Piezoelectric component having multilayer composite structure and preparation method thereof

A technology of piezoelectric components and multi-layer composites, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of transducer resistance Poor impact performance, difficult to match, narrow working range and other problems, to achieve the effect of controllable performance, simple production, high strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

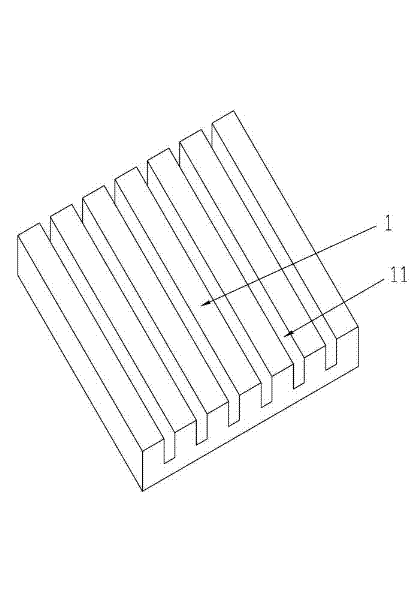

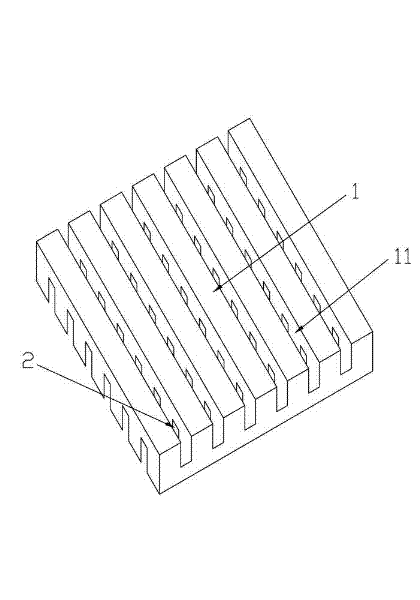

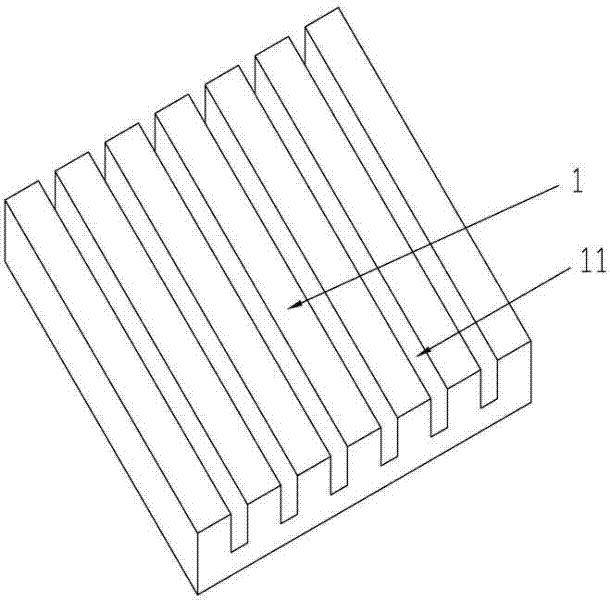

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings: As shown in the accompanying drawings, the present invention provides a multi-layer composite structure piezoelectric component, the component structure includes three layers, and the two ends are piezoelectric components arranged in the shape of strips. The distance between the electric ceramic strips can be the same or different, which can be set according to the needs; the dimensions of the piezoelectric material strips 11 on the two end surface layers 1 can be the same or different, and the piezoelectric material on the two end surface layers 1 The arrangement direction of the strips 11 forms a certain angle, and the angle is greater than 0° and less than 180°; the middle layer 2 is a piezoelectric material particle column, and the cross-section of the piezoelectric material particle column is a parallelogram, and the angles of the two diagonal angles are the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com