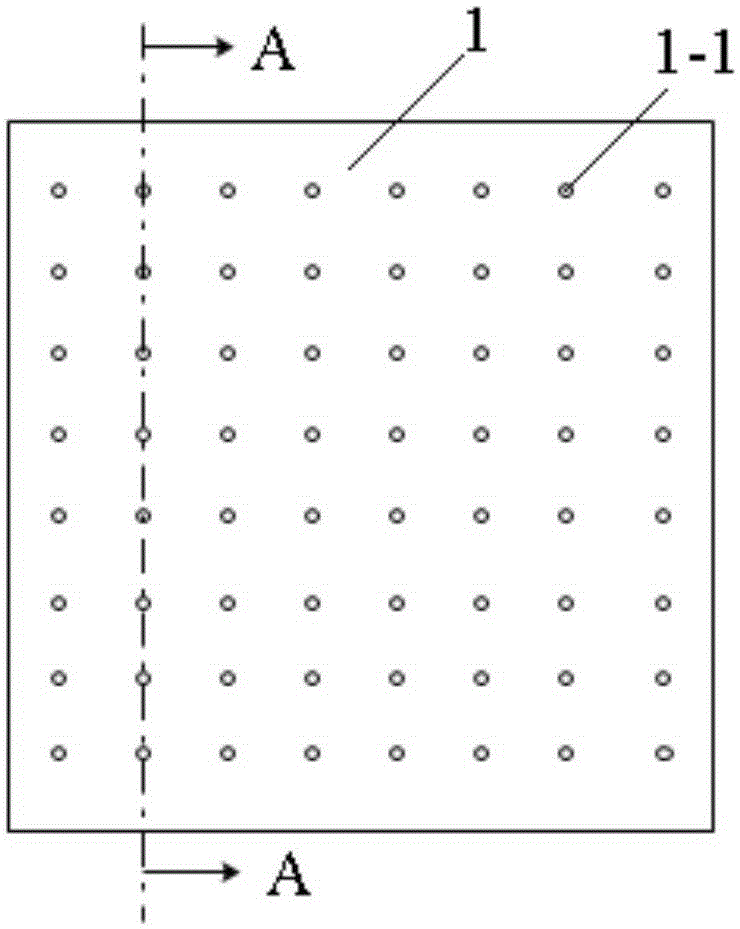

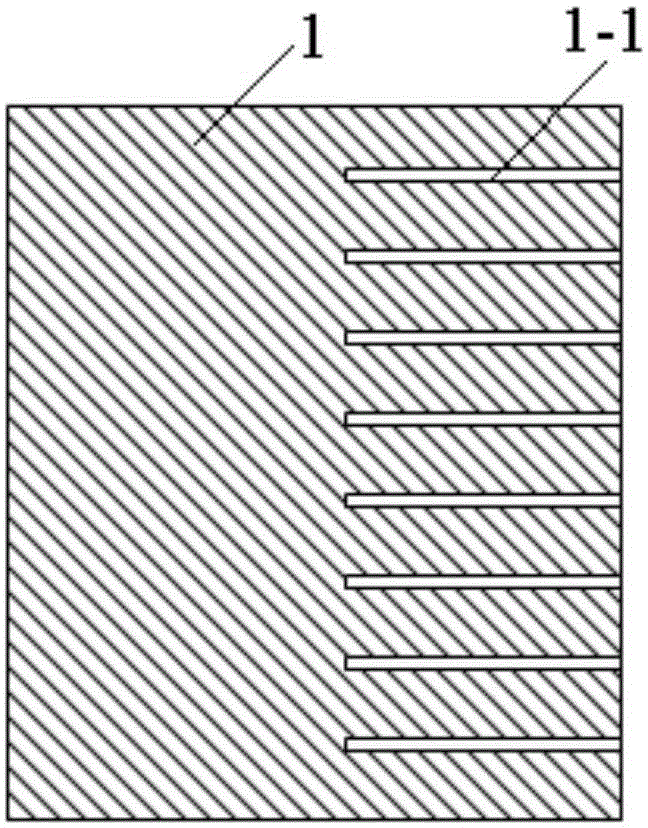

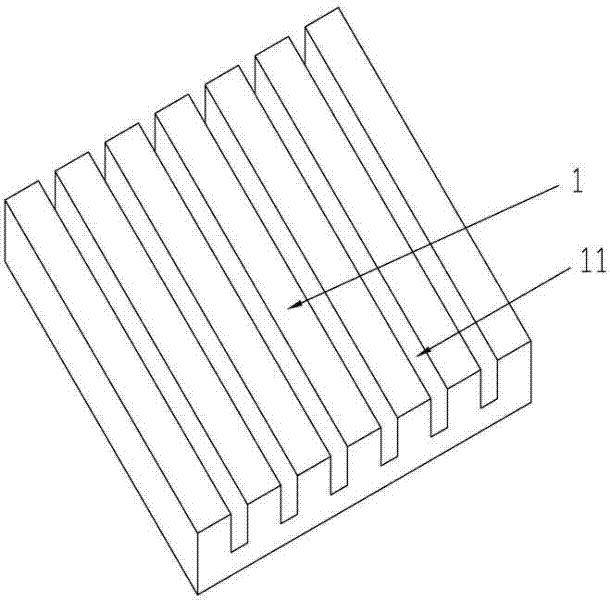

Multi-scale combined method for improving high hard and brittle ceramic base material soldering connection strength

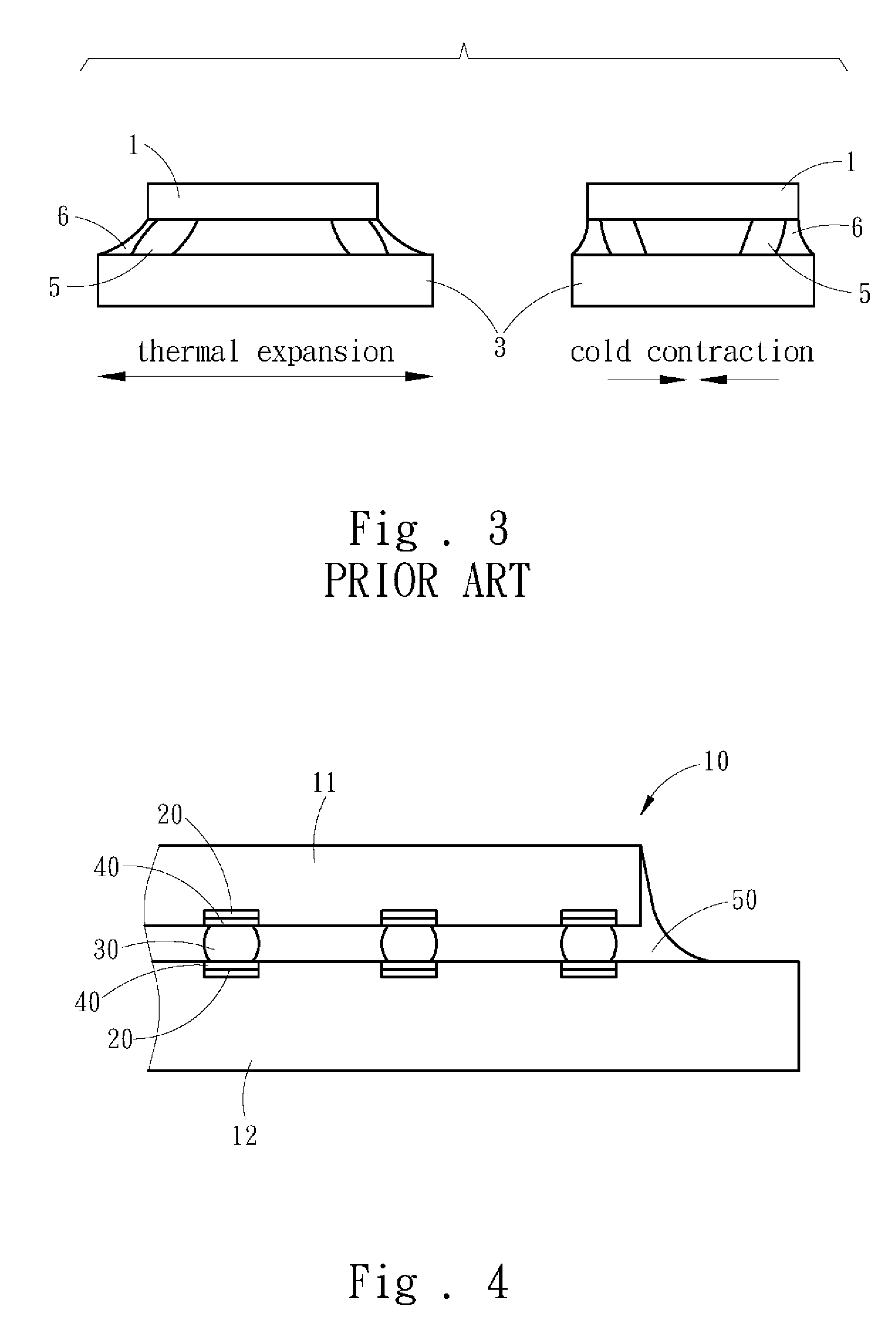

ActiveCN105195847AReduce stress concentrationImprove processing efficiencySoldering apparatusWorkpiece edge portionsCombined methodThermal expansion

The invention relates to a method for improving the ceramic base material soldering connection strength, in particular to a multi-scale combined method for improving the high hard and brittle ceramic base material soldering connection strength. The method solves the problems that a joint connected through an existing ceramic base material soldering method is low in strength and the residual stress is large and the reliability is low due to the thermal expansion coefficient difference of ceramic base materials and metal. The method comprises the steps of 1, surface treatment of a high hard and brittle ceramic base material connection surface, 2, solder powder preparation, 3, composite solder paste preparation, 4, coating and 5, vacuum soldering connection, so that a high-strength high hard and brittle ceramic base material soldered joint is obtained. The compression-shear resistant strength of the obtained high hard and brittle ceramic base material soldered joint is 105-196 MPa, and the strength of the soldered joint is improved by 115-275% compared with a soldered joint adopting a conventional straight interface and no wild phase.

Owner:HARBIN INST OF TECH

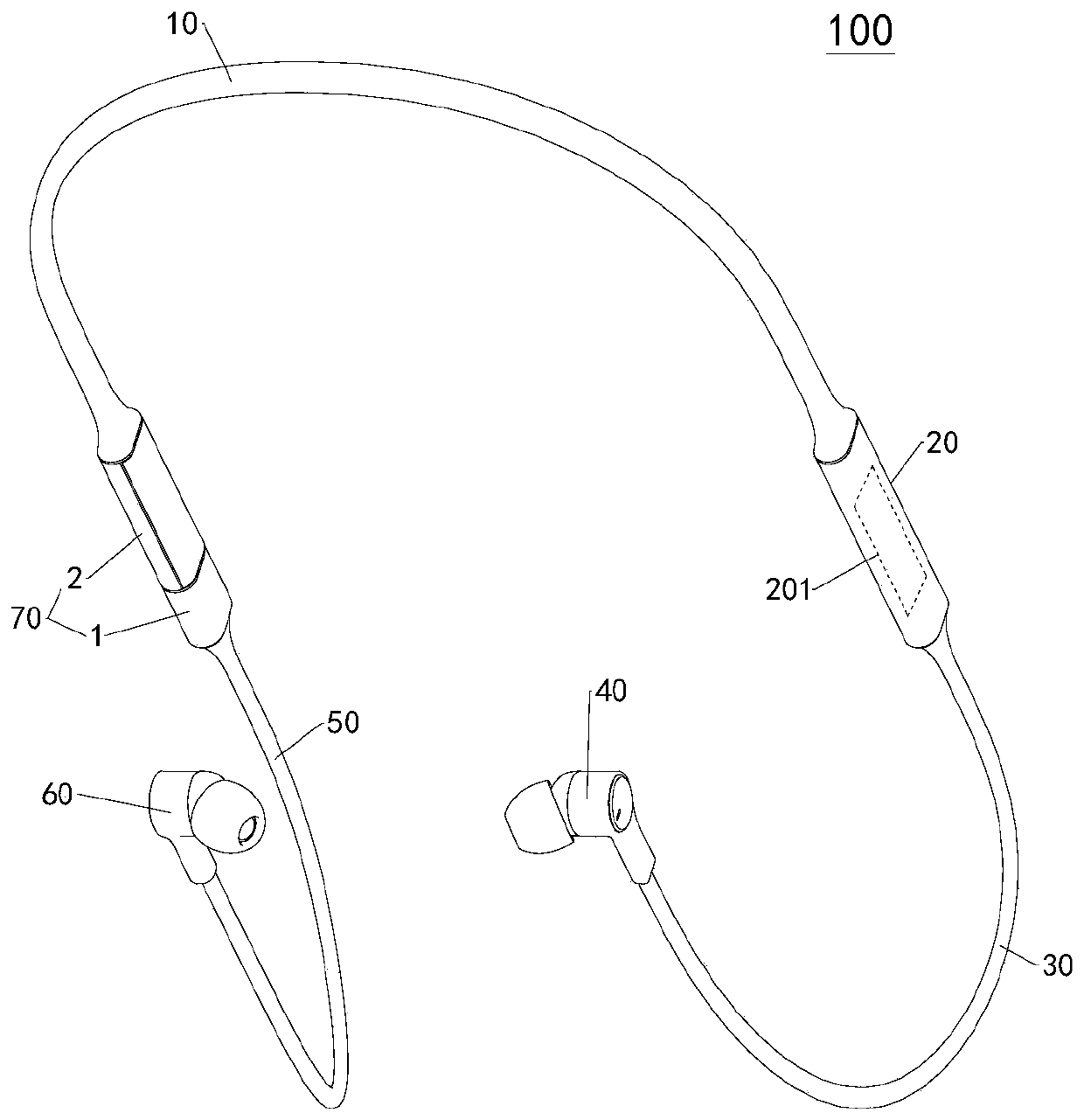

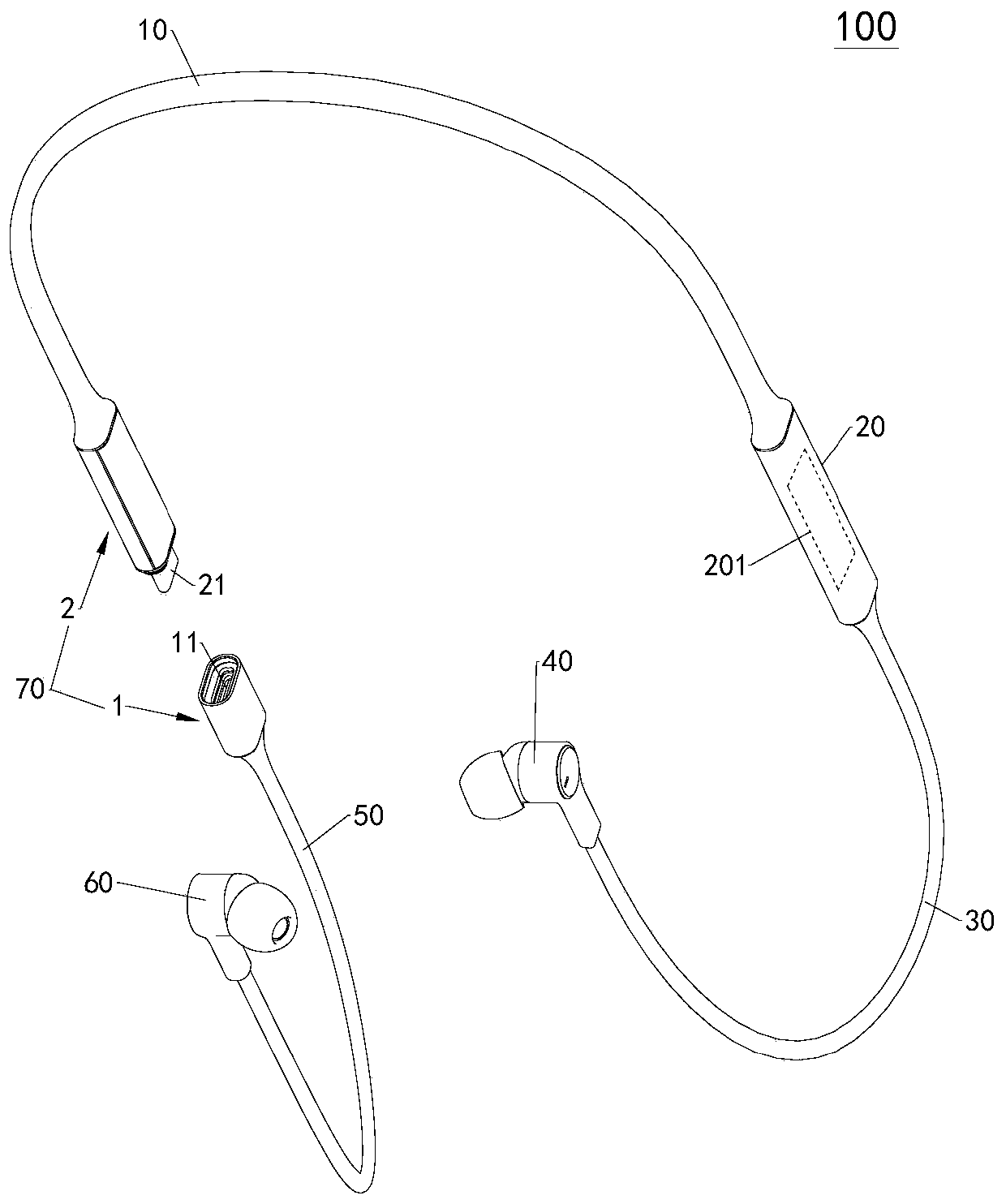

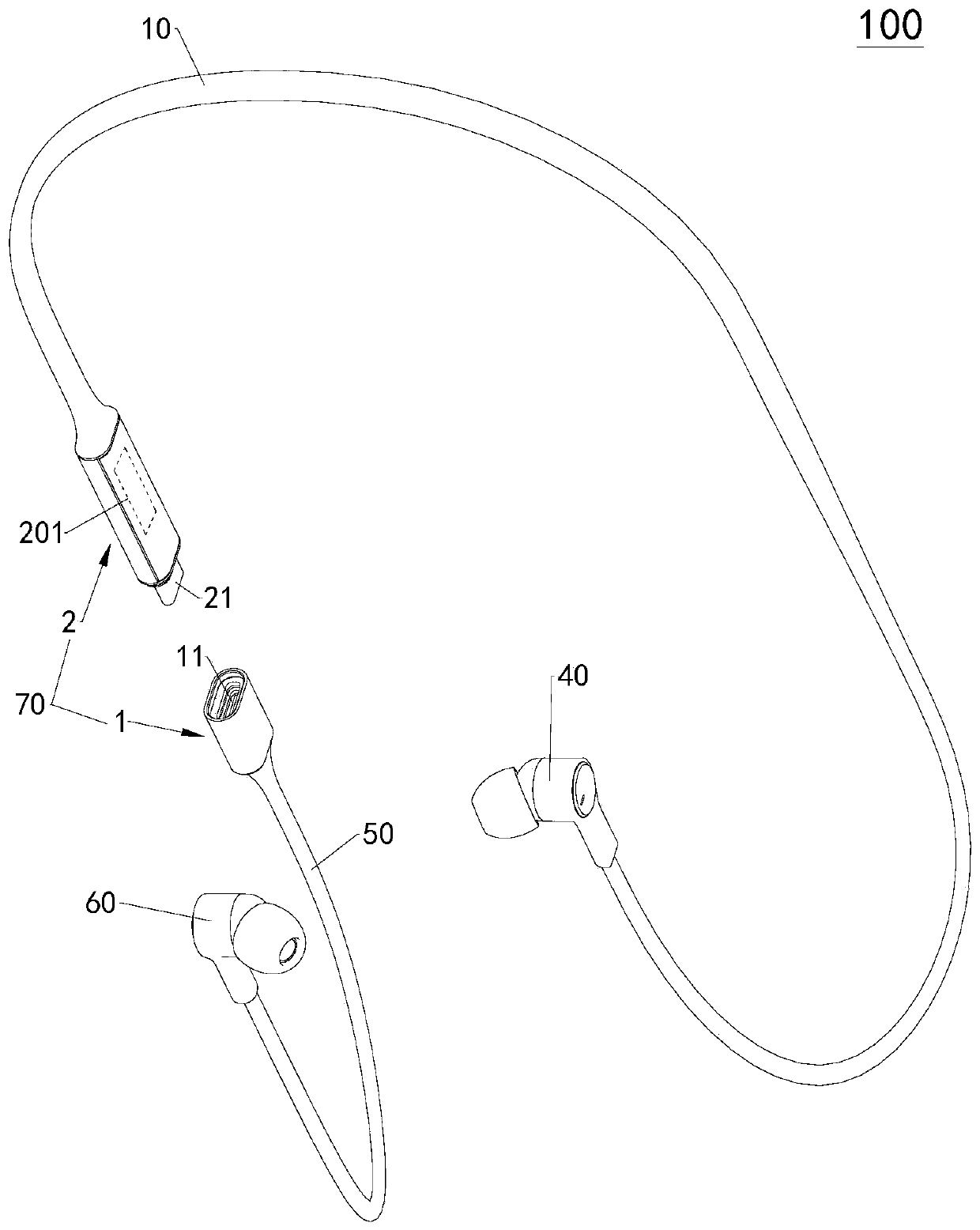

Wire control box for a wireless earphone and the wireless earphone

ActiveCN109756811AReduced risk of damage such as bendingIncreased Strength ReliabilityCoupling device detailsTwo-part coupling devicesHollow cylinderEngineering

The embodiment of the invention discloses a wire control box for a wireless earphone. The connector comprises a female head part and a male head part detachably connected to the female portion. The Male head part comprises a bracket, a male head sleeve and a male head, Support in hollow cylinder shape, The male joint sleeve comprises a fixing part and an extending part connected to one end of thefixing part. the fixed part is accommodated inside the bracket; The extending part is located on the outer side of the support, the male head comprises an inserting end and a fixing end connected to one end of the inserting end, the inserting end is located on the outer side of the support, the fixing end penetrates through the extending part and then is fixed to the inner side of the fixing part,and when the male head is connected with the female head, the inserting end is contained in the female head and the male head is separated from the female head. According to the wire control box, thecharging convenience of the wireless earphone can be improved. The embodiment of the invention also discloses a wireless earphone.

Owner:HUAWEI TECH CO LTD

Turbine rotor, manufacturing method thereof and steam turbine using turbine rotor

InactiveCN103510996AInhibitionIncreased Strength ReliabilityTurbinesBlade accessoriesAlloyEngineering

A stable penetration weld bead can be formed in a dissimilar material welded rotor combining two alloy materials under the condition that an enclosed space part is provided with a rotor near a weld section of the weld rotor. A turbine rotor provided by the invention has a high temperature side rotor base material (61) and a low temperature side rotor base material (64). The high temperature side rotor base material (61) is provided with a concavity and a groove (63). The low temperature side rotor base material (64) is provided with a concavity and a groove (65). The concavity of the high temperature side rotor base material and the concavity of the low temperature side rotor base material are oppositely disposed and the enclosed space part is formed between the concavities; the groove of the high temperature side rotor base material and the groove of the low temperature side rotor base material are oppositely disposed and a slot part (66) is formed between the grooves; a buildup welding section (62) having the same components with the high temperature side rotor base material or the low temperature side rotor base material is formed between the high temperature side rotor base material and the low temperature side rotor base material. One side of the buildup welding section in the enclosed space part is provided with a penetration weld bead (67); and the slot part is filled with a weld metal (68).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

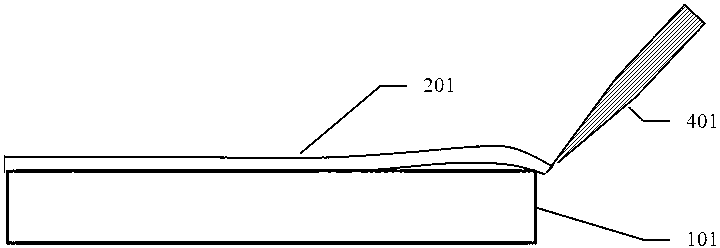

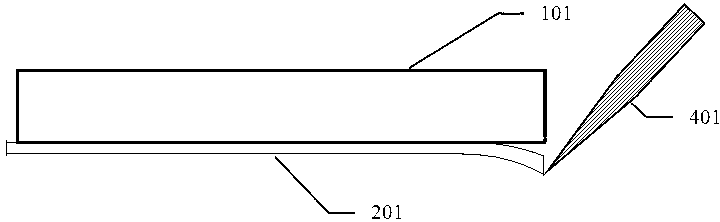

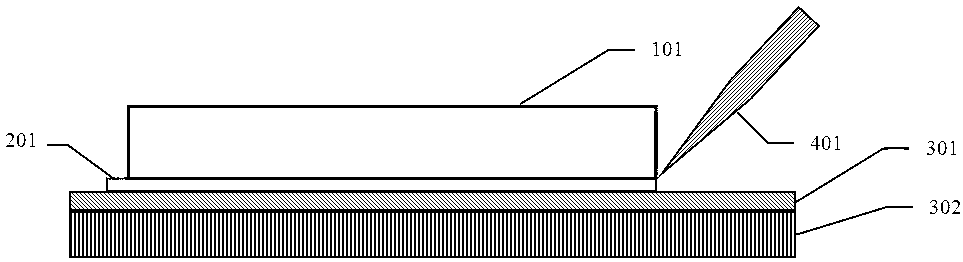

Production sample making method of flexible display panel

InactiveCN103286809APrevent impactImprove uniformityMetal working apparatusEngineeringUltimate tensile strength

The invention belongs to the technical field of information display, and particularly relates to a production sample making method of a flexible display panel. The production sample making method includes: adhering a flexible substrate and a carrier substrate, cutting the adhered combined substrate, primarily cutting the combined substrate with a pad flexibly and rigidly and secondarily cutting the edge of the same through an angle fixing device to obtain a production sample product. The production sample product is cut twice, so that no air gap is generated at the edge, adhering strength of the substrates during technical process is unaffected, and affection on production process of the substrates from edge burrs can be eliminated.

Owner:FUDAN UNIV +1

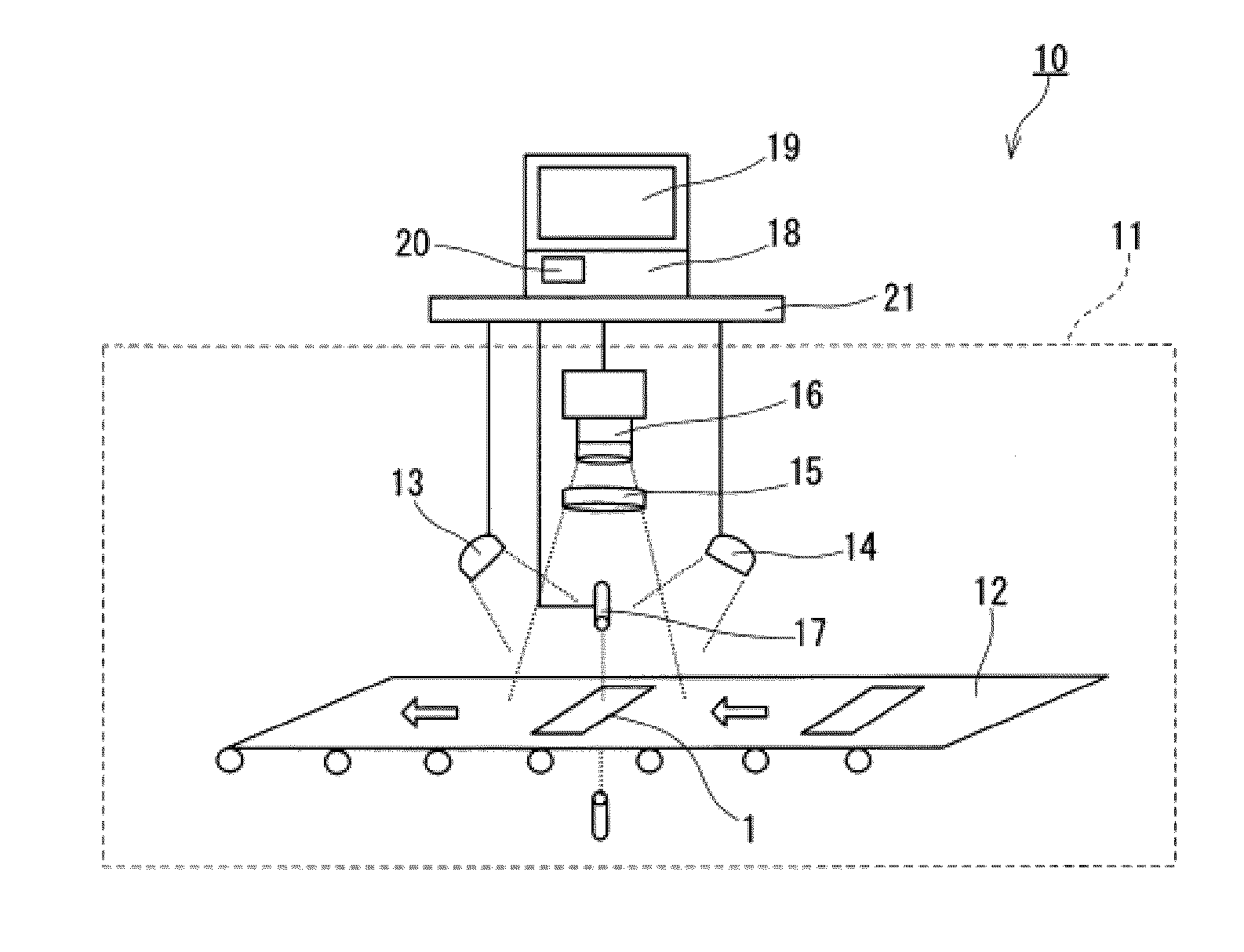

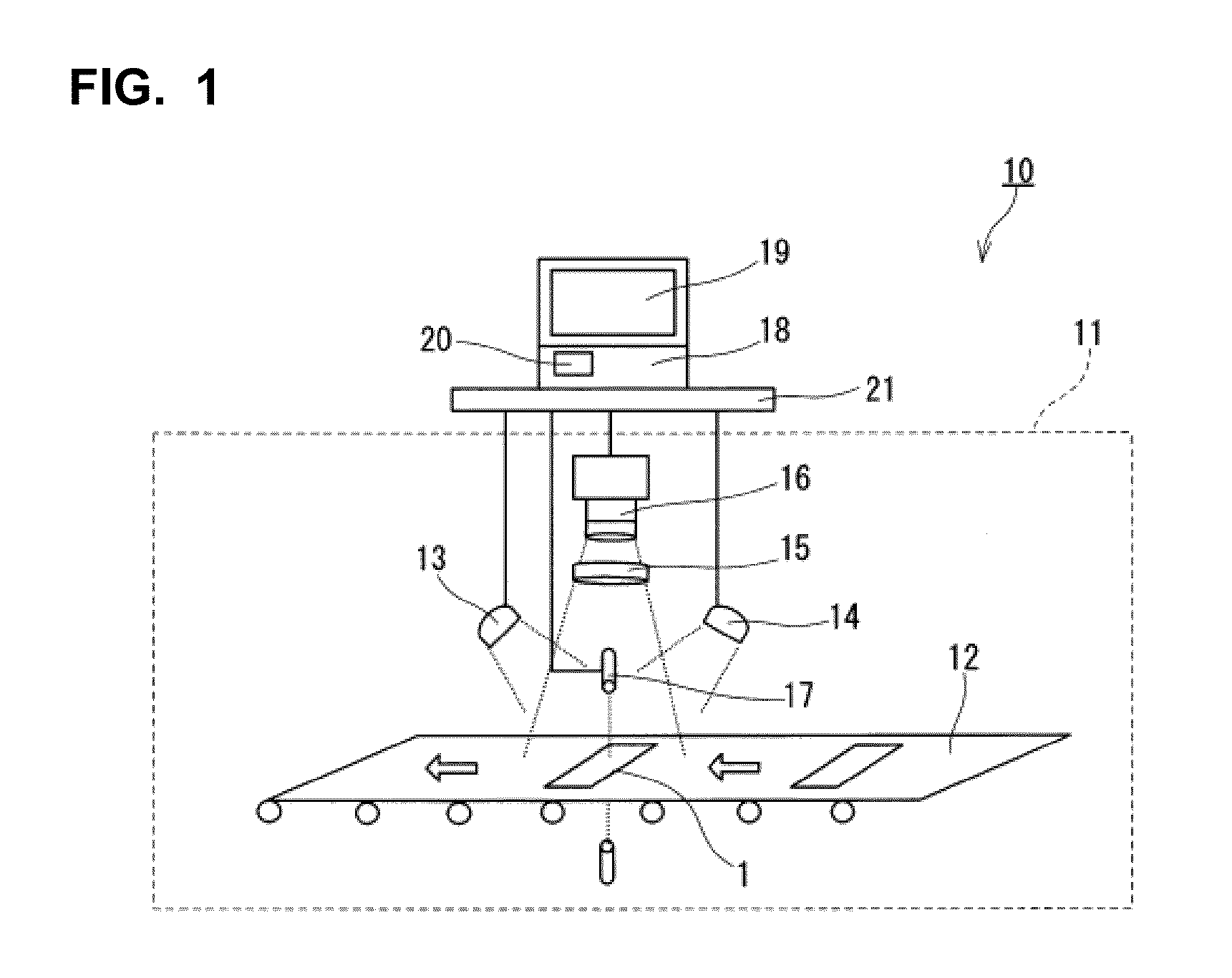

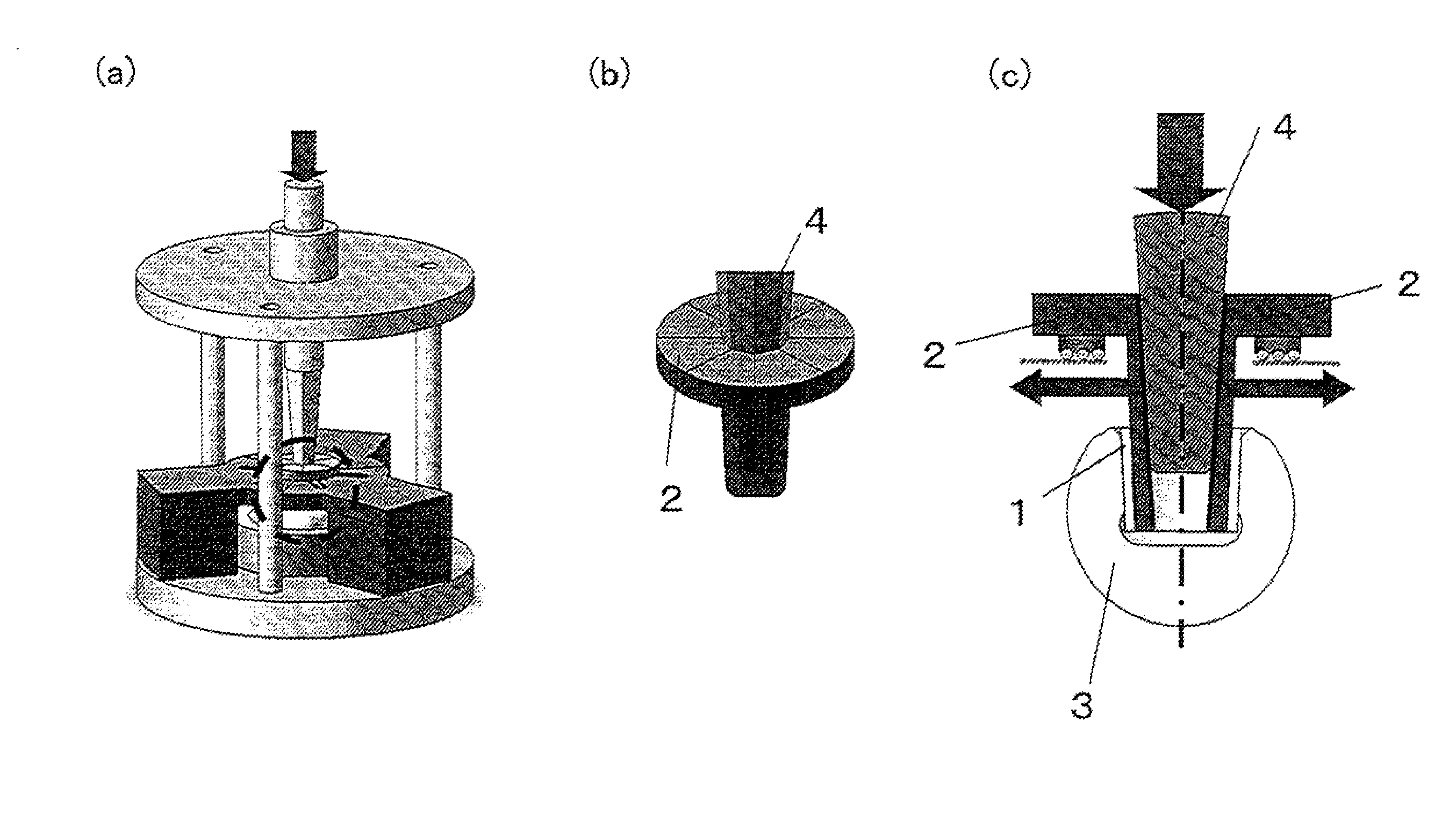

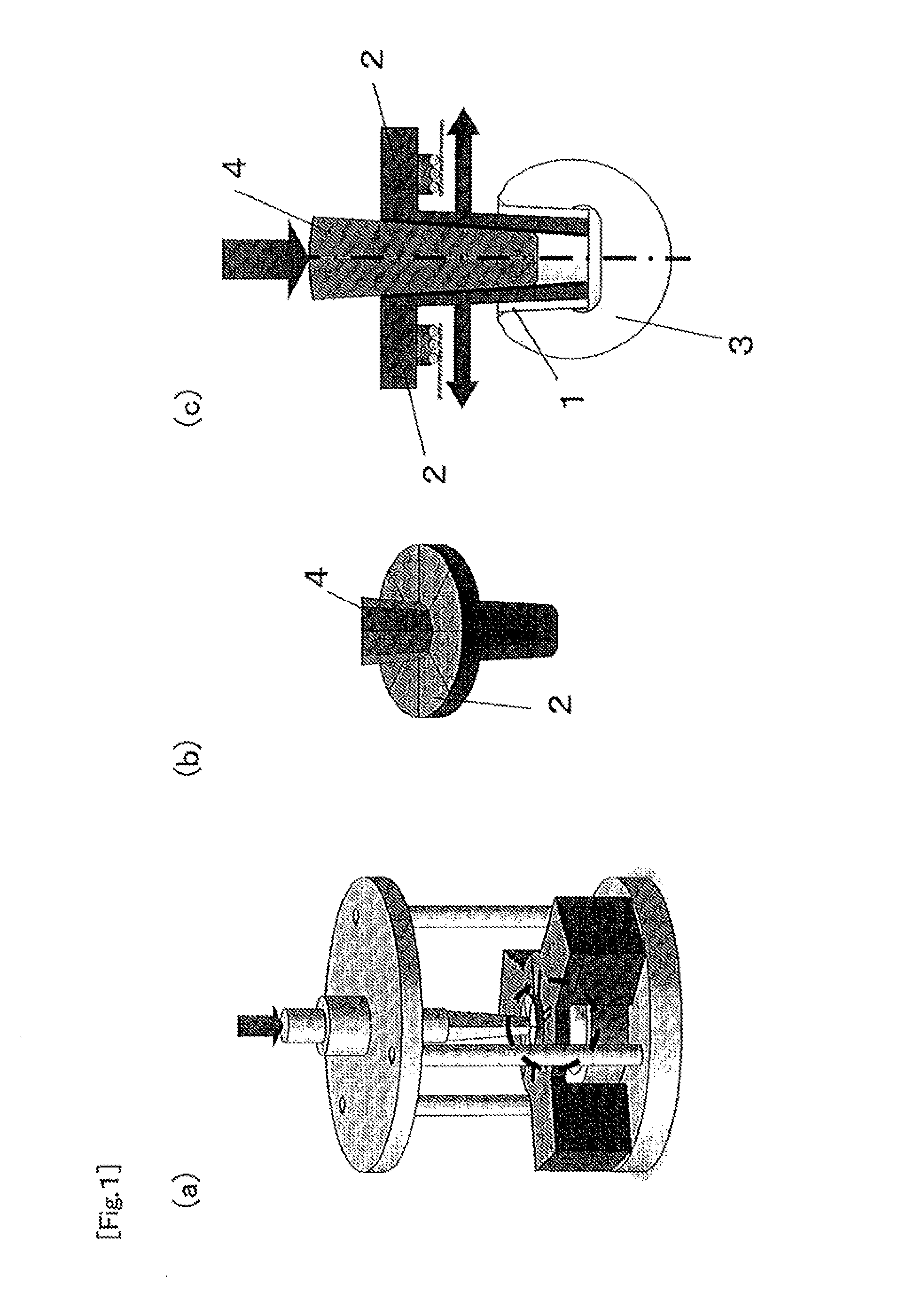

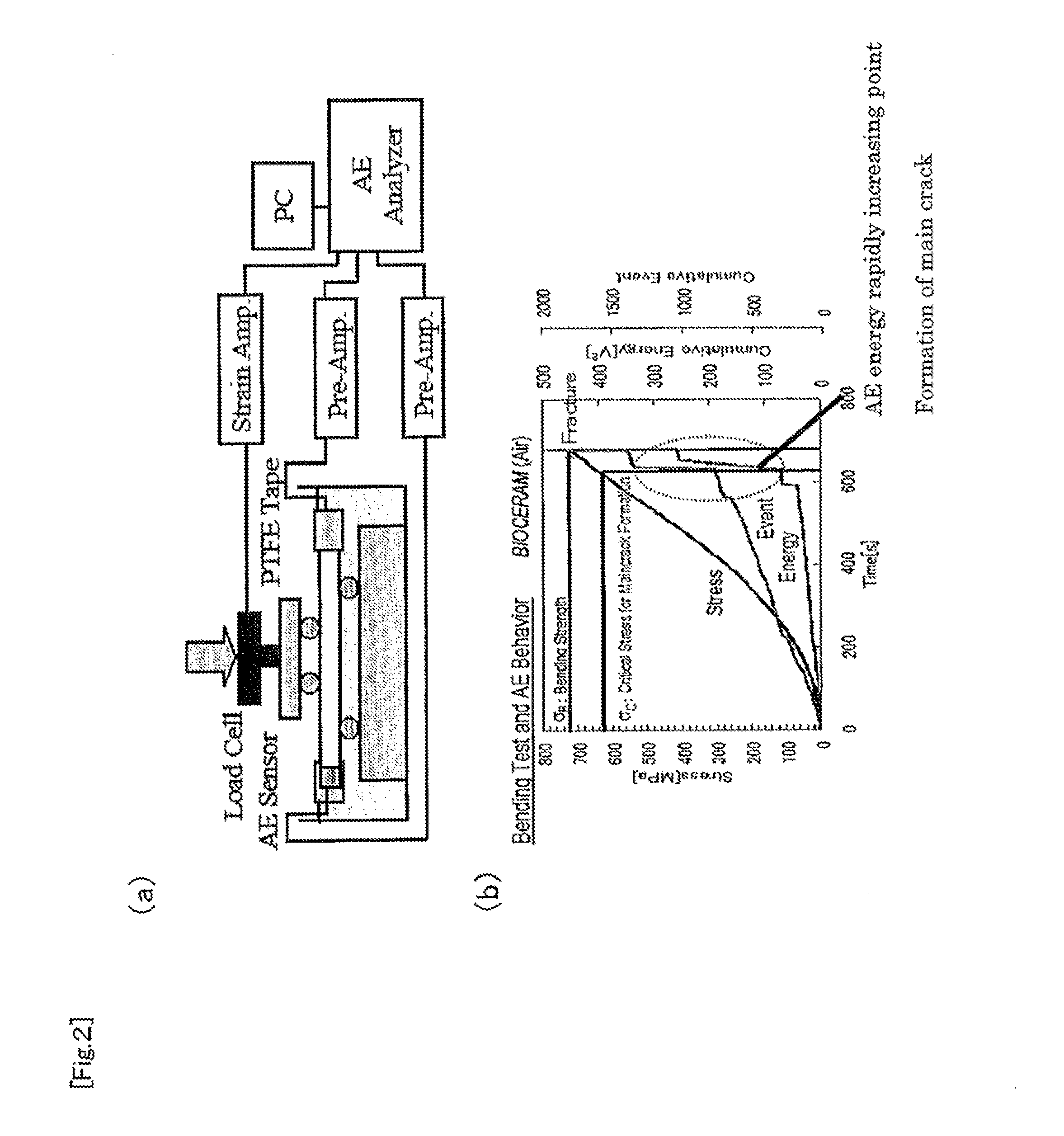

Strength proof test method and device to be used therein

InactiveUS20140033820A1Increased Strength ReliabilityVibration measurement in solidsMaterial analysis using acoustic emission techniquesAcoustic emissionProof test

The present invention is intended for improving the reliability of a strength proof test method for ceramic parts. The present invention is directed to a strength proof test method for making total inspection of ceramic parts, including: applying a prescribed load to the ceramic parts; and at the same time, making an acoustic emission measurement, in which the ceramic parts are considered as passing when the ceramic parts are not fractured in the test and the variation of acoustic emission energy is not more than a threshold.

Owner:TOKYO METROPOLITAN UNIVERSITY +1

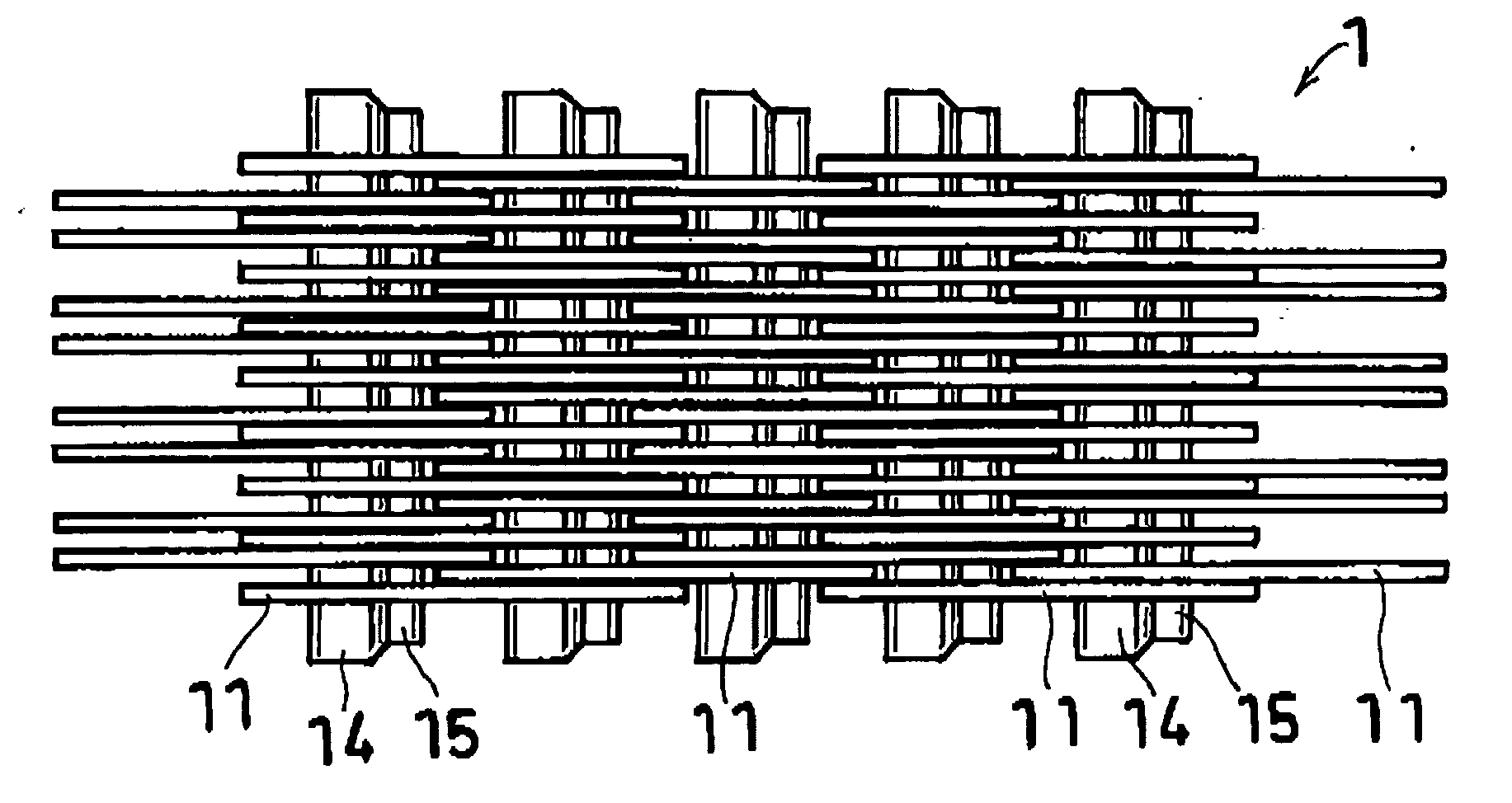

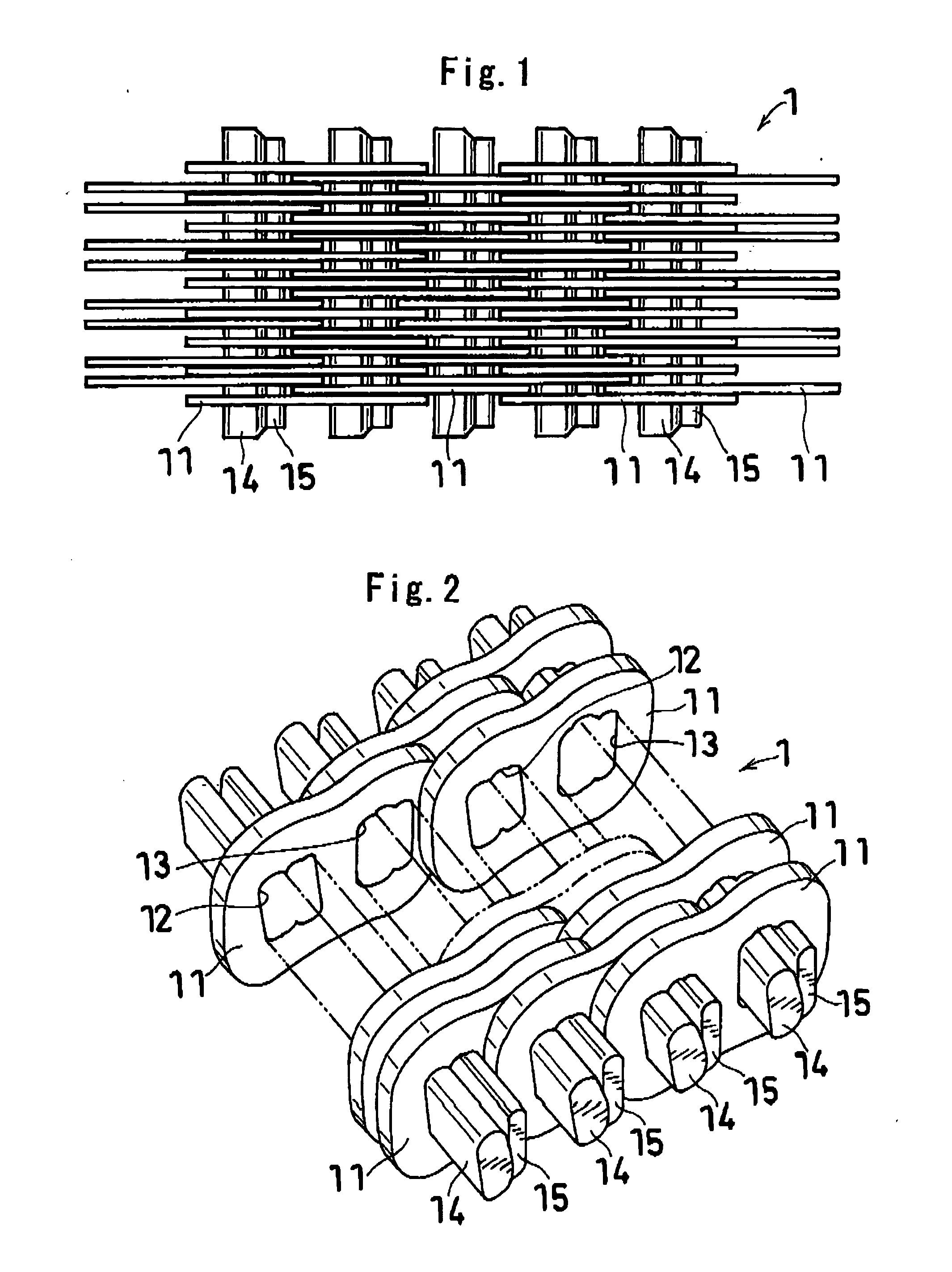

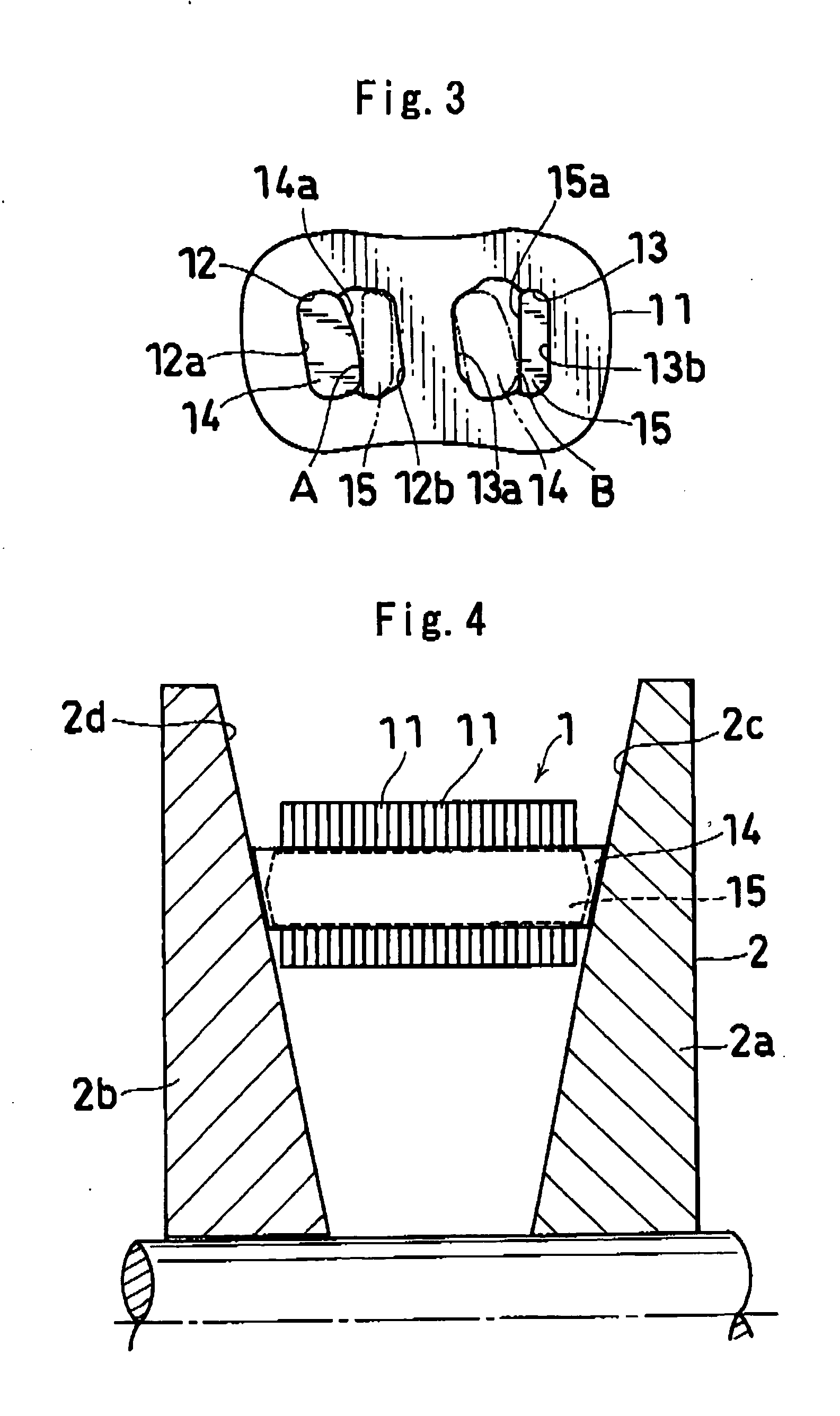

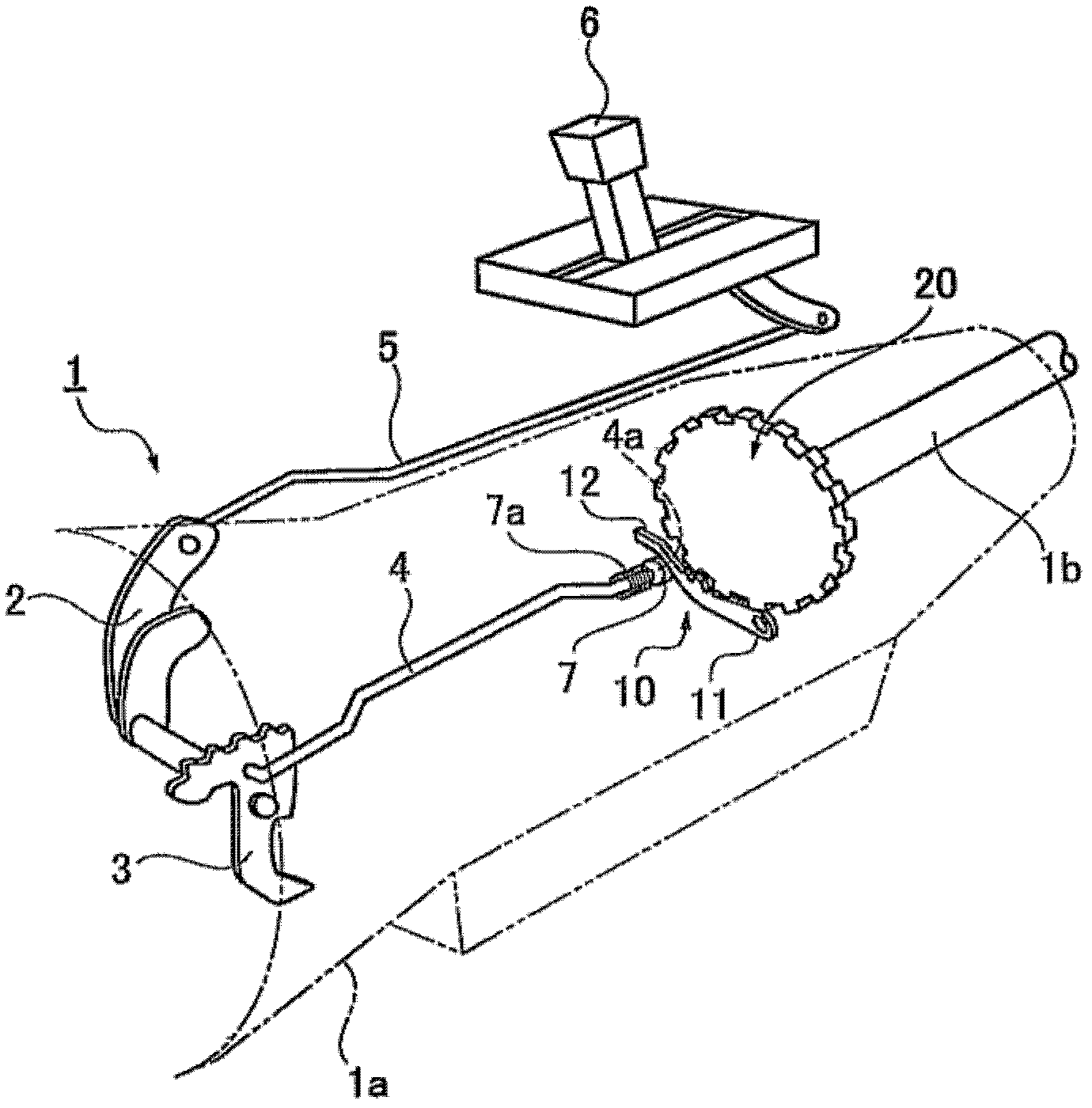

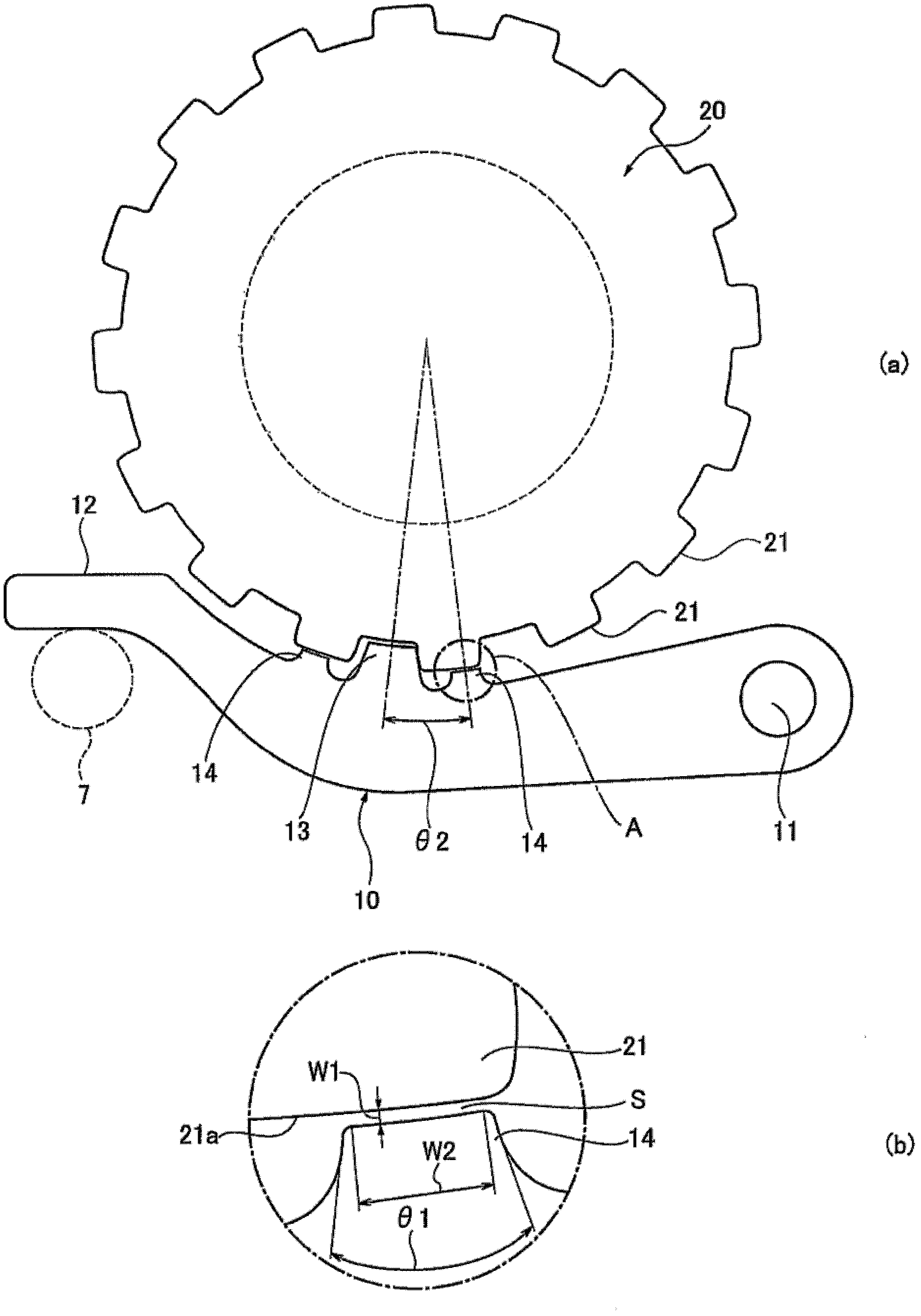

Power transmission chain, power transmission device, and method of producing the chain

InactiveUS20070178738A1Increased Strength ReliabilityReduced strengthEngagement/disengagement of coupling partsV-beltsEngineeringMechanical engineering

A power transmission chain 1 includes a plurality of links 11 having front and back insertion parts 12, 13 into which pins are inserted, and a plurality of pins 14 and a plurality of interpieces 15 for connecting the links 11 aligned in a chain width direction so as to be bendable in a longitudinal direction such that a front insertion part 12 of one link 11 and a back insertion part 13 of another link 11 correspond to each other. Each pin 14 and each interpiece 15 are fitted and fixed to the peripheral faces of the insertion parts 12, 13 by fitting, and a difference in dimension before the fitting is 0.005 mm to 0.1 mm.

Owner:JTEKT CORP

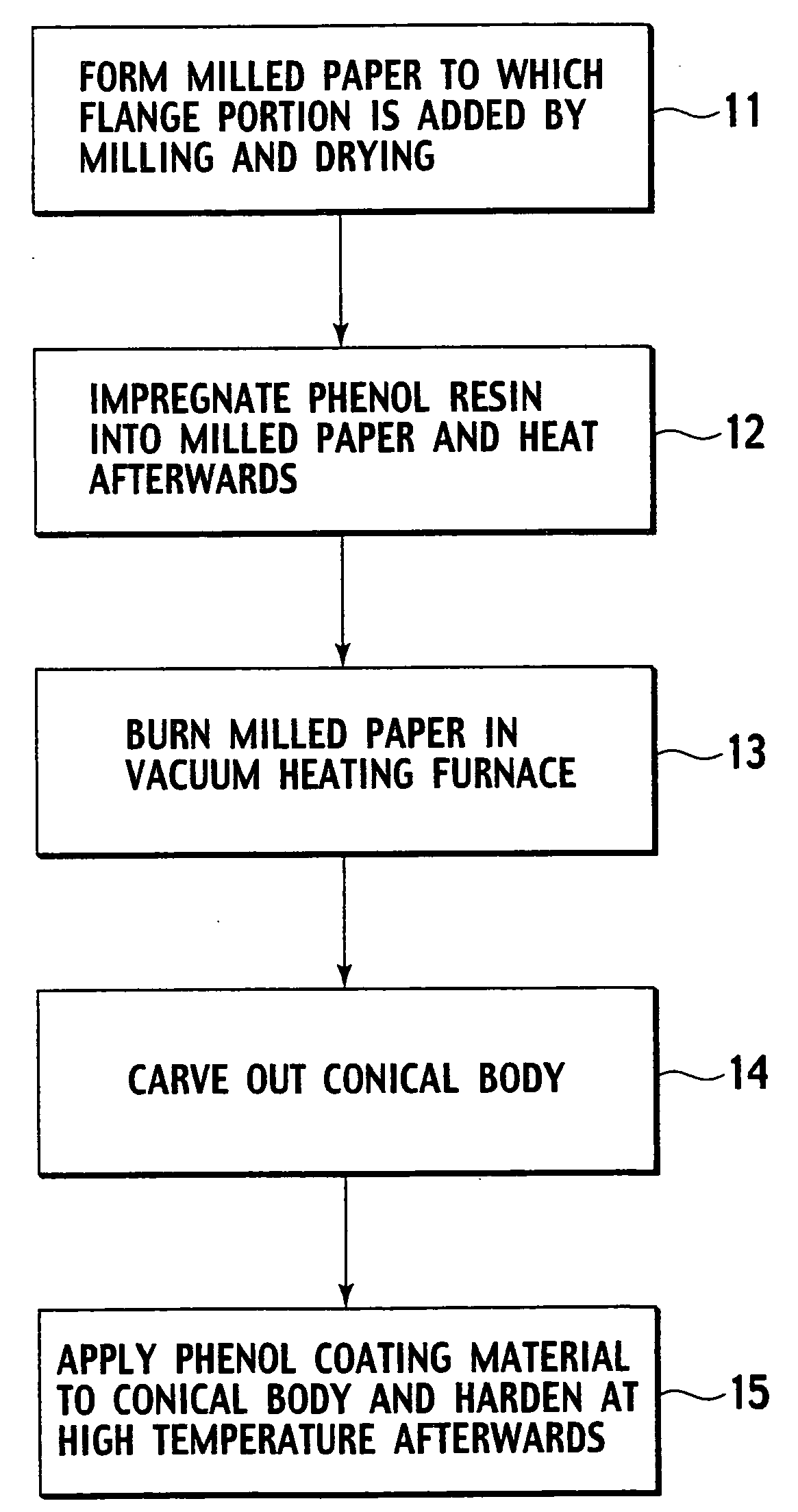

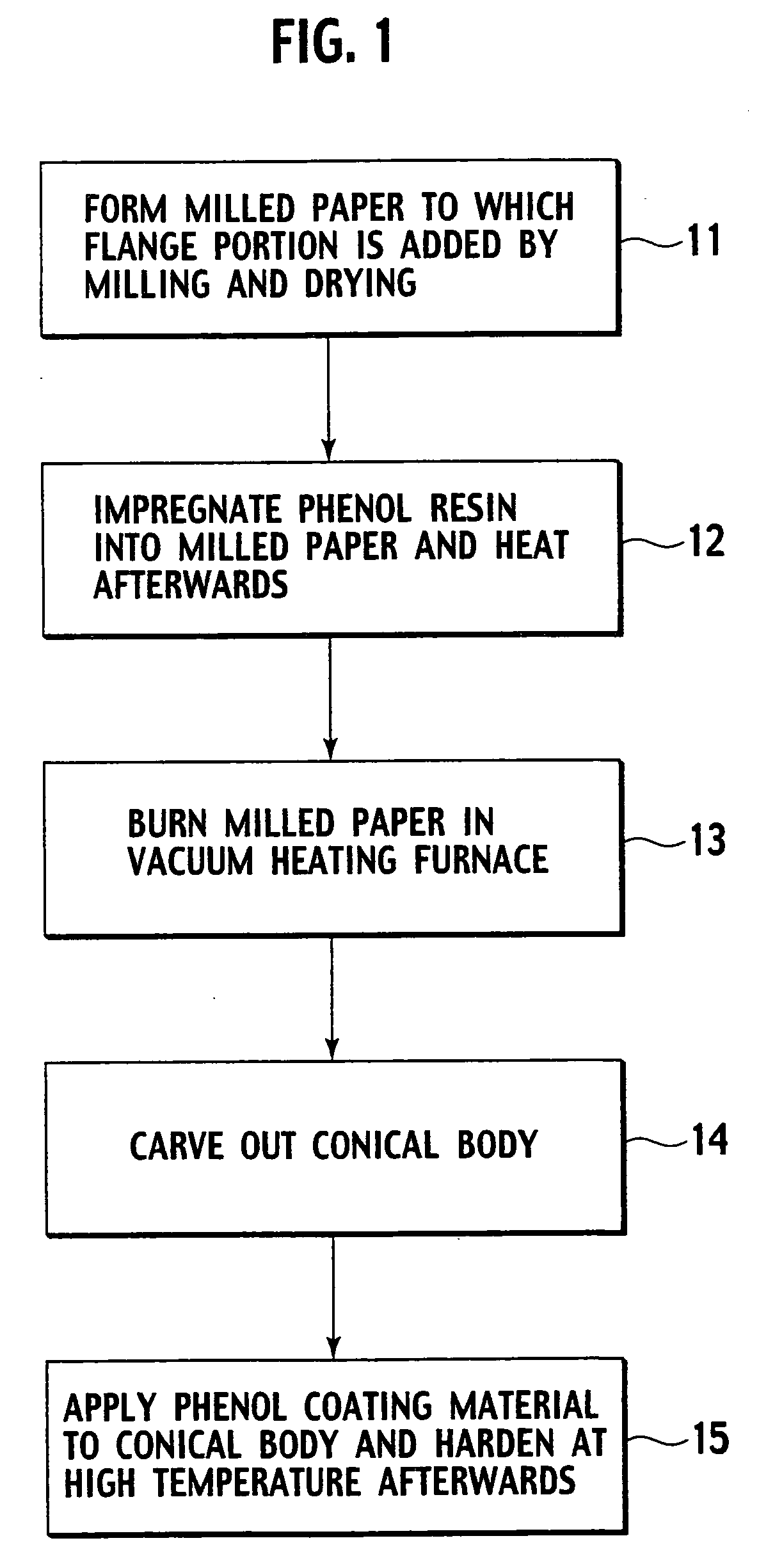

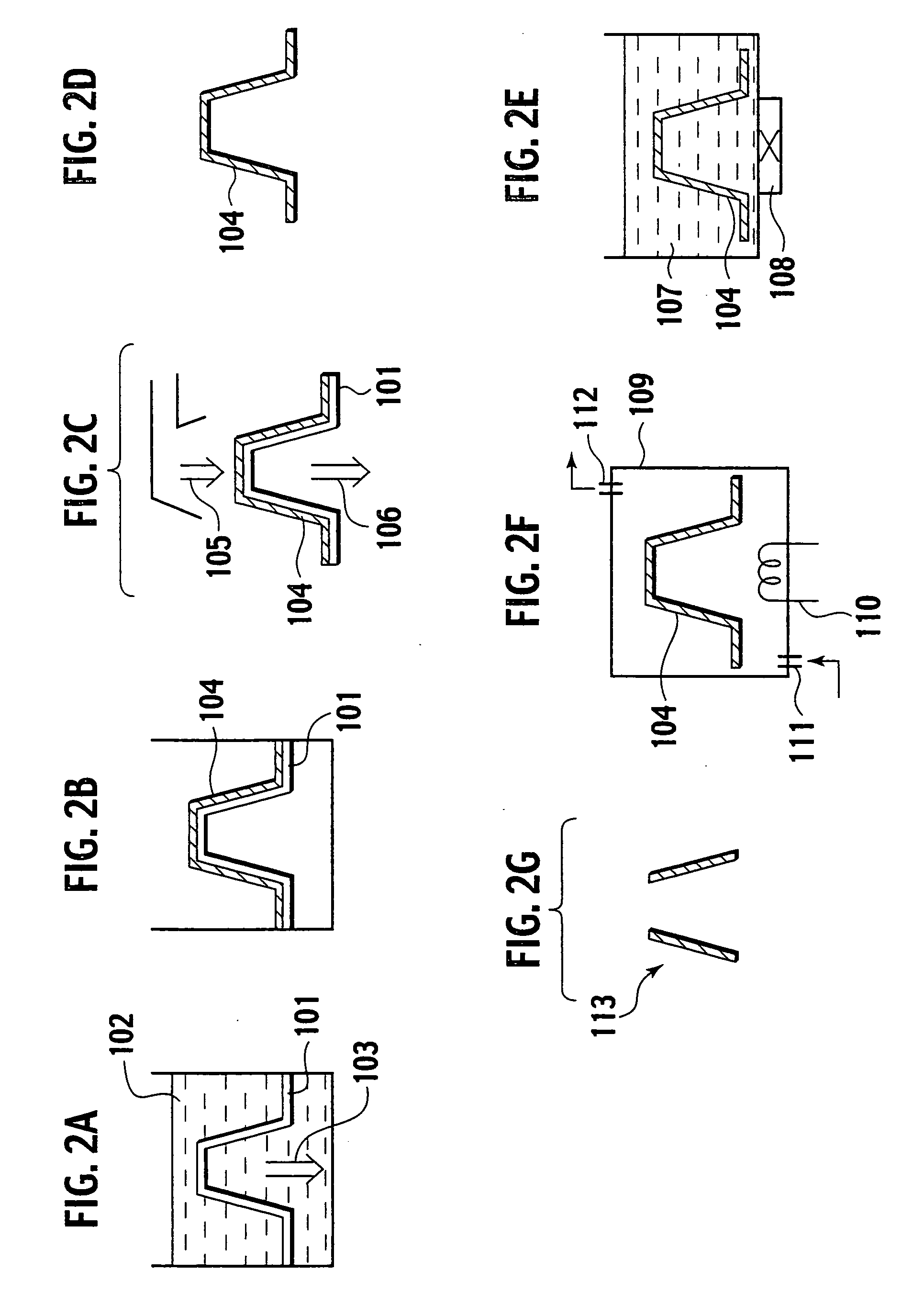

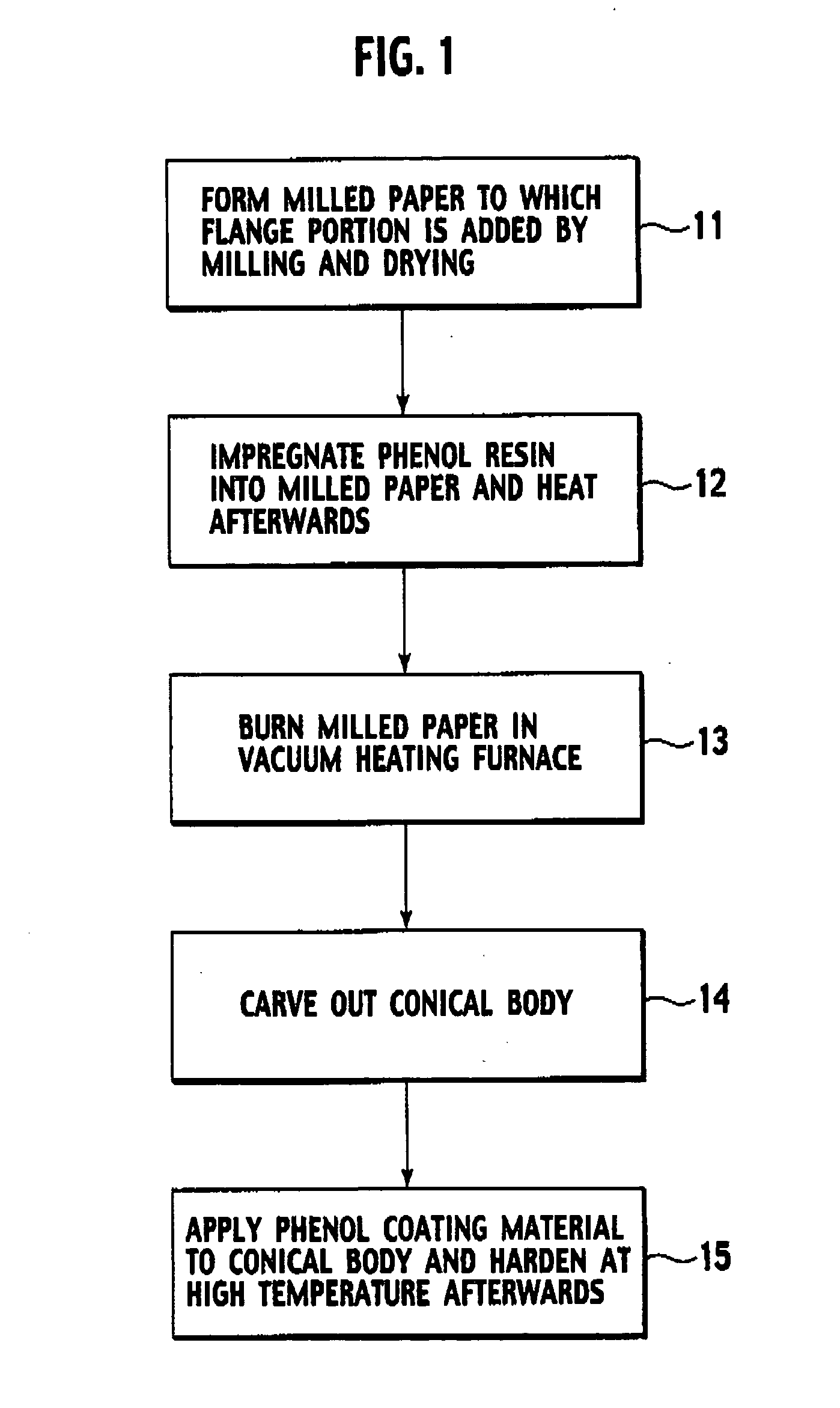

Production method of an acoustic diaphragm, acoustic diaphragm, and a speaker

InactiveUS20070187171A1Reduce hardeningLow viscosityFibre diaphragmsPolymeric diaphragmsPhenolLoudspeaker

A method of producing an acoustic diaphragm includes forming a workpiece having a shape of the acoustic diaphragm by using a natural material which can be carbonized by burning, impregnating a solution including phenol resin into the workpiece, heating the workpiece to bring the phenol resin into a high polymer state, burning the workpiece in a substantially anoxic atmosphere to carbonize the natural material after the heating step, and applying or impregnating the workpiece with a coating material of a solution including phenol resin after the burning step.

Owner:JVC KENWOOD CORP A CORP OF JAPAN

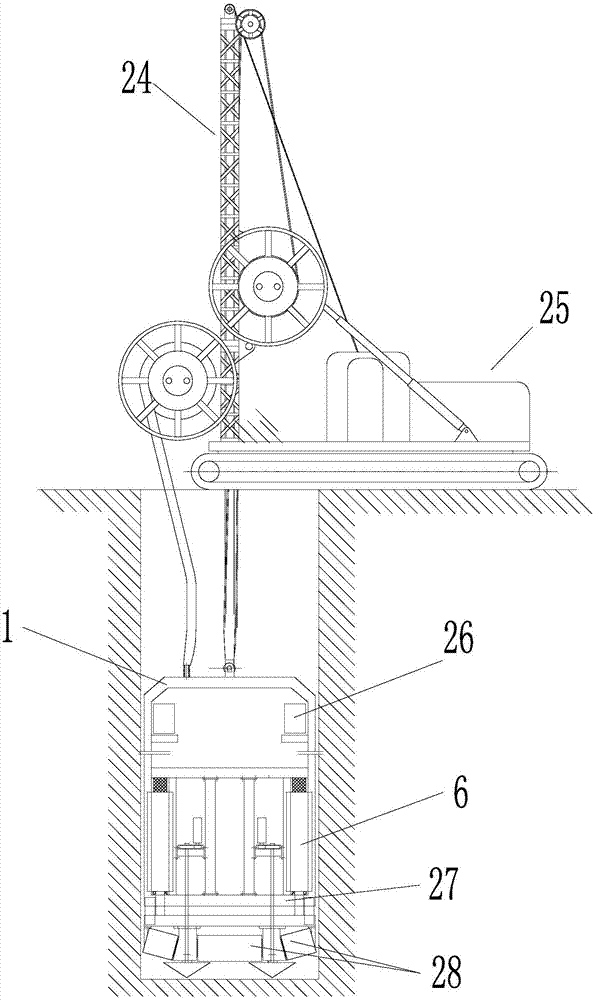

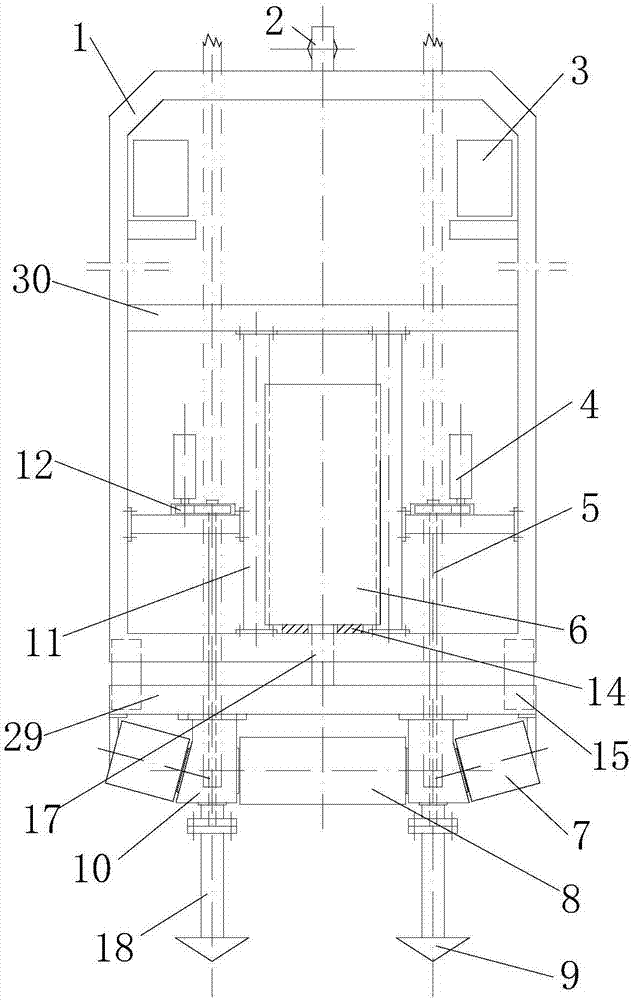

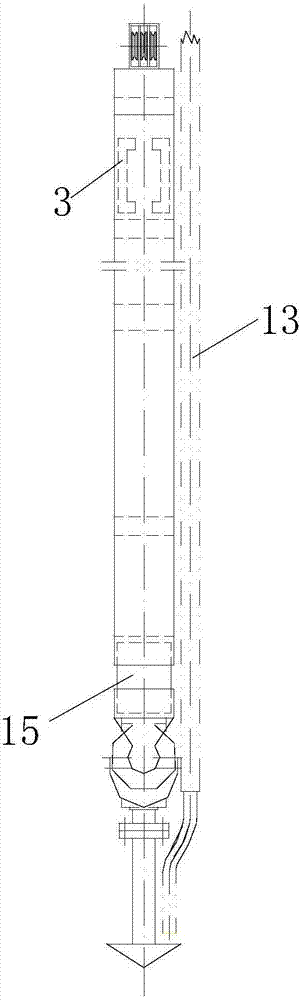

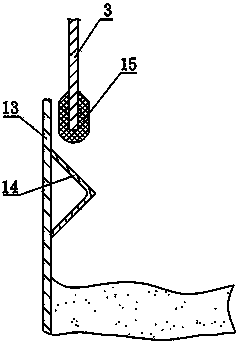

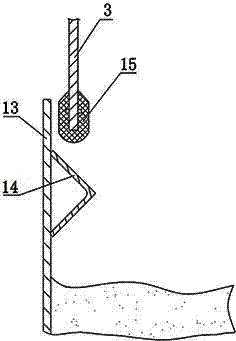

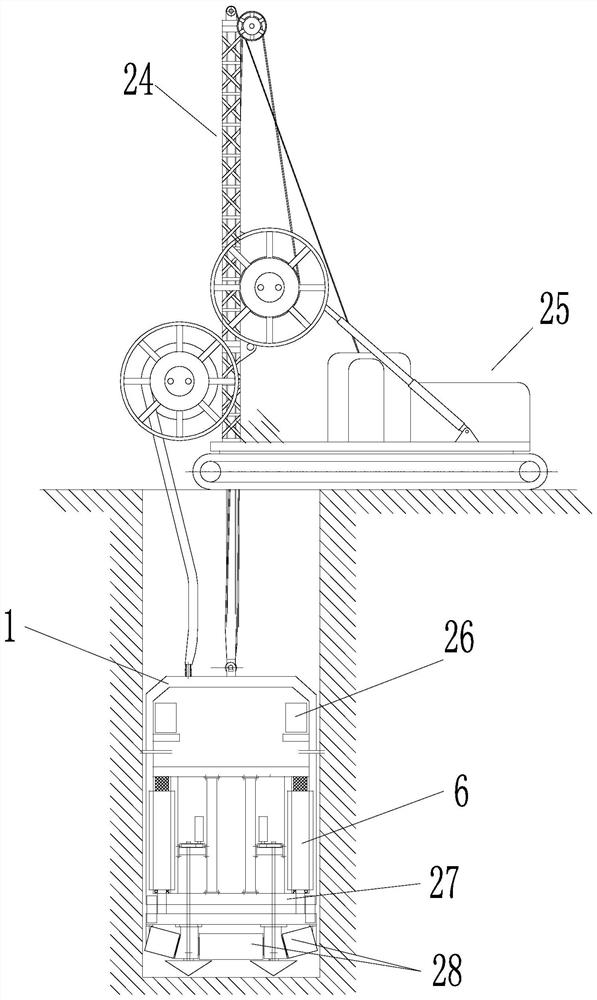

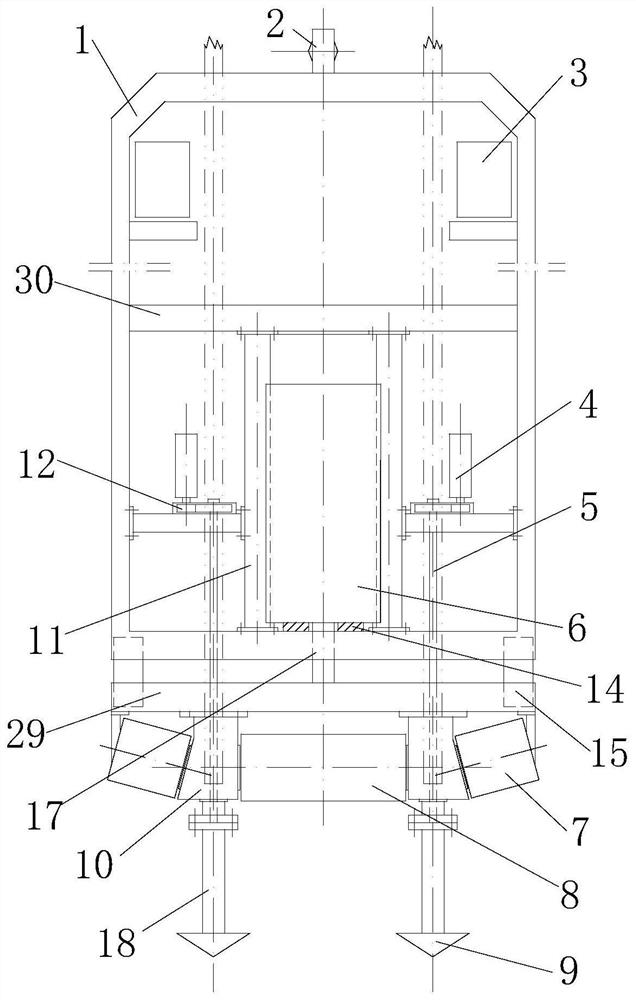

Horizontal single-shaft directional rotation-impact combined excavation type engineering grooving machine

ActiveCN107059975AStable operationImprove tunneling efficiencySoil-shifting machines/dredgersEngineeringDrill bit

The invention relates to a horizontal single-shaft directional rotation-impact combined excavation type engineering grooving machine which comprises a travelling device provided with winch equipment and a power system and a monitoring device. An impact milling device is hung at the traction end of the winch equipment and comprises a vertical guide frame, a correction device, a milling shaft and an impact device. The axis of the milling shaft is located in the plane where the guide frame is located, and the milling shaft is horizontally or obliquely arranged, is driven by a horizontal hydraulic motor or driven by a vertical hydraulic motor through a reversing device and has a directional rotary milling state of segmental balance reverse rotation. The impact device is arranged in the guide frame. A connecting cross beam above the milling shaft is connected below a guide frame bottom beam through a suspension slide device in a hanging mode. A drill rod of the impact device impacts the connecting cross beam, the milling shaft and a positioning drill bit under hydraulic drive. By adoption of the horizontal single-shaft directional rotation-impact combined excavation type engineering grooving machine, the blade direction and angle can be conditionally selected, and the excavation mode can be rapidly changed according to formation lithology, and high excavation efficiency and reliably are achieved.

Owner:项栋才 +1

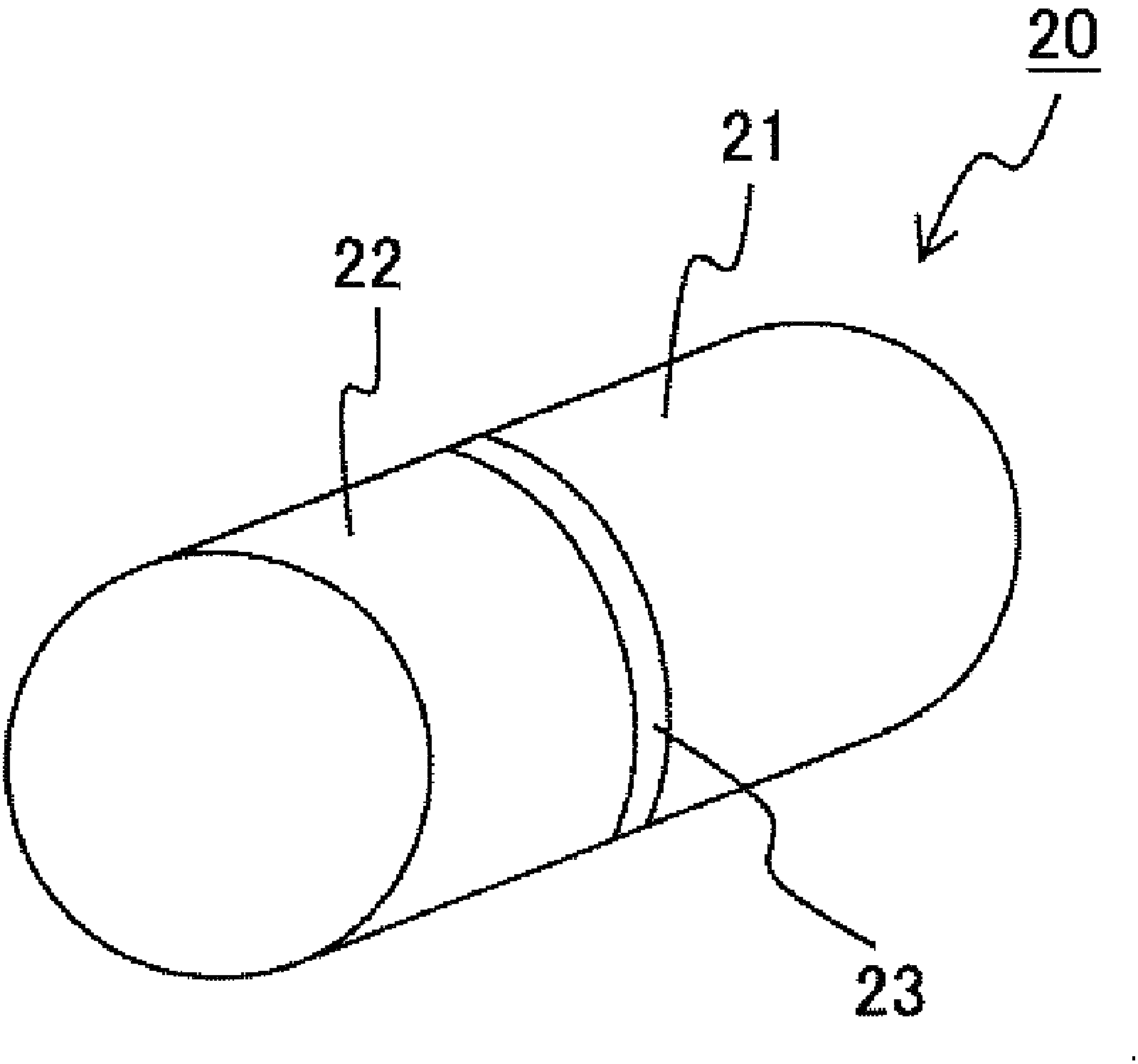

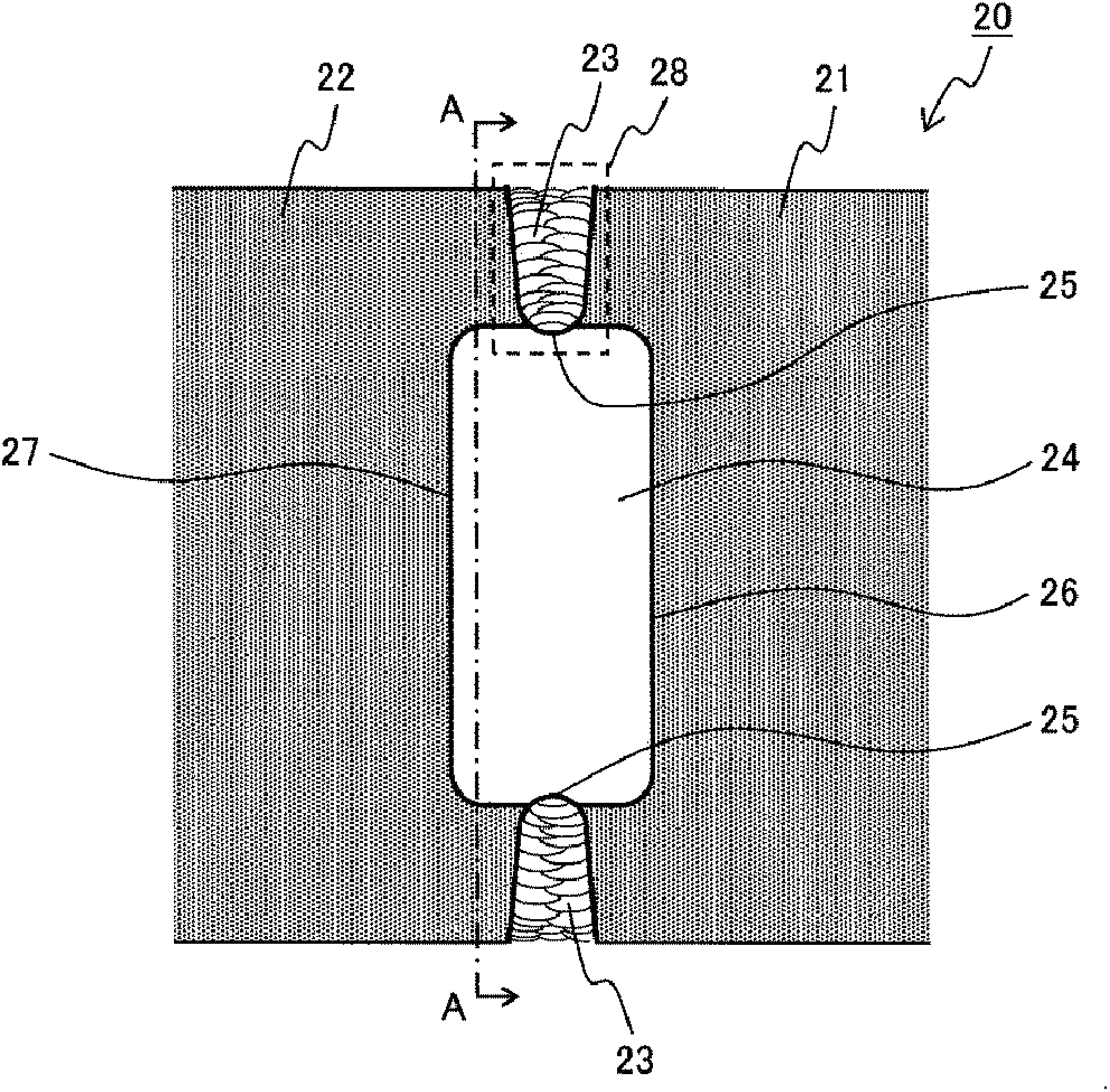

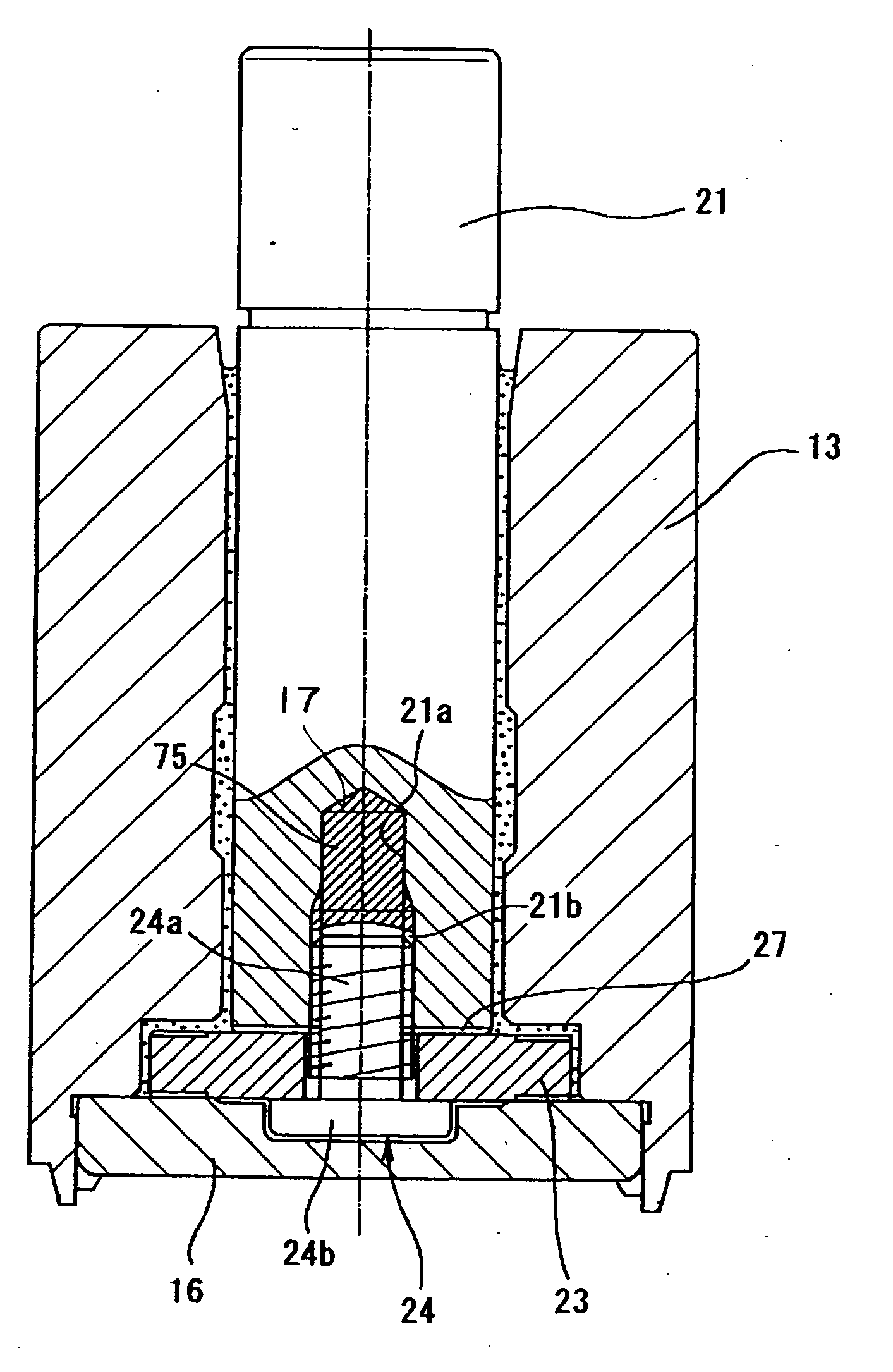

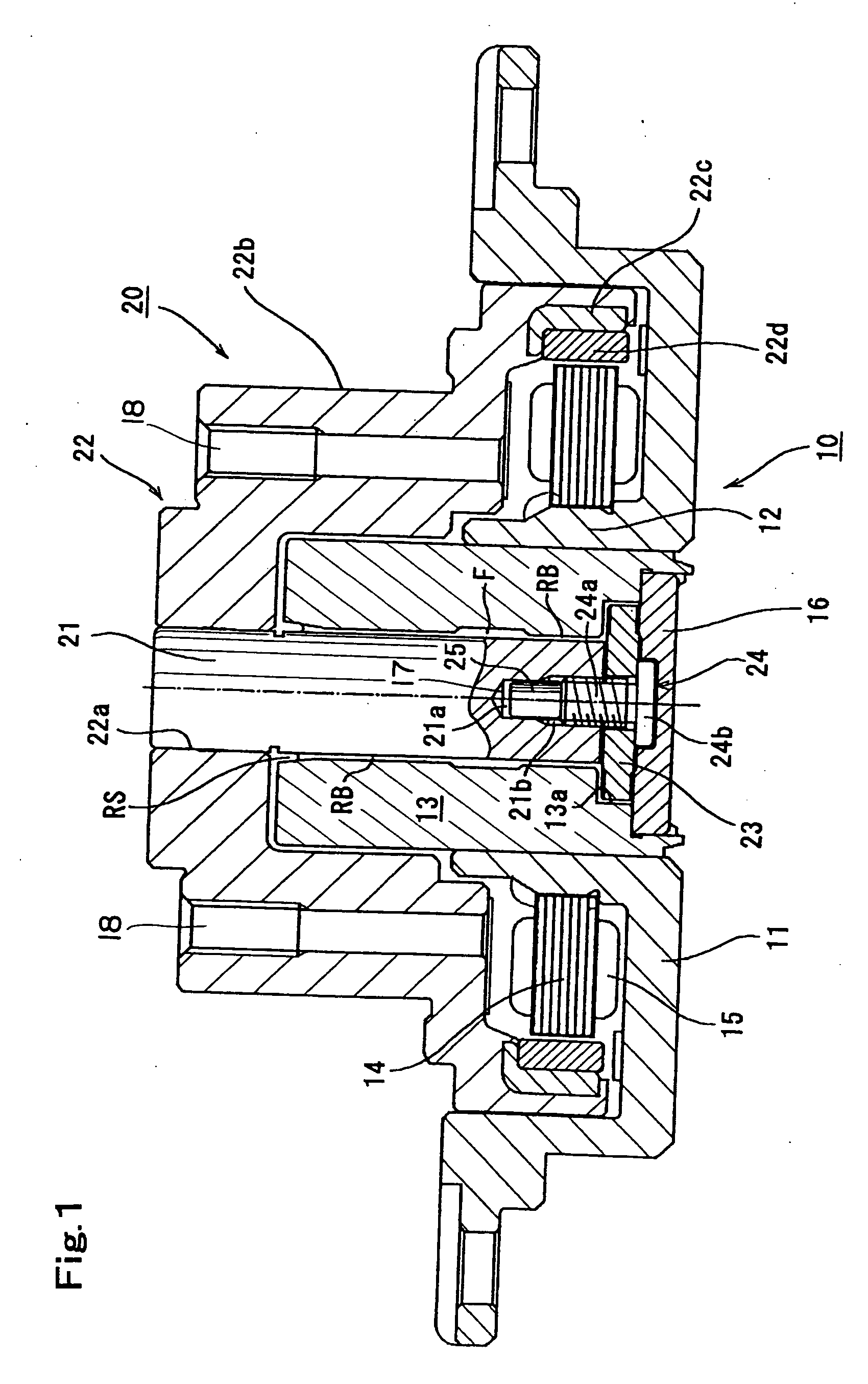

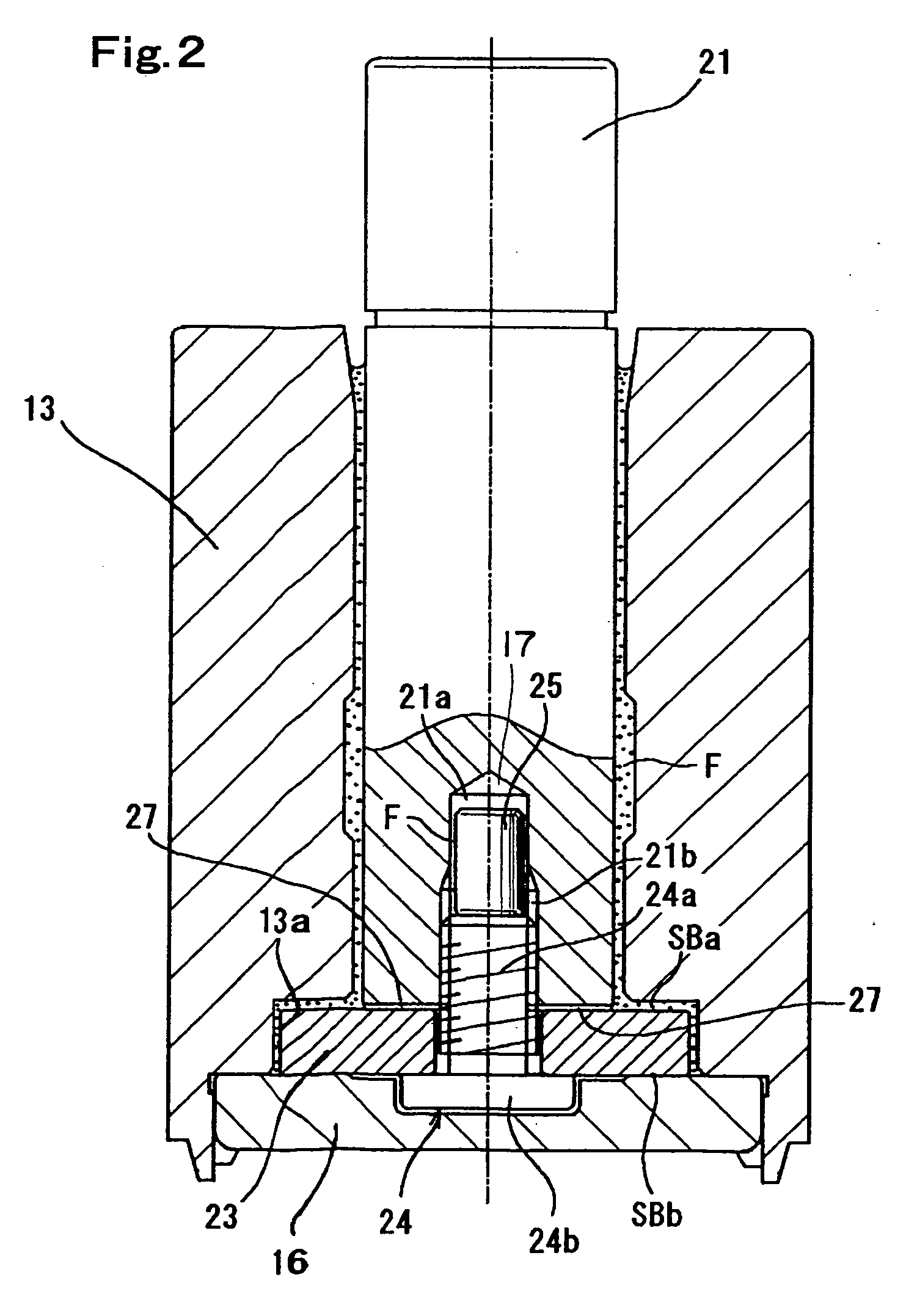

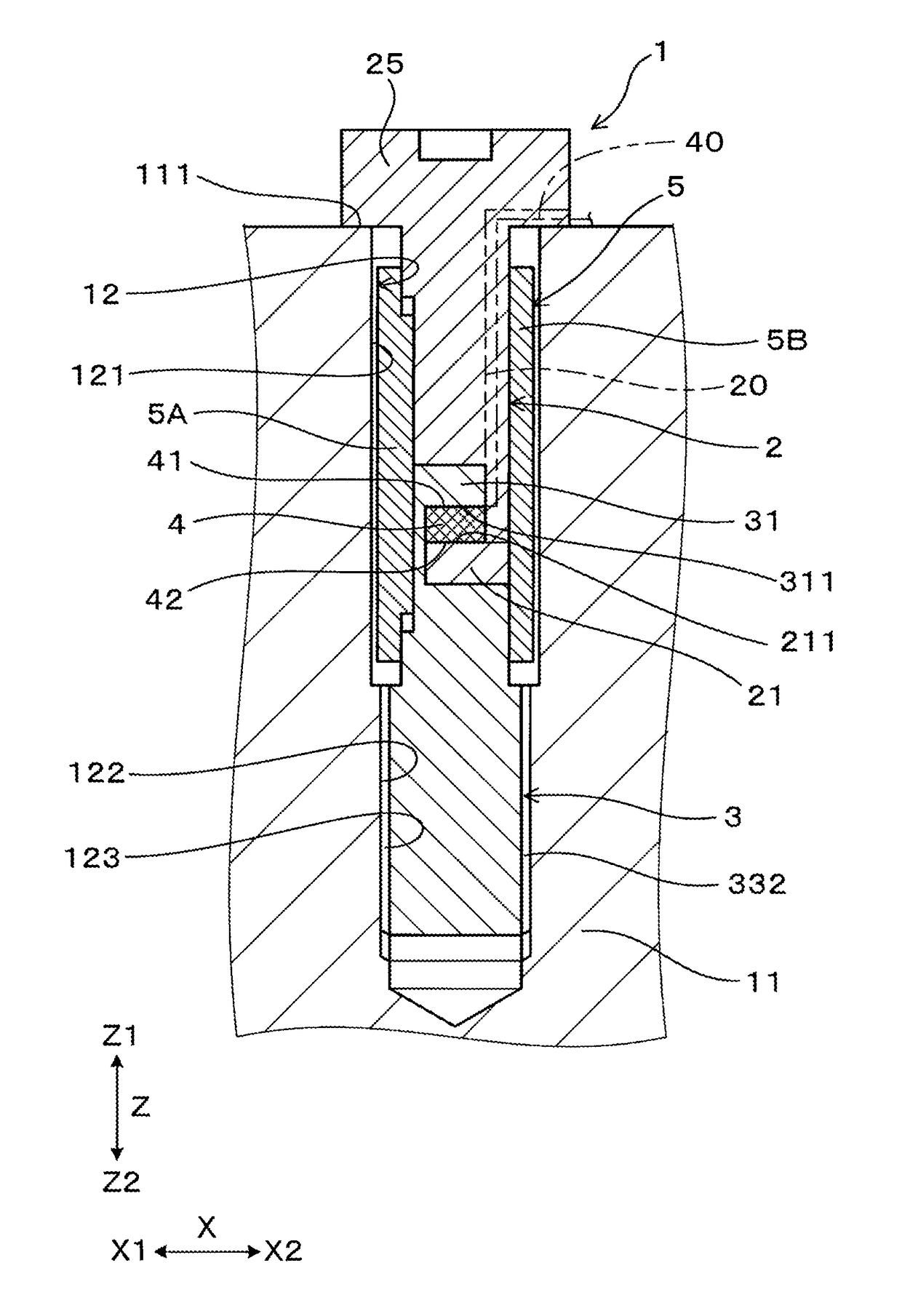

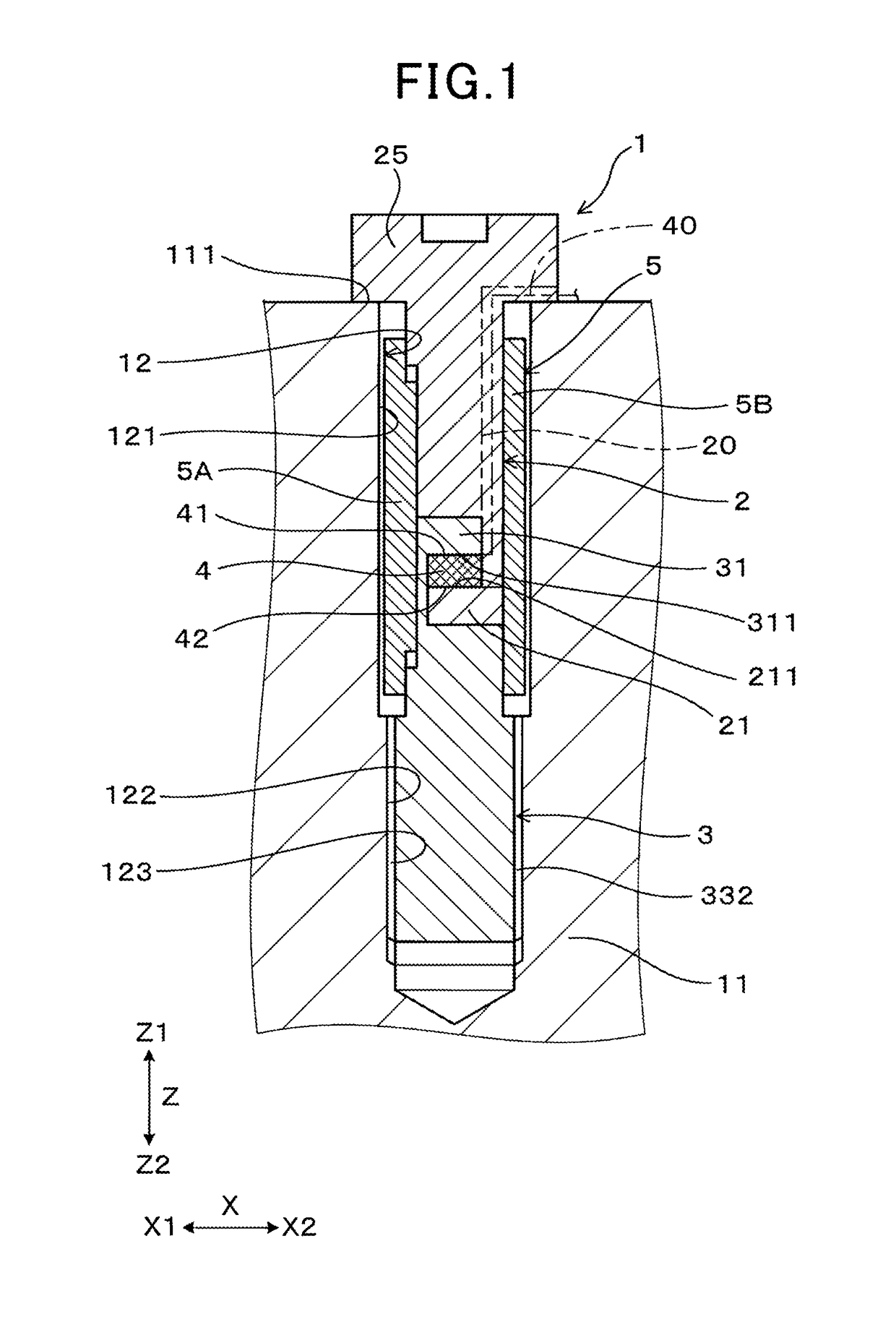

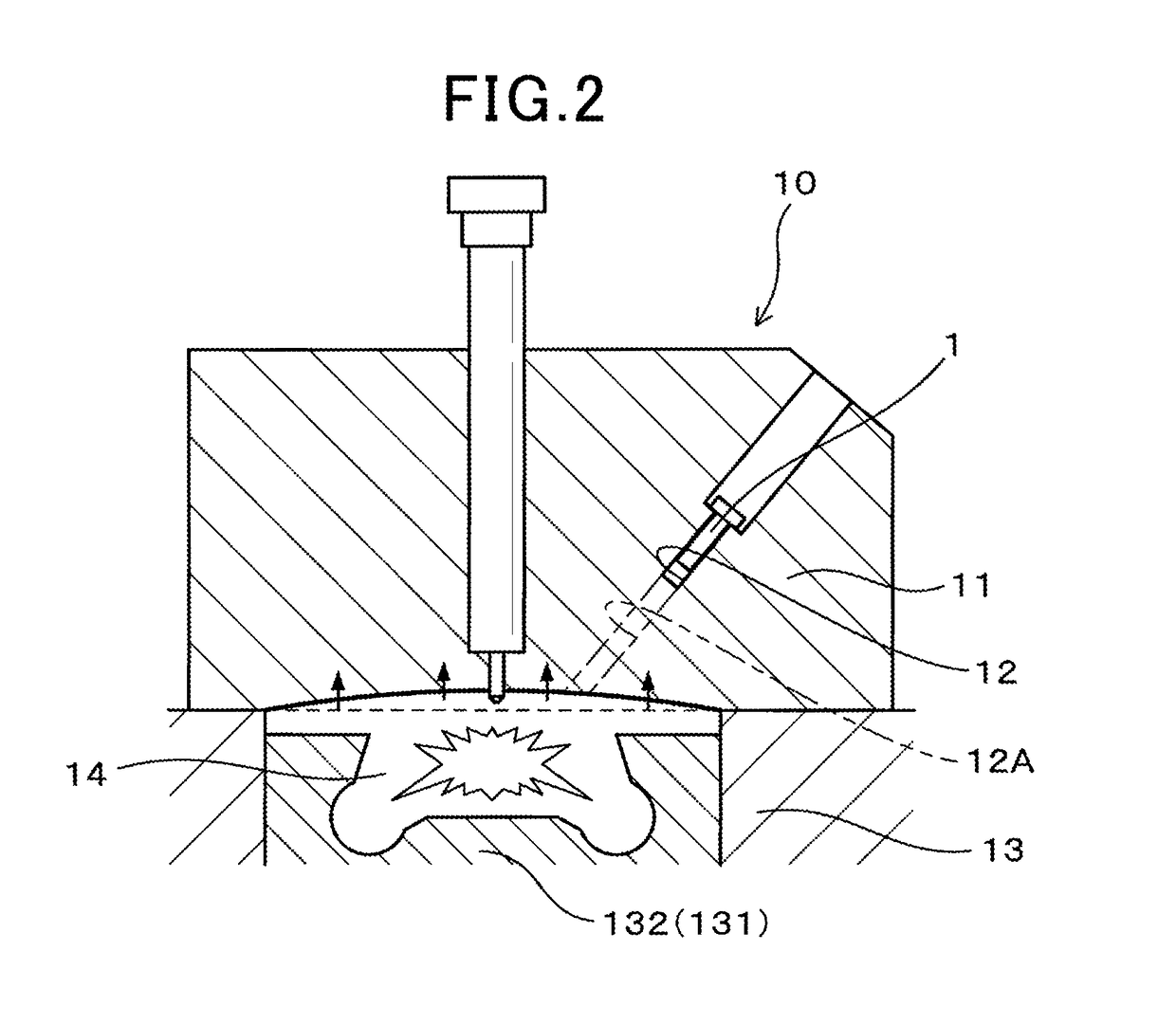

Dynamic pressure bearing apparatus

InactiveUS20060251351A1Improve hygieneImproving dynamic pressure characteristicShaftsBearing componentsEngineeringMechanical engineering

A dynamic bearing apparatus which supports a shaft and a bearing so as to be capable of relative rotation by a dynamic pressure of a lubricating fluid. A bottomed screw hole (21a) is provided to at least one end of the shaft (21) to screw a headed screw (24) for attaching a thrust plate (23) a lubricating fluid (F) is filled in a gap of a screw portion between the screw (24) and the screw hole (21a) or a screw non-occupied space (17), and an interposing member (25) which reduces a void cubic content in the screw non-occupied space (17) is attached to the screw non-occupied space (17).

Owner:NIDEC CORP

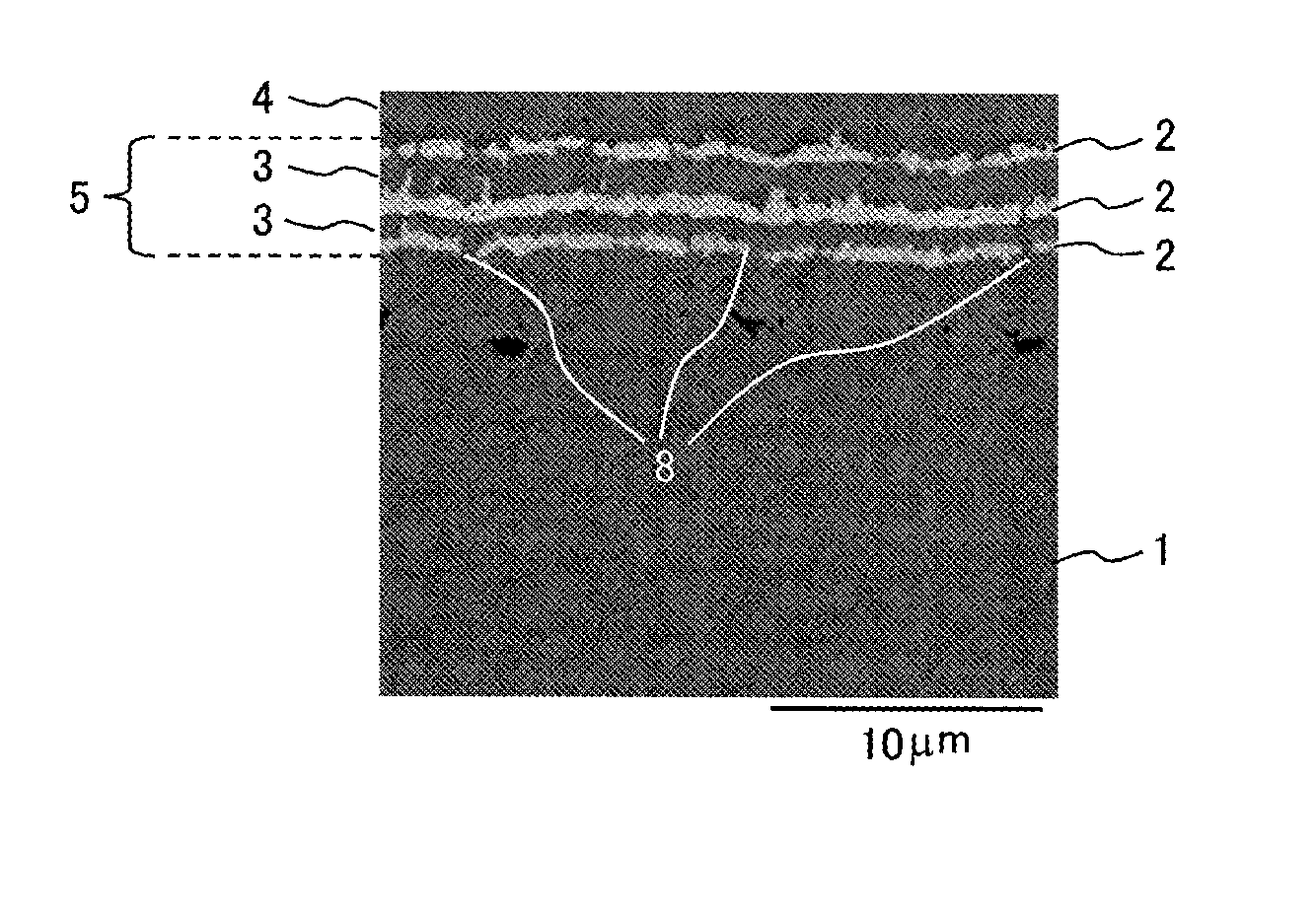

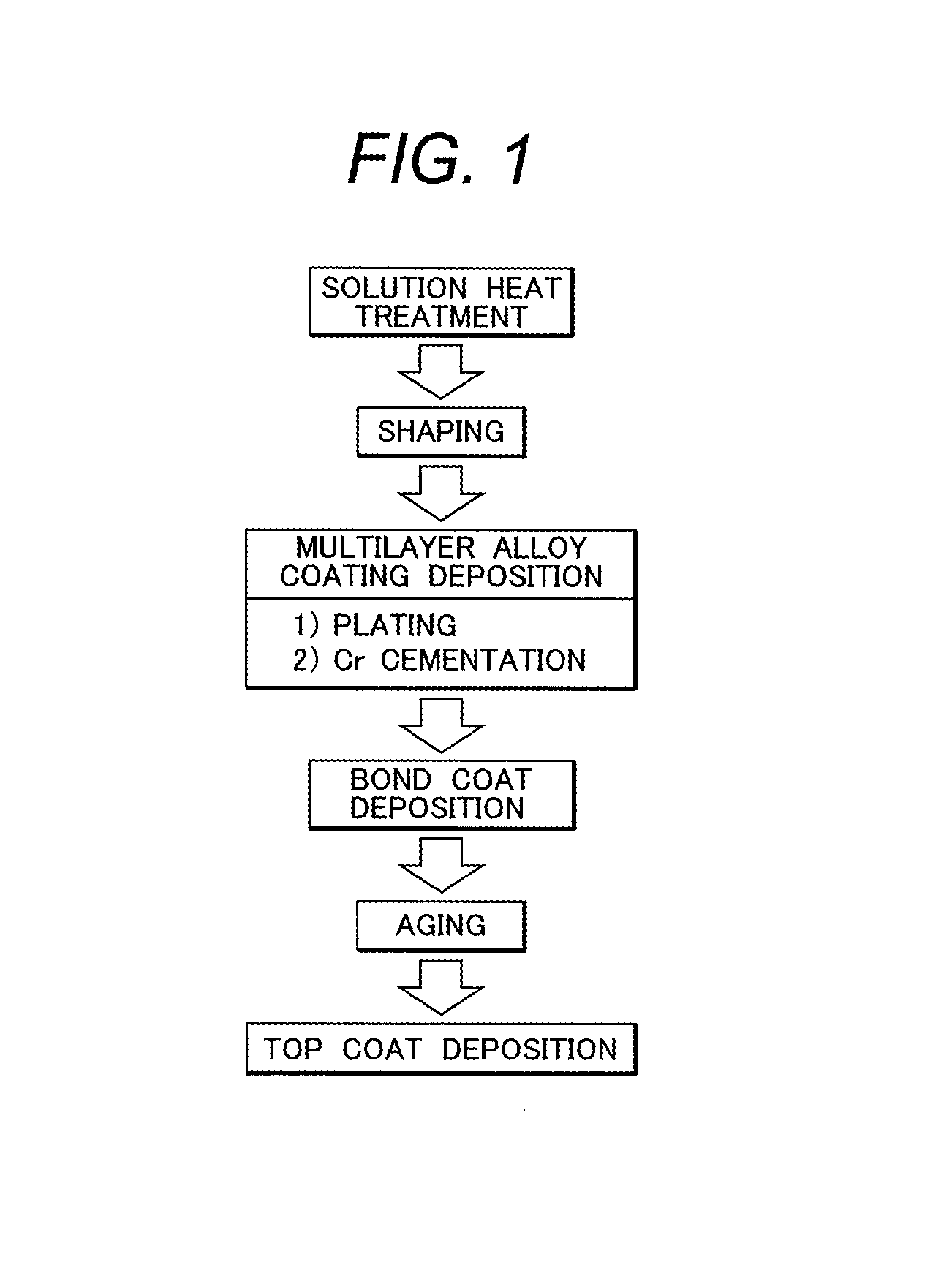

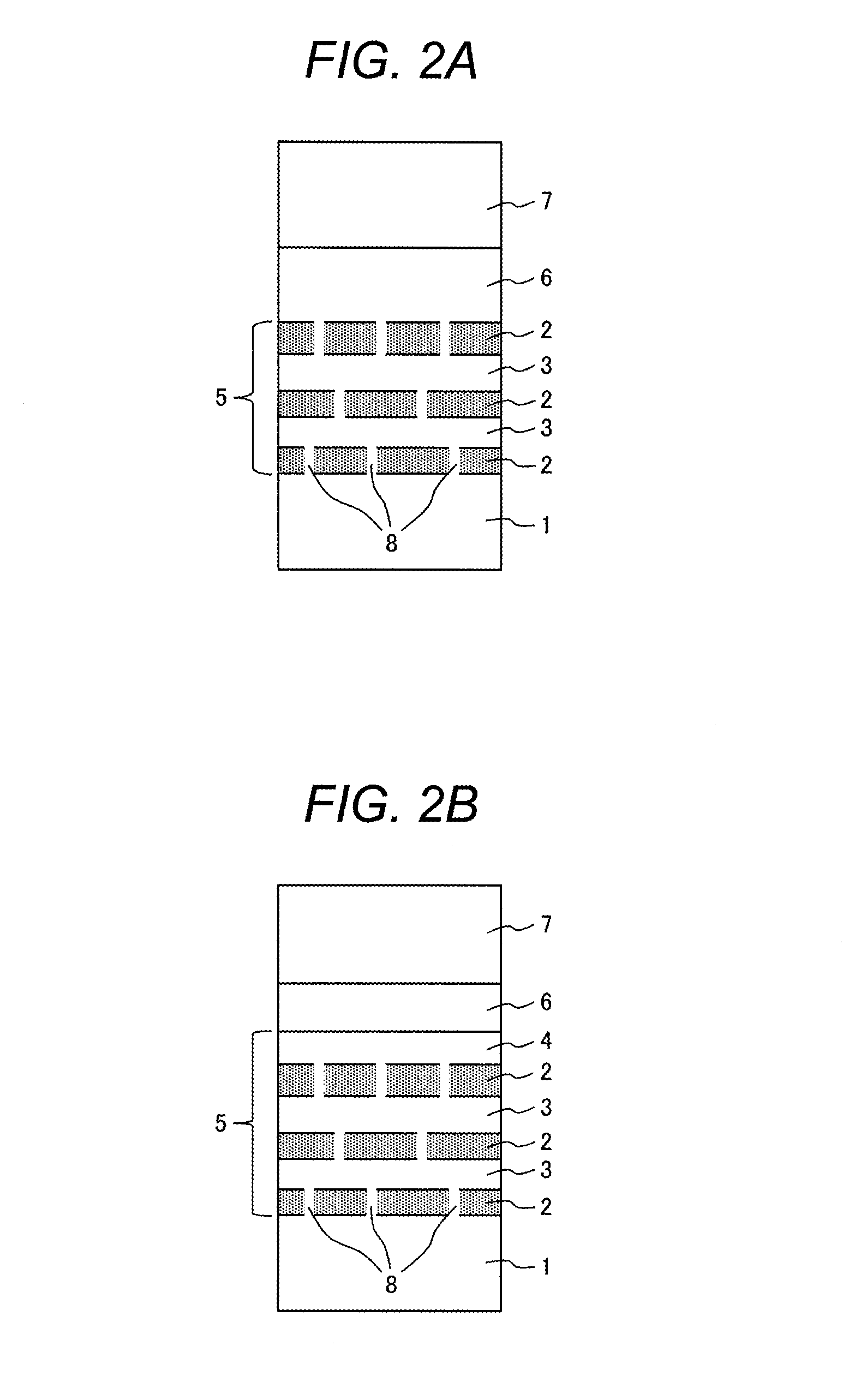

Thermal barrier coating for industrial gas turbine blade, and industrial gas turbine using the same

InactiveUS20140017511A1Increased Strength ReliabilityExtended service lifeBlade accessoriesEfficient propulsion technologiesIndustrial gasTurbine blade

Disclosed is a turbine blade for an industrial gas turbine including a blade substrate; a multilayer alloy coating containing a diffusion barrier layer; a bond coat; and a top coat. The blade substrate being formed of a single crystal alloy which consists essentially of 0.06 to 0.08% of C, 0.016 to 0.035% of B, 0.2 to 0.3% of Hf, 6.9 to 7.3% of Cr, 0.7 to 1.0% of Mo, 7.0 to 9.0% of W, 1.2 to 1.6% of Re, 8.5 to 9.5% of Ta, 0.6 to 1.0% of Nb, 4.9 to 5.2% of Al, 0.8 to 1.2% of Co, and the balance being Ni and incidental impurities by weight. The multilayer alloy coating, the bond coat and the top coat being directly and sequentially laminated on a surface of the blade substrate, in which the diffusion barrier layer is a multilayer and a discontinuous layer.

Owner:HOKKAIDO UNIVERSITY +1

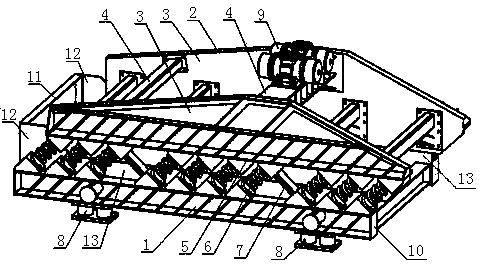

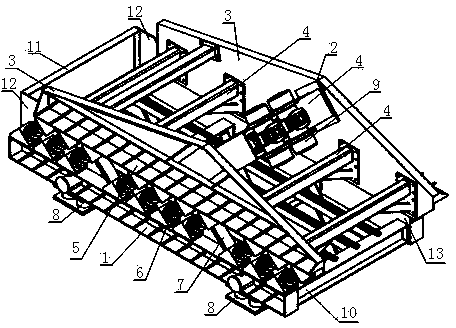

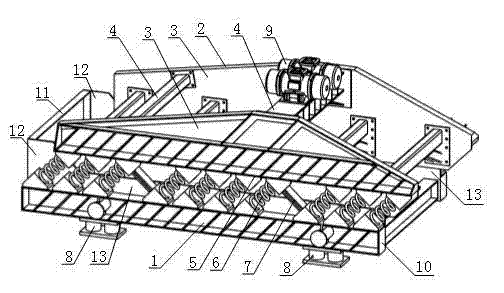

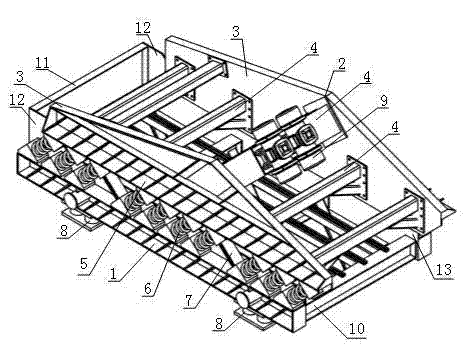

Screen frame and screen bed separated double-plastid near resonance screen

ActiveCN103394462APrevent leakage and splashAvoid Independent ExcitersSievingScreeningResonanceEngineering

The invention discloses a screen frame and screen bed separated double-plastid near resonance screen which comprises a screen bed (1) and a screen frame (2), wherein main vibration springs (6) are arranged between the screen bed (1) and the screen frame (2); the screen bed (1) is mounted on the ground by isolation springs (8); exciting vibration motors (9) are mounted on the screen frame (2); the screen frame (2) consists of side plates (3) and transverse beams (4); the main vibration springs (6) are arranged between connecting seats (5) of the side plates (3) and the screen bed (1); and the exciting vibration motors (9) are mounted on the transverse beams (4). The double-plastid near resonance screen has the benefits that the screen frame serves as an exciting vibration body, so that the double-plastid near resonance screen has no extra metal consumption, and a purpose that totally consumed steel is reduced greatly under the same design function parameter; the screen frame serves as an exciter, so that the vibration strength is less, and the structural strength is high in reliability; the double-plastid near resonance screen is designed based on a principle of double-plastid near resonance, and is a large-scale rectilinear vibration screen; the power consumption is less; and an impact of equipment on a foundation is smaller.

Owner:CHENGDU WEST PETROLEUM EQUIP

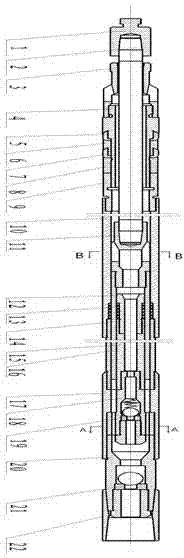

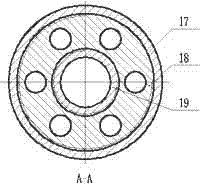

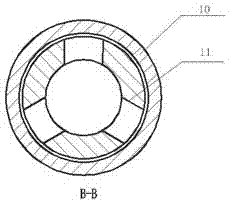

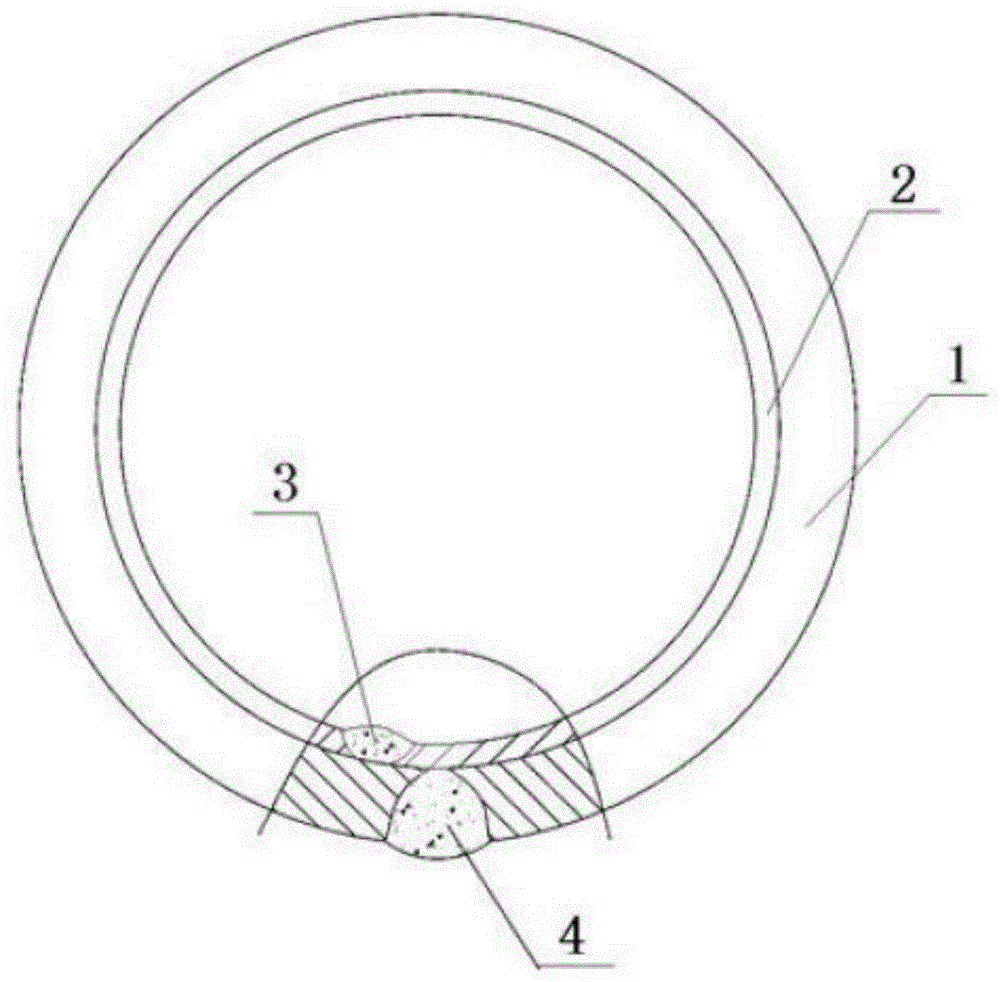

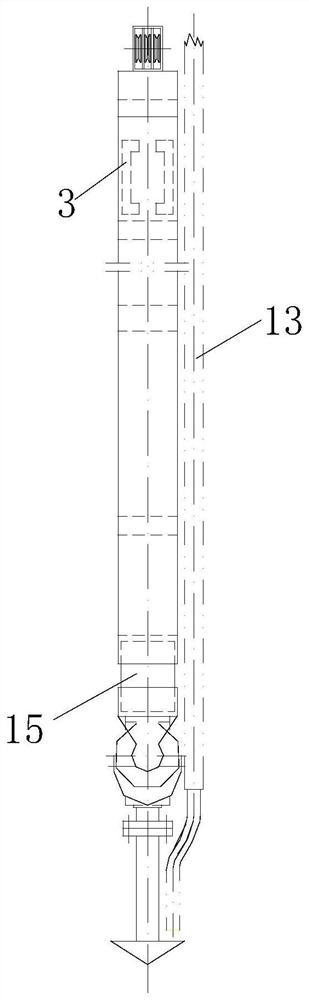

Small-displacement rod type oil well pump with annular plunger

InactiveCN103883503AReduce oil pipe workReduce workloadFlexible member pumpsPositive-displacement liquid enginesWellheadEngineering

A small-displacement rod type oil well pump with an annular plunger comprises an outer pump barrel, an inner pump barrel and the annular plunger. The upper end of the outer pump barrel is connected with a supporting leather cup assembly through a lengthening coupling, and the lower end of the outer pump barrel is connected with a valve housing of an oil inlet valve through a pump barrel coupling. The upper end of the inner pump barrel is connected with a sealing segment joint, and the lower end of the inner pump barrel is connected with the pump barrel coupling through a valve housing of an oil outlet valve. An annular work cavity is formed between the inner pump barrel and the outer pump barrel, the annular plunger is in small clearance fit with the inner pump barrel and the outer pump barrel, the annular plunger is connected with a valve rod through a valve rod lower joint, and the lower end of the valve housing of the oil inlet valve is connected with a tail pipe joint in a threaded mode through the lower joint. The annular plunger moves upwards along with the oil pump, an oil outlet valve ball is closed, an oil inlet valve ball is opened, well fluid is sucked in, fluid with a receding size of the plunger is discharged out of a well mouth, the oil inlet valve is closed, and well fluid stops from entering. In the downstroke, fluid in a pump cavity is extruded downward, and liquid is discharged into an oil pipe through a liquid outlet of a valve rod guiding sleeve after passing through the oil outlet valve assembly. The small-displacement rod type oil well pump with the annular plunger has the advantages of being high in efficiency and free of pump seizure and blocking.

Owner:XI'AN PETROLEUM UNIVERSITY

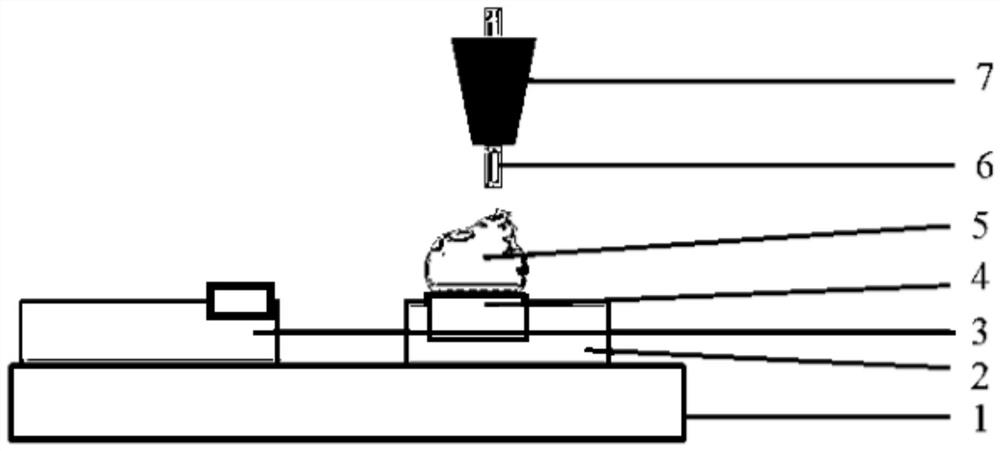

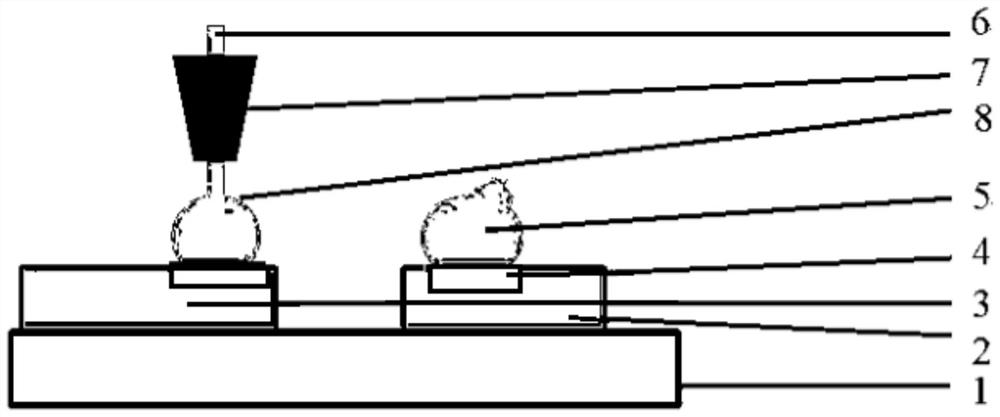

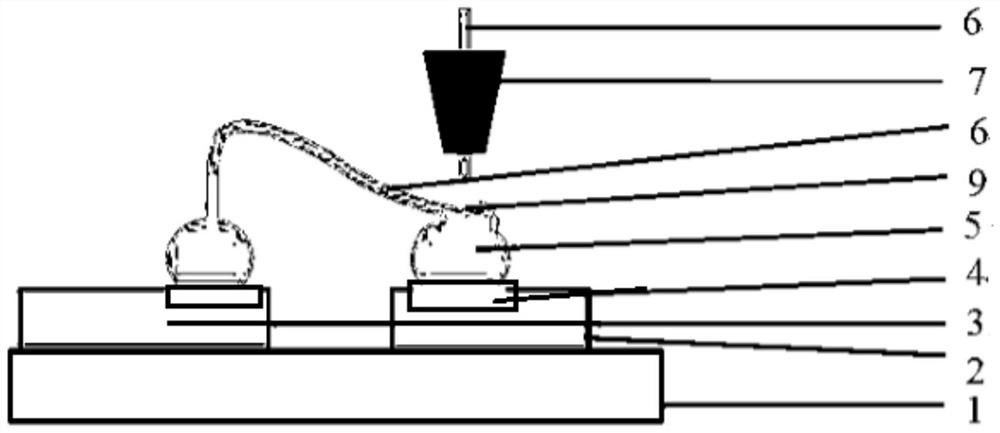

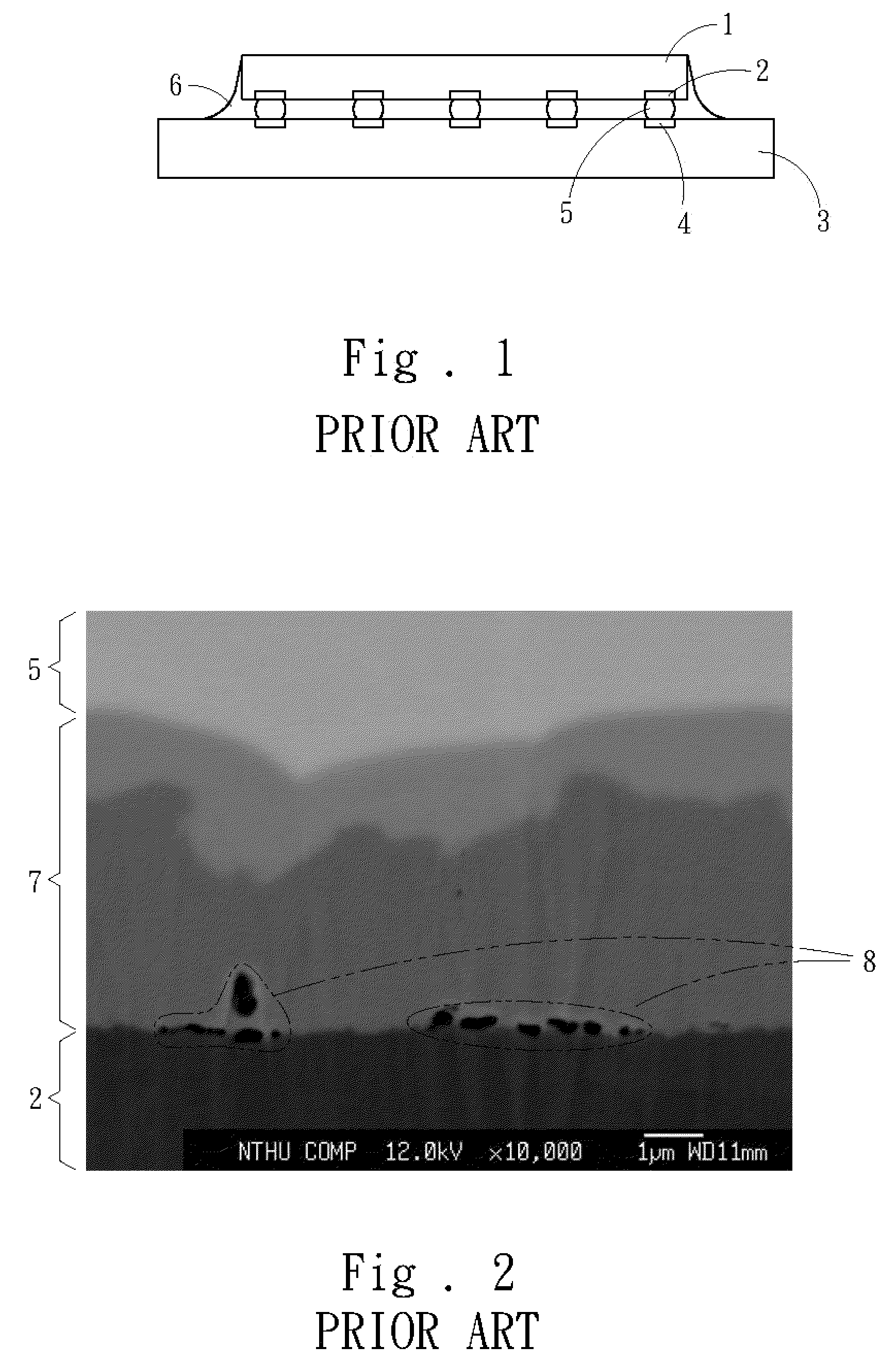

Chip bonding pad ball mounting leveling and secondary welding method

PendingCN114050136AIncreased Strength ReliabilityGood lookingSemiconductor/solid-state device detailsSolid-state devicesSolder ballStructural engineering

The invention provides a chip bonding pad ball-mounting leveling and secondary welding method, and the method achieves the fishtail bonding of a lead and a flat interface at the top end of a ball-mounting during secondary welding through introducing a ball-mounting shaping process. According to the method, the welding process sequence for secondary welding of a plurality of chip bonding pads in the prior art is changed, the process sequence of centralized ball mounting, centralized sharp-cap-shaped welding ball flattening and shaping and centralized secondary welding is adopted, the consistency of ball mounting morphology is improved, and the stability of the secondary welding process is improved. Aiming at an electronic device adopting a chip bonding pad secondary welding process, the consistency in the welding process is improved, the abnormities of fishtail wire warping, wire shrinkage after fishtail bonding and the like in the welding process are reduced, and the strength reliability of chip bonding pad secondary welding is improved. The method has the advantages of high yield, high efficiency, high welding strength and the like under the conditions of multi-chip interconnection, laminated chip interconnection, reverse welding of the frame carrier and the chips under the condition of complex wiring and the like.

Owner:XIAN MICROELECTRONICS TECH INST

Production method of an acoustic diaphragm, acoustic diaphragm, and a speaker

InactiveUS20080257638A1High carbonation ratePrevent sound deteriorationFibre diaphragmsPolymeric diaphragmsEngineeringPhenol

A method of producing an acoustic diaphragm includes forming a workpiece having a shape of the acoustic diaphragm by using a natural material which can be carbonized by burning; forming a first film including phenol resin on a surface and an interior of the workpiece; heating the workpiece to bring the phenol resin into a high polymer state; burning the workpiece in a substantially anoxic atmosphere to carbonize the workpiece and the first film; and forming a second film including gelatin on at least one of a surface and an interior of carbonized workpiece.

Owner:VICTOR CO OF JAPAN LTD

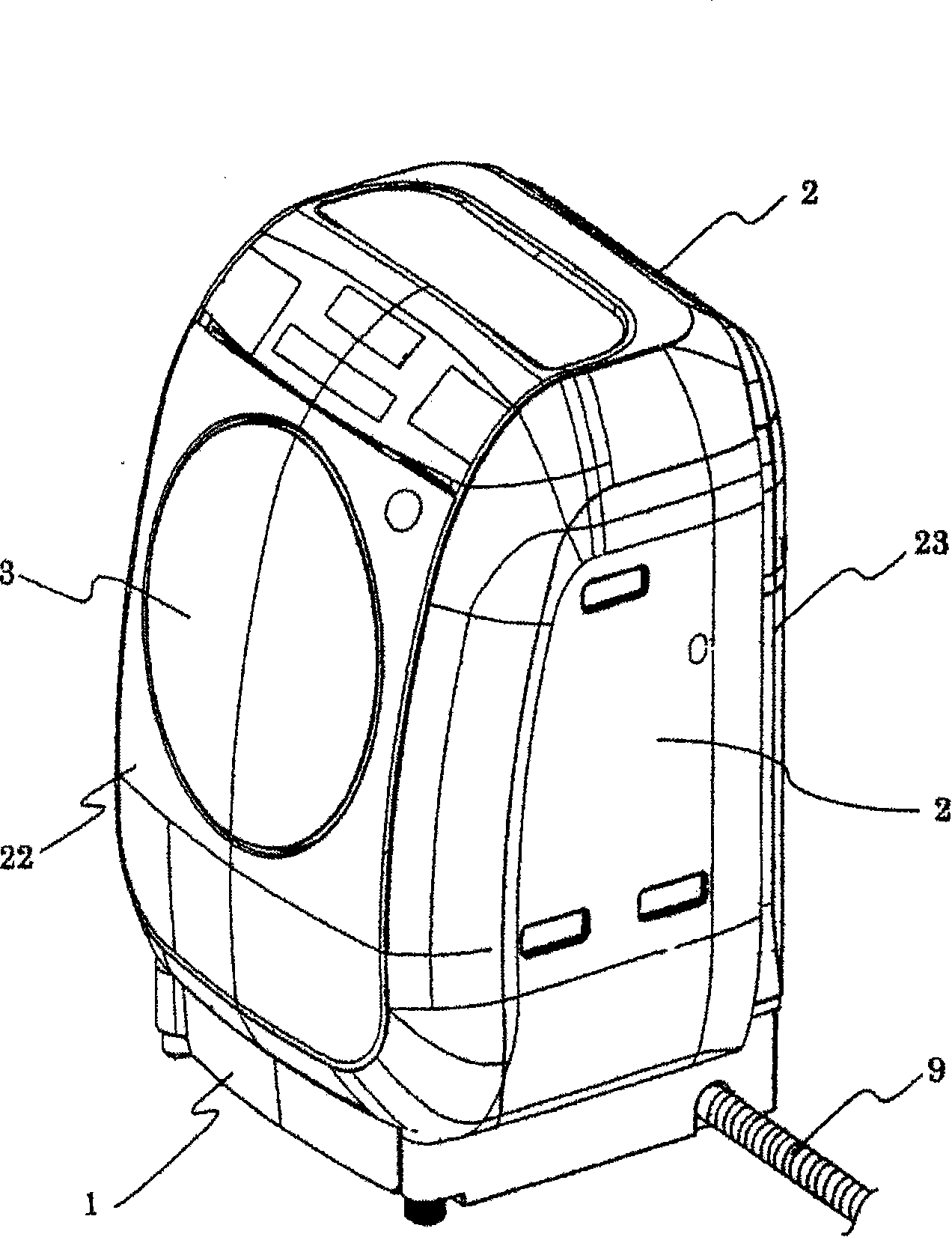

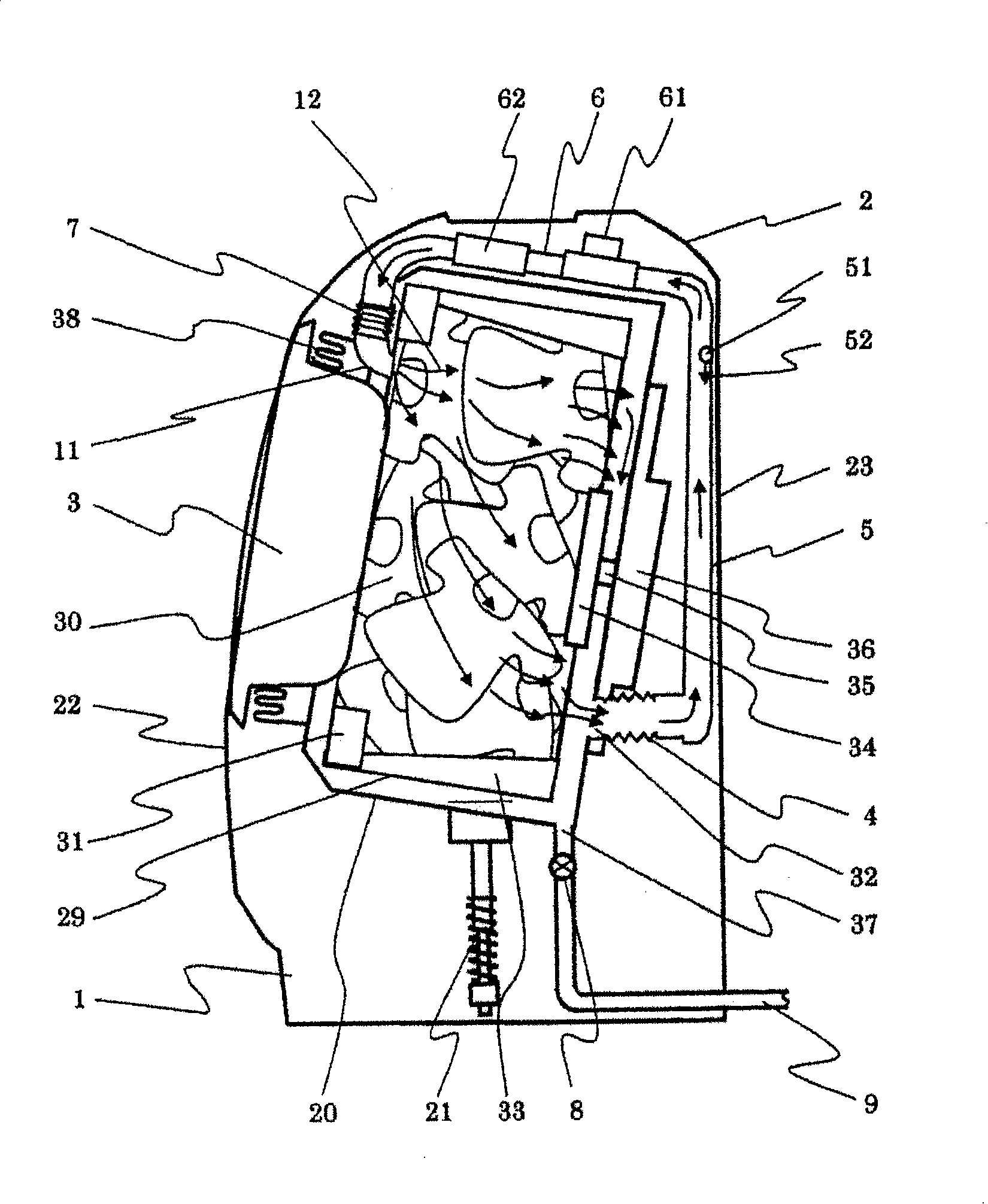

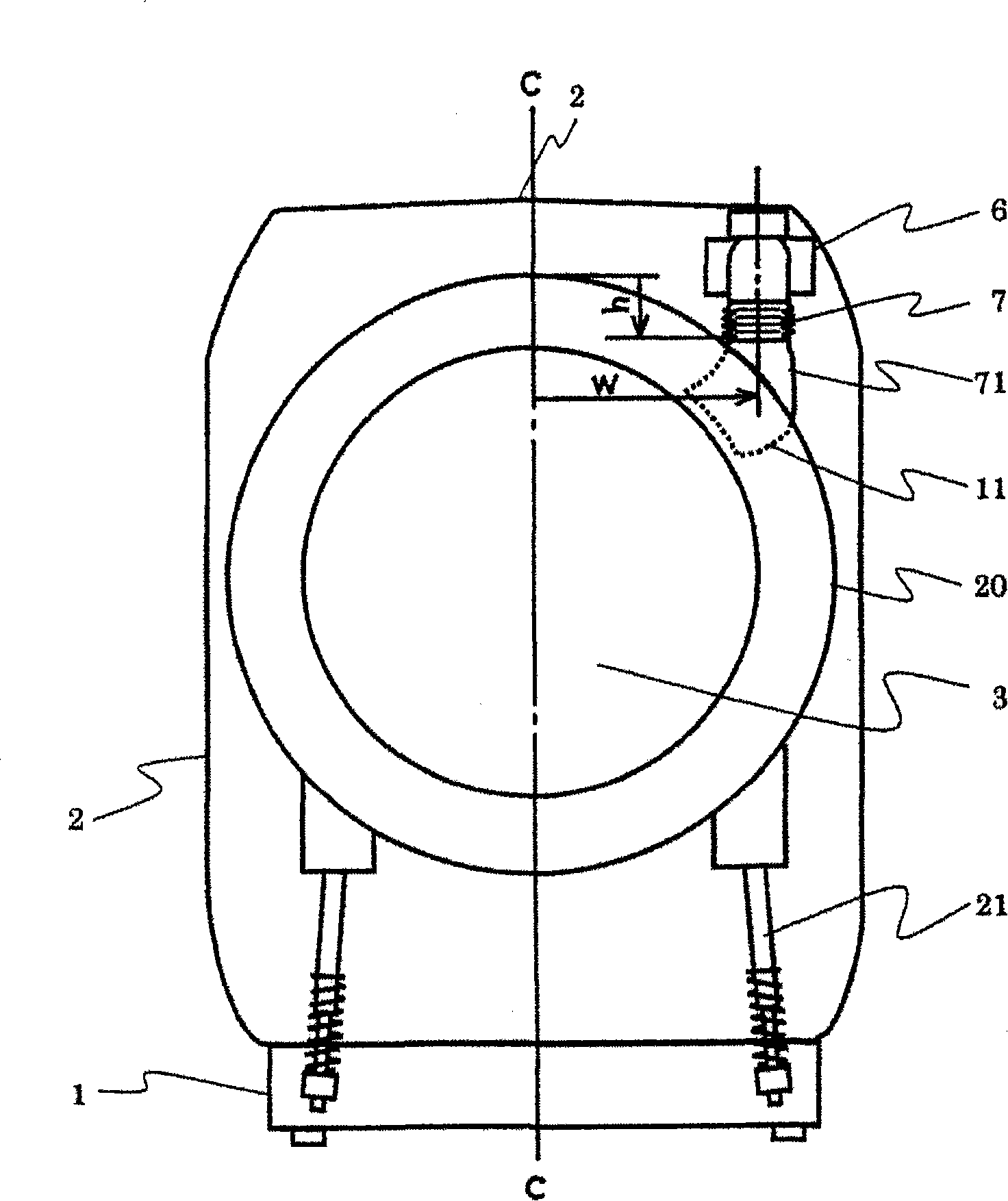

Drum type washing drier

ActiveCN101177864AIncreased Strength ReliabilityOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The proposal of the invention is to provide a small-scale drum-type washing and drying device which can increase the reliability of the intensity of the pipeline connection part at the same time of reducing the vibration noise thereof. The invention comprises a rotary roller (29) which can be rotated optionally and provided with a rotating shaft transversely; an outer tank (20) used for surrounding the rotary roller (29) and storing the washing water; an outer frame (2) surrounding the outer tank (20) inside; and a drying device (6) comprising a dehumidifying part, a heater and a air-feeding fan which are used for feeding hot air into the rotary roller (29). At least part of the drying device (6) is arranged at the outer frame (2) side. The ventilation channel positioned at the drying device (6) side is connected with the outer tank (20) side so as to arrange a corrugated tube (7) in such a way that the flexible direction of the corrugated tube is along the front side of the outer tank or along the basically straight direction. The corrugated tube (7) is arranged at the external side of the external periphery at the front of the outer tank.

Owner:HITACHI APPLIANCES INC

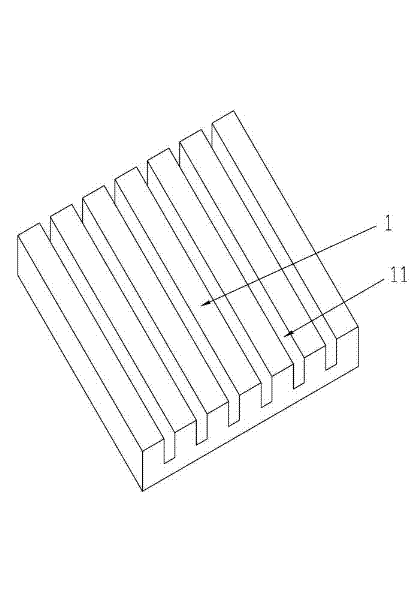

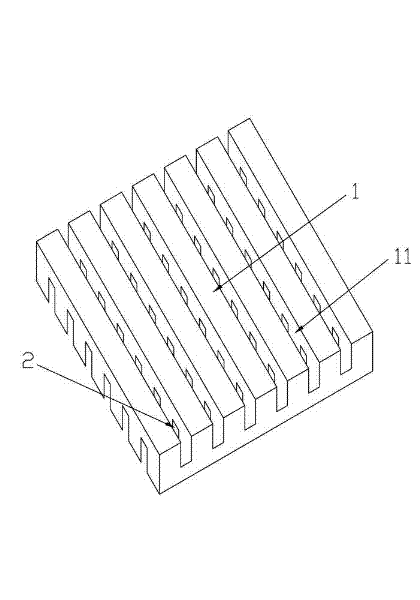

Piezoelectric component having multilayer composite structure and preparation method thereof

InactiveCN102420286AEasy to manufacturePerformance is easy to controlPiezoelectric/electrostrictive device manufacture/assemblyUltimate tensile strengthPiezoelectricity

The invention relates to a piezoelectric component having a multilayer composite structure and a preparation method thereof. The component is made of a material with piezoelectricity, the piezoelectric component having the multilayer composite structure has three-layer structure, and the structures of three layers are communicated together to form a whole; two end face layers are provided with piezoelectric material strips arranged in parallel, and the middle layer is provided with a piezoelectric material granule post; and legacy electrode layers are formed on the surfaces of the piezoelectric material strips on the two end face layers. The piezoelectric component having the multilayer composite structure is a circular, square or polygonal planar component. The invention is characterized in that: the piezoelectric component is easy and convenient to prepare and controllable in performance; the electrode layers of two ends can be welded through high-temperature leads, and all the structures of three layers are communicated, so the piezoelectric component has high strength and reliability; and the parameters of the piezoelectric component are superior to those of a solid piezoelectric component of the same overall dimension.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

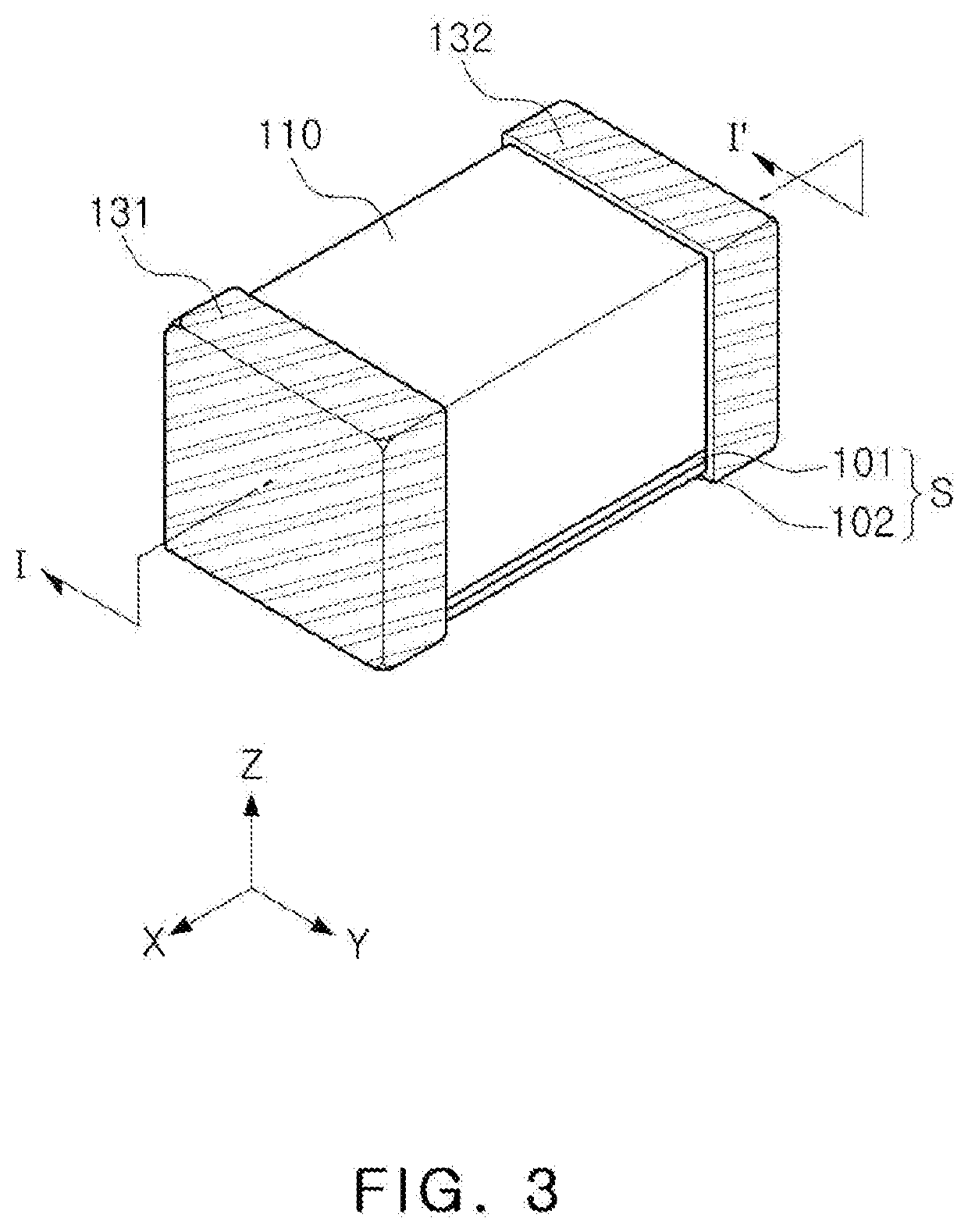

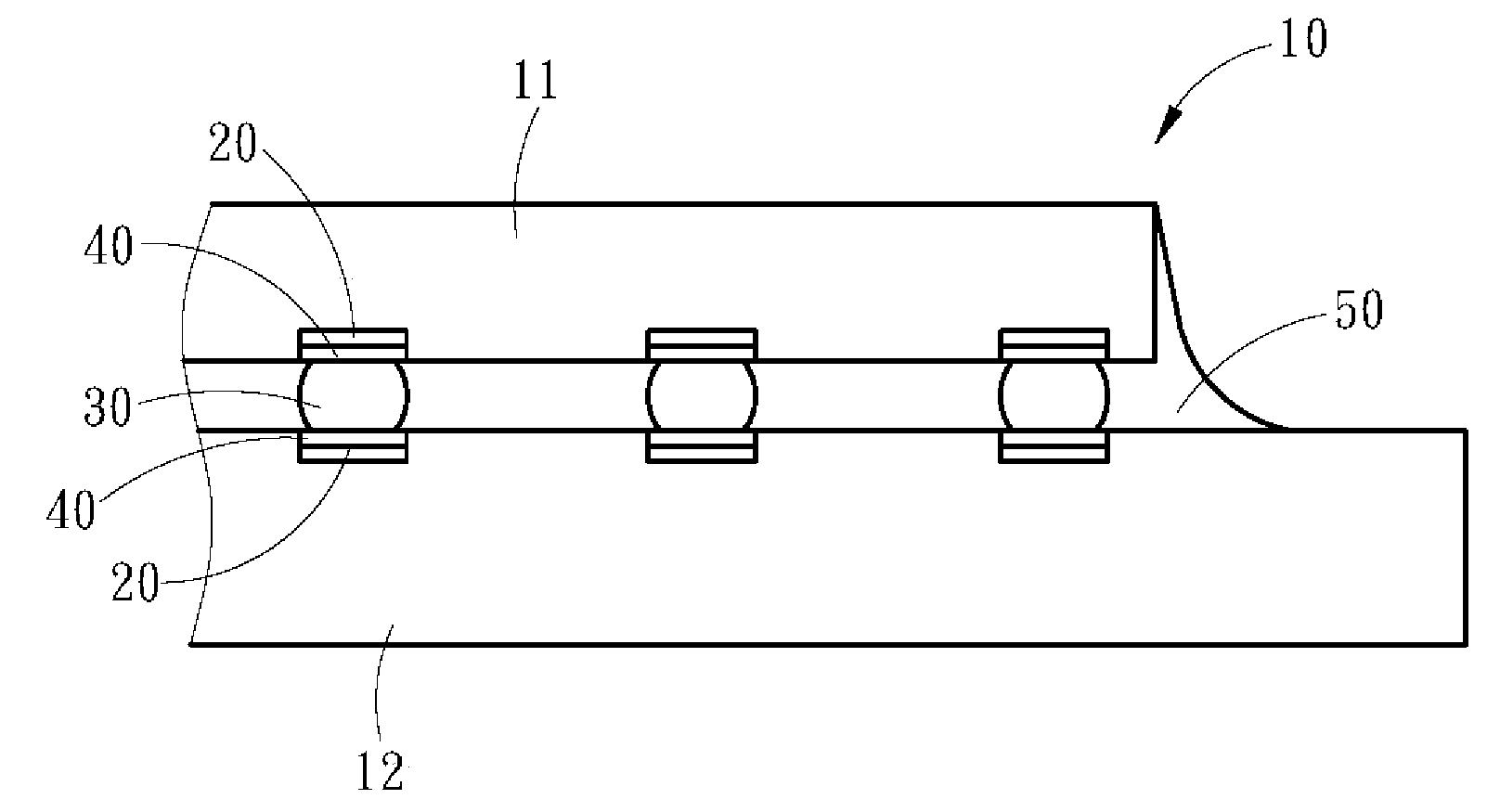

Multilayer capacitor

ActiveUS20200090871A1Improve moisture resistance reliabilityIncreased Strength ReliabilityFixed capacitor electrodesHybrid capacitor electrodesStress alleviationDielectric layer

A multilayer capacitor includes a body including a stack structure of a plurality of dielectric layers, and a plurality of internal electrodes stacked with the dielectric layers interposed therebetween. A stress alleviation portion is disposed on at least one surface among surfaces of the body, and an external electrode is disposed on an external portion of the body and connected to the internal electrodes. The stress alleviation portion includes a first resin layer adjacent to the body, and a second resin layer covering the first resin layer and including a filler dispersed in a resin of the second resin layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

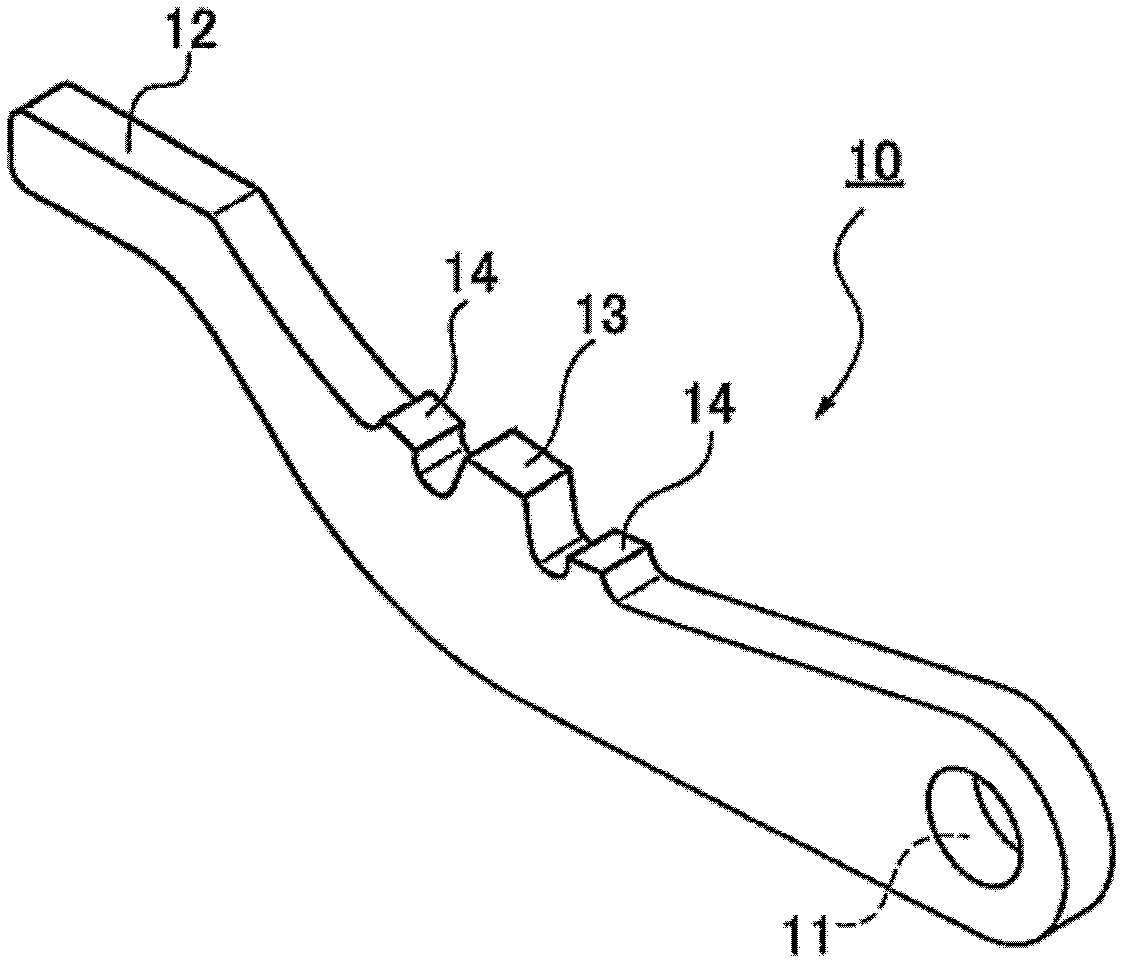

Parking mechnism for automatic transmission

InactiveCN102454779AInhibition of elastic deformationReduce bending momentGearing controlAutomatic transmissionUltimate tensile strength

The present invention provides a parking mechanism for an automatic transmission, which can restrain elastic deformation of a parking rod when a pulling-out force is applied and improves strength reliability. According to the parking mechanism for the automatic transmission, through engaging or releasing between a pawl (13) which is equipped on the parking rod (10) and tooth part (21) of a parking gear (20), the parking gear (20) is rotated and fixed, wherein, the parking rod (10) is adjacent with the pawl (13), and a projection part (14) which contacts with the tooth part (21) through elastic deformation of the parking rod (10) is provided.

Owner:JATCO LTD

A multi-scale joint method for improving the strength of brazed joints of high-hard and brittle ceramic-based materials

ActiveCN105195847BReduce stress concentrationImprove processing efficiencySoldering apparatusWorkpiece edge portionsCombined methodThermal expansion

Owner:HARBIN INST OF TECH

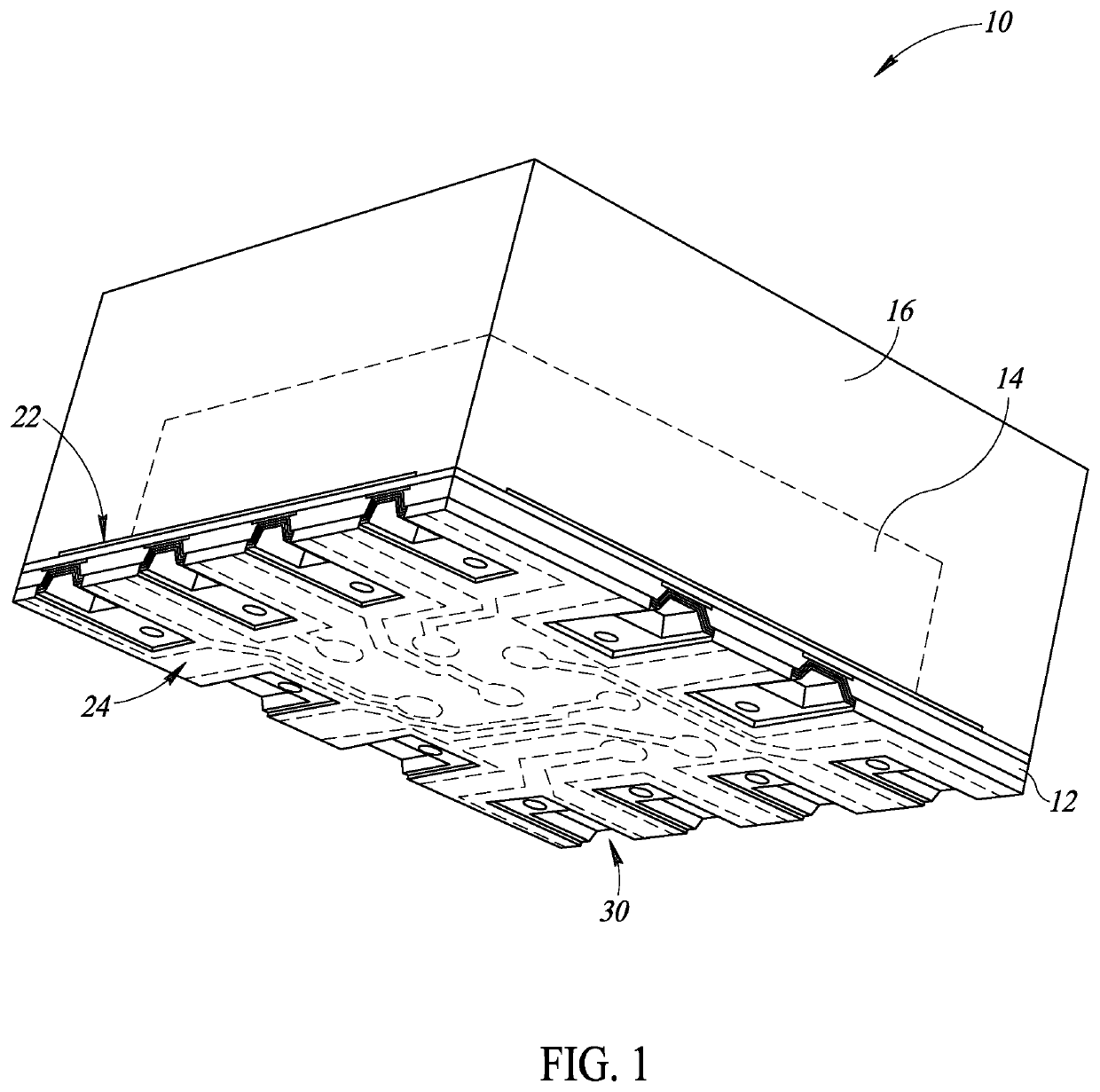

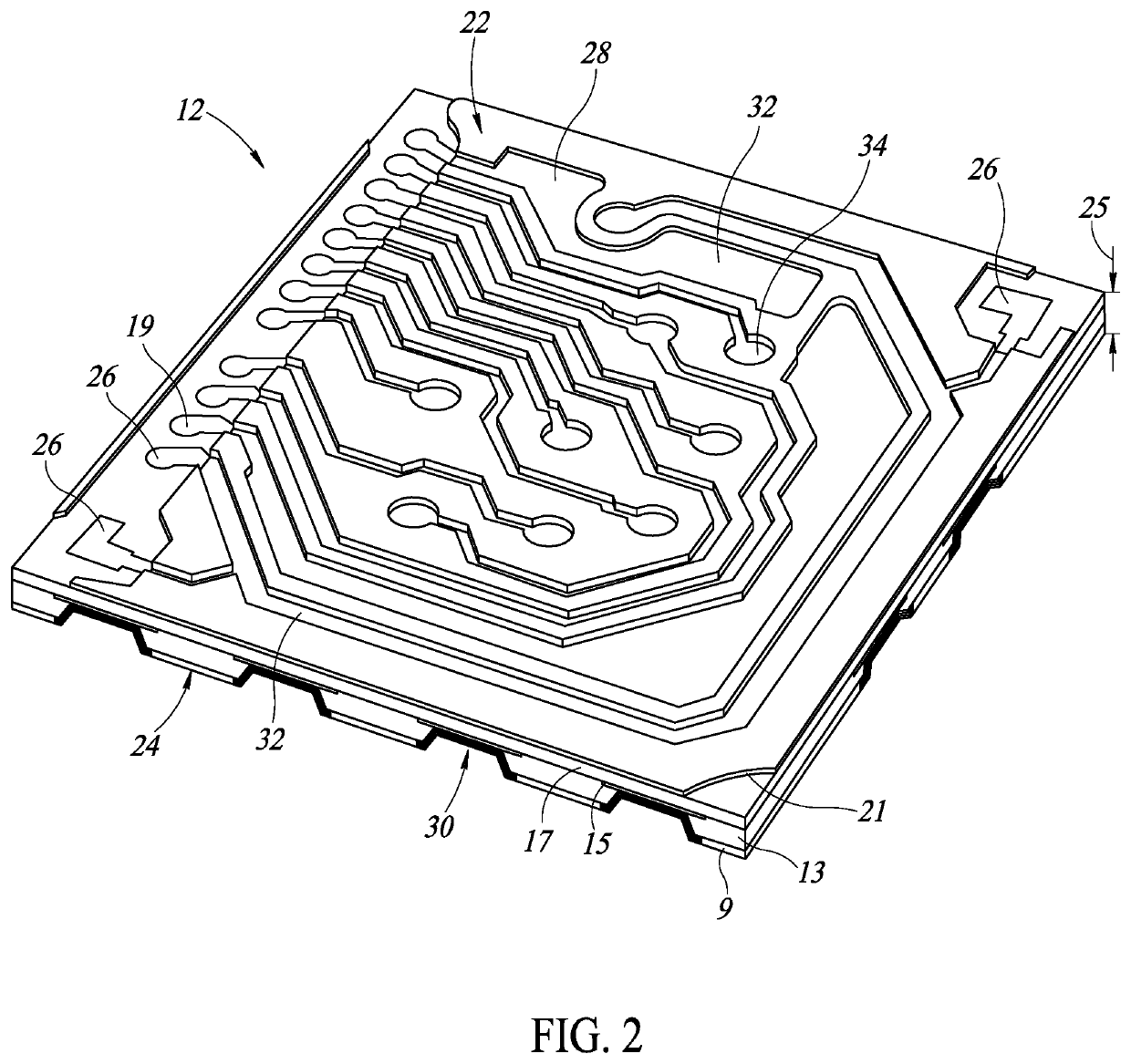

Semiconductor package with wettable slot structures

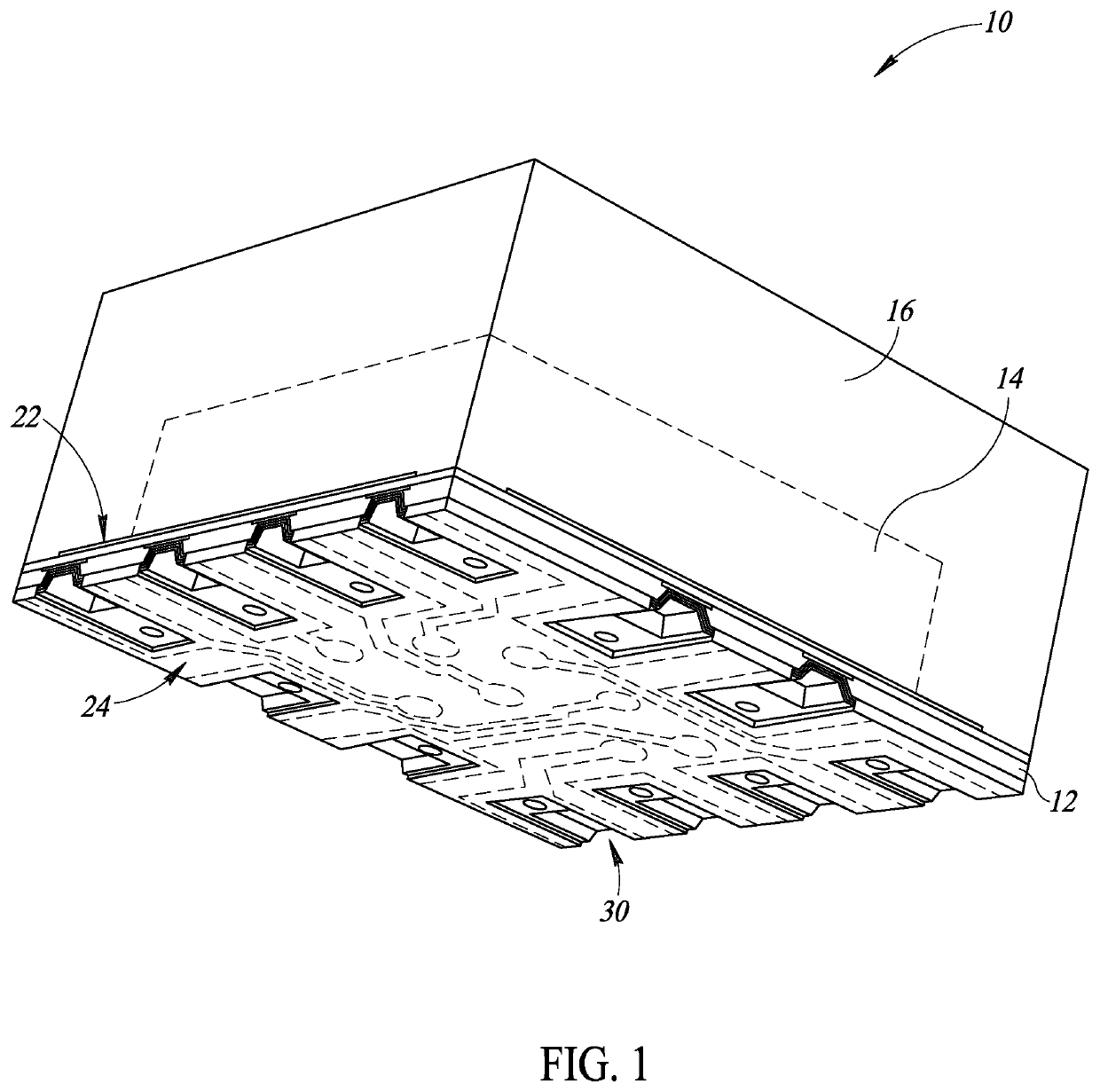

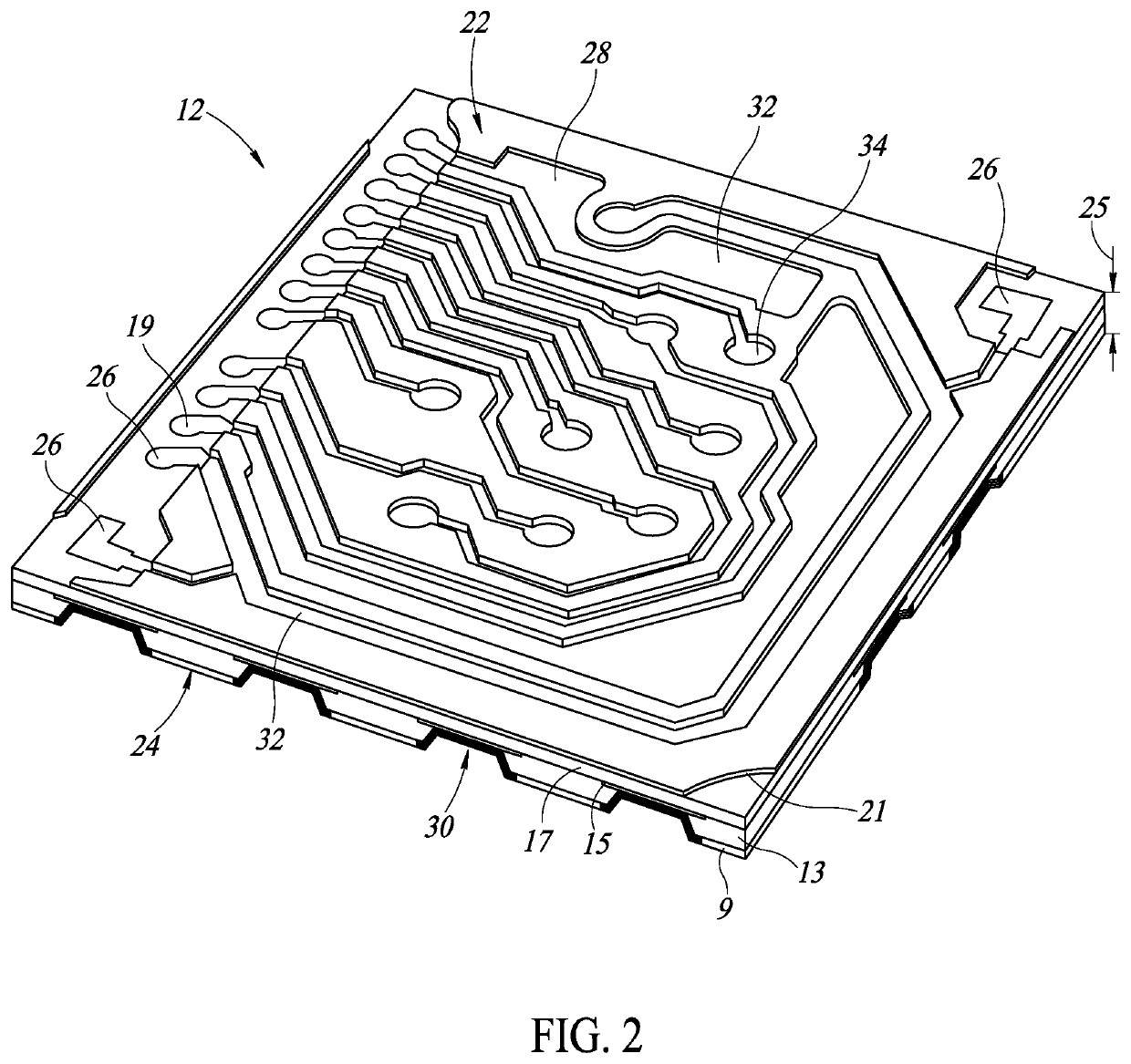

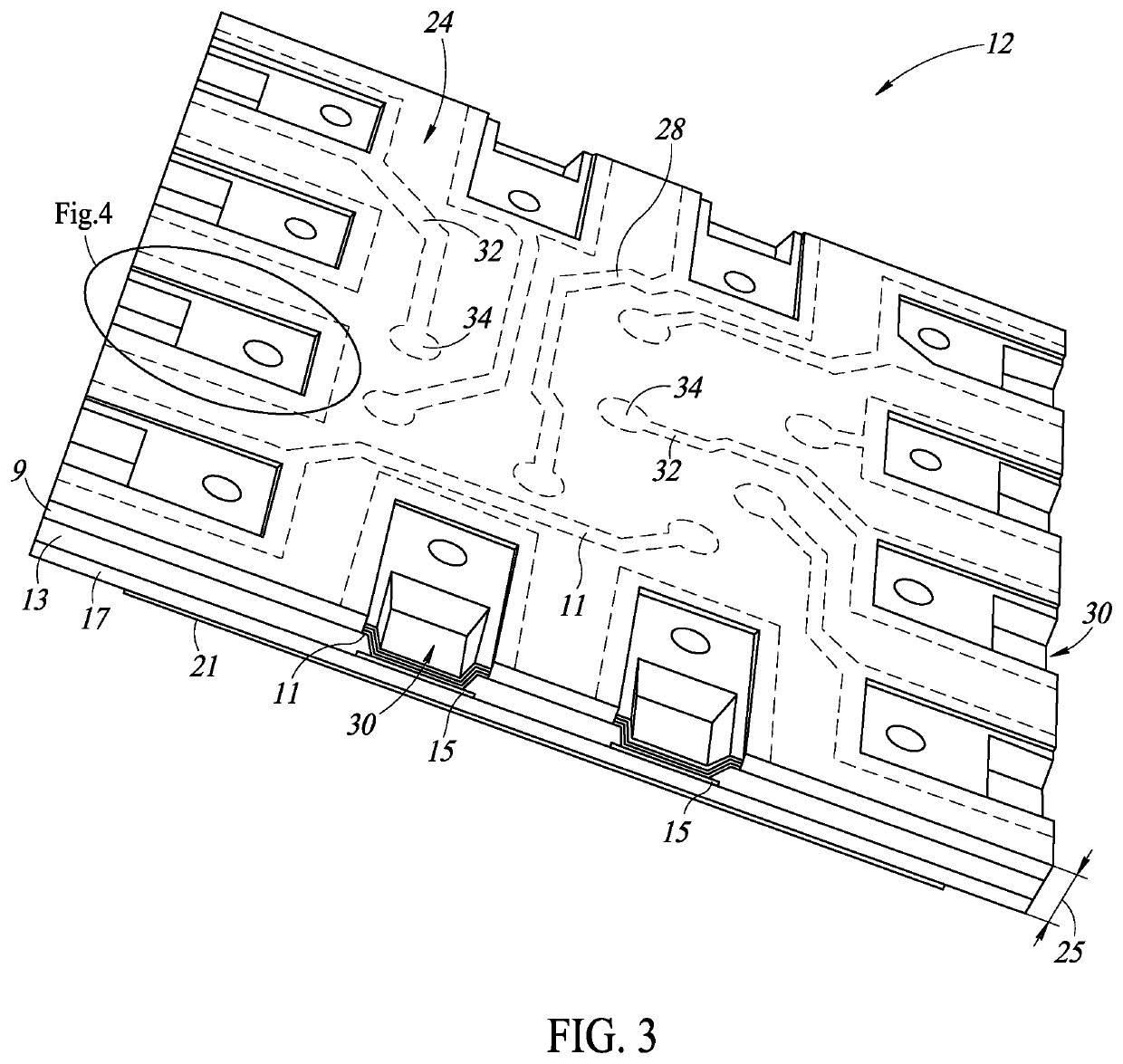

ActiveUS20210098355A1Promote formationEasy to detectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectrical connection

The present disclosure is directed to a semiconductor package including a substrate having a lower surface with a plurality of slot structures. The plurality of slot structures are multi-layer structures that encourage the formation of solder joints. The semiconductor package is desirable for high reliability applications in which each solder joint termination should be checked by visual systems to ensure a proper electrical connection has been made.

Owner:STMICROELECTRONICS MALTA +1

Strain sensor

ActiveUS10119879B2Increased Strength ReliabilityHold steadyForce measurement using piezo-electric devicesRapid change measurementCylinder headEngineering

A strain sensor is provided which includes a strain sensor, a first housing, a second housing joined to the first housing, and a pressure measuring mechanism firmly retained between the first housing and the second housing. The pressure measuring mechanism is gripped between a first face of the first housing and a second face of the second housing to measure compressive stress exerted by a cylinder head of an internal combustion engine on the first housing and the second housing. This structure improves the reliability of mechanical strength of the housings and the pressure measuring mechanism and provides flexibility in selecting the type of the pressure measuring mechanism.

Owner:DENSO CORP

Composite welding steel pipe lined with inner thin-wall stainless steel layer

InactiveCN104565586AHigh strengthIncreased Strength ReliabilityRigid pipesWeld seamUltimate tensile strength

The invention provides a composite welding steel pipe lined with an inner thin-wall stainless steel layer. The composite welding steel pipe comprises a base carbon steel layer and an inner thin-wall stainless steel layer. The composite welding steel pipe lined with the inner thin-wall stainless steel layer is formed by compounding of the carbon steel layer and the thin-wall stainless steel layer, prebending and forming, and welding of welding seams; the welding seams consist of thin-wall stainless inner layer welding seams and carbon steel layer welding seams, and the thin-wall stainless inner layer welding seams and the carbon steel layer welding seams are positioned in different positions. The composite welding steel pipe has the advantages that the structure is reasonable, the strength is high, the anti-corrosive property is good, the conveying efficiency is high, the service life is long, the economic and environment-friendly effects are realized, the manufacturing cost is low, the application field is wide, and the steel pipe is suitable for being popularized and applied in a large-scale way.

Owner:NINGBO ZHENHAI XIANGAO ELECTROMECHANICAL

A two-mass near-resonance sieve with sieve frame and sieve bed separated

ActiveCN103394462BPrevent leakage and splashAvoid Independent ExcitersSievingScreeningResonanceEngineering

The invention discloses a screen frame and screen bed separated double-plastid near resonance screen which comprises a screen bed (1) and a screen frame (2), wherein main vibration springs (6) are arranged between the screen bed (1) and the screen frame (2); the screen bed (1) is mounted on the ground by isolation springs (8); exciting vibration motors (9) are mounted on the screen frame (2); the screen frame (2) consists of side plates (3) and transverse beams (4); the main vibration springs (6) are arranged between connecting seats (5) of the side plates (3) and the screen bed (1); and the exciting vibration motors (9) are mounted on the transverse beams (4). The double-plastid near resonance screen has the benefits that the screen frame serves as an exciting vibration body, so that the double-plastid near resonance screen has no extra metal consumption, and a purpose that totally consumed steel is reduced greatly under the same design function parameter; the screen frame serves as an exciter, so that the vibration strength is less, and the structural strength is high in reliability; the double-plastid near resonance screen is designed based on a principle of double-plastid near resonance, and is a large-scale rectilinear vibration screen; the power consumption is less; and an impact of equipment on a foundation is smaller.

Owner:CHENGDU WEST PETROLEUM EQUIP

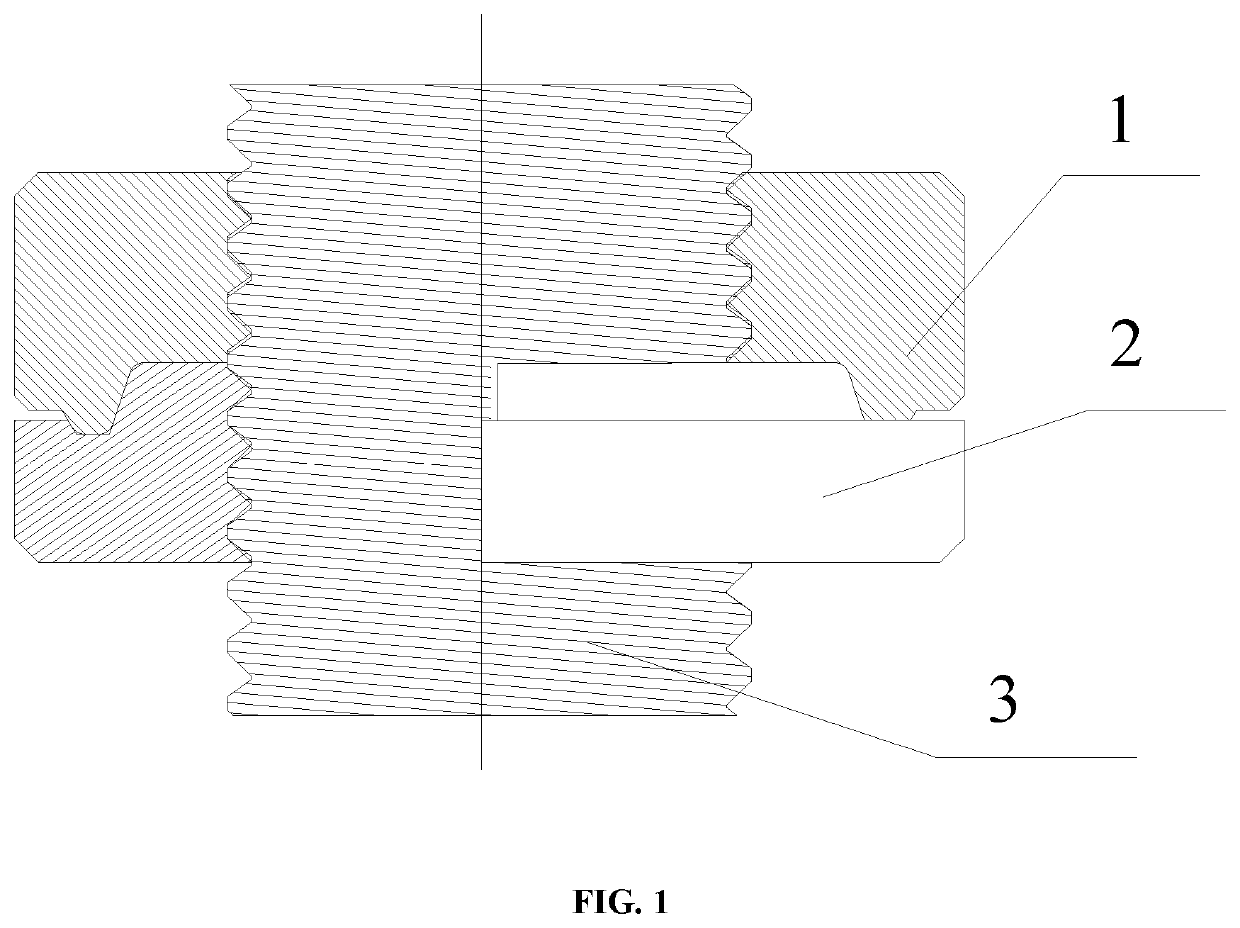

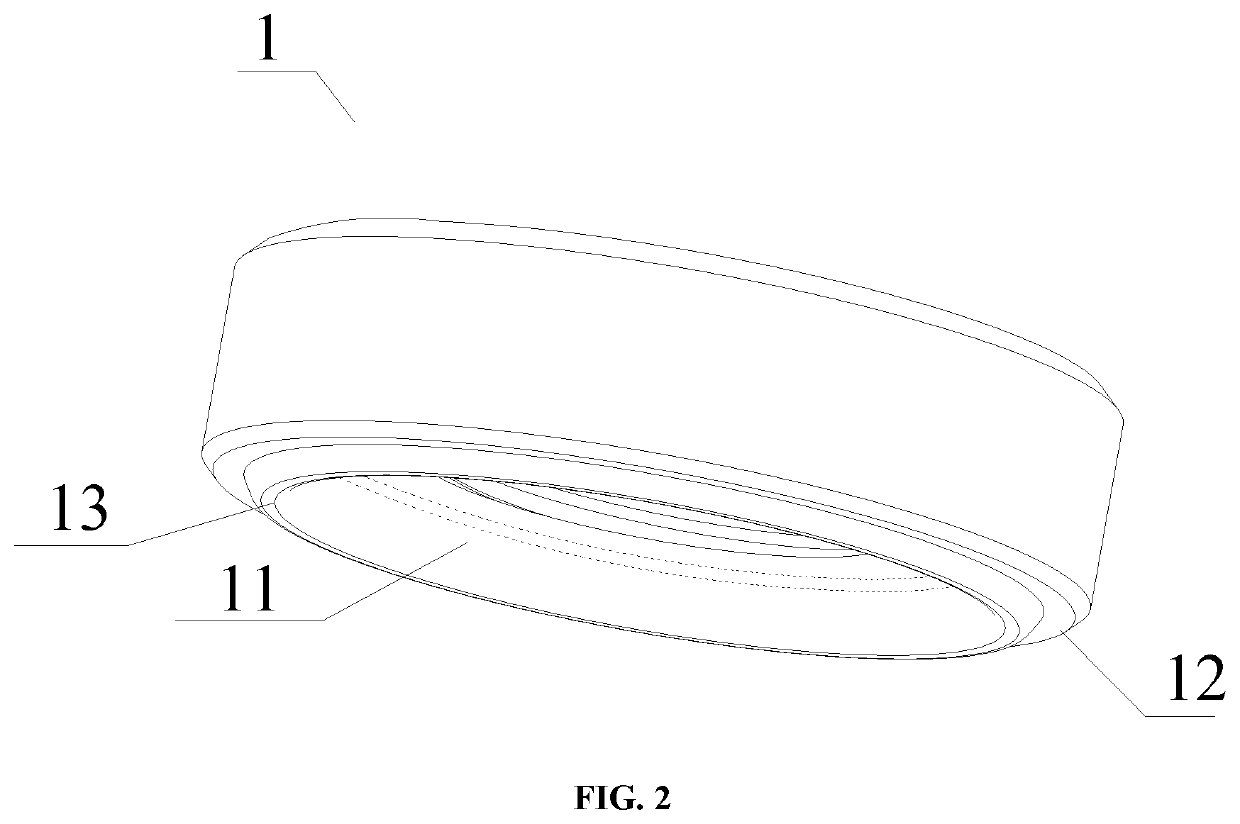

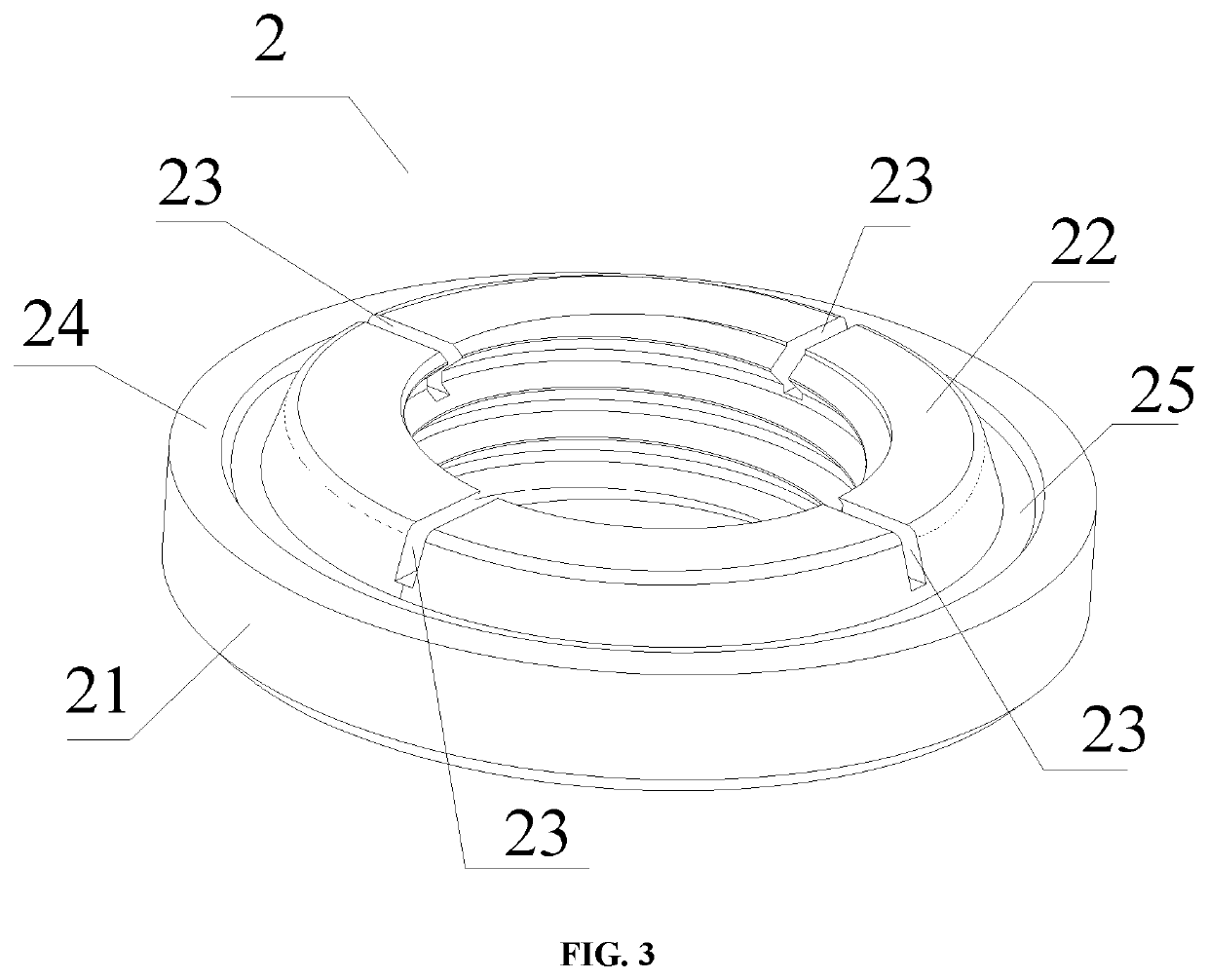

Lock nut

PendingUS20220136555A1High locking reliabilityIncreased Strength ReliabilityNutsBoltsStructural engineeringMechanical engineering

A lock nut includes: a first nut having a tapered cavity; and a second nut including a base portion and a tapered lug boss arranged the base portion. The tapered lug boss can be coupled inside the tapered cavity. The first and second nuts are used in pair by self-locking. A straight slot is formed in the lug boss. Under the locking action of the first nut, the straight slot is deformed to further lock a bolt, or is discontinuously engaged with teeth of the bolt to increase an effective stress surface and locking performance of the second nut for locking the bolt. A convex reinforcing rib extends on a first surface of the first nut. An annular groove is formed in a second surface of the second nut. The convex reinforcing rib is coupled with the annular groove to enhance the strength and reliability of locking.

Owner:YE CHUNLIN

A horizontal single-axis directional rotary-impact combined excavation type engineering slotting machine

The invention relates to a horizontal single-axis directional rotary-impact combined excavation type engineering grooving machine, including a traveling device with a hoisting device and a power system and a monitoring device; an impact milling device is suspended at the traction end of the hoisting device, and the impact milling device includes a vertical Directional guide frame, rectifying device, milling shaft, impact device; the axis of the milling shaft is located in the plane of the guide frame, and is arranged horizontally or obliquely, driven by the horizontal hydraulic motor or the vertical hydraulic motor through the reversing device. , the milling shaft has a directional rotation milling state of segmental balance and reverse rotation, and the impact device is placed in the guide frame; the connecting beam above the milling shaft is hung under the bottom beam of the guide frame through a suspension sliding device, and the drill rod of the impact device is attached to the bottom beam of the guide frame. The impact on the connecting beam and the milling axis and the positioning drill bit is driven by hydraulic pressure. The invention can conditionally select the direction and angle of the cutting edge, and can quickly change the excavation mode according to the stratum lithology, so as to obtain higher excavation efficiency and reliability.

Owner:项栋才 +1

Metallic bonding structure for copper and solder

InactiveUS20100244266A1Inhibition formationPromote quality lifePrinted circuit detailsSemiconductor/solid-state device detailsMetallic bondingElectronic component

The present invention discloses a metallic bonding structure for copper and solder, which applies to connect at least one electronic element. The metallic bonding structure comprises at least one copper-based member and at least one zinc bonding member. The copper-based members are arranged on the electronic element through at least one solder member. The zinc bonding members are arranged between the copper-based members and the solder members. The solder members are tin-based solder bumps.

Owner:NATIONAL TSING HUA UNIVERSITY

Semiconductor package with wettable slot structures

ActiveUS11309237B2Promote formationEasy to detectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectrical connection

The present disclosure is directed to a semiconductor package including a substrate having a lower surface with a plurality of slot structures. The plurality of slot structures are multi-layer structures that encourage the formation of solder joints. The semiconductor package is desirable for high reliability applications in which each solder joint termination should be checked by visual systems to ensure a proper electrical connection has been made.

Owner:STMICROELECTRONICS MALTA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com