Production sample making method of flexible display panel

A flexible display, panel technology, used in metal processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

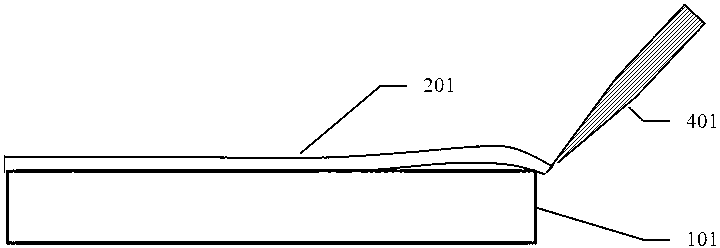

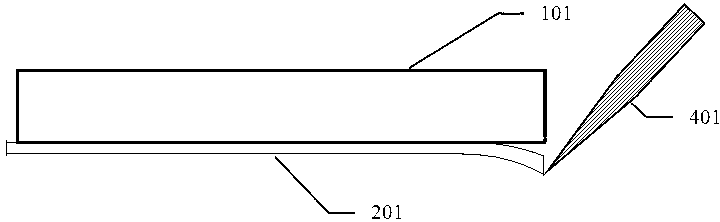

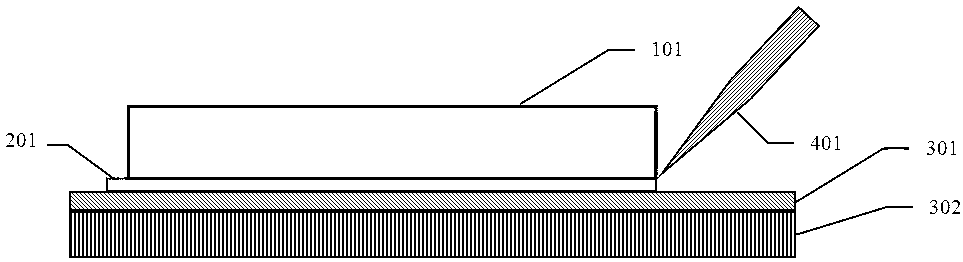

[0023] The embodiment of the present invention discloses a production sample preparation method of a flexible display panel. Firstly, an adhesive film is used to bond the flexible substrate and the carrier substrate, and then the redundant adhesive film and the flexible substrate larger than the size of the carrier substrate are placed on a cushioned The cutting is carried out under the environment, and the edge of the sample preparation product after cutting is precisely cut by the fixed angle device. Get the final product for production sample preparation. The production process can be carried out.

[0024] In an embodiment of the present invention, a sample preparation method for a flexible display panel, the step of cutting an adhesive film material includes:

[0025] First cut the adhesive film material into a size slightly larger than the glass substrate, uncover one side of the protective surface (for a multi-layer structure, the side with weaker adhesion is uncovered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com