A horizontal single-axis directional rotary-impact combined excavation type engineering slotting machine

A tunneling and grooving machine technology, which is applied to earth moving machines/shovels, construction, etc., can solve the problems of difficulty in improving tunneling efficiency, a large proportion of engineering costs, and damage to excavation components, so as to improve tunneling efficiency and optimize tunneling. Efficiency, the effect of reducing tooth wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

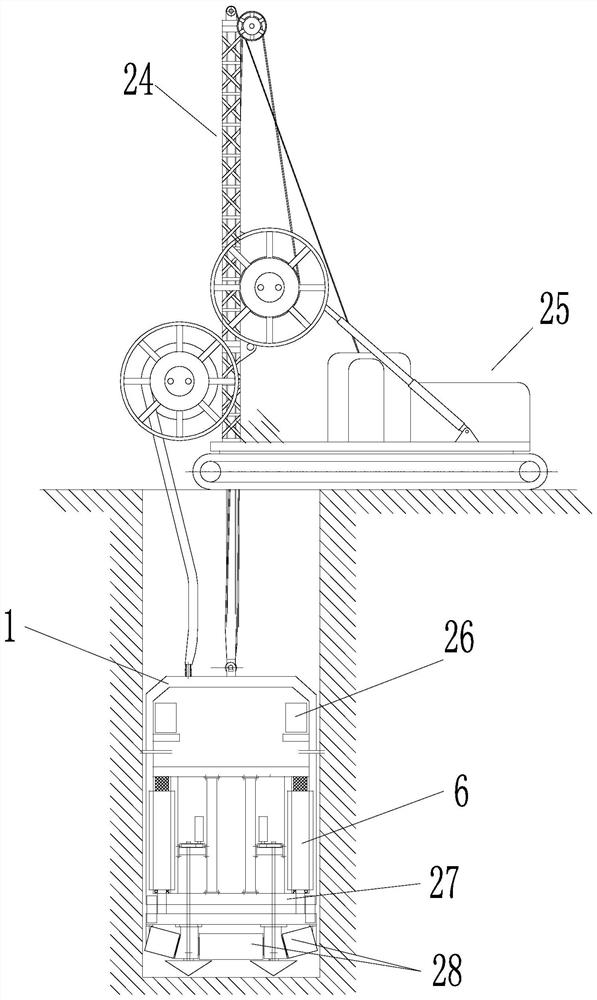

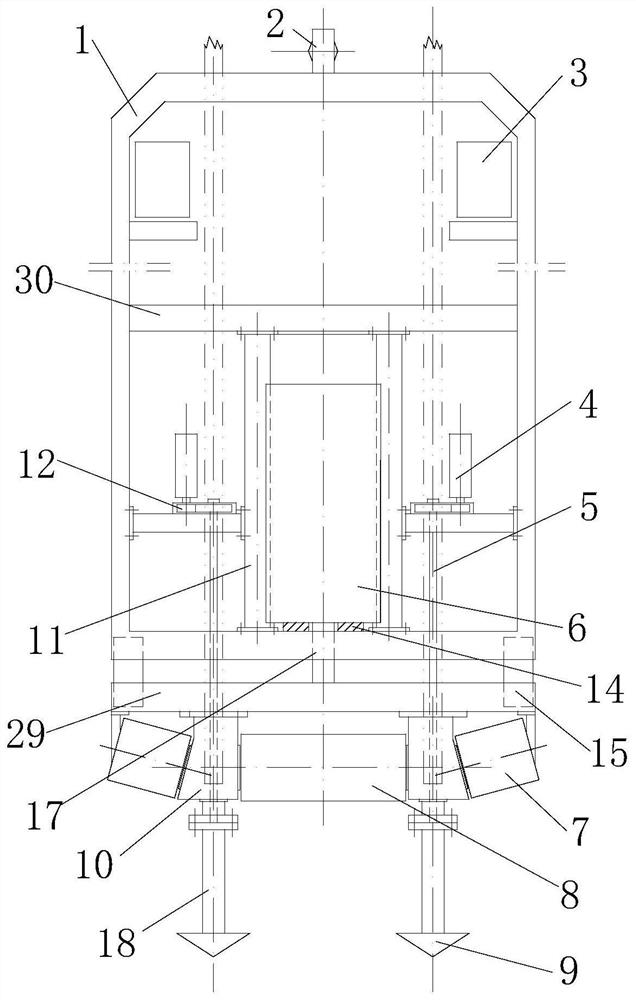

[0047] like Figure 1 to Figure 5 As shown in the figure, the horizontal single-axis directional rotary-impact combined tunnel-type engineering grooving machine in this embodiment includes a traveling device 25 with a hoisting device 24 and a power system, and a monitoring device (not shown in the figure); the hoisting device 24 A symmetrically arranged impact milling device is suspended from the traction end. The impact milling device includes a vertical guide frame 1, a deviation correction device 26, a milling shaft 28 with a milling tool, and an impact device. The impact device is a vertical high-frequency hydraulic impact hammer. 6. The axis of the milling shaft 28 is located in the plane where the guide frame 1 is located, and is arranged horizontally; the milling shaft 28 is driven by the vertical hydraulic motor 4 through the reversing device 10, and the milling shaft 28 has a segmented balanced counter-rotation directional rotation In the milling state, the connecting...

Embodiment 2

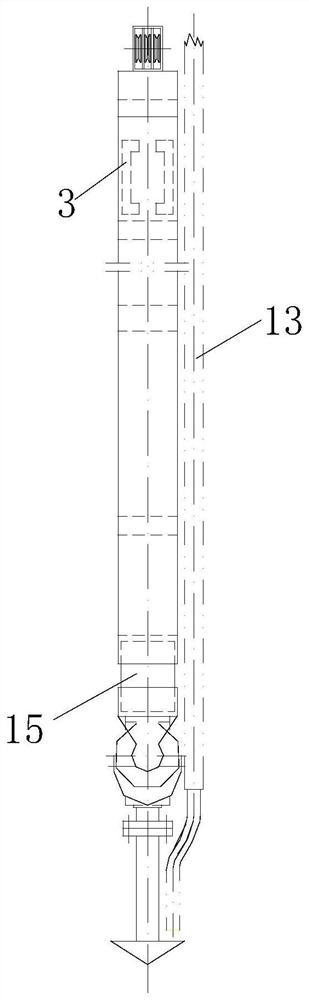

[0056] The difference between this embodiment and Embodiment 1 is that, such as Figure 8 and Figure 9 As shown, the impact device is two smaller impact hammers 6 , and the impact hammers 6 are arranged outside the hydraulic motor 4 and its gearbox 12 . The top end of the impact hammer 6 and the middle beam 30 of the guide frame 1 are fixedly connected through the buffer device 16, and a vertical beam is provided between the bottom beam 27 of the guide frame 1 and the middle beam 30, and the vertical beams on both sides of the impact hammer 6 There is a slideway 11 on it, so that the impact hammer 6 slides up and down along the slideway 11 .

[0057] The milling tool is a cutter tooth base 23 protruding outward, the cross section of the cutter tooth base 23 is a convex arc surface, and the top of the convex arc surface is inlaid with cutter teeth (see Figure 12 and Figure 13 ).

Embodiment 3

[0059] The milling shaft 28 includes a plurality of three-axis symmetrical balance structures combined in parallel, and the milling range of the upper end of the inclined milling shaft covers the bottom surface of its supporting column.

[0060] Compared with the previous slotting machine, the present invention has the following advantages:

[0061] 1. The suspension guide frame 1 is adopted, which cancels the travel drill pipe from the ground to the bottom of the groove, and omits the process of connecting the drill pipe, which makes the excavation device move easily, the whole machine is flexible, and avoids the easy breakage of the rigid double drill pipe. , buried drilling and other accidents.

[0062] 2. Using single-axis milling, compared with double-wheel milling, the thickness of the entire guide frame 1 and the milling device can be further reduced, so that narrower grooves can be cut (narrow grooves with a thickness of only less than 30cm can be cut). In many practi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com