Turbine rotor, manufacturing method thereof and steam turbine using turbine rotor

A turbine rotor and rotor technology, applied to turbines, engine components, machines/engines, etc., can solve problems such as differences in thermal physical properties, reduce the frequency of defects, and improve the strength and reliability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment relates to an example in which a Ni-based superalloy and a 12% Cr steel are used from the rotor base materials shown in Table 1 and welded.

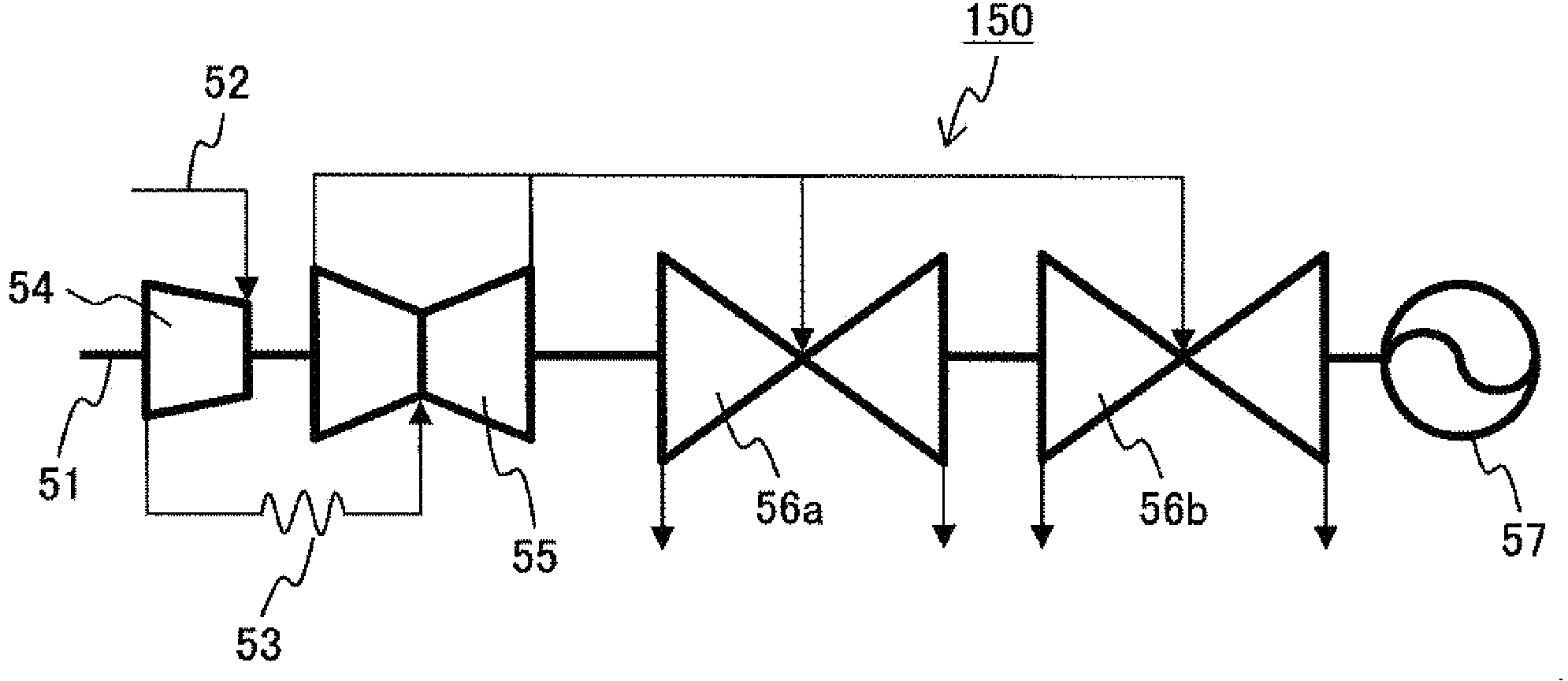

[0079] Figure 4 It is a figure which shows the outline|summary of the tungsten inert gas shielded welding apparatus used for the welding of a turbine rotor as an example.

[0080] In this figure, the welding device 40 has a driving device 43 , a welding mechanism 44 , a welding torch 48 , and a control device 47 , and is connected to a gas high-pressure storage tank 49 via a gas hose 52 . The inert gas of the gas high-pressure tank 49 is delivered to the welding torch 48 via a gas hose 51 . As the inert gas, nitrogen, argon, or the like is used. A signal cable 45 for transmitting and receiving signals is provided between the driving device 43 and the control device 47 . A signal cable 46 for transmitting and receiving signals is provided between the welding mechanism 44 and the control device 47 .

[0081] The...

Embodiment 2

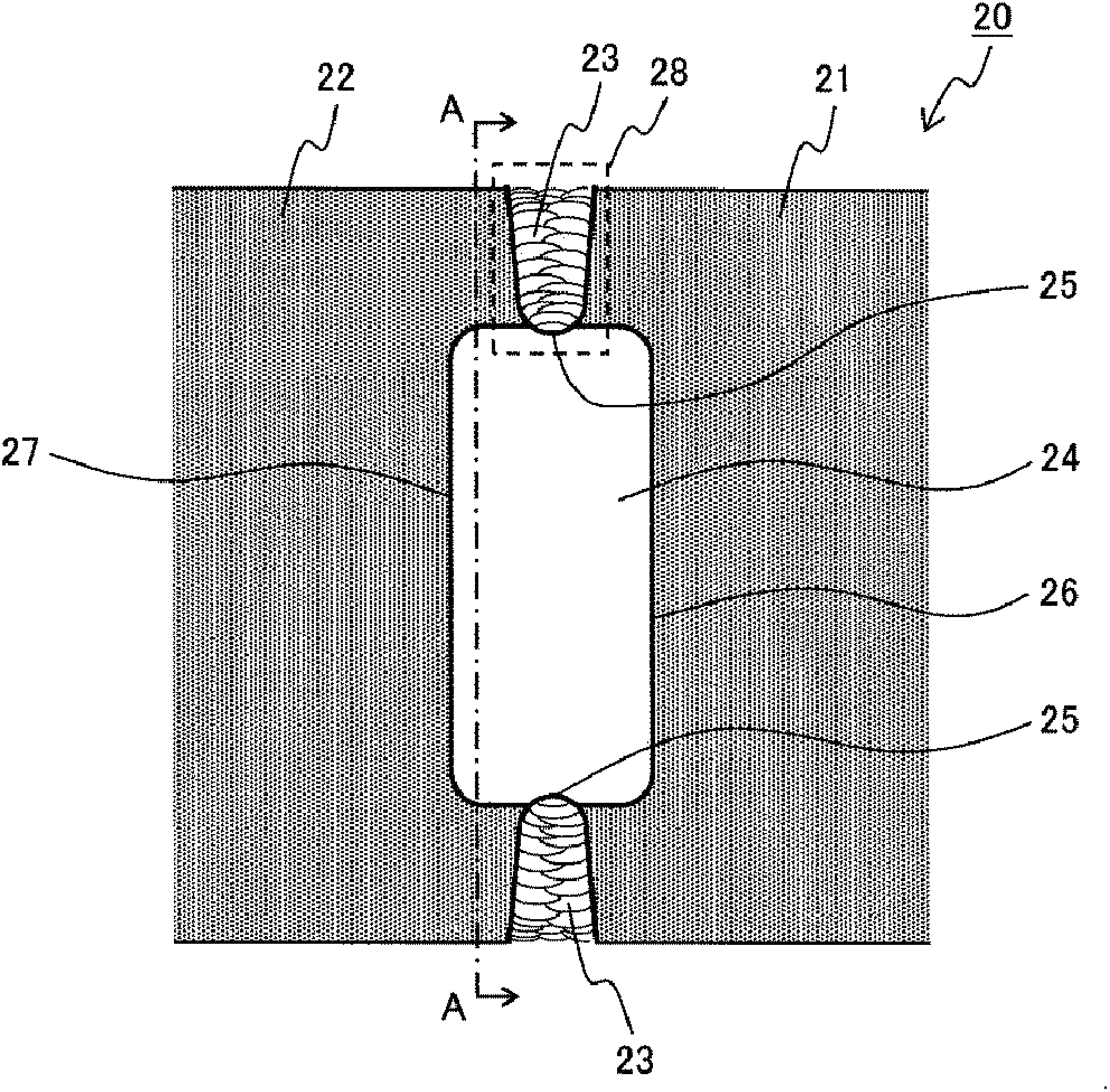

[0107] Such as Figure 6 As shown, in Example 1, the overlay 62 is directly applied to the surface of the rotor base material 61 . In contrast, this embodiment is characterized in that in order to eliminate the differences in chemical composition and heat treatment conditions between the high-temperature side rotor base material and the low-temperature side rotor base material, pre-surfacing welding is performed on the groove portion of the high-temperature side rotor base material. . Here, the same parts as those in Embodiment 1 will be omitted, and only the points of difference from Embodiment 1 will be described.

[0108] Figure 7 It is a flow chart showing the welding process of the turbine rotor in this embodiment.

[0109] Compared with the first embodiment, the additional flow in this embodiment is S201-S203.

[0110] First, S101 and S102 are executed in the same manner as in the first embodiment.

[0111] In the pre-surfacing step S201, pre-surfacing welding is p...

Embodiment 3

[0121] Figure 9 It is a continuous sectional view showing the welding process of Example 3.

[0122] Differences between this example and Example 2 will be described using this figure.

[0123] In Example 2, a build-up part 72 is provided on a part of the entire-surface pre-build-up part 71 . On the other hand, in the present embodiment, the overlay welding portion 91 (B) is provided on the low temperature side rotor base material 64 to form the bevel portion 95 (C). Then, the high temperature side rotor base material 61 and the low temperature side rotor base material 64 are butted to form a groove portion 96 (D), a penetration weld bead 97 (E) is formed, and the groove portion 96 is butt welded using a weld metal 98 (F) .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com