Drum type washing drier

A washing and drying machine, drum-type technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as difficulty in absorbing vibrations, unfavorable miniaturization of drum-type washing and drying machines, and achieve the effect of improving strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

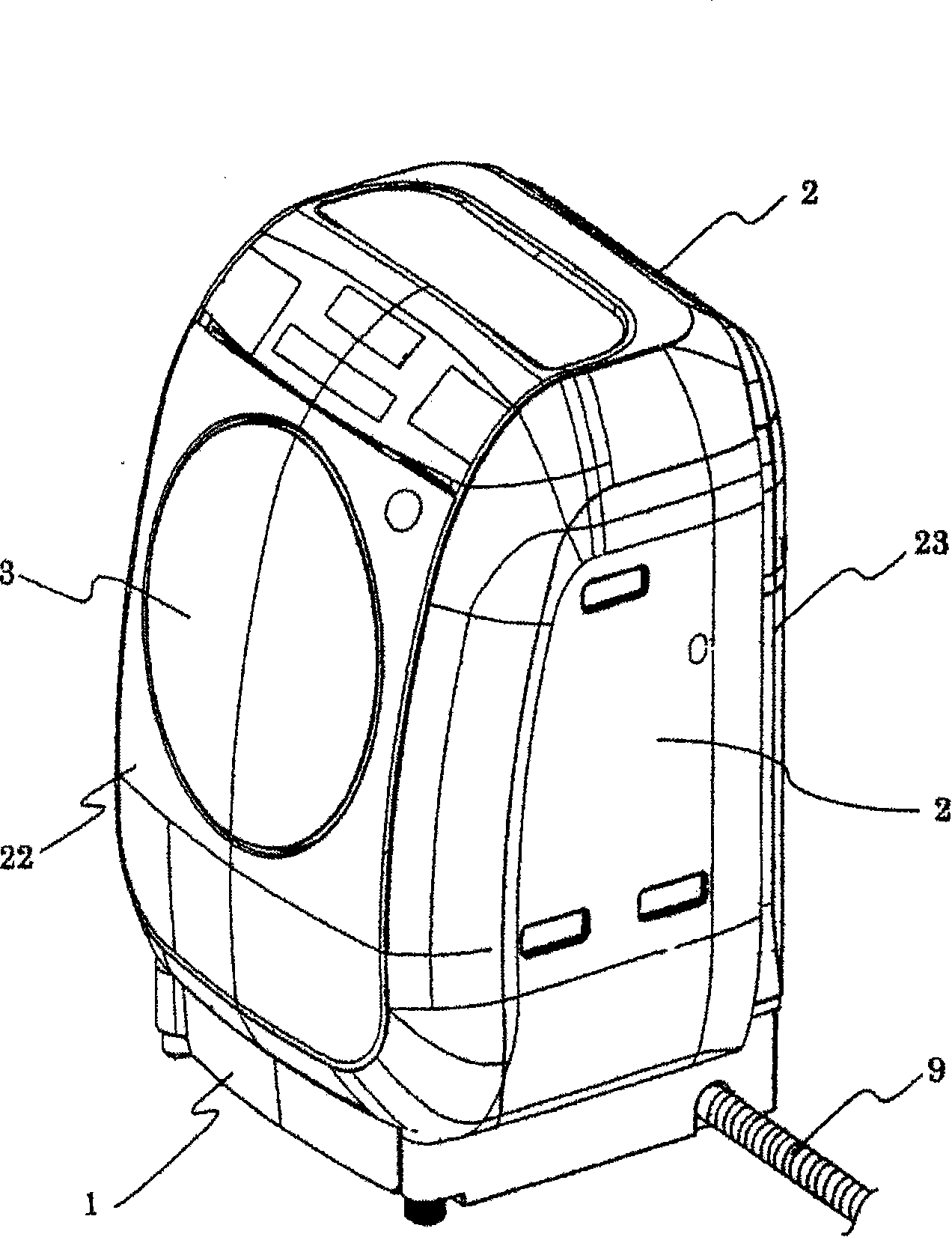

[0013] figure 1 It is a perspective view which shows the washing-drying machine of the Example of this invention. On the upper part of the base 1 is placed an outer frame 2 composed of a combination of a steel plate and a resin molding. The front of the outer frame 2 is provided with a door 3 and a front cover 22 for taking out and putting in laundry 30, and a back cover 23 is provided at the back.

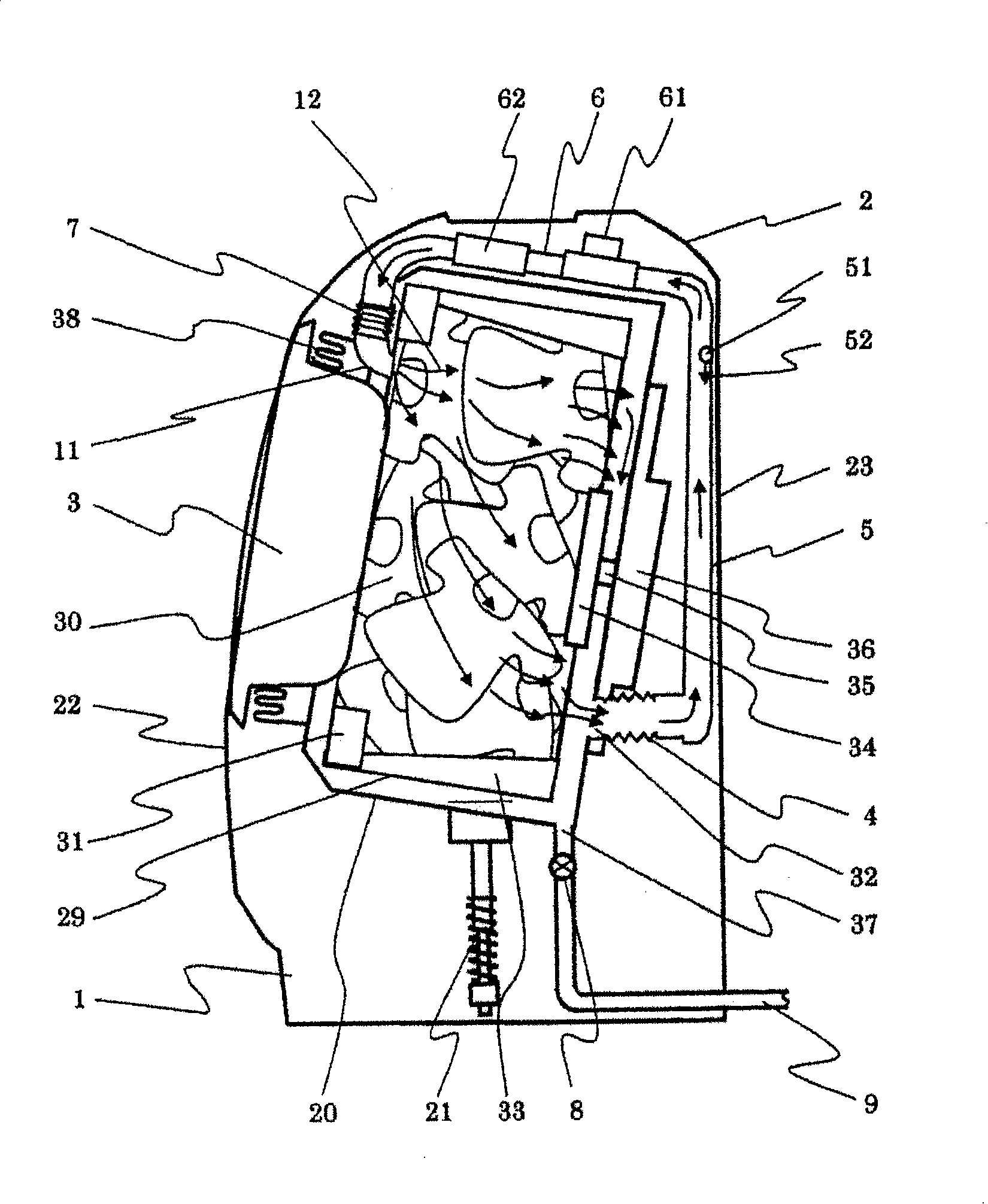

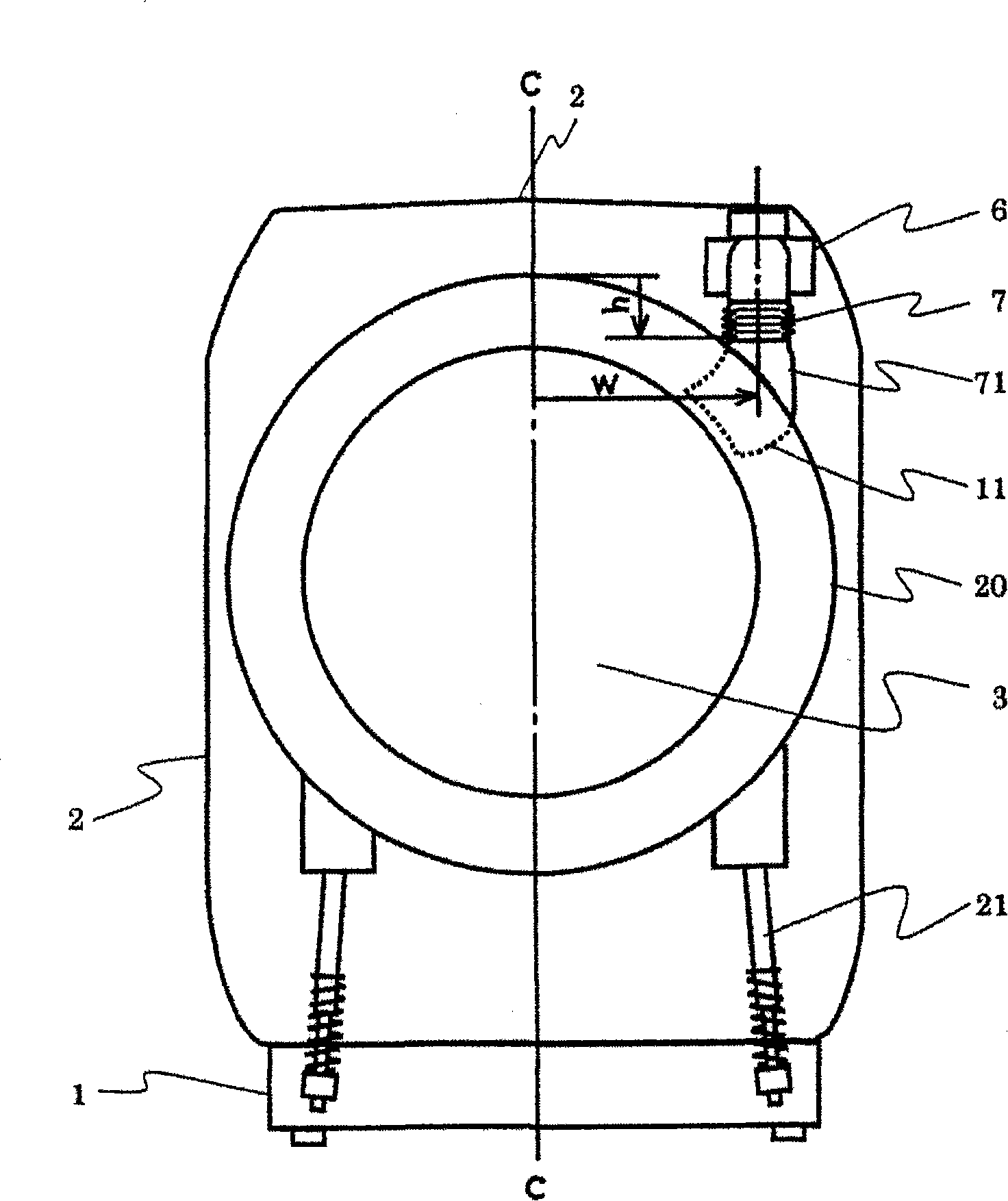

[0014] figure 2 It is a sectional view of the washing-drying machine which shows the Example of this invention. image 3 It is the front view of the washing-drying machine which showed the Example of this invention and removed the front cover. Figure 4 It is the rear view of the washing-drying machine which removed the rear cover which showed the Example of this invention. The inner side of the outer frame 2 has an outer groove 20 . The outer tank 20 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com