Patents

Literature

83results about How to "Improve high temperature reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

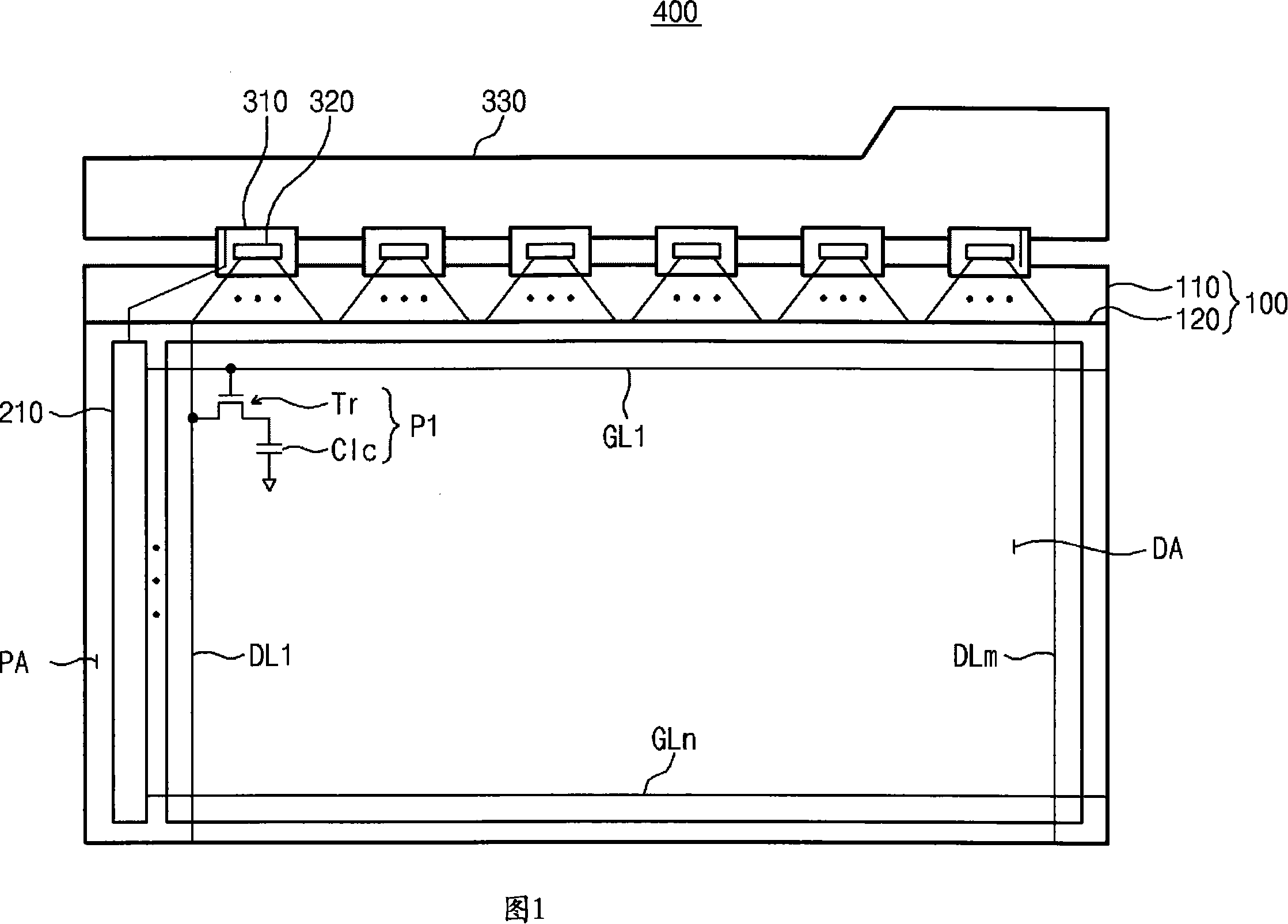

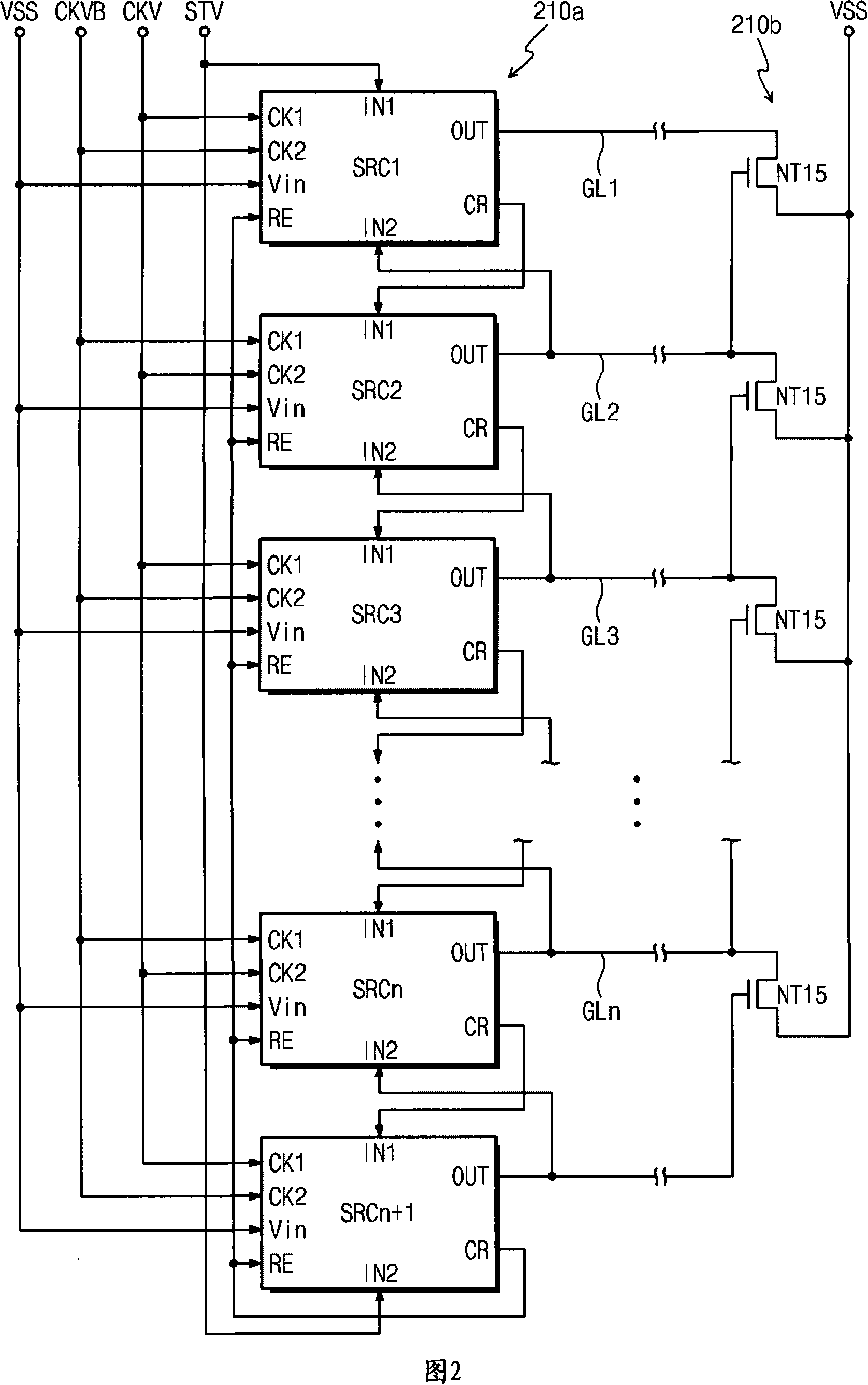

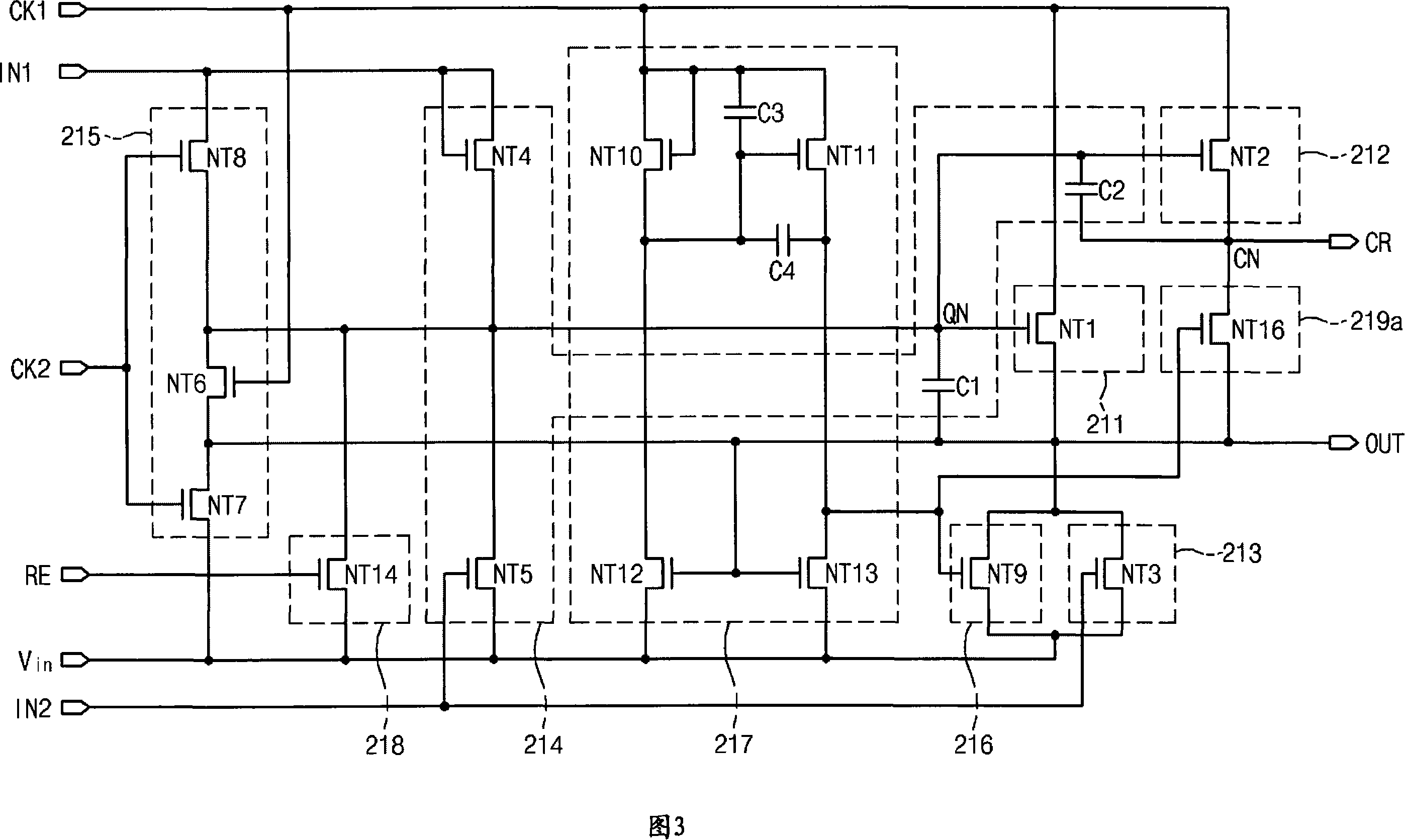

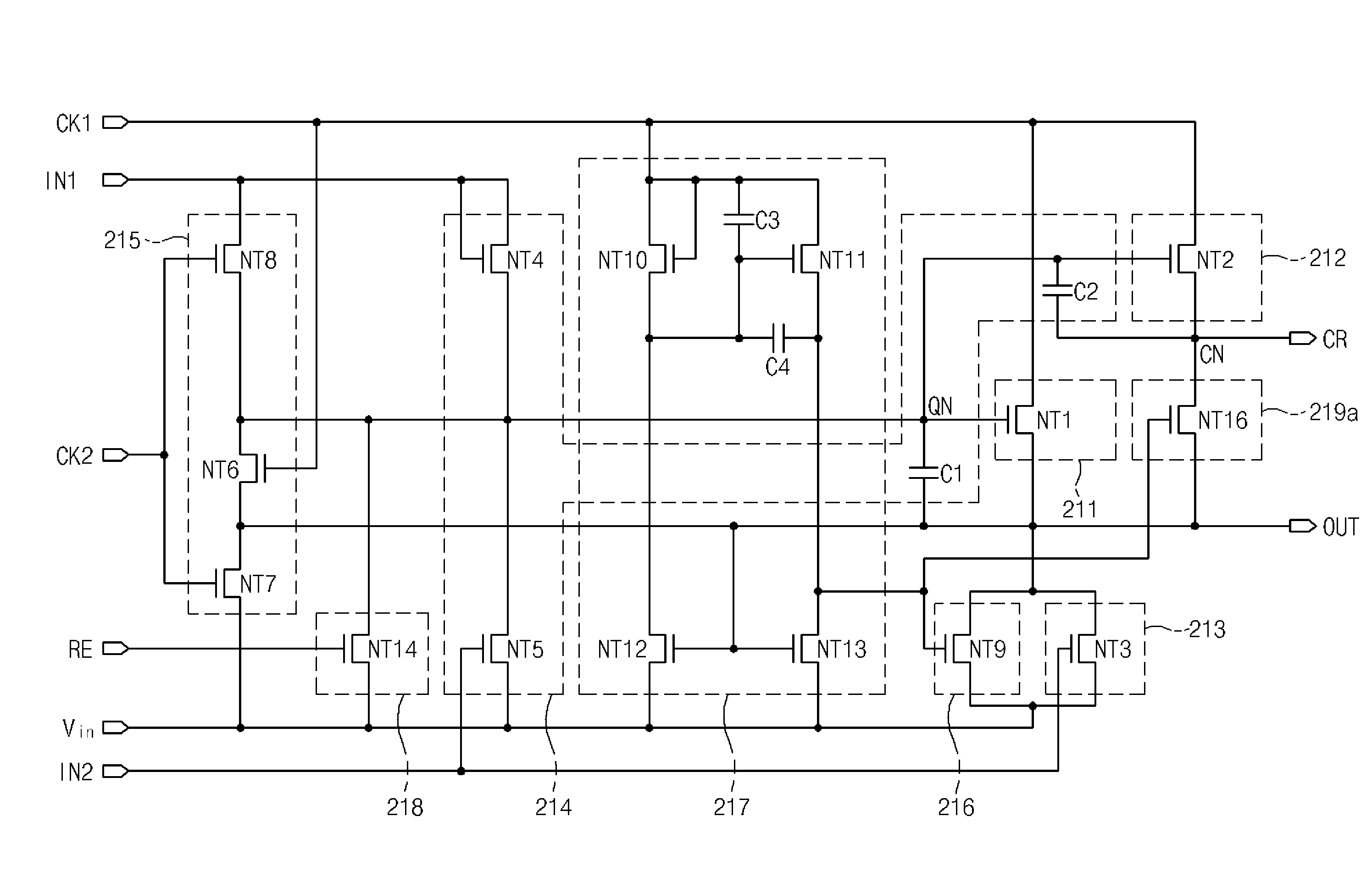

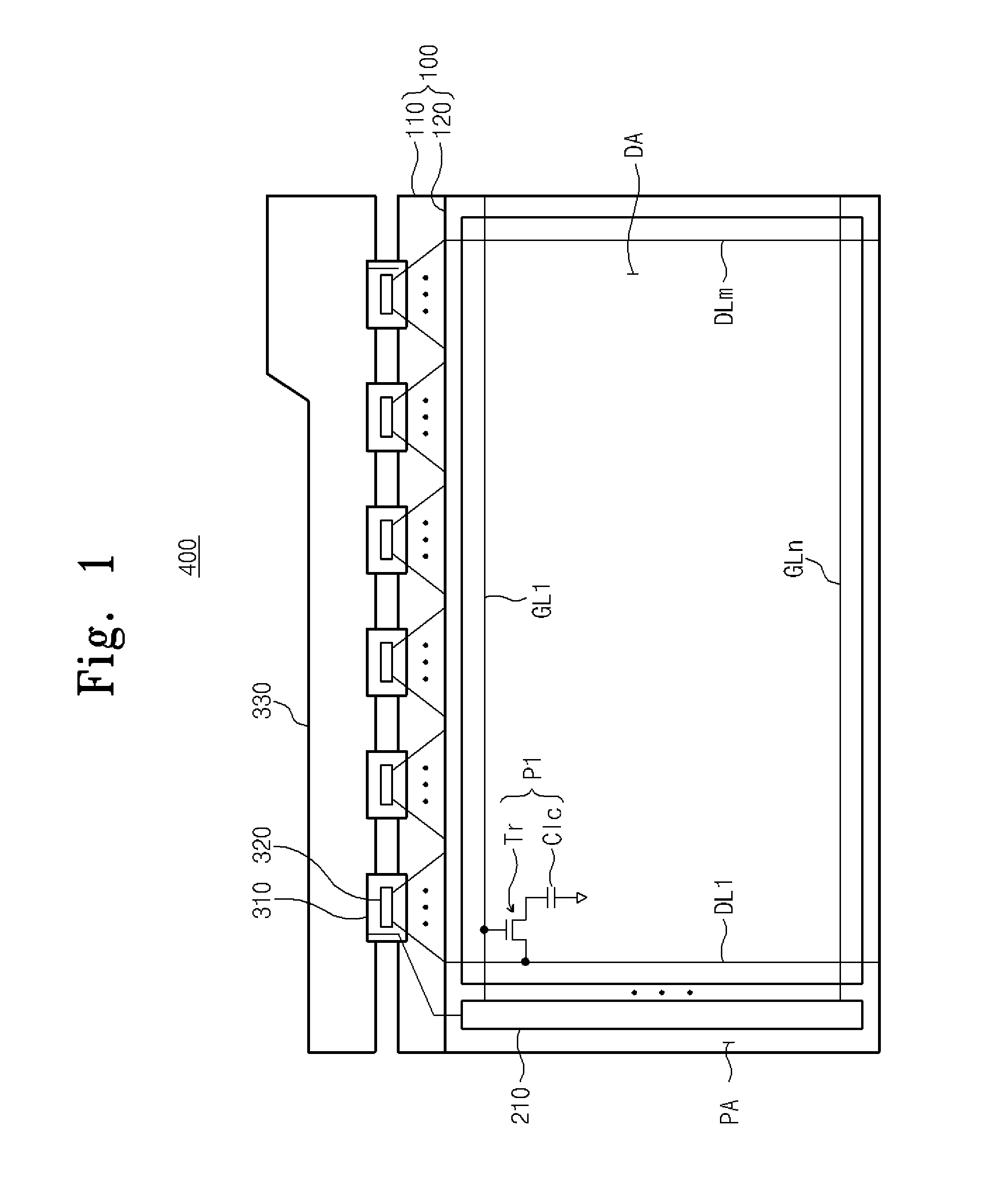

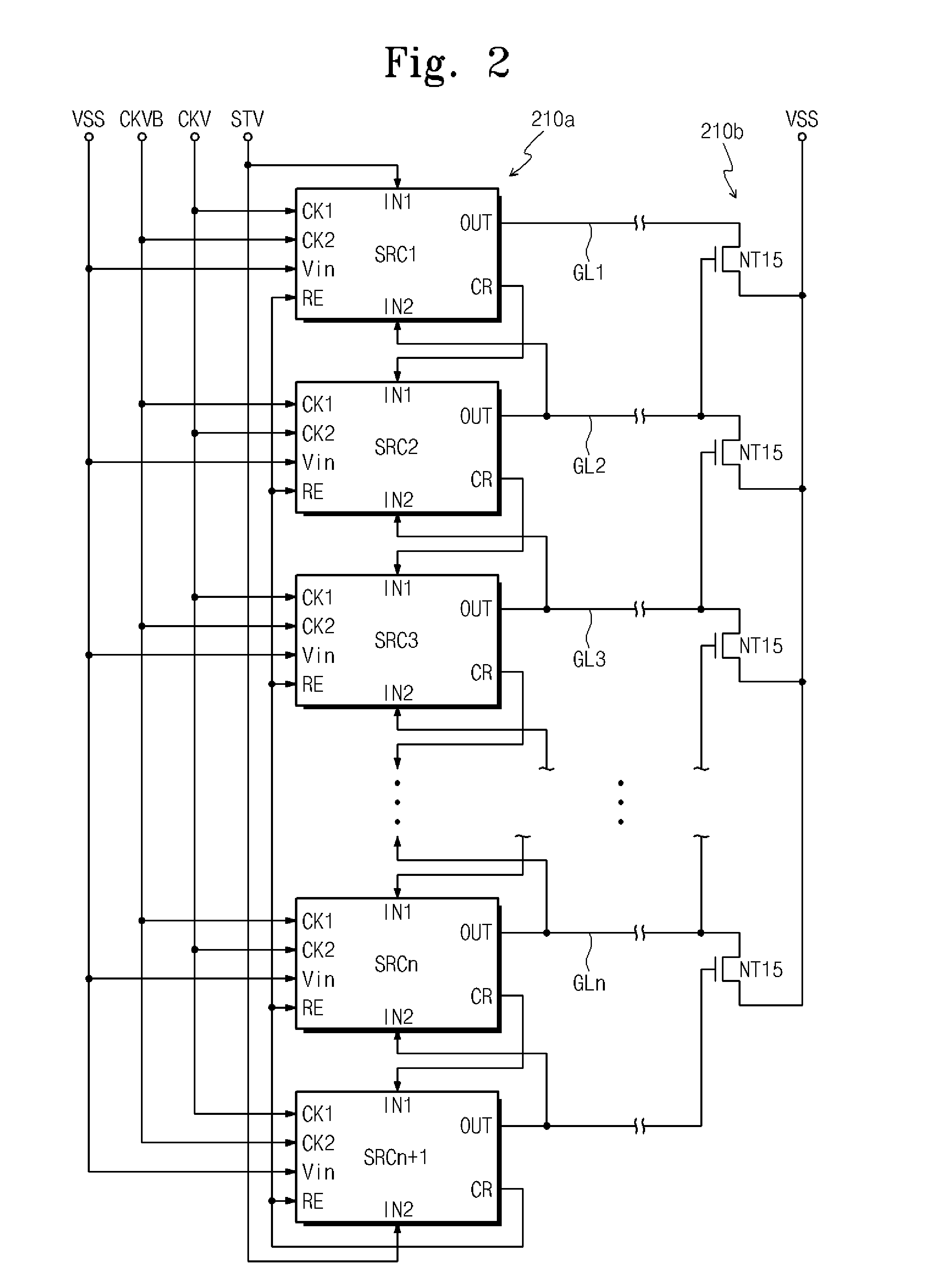

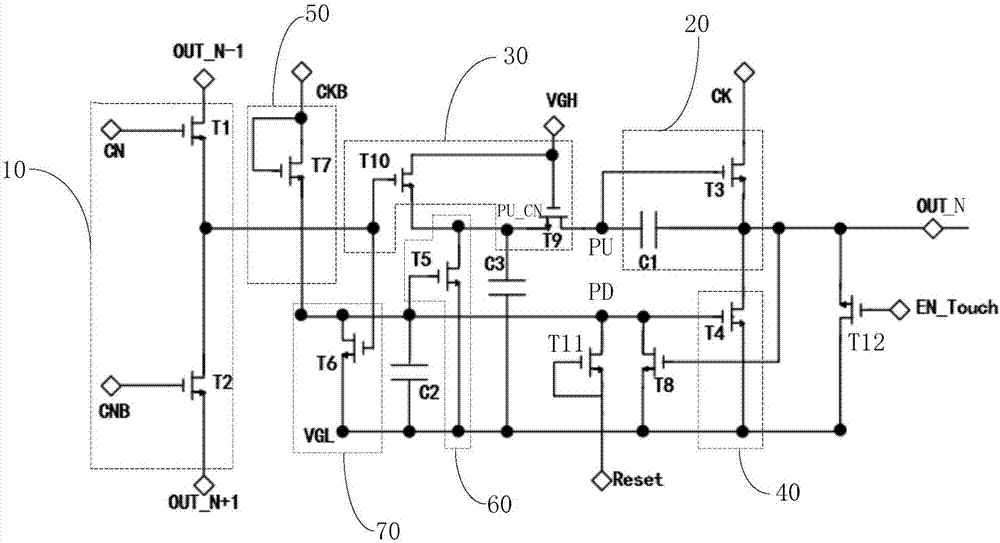

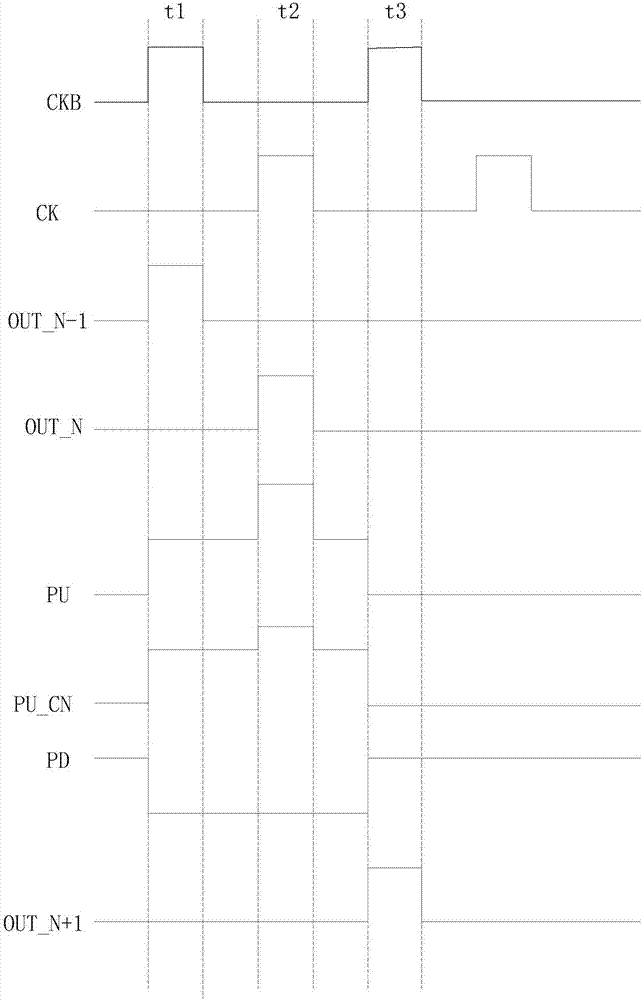

Gate driving circuit and display apparatus having the same

InactiveCN101089939AImprove high temperature reliabilityAvoid misuseStatic indicating devicesLogic circuitsEngineeringDriving circuit

A gate driving circuit and a display apparatus having the gate driving circuit include a pull-up part and a carry part pull up a present gate signal and a present carry signal, respectively, to a first clock during a first period within one frame. A pull-down part receives a next gate signal to discharge the present gate signal to a source power voltage. A pull-up driving part is connected to control terminals of the carry part and pull-up part (Q-node) to turn the carry part and pull-up part on and off. A floating preventing part prevents an output terminal of the carry part from being floated in response to the first clock during a second period within the one frame.

Owner:SAMSUNG DISPLAY CO LTD

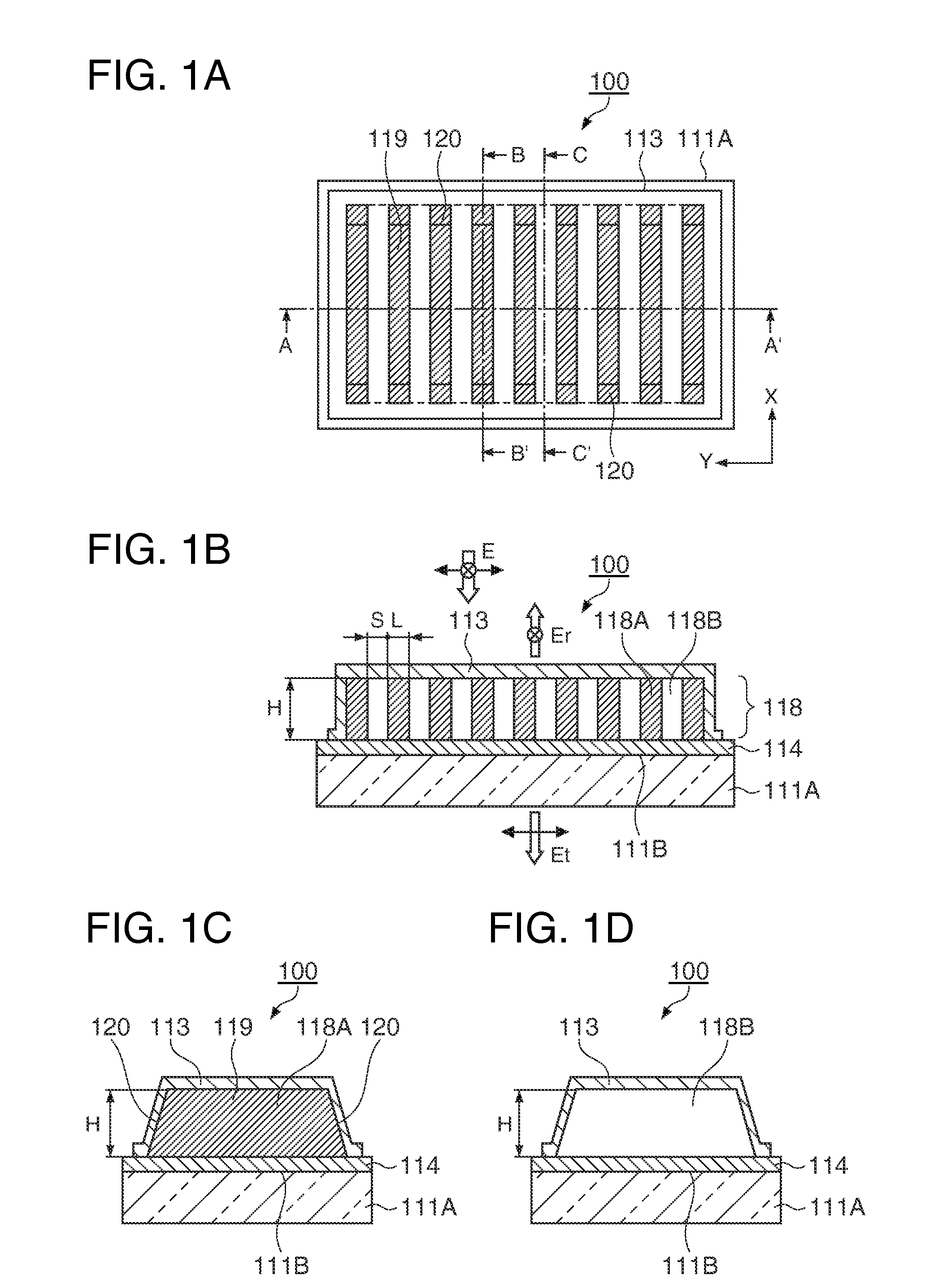

Polarization element, projector, liquid crystal device, electronic apparatus, and method of manufacturing polarization element

ActiveUS20120105745A1Improve high temperature reliabilityProjectorsPretreated surfacesDielectric layerElectron

A polarization element according to the invention includes a substrate, a metal layer and an absorber layer formed on the substrate to form a stripe in a plan view and stacked in a thickness direction of the substrate, a first dielectric layer formed on a surface of the metal layer and a second dielectric layer formed on a surface of the absorber layer. The first dielectric layer is made of an oxide of a metal constituting the metal layer, and the second dielectric layer is made of an oxide of a material constituting the absorber layer.

Owner:SEIKO EPSON CORP

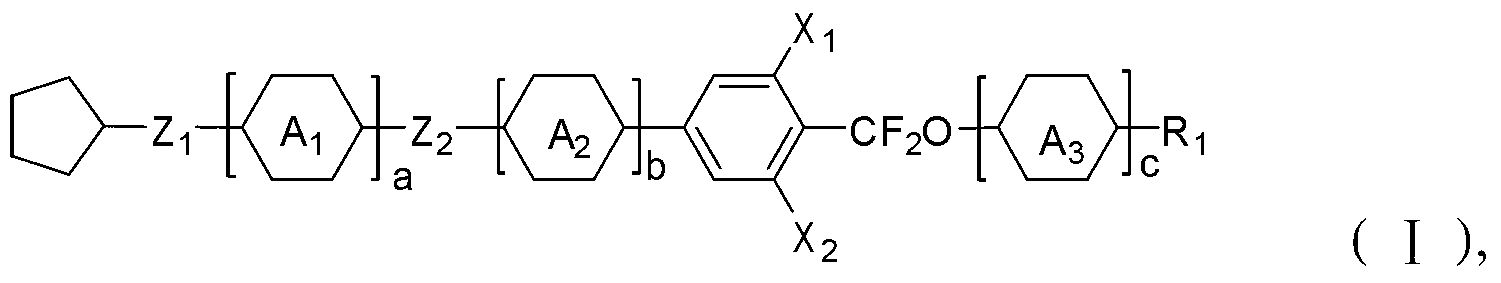

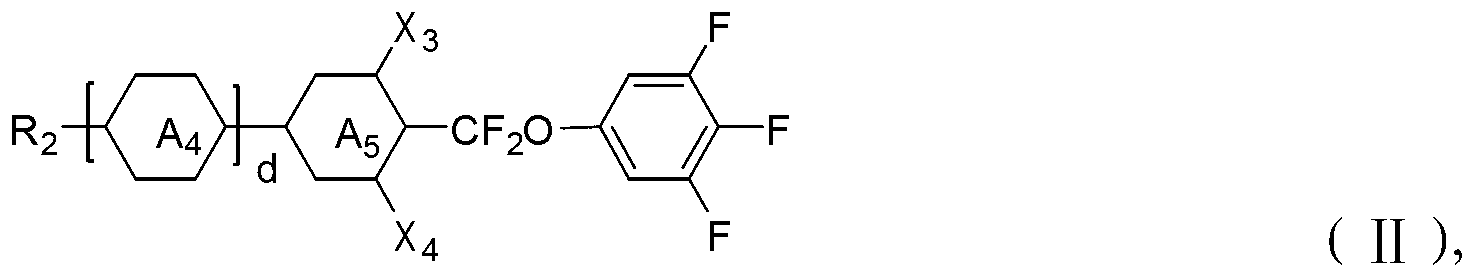

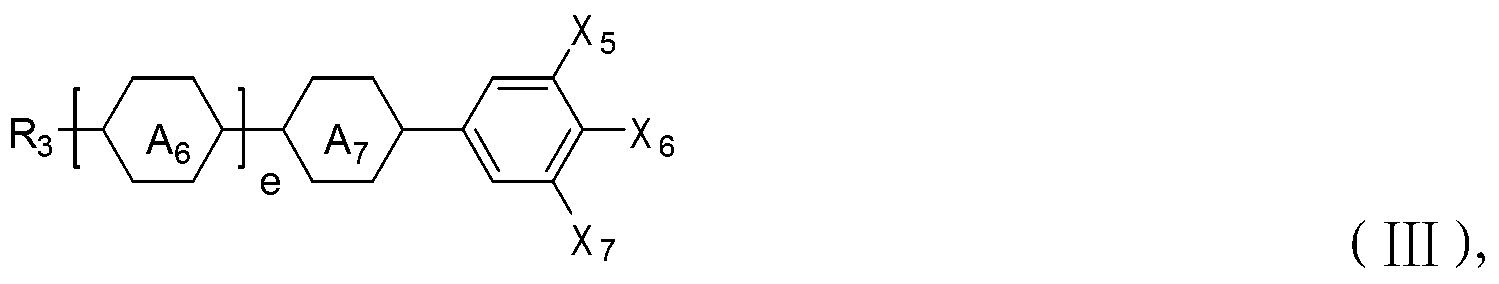

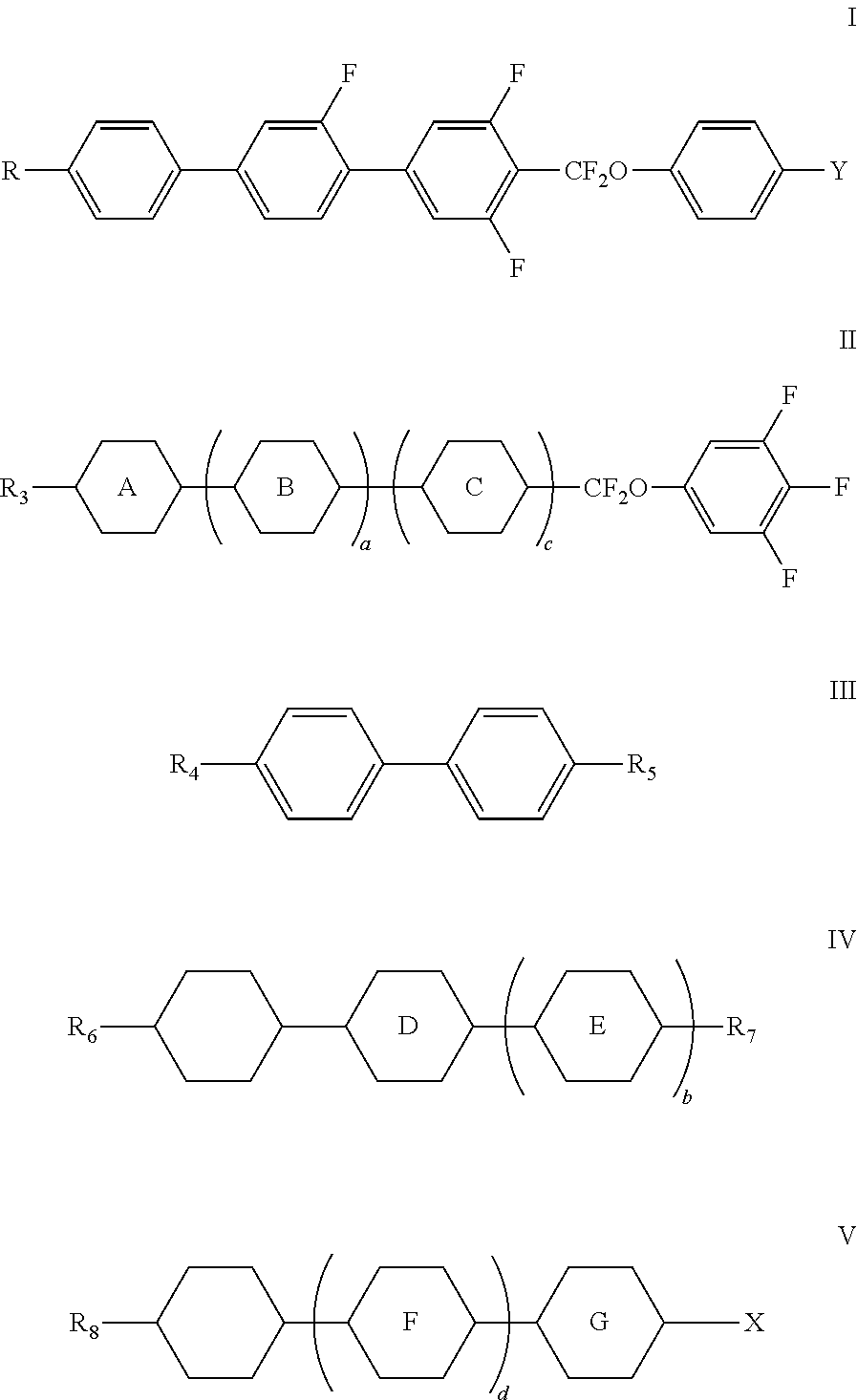

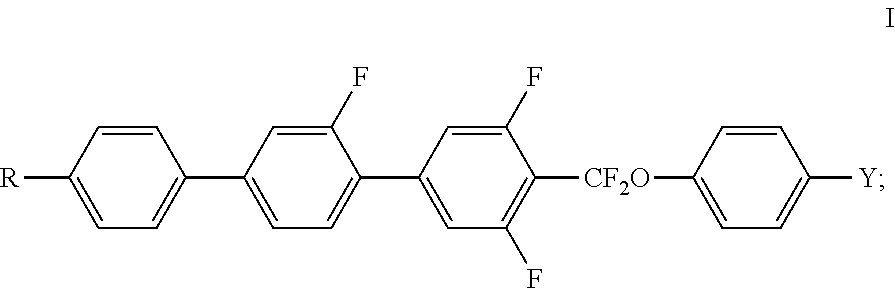

Positive dielectric anisotropic liquid crystal composition

ActiveCN103289708AProperly positive dielectric anisotropyAppropriate optical anisotropyLiquid crystal compositionsDielectric anisotropyTotal response

The invention discloses a positive dielectric anisotropic liquid crystal composition. The positive dielectric anisotropic liquid crystal composition comprises 1%-40% by weight of compound with a structural formula I, 1%-50% by weight of compound with a structural formula II, 1%-60% by weight of compound with a structural formula III and 1%-80% by weight of compound with a structural formula IV, and an optically active compound accounting for 0-0.5% of the total weight of the liquid crystal composition can be additionally added. The liquid crystal composition has the advantages of suitable positive dielectric anisotropy, lower rotary viscosity, very low total response time, lower voltage and higher resistivity and voltage holding ratio, and further has broad application prospects and application values in liquid crystal display.

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

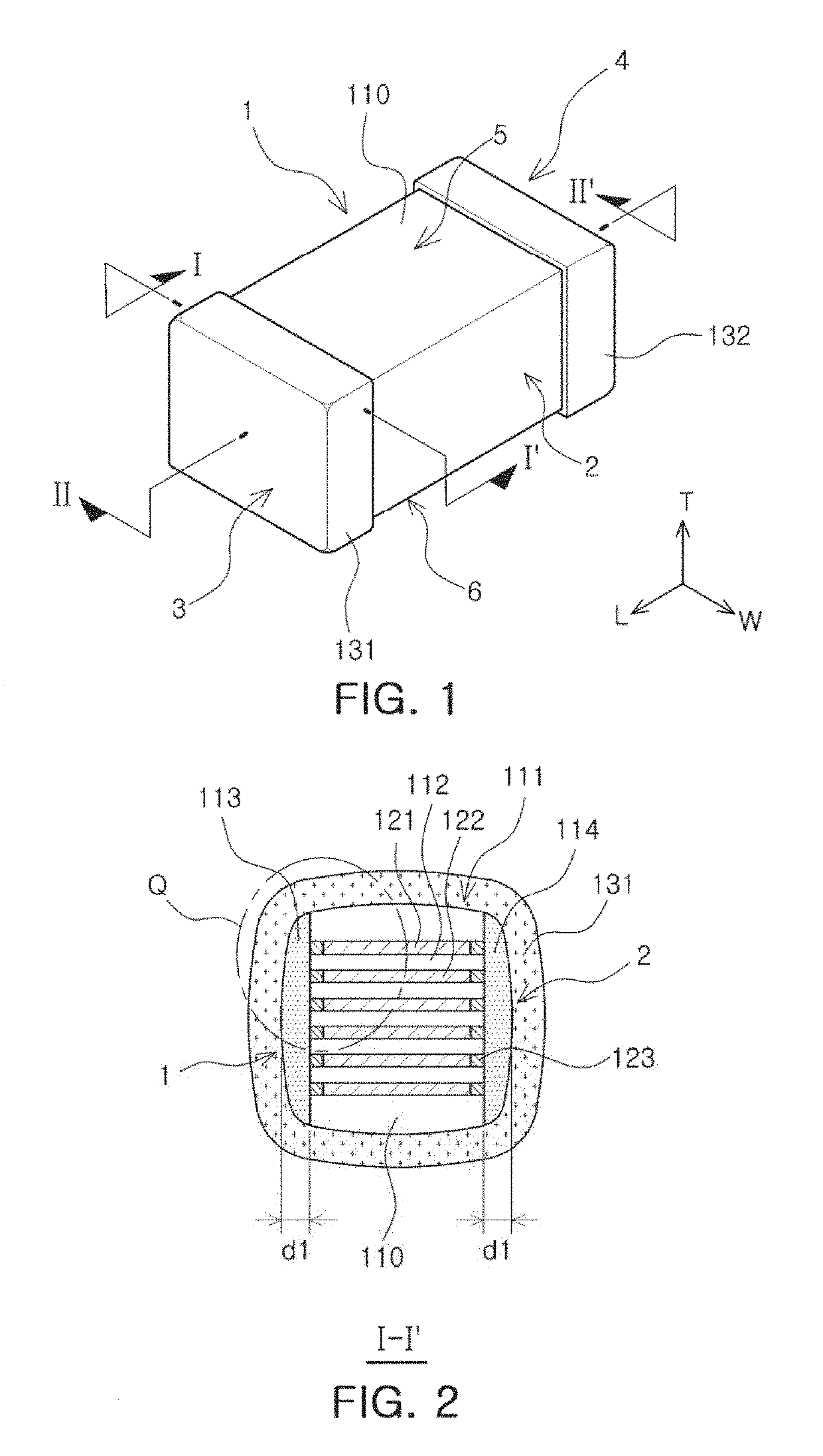

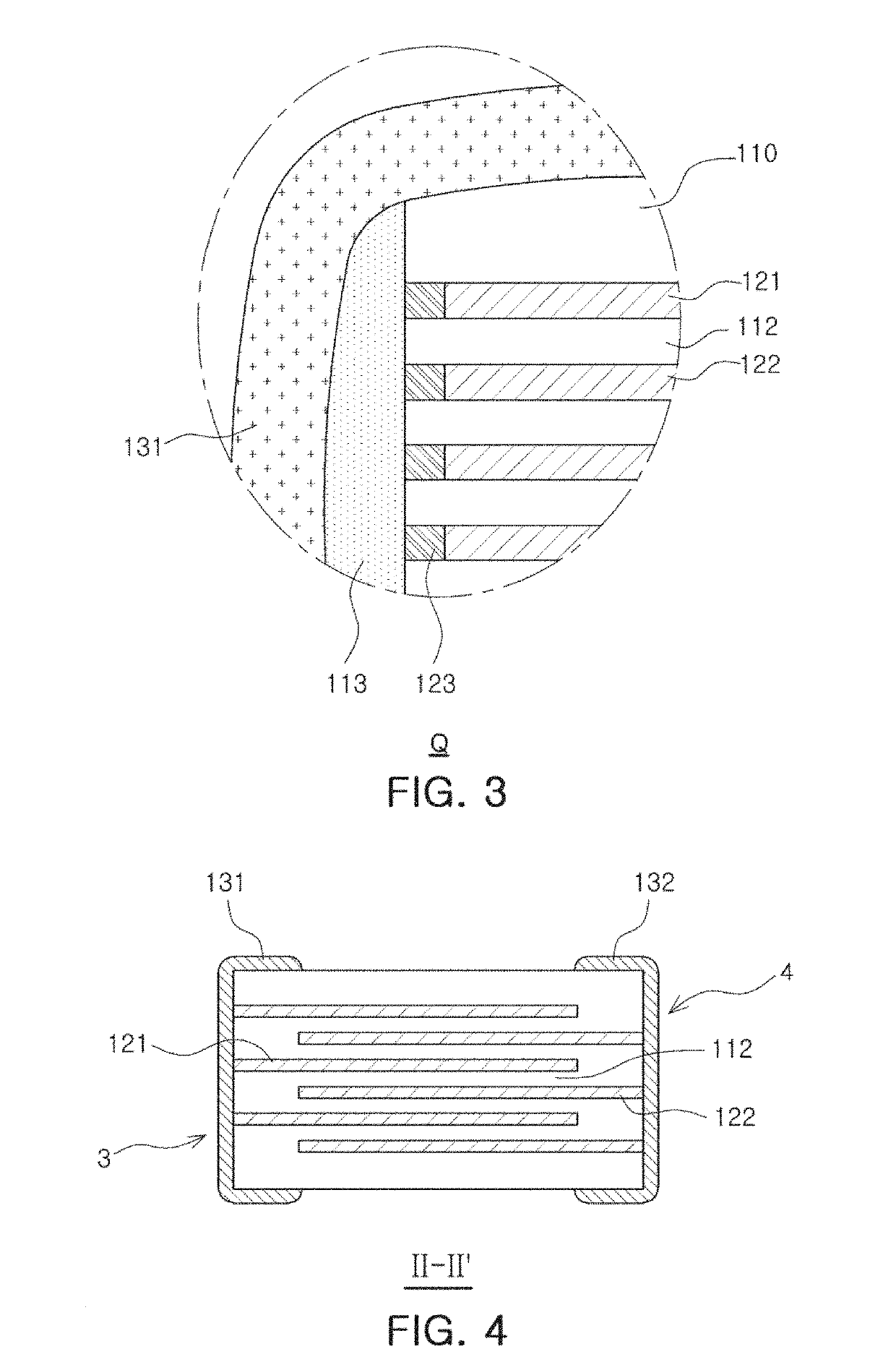

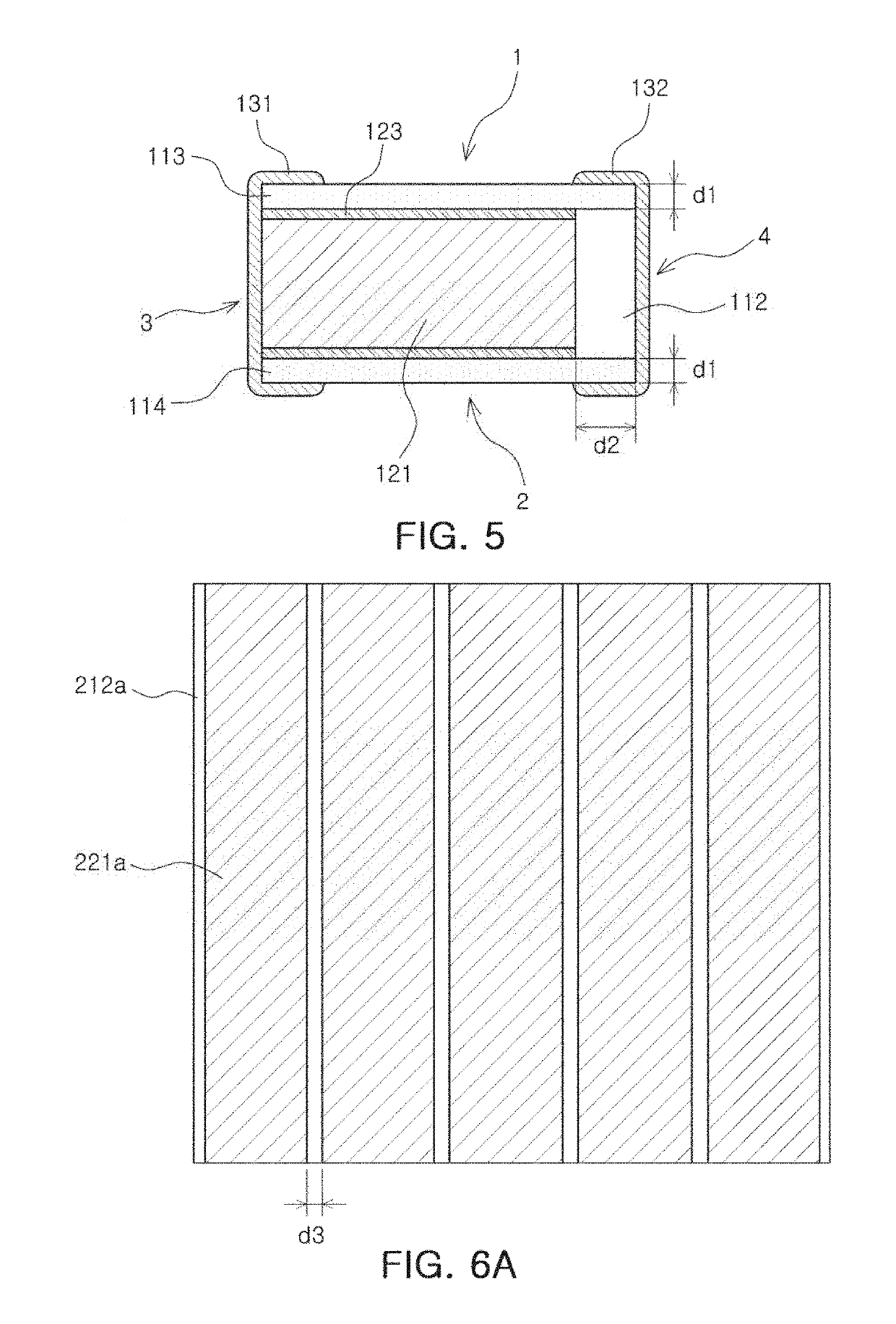

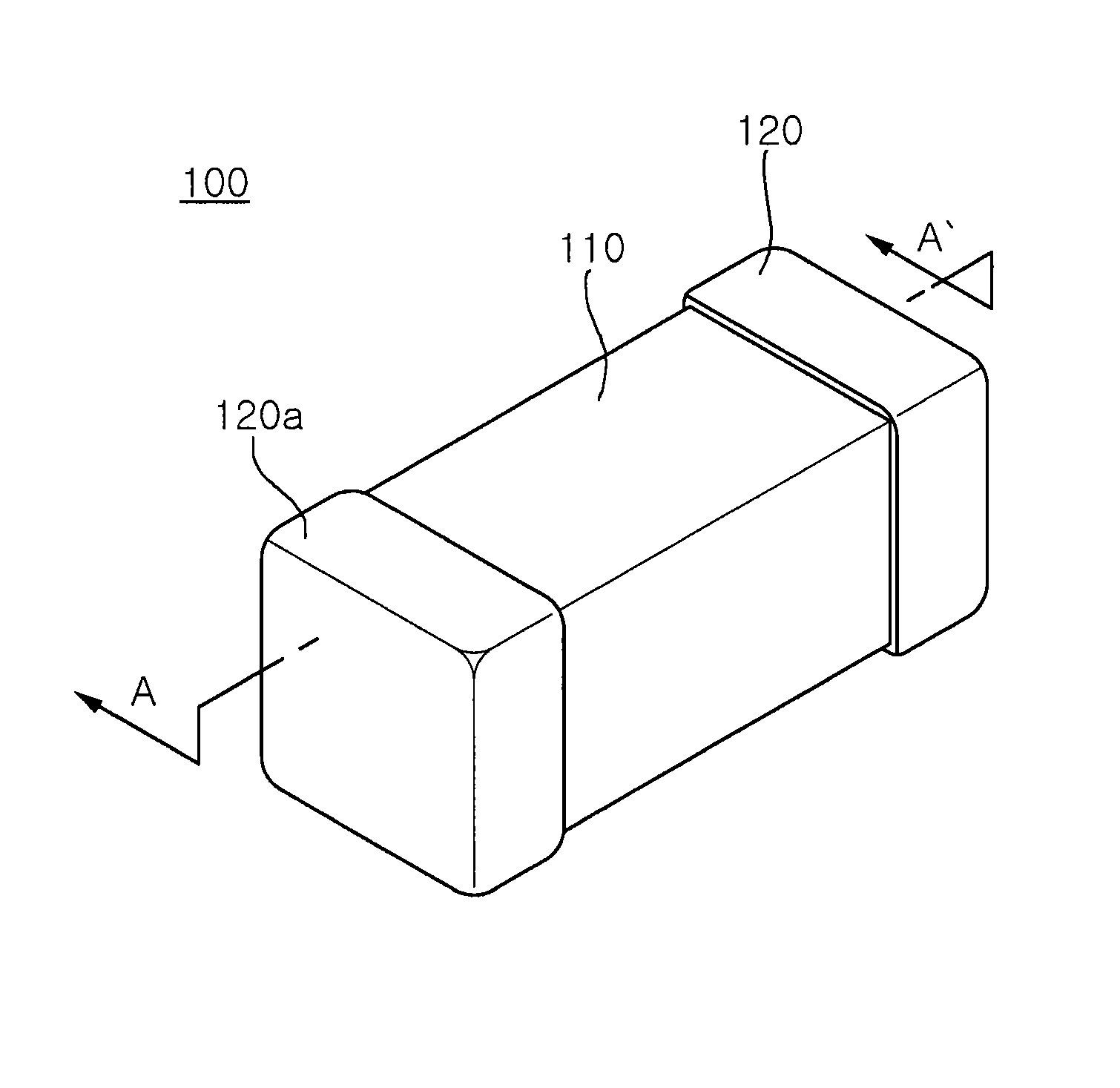

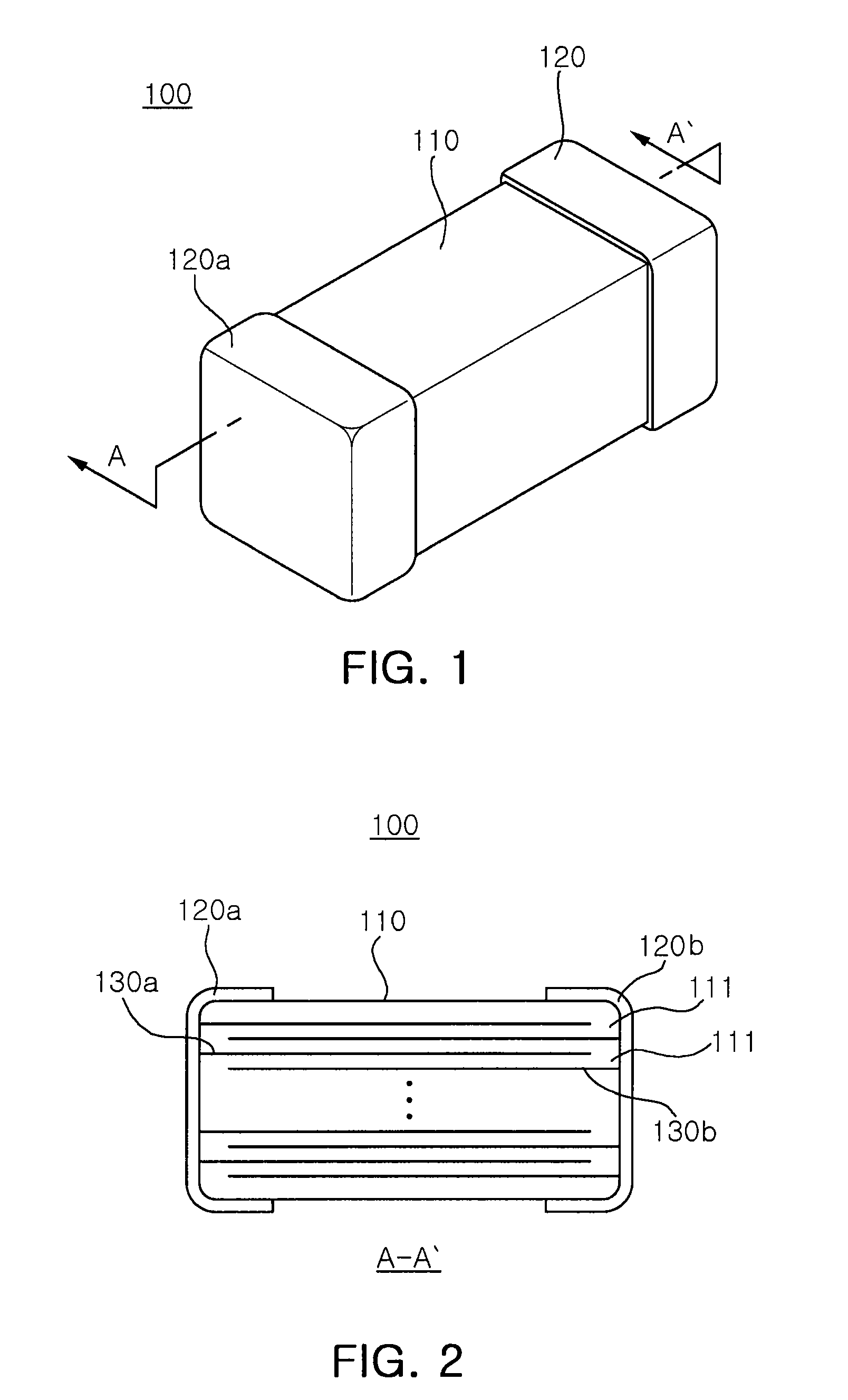

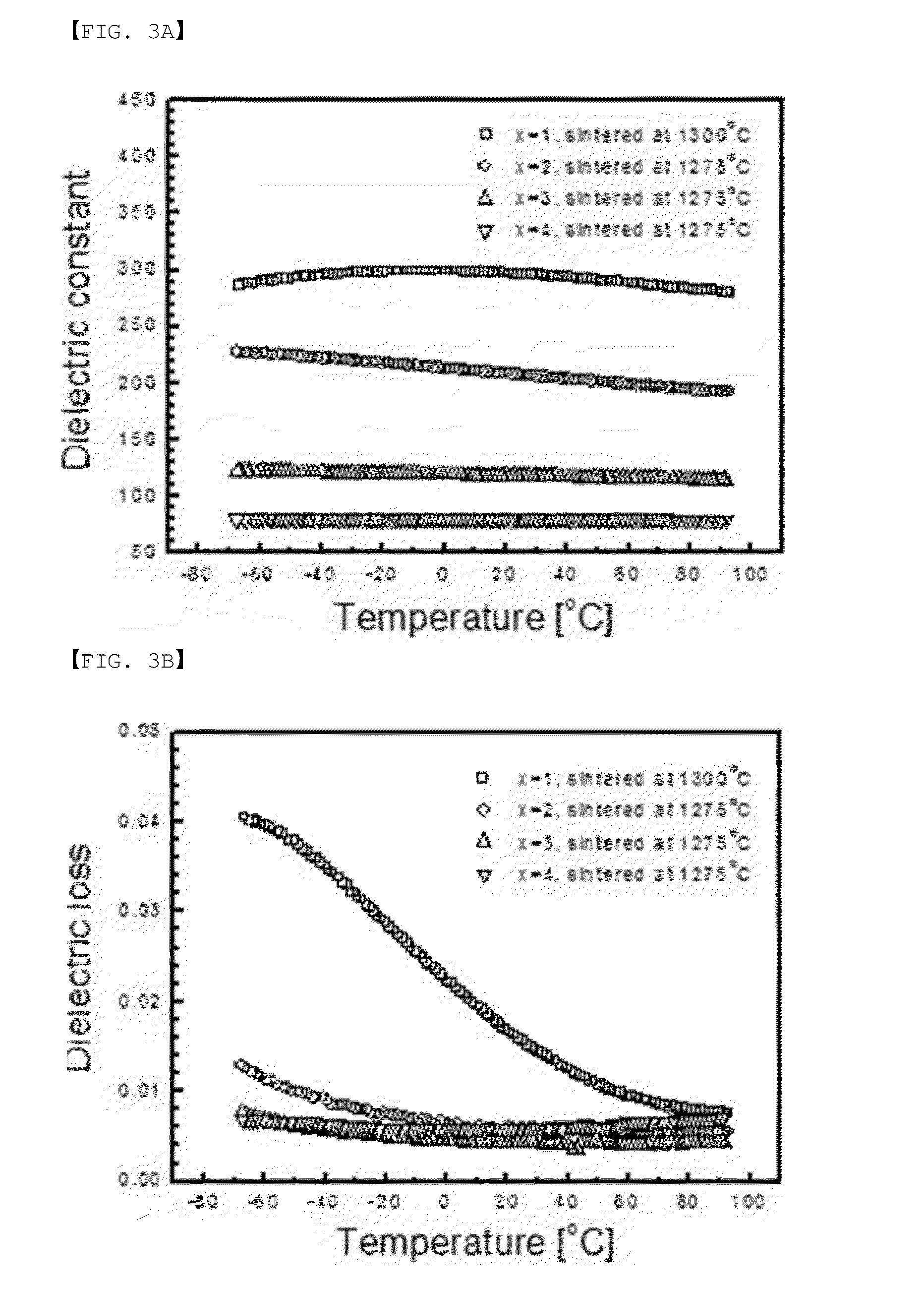

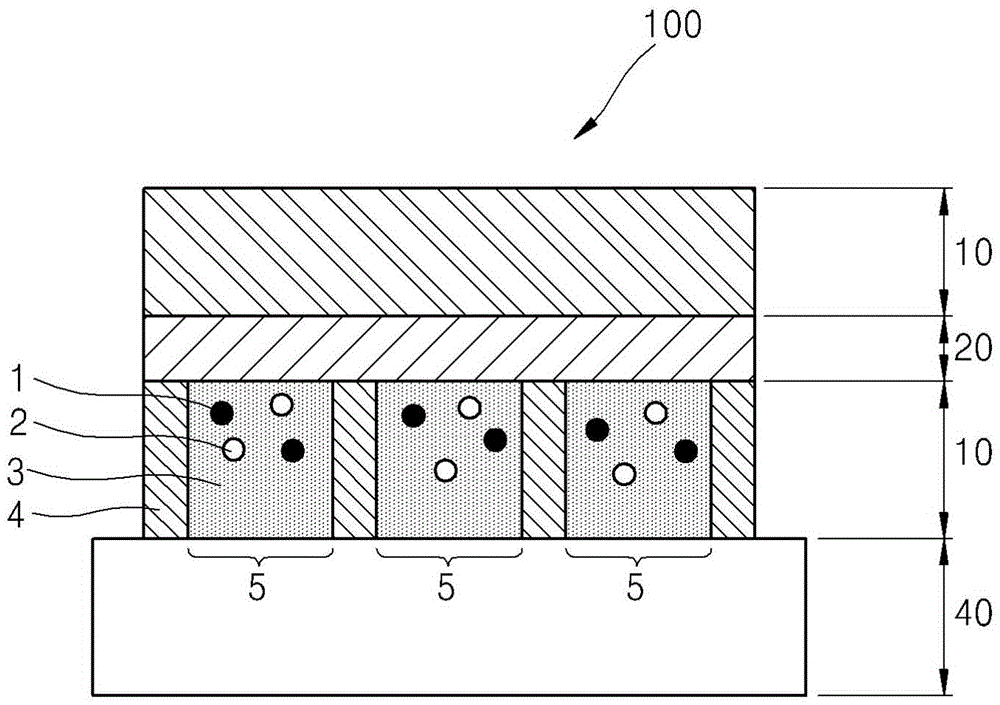

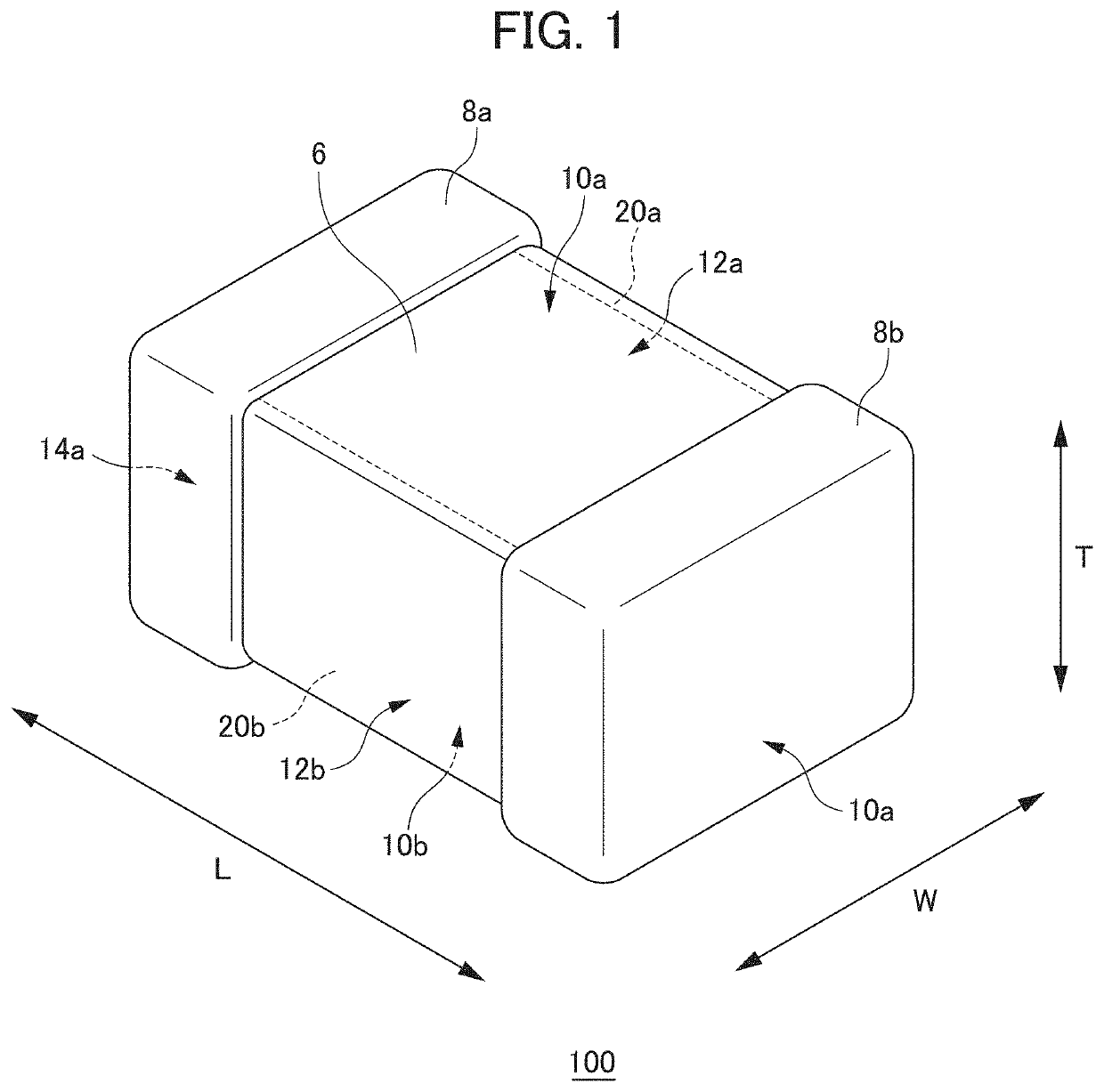

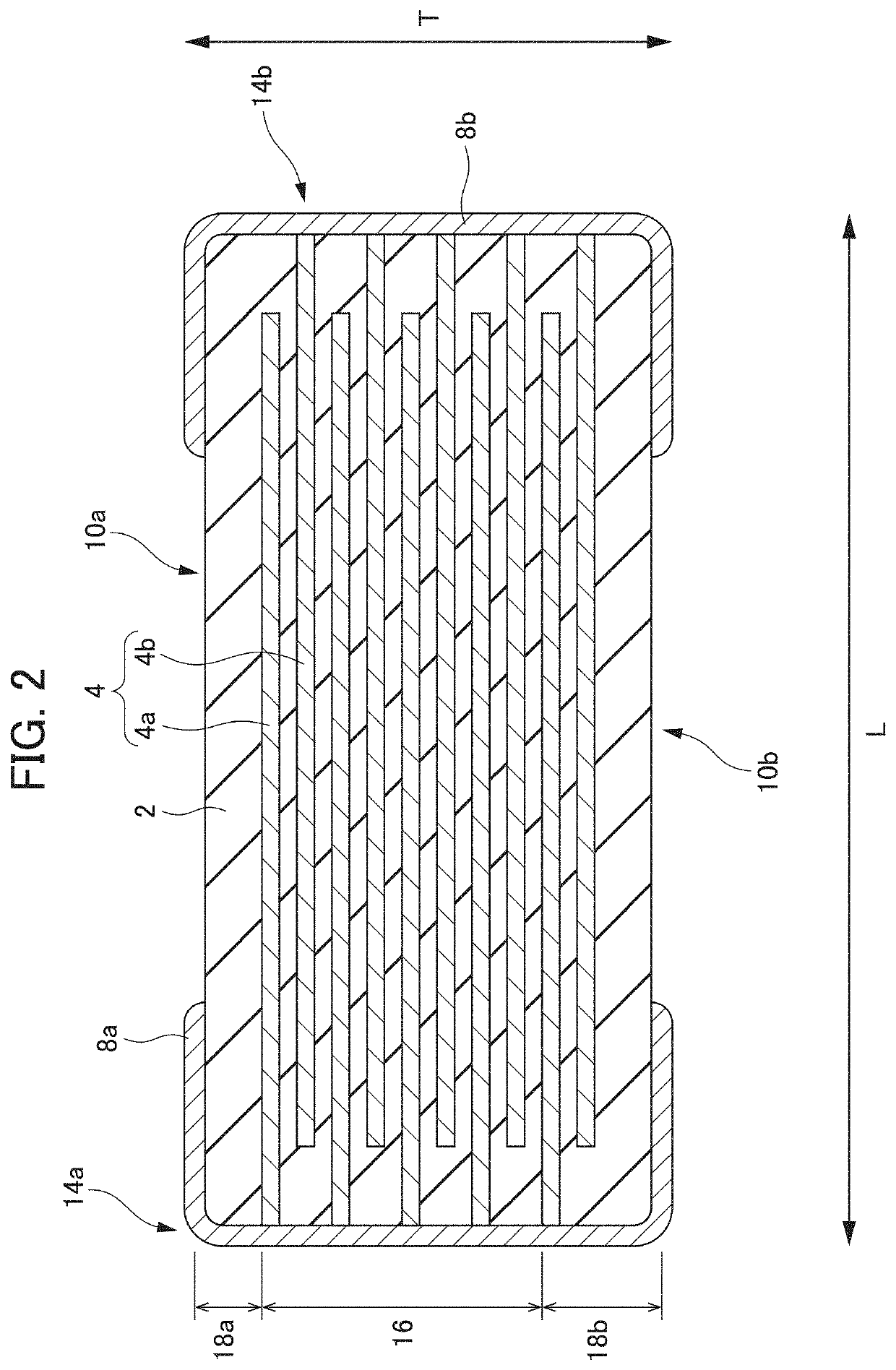

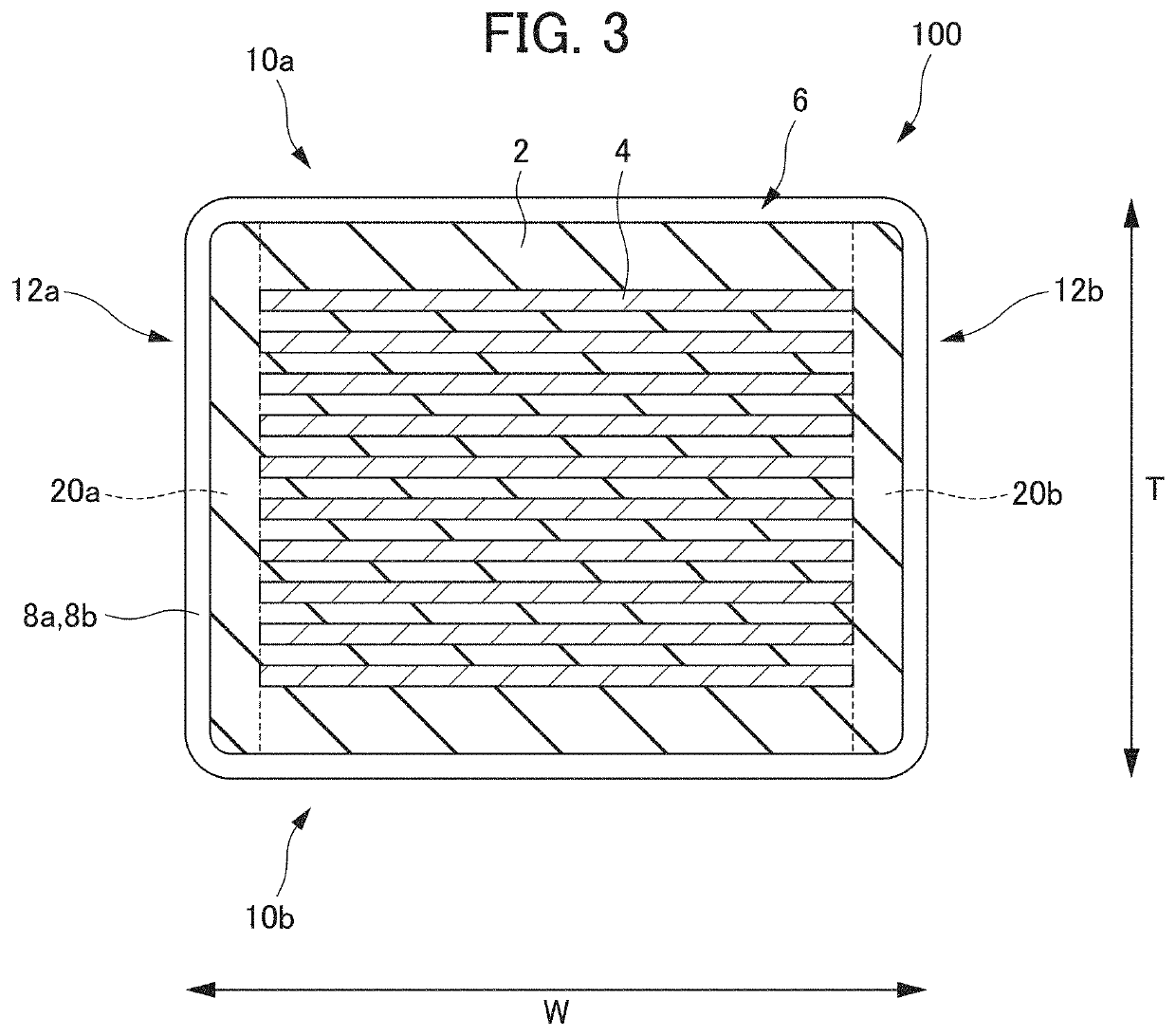

Multilayer ceramic capacitor

ActiveUS20190115153A1Improve high temperature reliabilityHigh mechanical strengthFixed capacitor electrodesFixed capacitor dielectricBarium titanateCeramic capacitor

A multilayer ceramic capacitor includes: a ceramic body having first and second surfaces opposing each other and third and fourth surfaces connecting the first and second surfaces to each other; a plurality of internal electrodes disposed in the ceramic body, exposed to the first and second surfaces, and each having one end exposed to the third or fourth surface; and first and second side margin portions disposed on the first and second surfaces and covering exposed surfaces of the internal electrodes. A dielectric composition contained in the first and second side margin portions is different from a dielectric composition contained in the ceramic body, the first and second side margin portions contain a barium titanate-based base material powder and magnesium (Mg), manganese (Mn), and aluminum (Al) as accessory ingredients, and a content ratio of manganese (Mn) to magnesium (Mg), manganese (Mn), and aluminum (Al) satisfies 0.316≤Mn / (Mn+Mg+Al)≤0.500, based on a molar content of Mn, Mg and Al in the first and second side margin portions.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Gate driving circuit and display apparatus having the same

ActiveUS8174478B2Avoid failureImprove high temperature reliabilityStatic indicating devicesDigital storageEngineeringDriving circuit

A gate driving circuit and a display apparatus having the gate driving circuit include a pull-up part and a carry part pull up a present gate signal and a present carry signal, respectively, to a first clock during a first period within one frame. A pull-down part receives a next gate signal to discharge the present gate signal to a source power voltage. A pull-up driving part is connected to control terminals of the carry part and pull-up part (Q-node) to turn the carry part and pull-up part on and off. A floating preventing part prevents an output terminal of the carry part from being floated in response to the first clock during a second period within the one frame.

Owner:SAMSUNG DISPLAY CO LTD

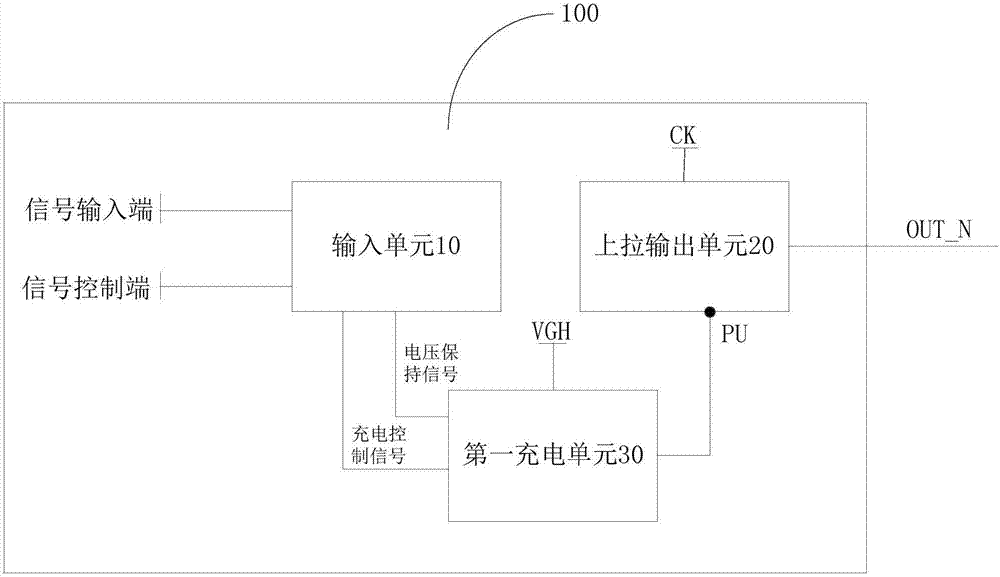

Shift register, array substrate grid electrode drive circuit and display apparatus

ActiveCN106940977AGuaranteed voltageHigh voltageStatic indicating devicesDigital storageShift registerControl signal

The invention discloses a shift register comprising an input unit, a pull-up output unit and a first charging unit, wherein the input unit is connected with a signal input end and a signal control end, the input unit is used for generating charging control signals and voltage maintaining signals according to input signals provided by the signal input end and control signals provided by a signal control end, and the pull-up output unit comprises pull-up nodes; the first charging unit is connected with the pull-up nodes, the input unit and a first electric level signal end; the first charging unit is used for charging the pull-up nodes according to electric level signals provided by charging control signals via the first electric level signal end, the first charging unit is also used for maintaining voltage of the pull-up nodes according to the voltage maintaining signals so as to preventing driving signals output via the shift register from voltage drop, that output at a level is prevented from drop can be ensured when high temperature TFT electric leakage occurs, and display effect can be improved during high temperature time. The invention also discloses an array substrate grid electrode drive circuit and a display apparatus.

Owner:BOE TECH GRP CO LTD +1

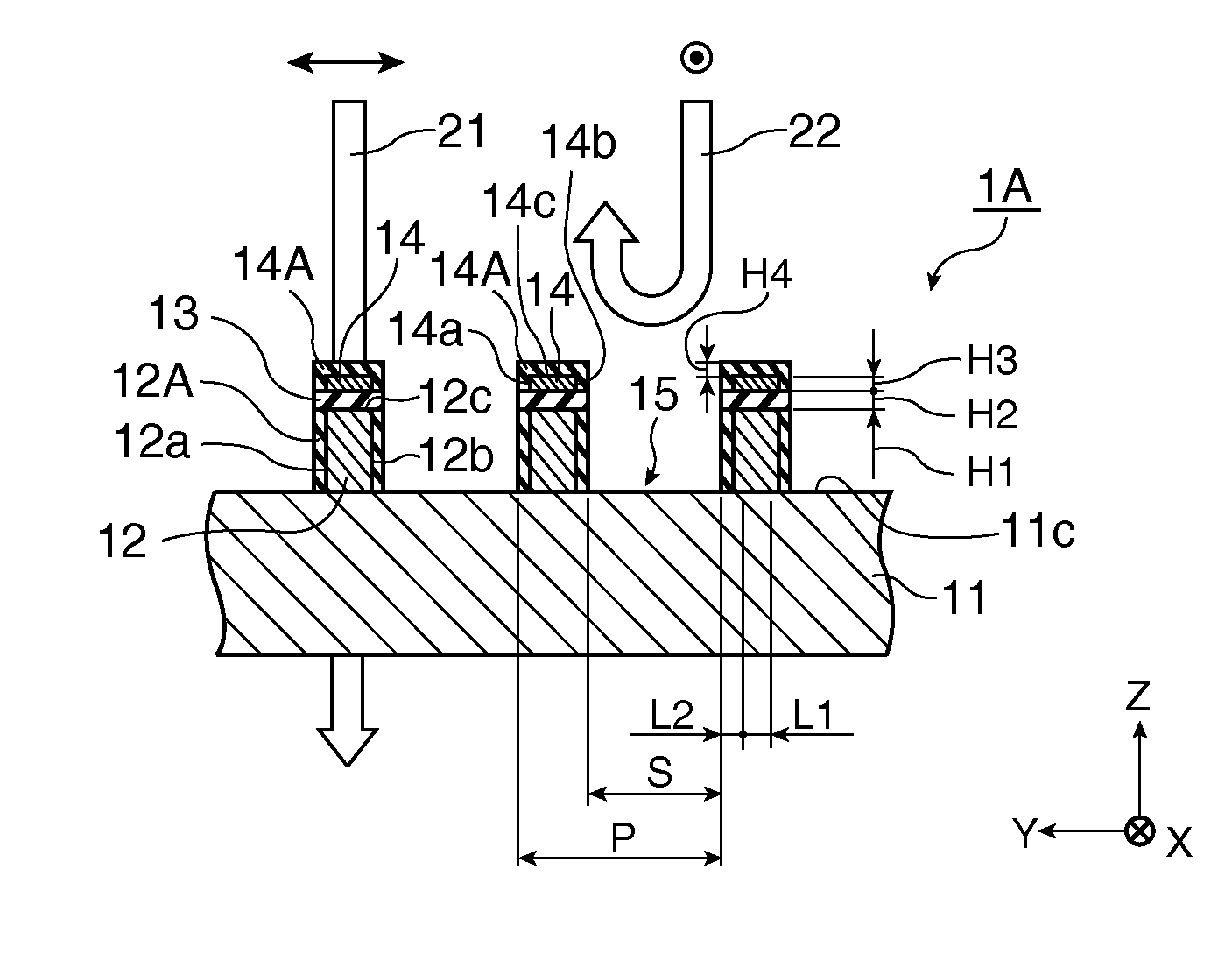

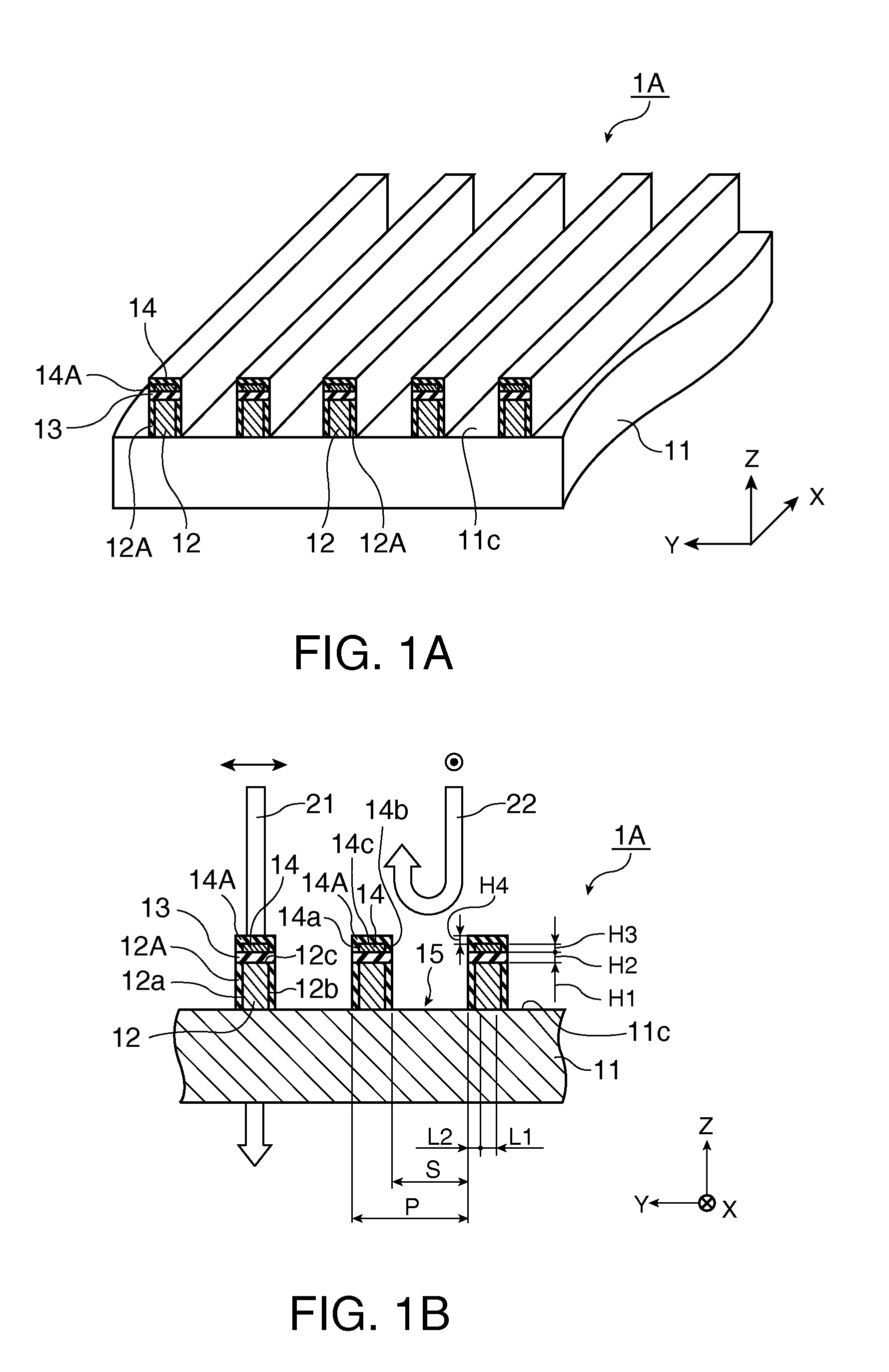

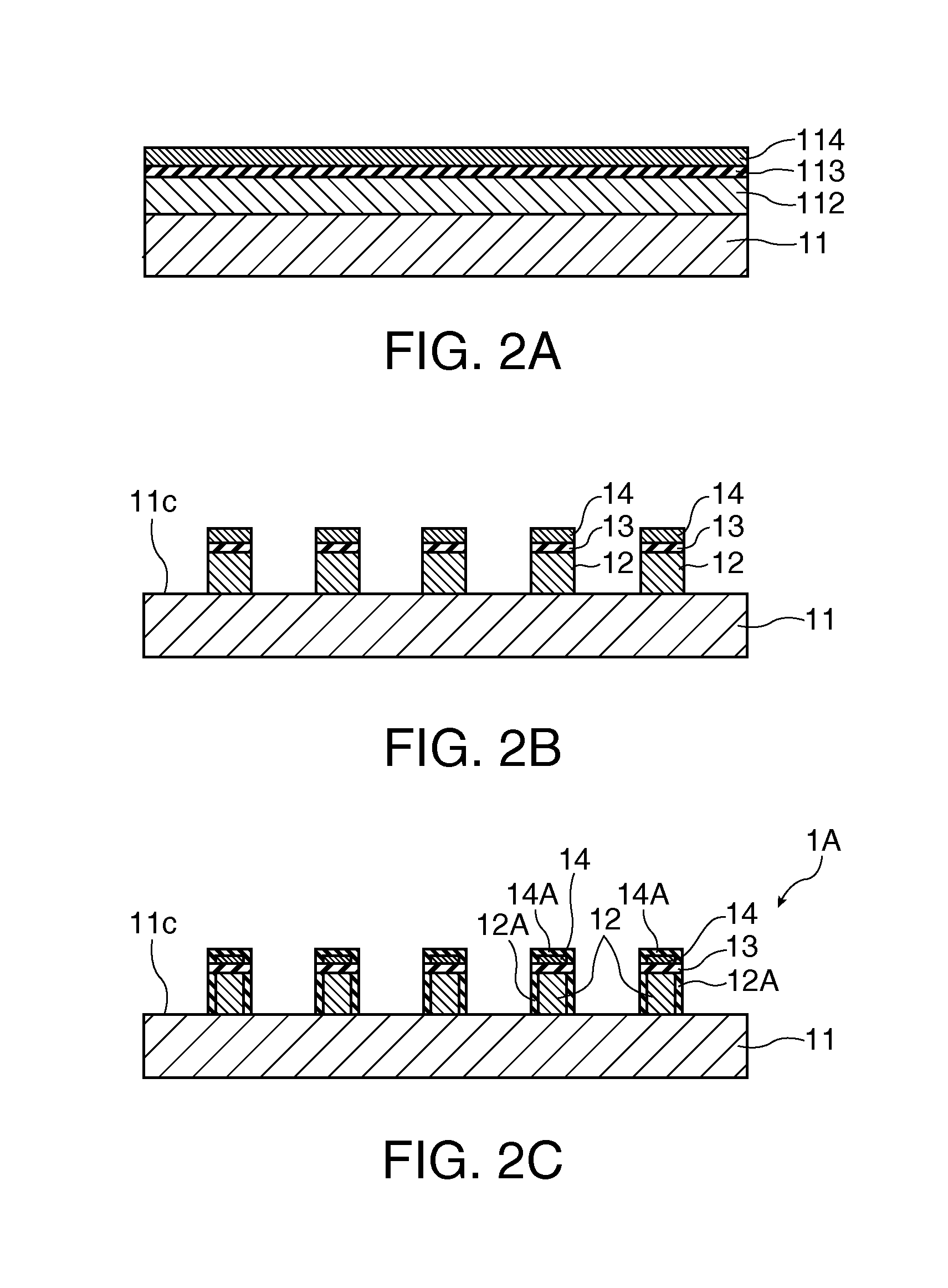

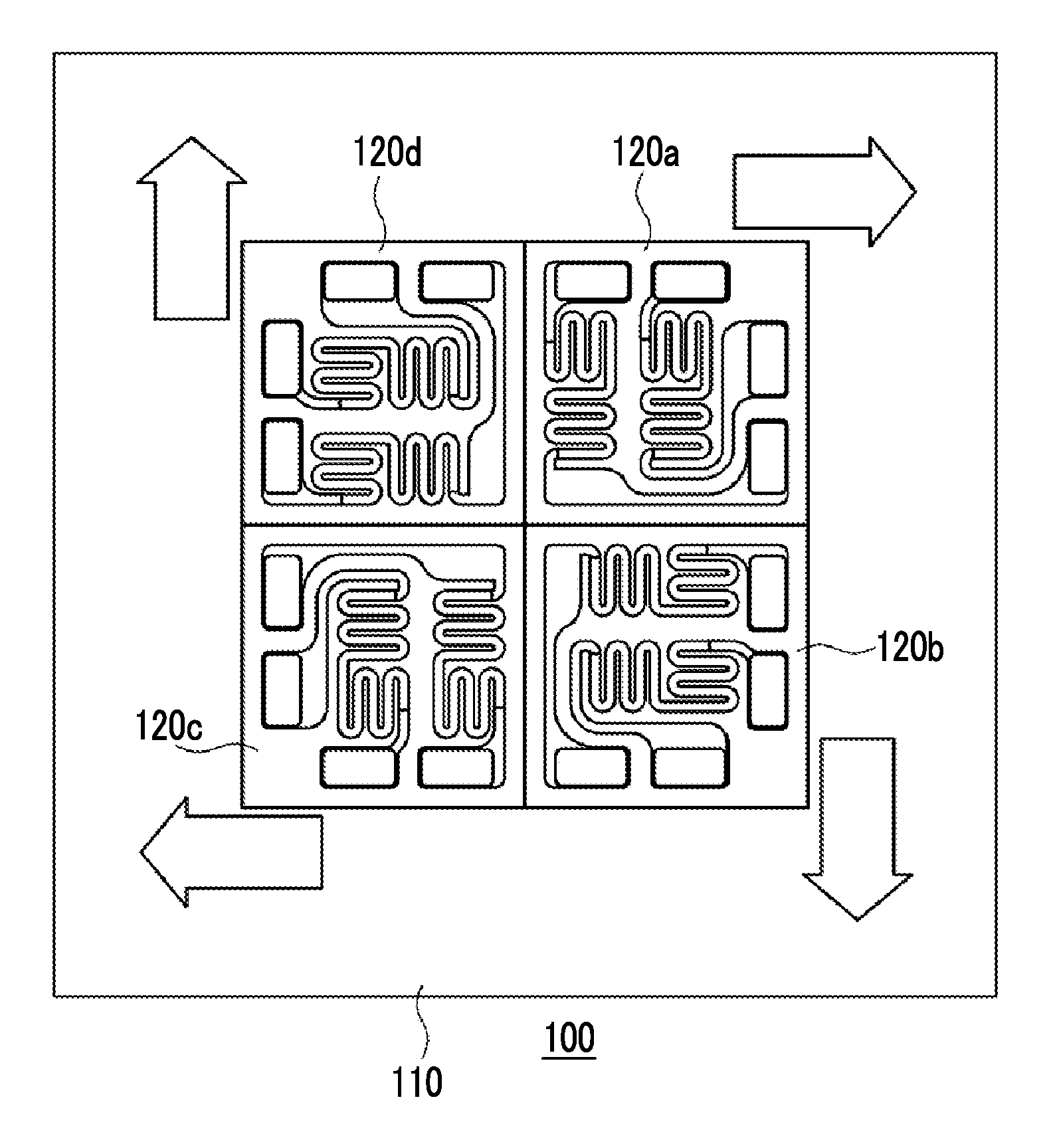

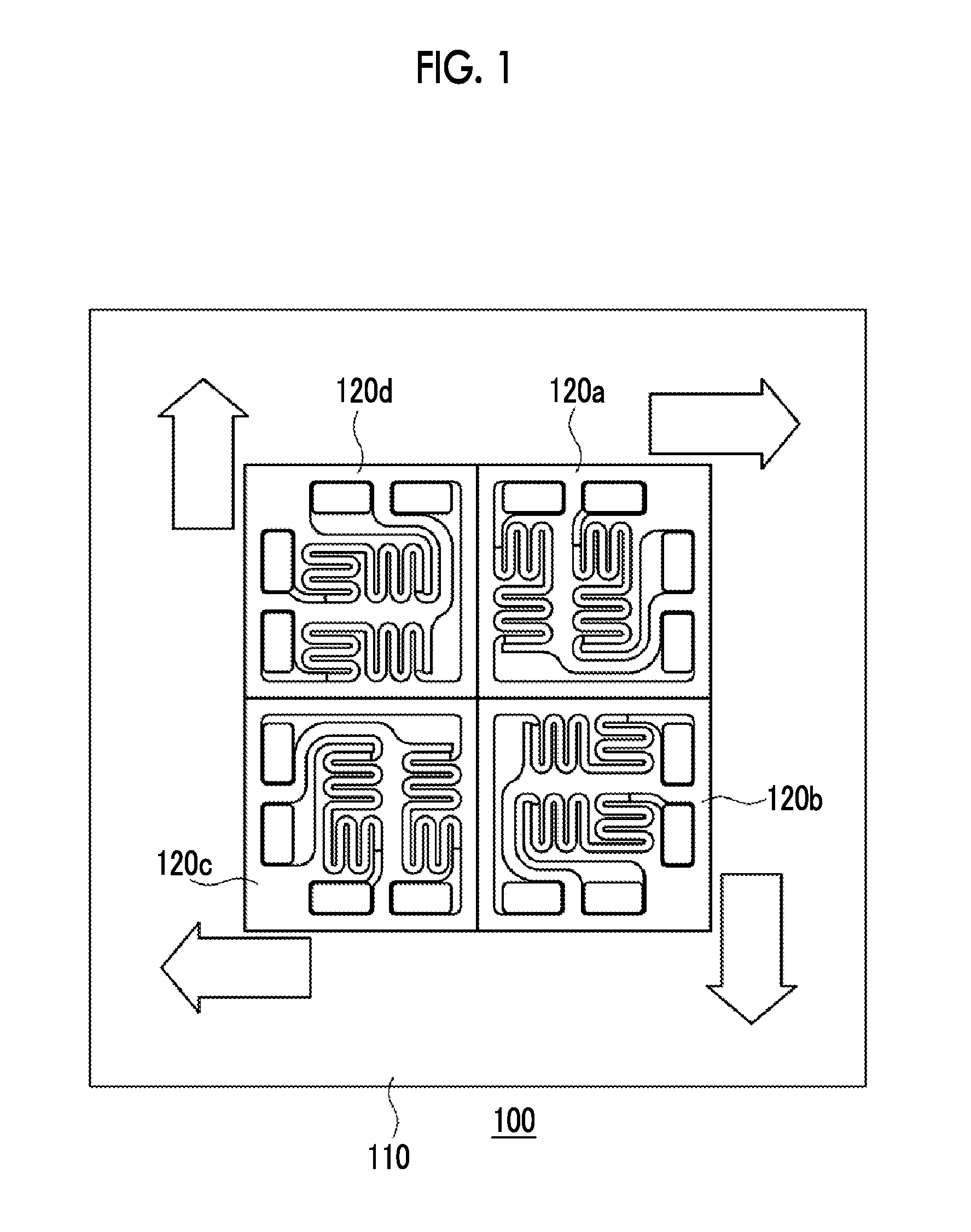

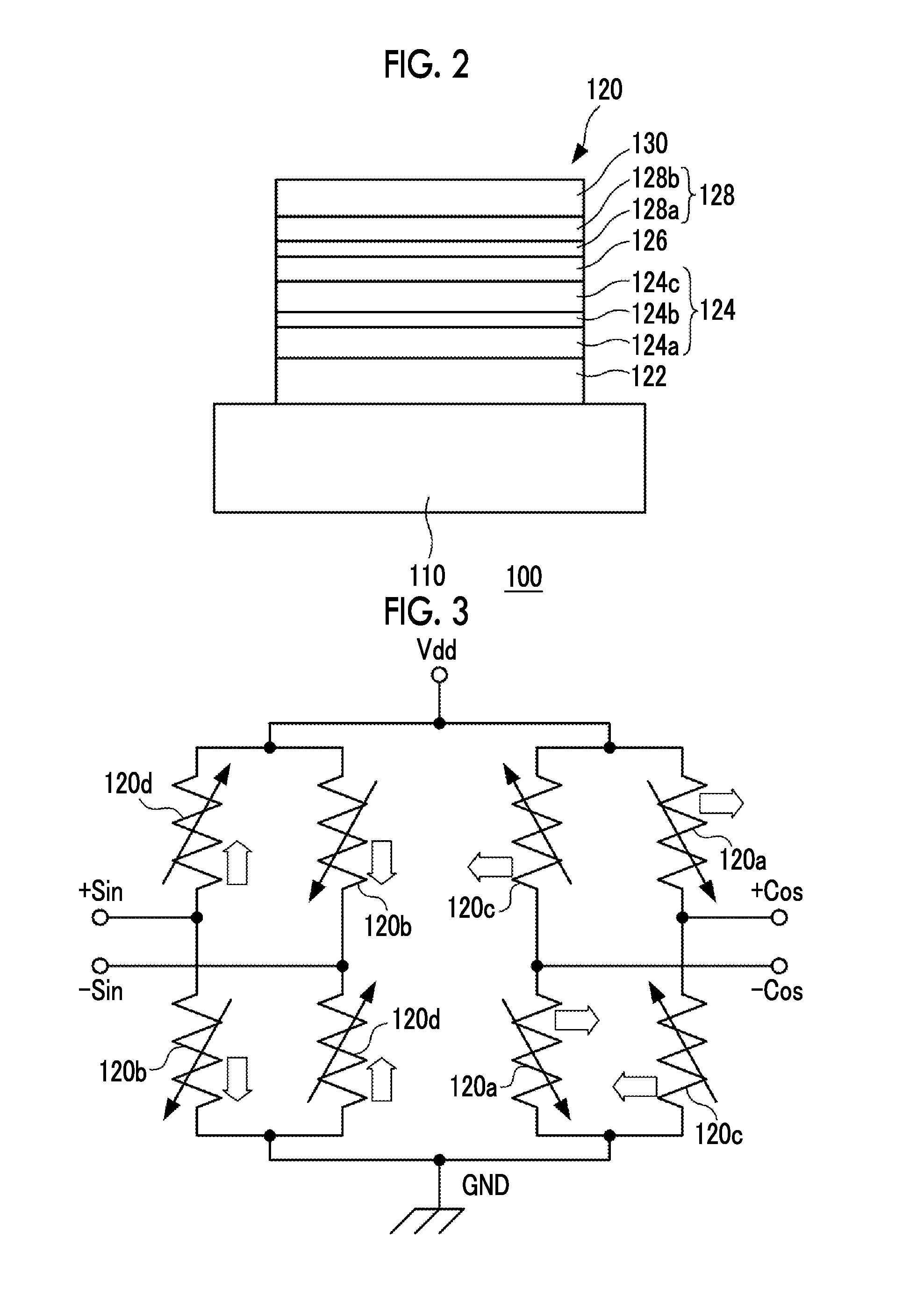

Magnetic sensor, method of manufacturing magnetic sensor, and method of designing magnetic sensor

ActiveUS20160313411A1Improve high temperature reliabilityElectrical measurement instrument detailsMechanical recordingNuclear magnetic resonanceMagnetic layer

A magnetic sensor is provided in which in a case where magnetization amounts of the first ferromagnetic layer and the second ferromagnetic layer in the first magnetic sensor element are respectively set to be Mst11 and Mst12 and magnetization amounts of the first ferromagnetic layer and the second ferromagnetic layer in the second magnetic sensor element are respectively set to be Mst21 and Mst22, in a case of Mst11>Mst12, a relationship of Mst21>Mst22 is satisfied, and in a case of Mst11<Mst12, a relationship of Mst21<Mst22 is satisfied.

Owner:ALPS ALPINE CO LTD

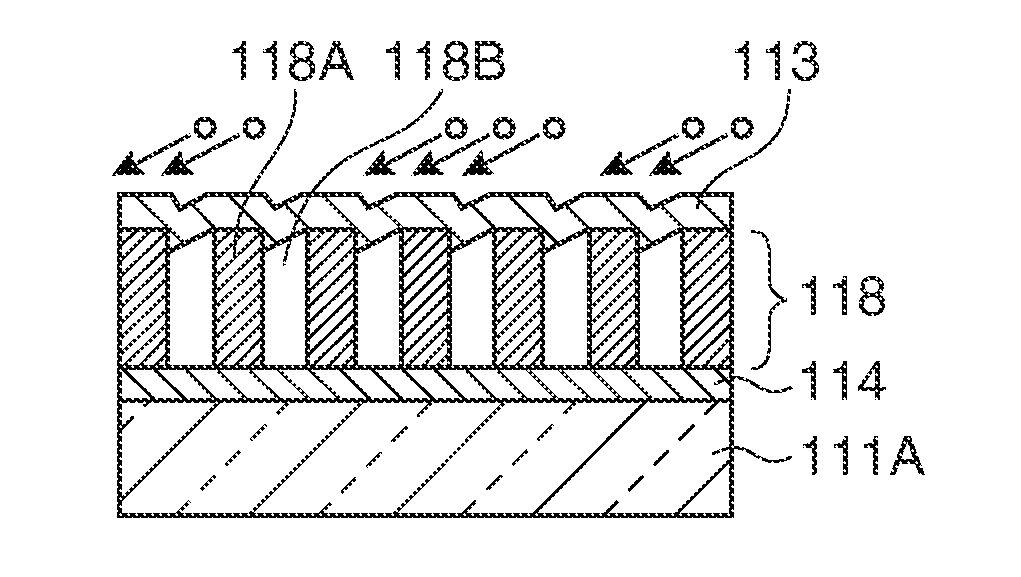

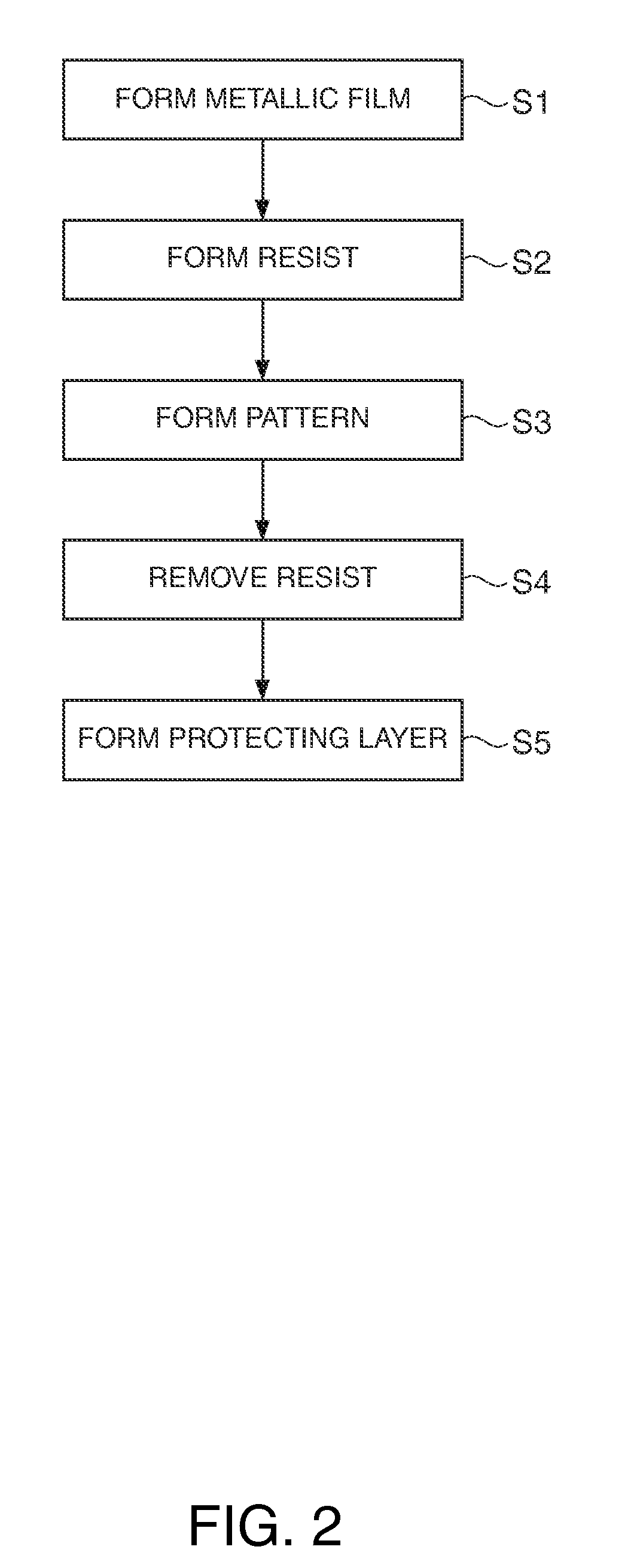

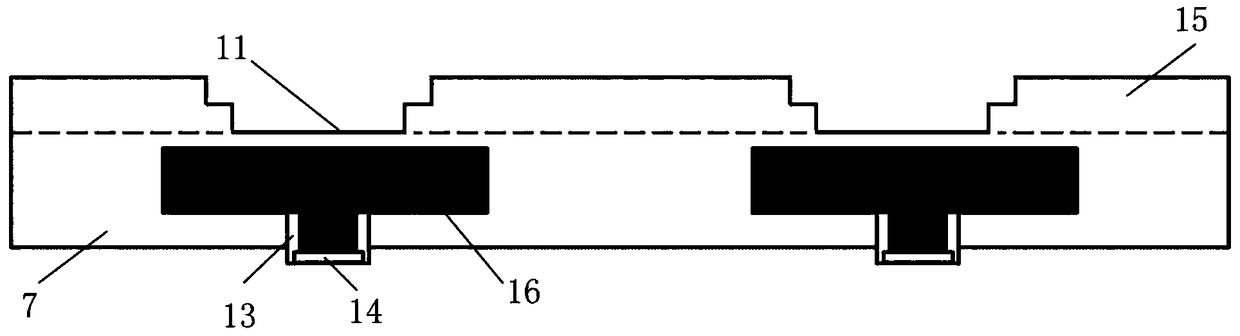

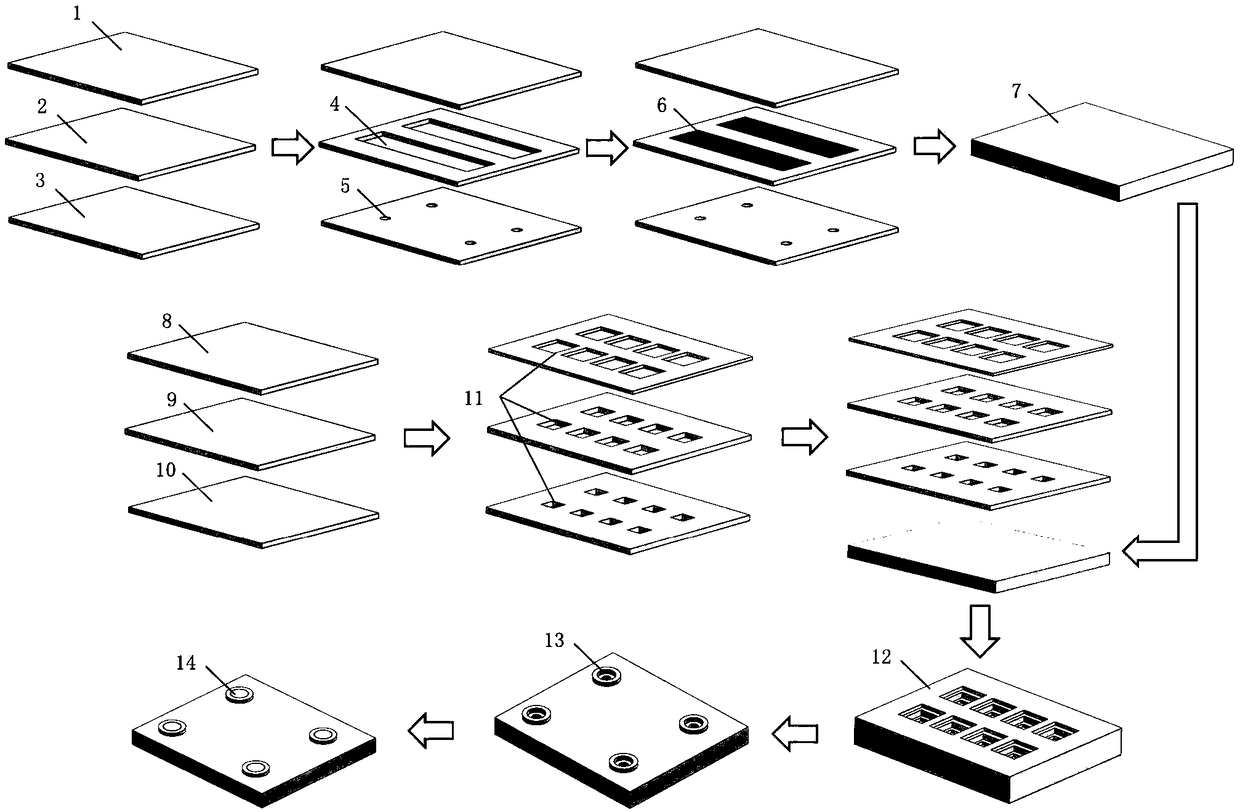

Polarization element and method of manufacturing polarization element

ActiveUS20130250412A1Improve display qualityImprove reliabilityProjectorsOptical articlesThin layerExtremity Part

A polarization element includes a plurality of metallic thin lines that extend in one direction on one surface of a substrate, a protecting layer that is provided on the plurality of metallic thin lines, and a cavity portion that is surrounded by two metallic thin lines which are adjacent to each other, the substrate, and the protecting layer. Each end portion of the plurality of metallic thin layers has a forward tapered shape in a cross-section parallel to the one direction, and the protecting layer extends from the upper portion of the plurality of metallic thin lines to the one surface of the substrate through each end portion.

Owner:SEIKO EPSON CORP

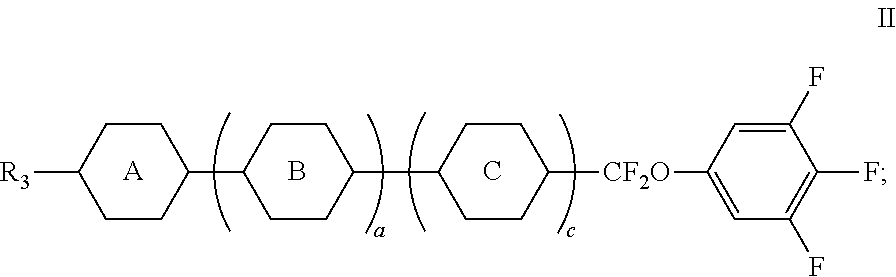

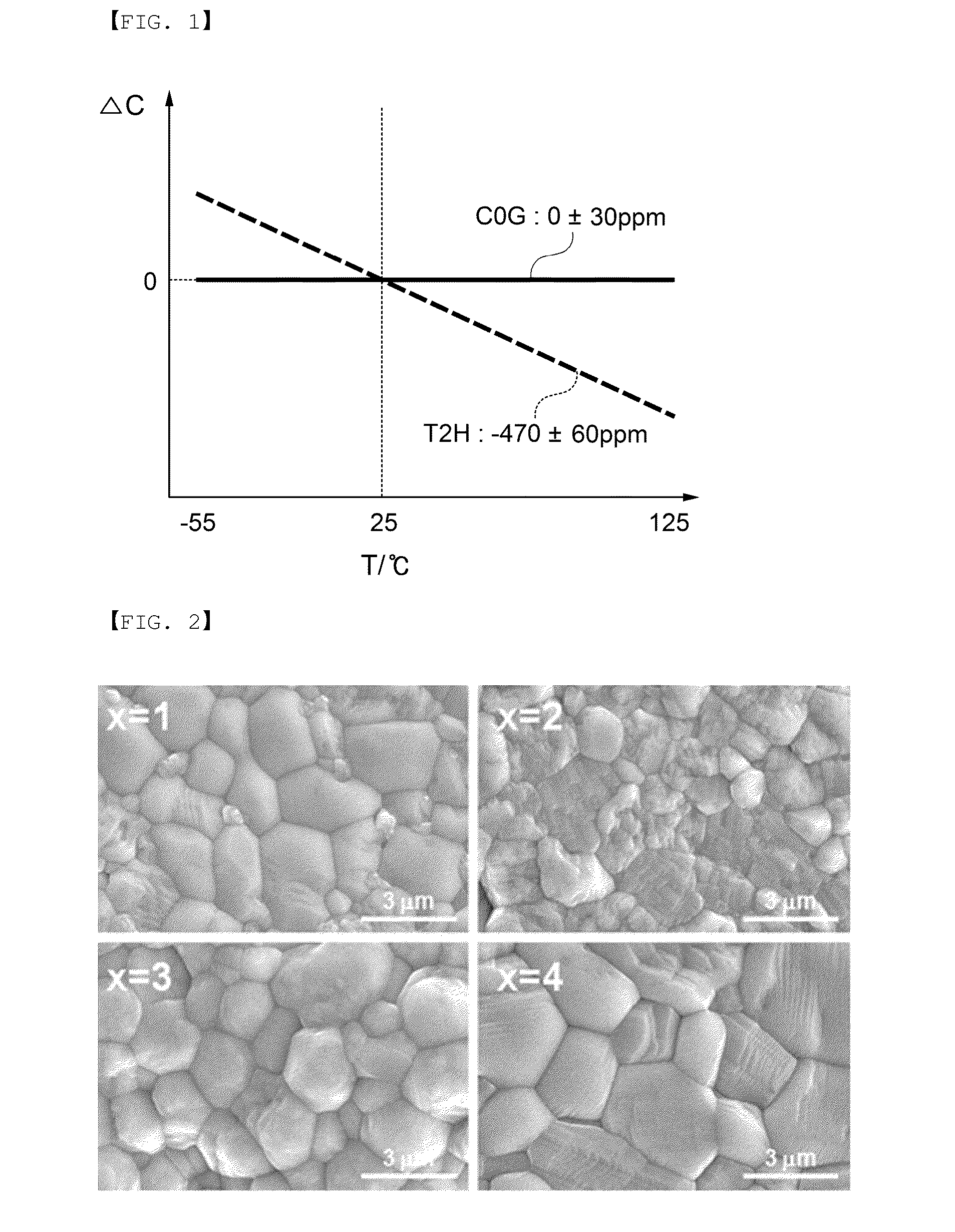

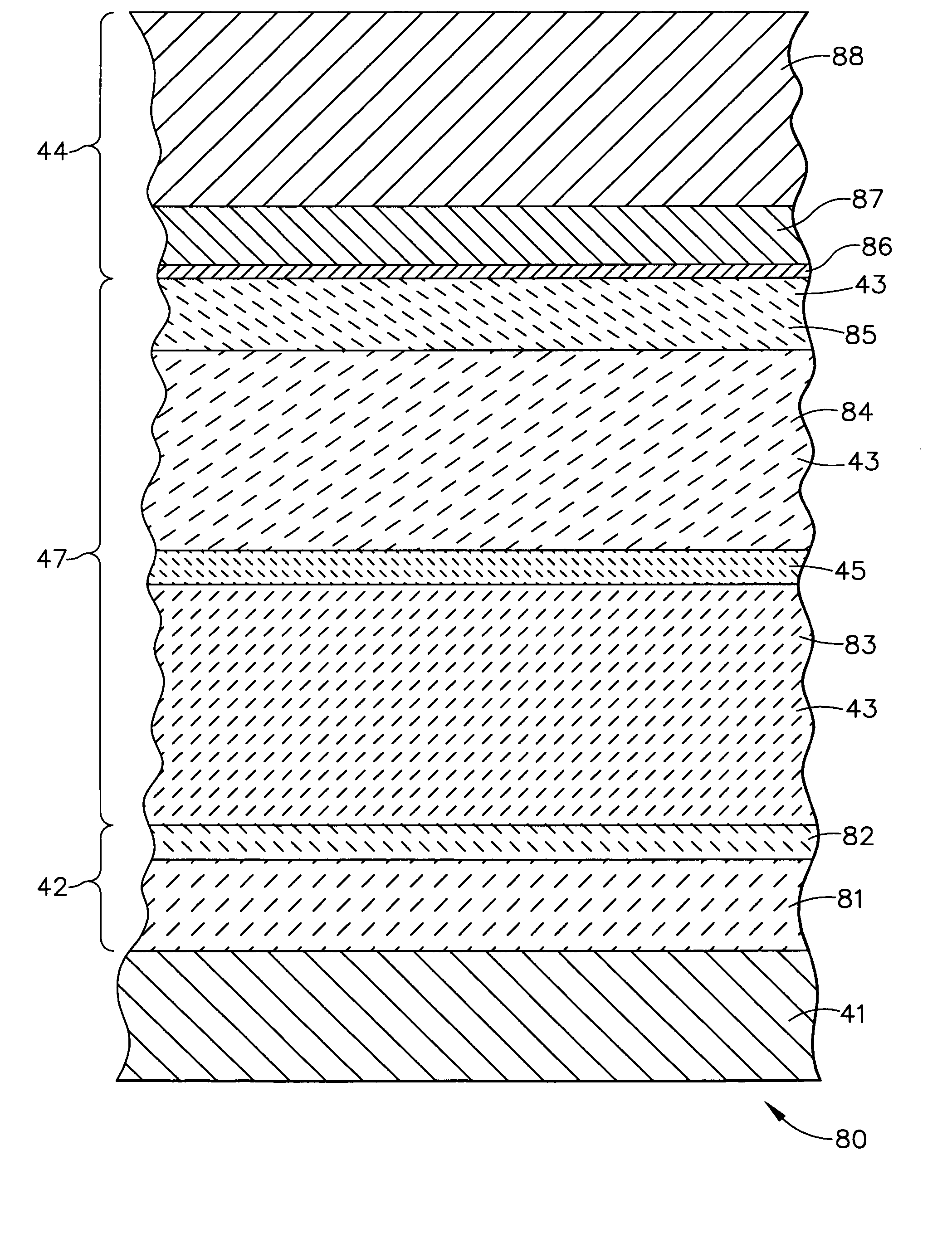

Dielectric ceramic composition and multilayer ceramic capacitor having the same

ActiveUS8164880B2High dielectric constantImprove high temperature reliabilityFixed capacitor dielectricStacked capacitorsMetallurgyCeramic capacitor

There is provided a dielectric ceramic composition including a base powder expressed by a composition formula of Bam(Ti1-xZrx)O3, where 0.995≦̸m≦̸1.010 and 0<x≦̸0.10, and first to fifth accessory components, and a multilayer ceramic capacitor having the same. The multilayer ceramic capacitor having the dielectric ceramic composition has a high dielectric constant and superior high-temperature reliability.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

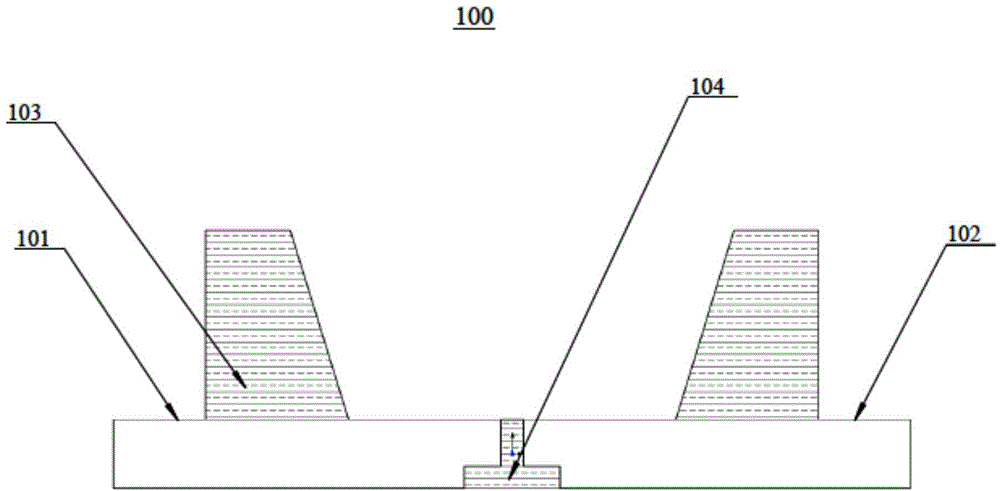

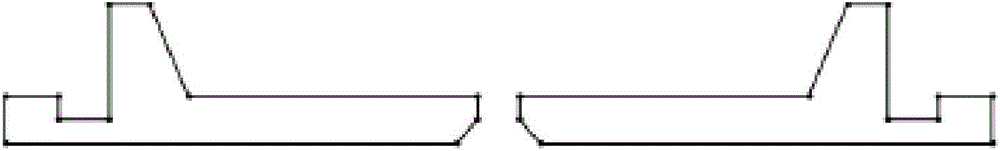

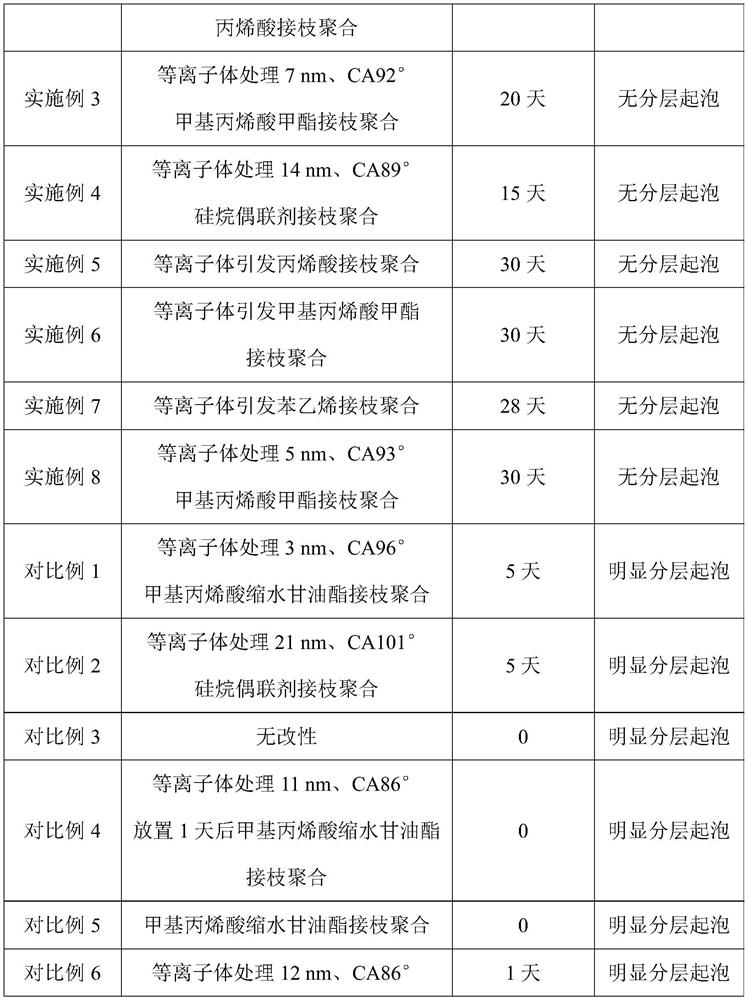

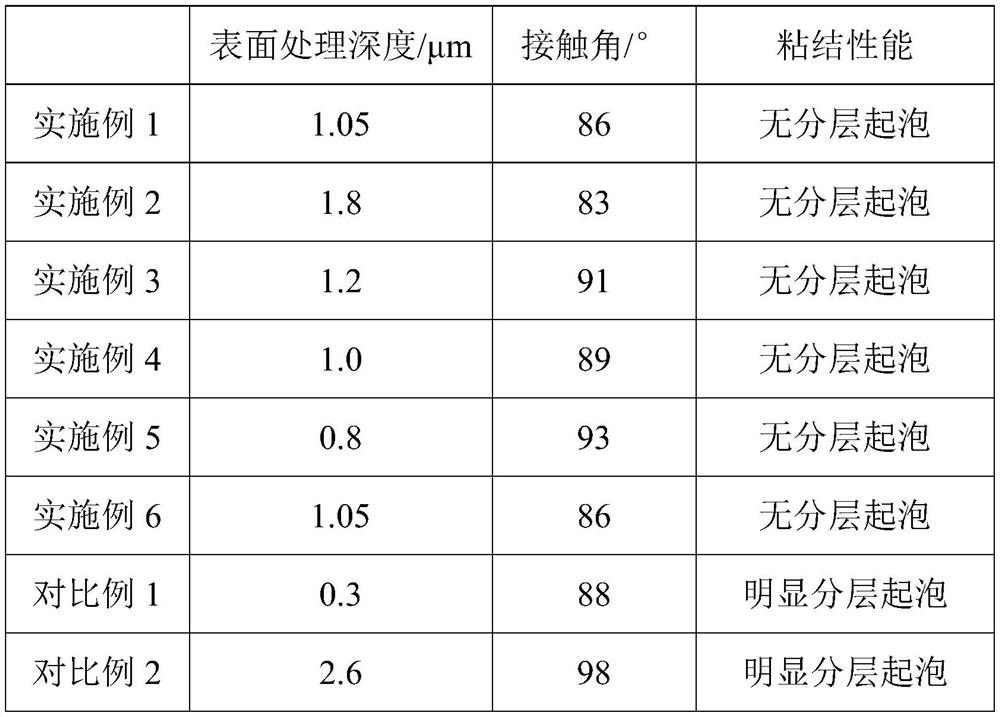

Inter-layer bonding sheet for multi-layer board and preparation method and application of inter-layer bonding sheet

ActiveCN112538184AMeet electrical performance requirementsExcellent dielectric propertiesSynthetic resin layered productsConjugated diene hydrocarbon coatingsBonding strengthPlasma treatment

The invention provides an inter-layer bonding sheet for a multi-layer board and a preparation method and application of the inter-layer bonding sheet. The inter-layer bonding sheet for the multi-layerboard comprises a PTFE substrate and a dielectric resin layer bonded to the surface of the PTFE substrate. The PTFE substrate is a PTFE substrate of which the surface is subjected to plasma treatment, and the surface treatment depth of the PTFE substrate is 5-15nm. After the surface of the PTFE substrate is subjected to plasma treatment, functional modification is achieved, wettability is remarkably improved, and the PTFE substrate can be stably bonded with the dielectric resin layer in a high-strength mode. According to the inter-layer bonding sheet for the multi-layer board, through the synergistic cooperation of the PTFE substrate with the surface subjected to plasma treatment and the dielectric resin layer, the inter-layer bonding sheet for the multi-layer board has excellent dielectric property, fluidity and bonding strength, the bonding stability is high, and the signal high-frequency requirement and the stability and reliability requirements of the multi-layer board can be fully met.

Owner:GUANGDONG SHENGYI SCI TECH

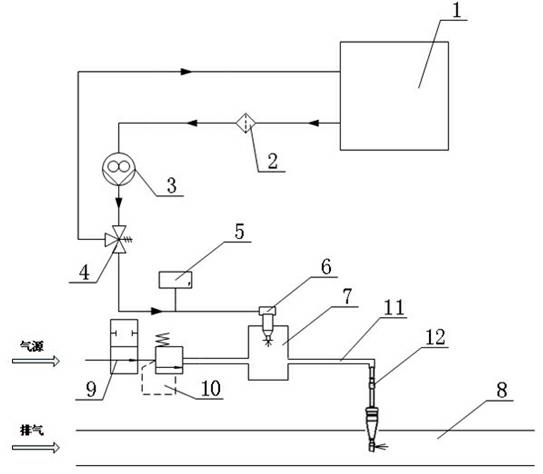

A diesel engine scr urea injection device

ActiveCN102297005ANo leaksImprove reliabilityExhaust apparatusSilencing apparatusSpray nozzleEngineering

The invention discloses a selective catalytic reduction (SCR) urea jet device of a diesel engine, and belongs to the technical field of engine exhaust purification treatment. The SCR urea jet device comprises a mixing cavity; the mixing cavity is provided with a gas source inlet, a urea inlet and a liquid outlet pipe; the gas source inlet is sequentially connected with an air pressure maintainingvalve and an air electromagnetic valve through pipelines; a nozzle is fixedly arranged on the urea inlet; the nozzle is sequentially connected with a safety pressure limiting valve, a gear pump, a urea filter and a urea tank through pipelines; the tail end of the liquid outlet pipe is connected with a mechanical atomizer; and the atomizer is arranged on an exhaust pipe of the external diesel engine. The SCR urea jet device of the diesel engine has simple structure and is reasonable in design. Quantitative jet of aqueous solution of urea is realized through the electromagnetic nozzle; and meanwhile, the urea corrosion and high temperature resistant mechanical atomizer is directly arranged on the high temperature exhaust pipe by adopting an air assisting mode, so that the reliability of thesystem is promoted.

Owner:ZHEJIANG BONDLYE ENVIRONMENTAL TECH CO LTD

LED bracket with good moisture-proof performance, LED device and preparation method thereof

ActiveCN104064656AExtend the infiltration pathImprove moisture resistanceSemiconductor devicesMoistureMetal

The invention discloses an LED bracket with good moisture-proof performance, an LED device and a preparation method thereof. The LED bracket comprises as a first pad and a second pad as conductive pins and reflective cups arranged on the pads. The first pad and the second pad are connected through an insulation block. The contact surfaces of the first pad and the second pad with the bottoms of the reflective cups are provided with metal lugs, and the metal lugs and the pads are integrally formed. Reflective side walls are formed by the inner side walls of the metal lugs and the inner walls of the reflective cups. The upper surfaces of the metal lugs are tightly attached with outer side walls and the bottom of the reflective cup, the outer side walls of the metal lugs are tightly attached with the bottoms of the reflective cups. The first pad and the second pad are also provided with water-adsorbing grooves which are arranged around the periphery of the metal lugs. Water-adsorbing material layers are filling the water-adsorbing grooves and are covered by the bottoms of the reflective cups. According to the LED bracket with good moisture-proof performance, the LED device and the preparation method, double water resistance with the use of the metal lugs and the water-adsorbing material layers in the water-adsorbing grooves is used, and the LED bracket and a package device with good moisture-proof performance and high reliability are obtained.

Owner:APT ELECTRONICS

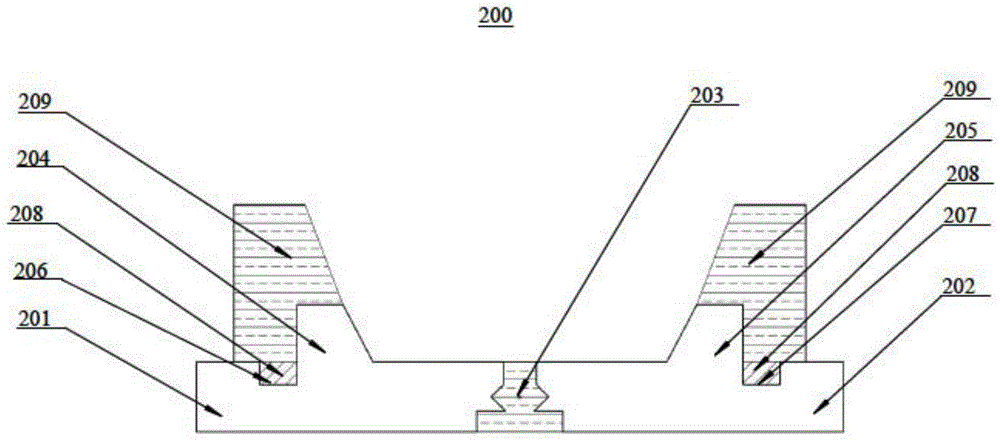

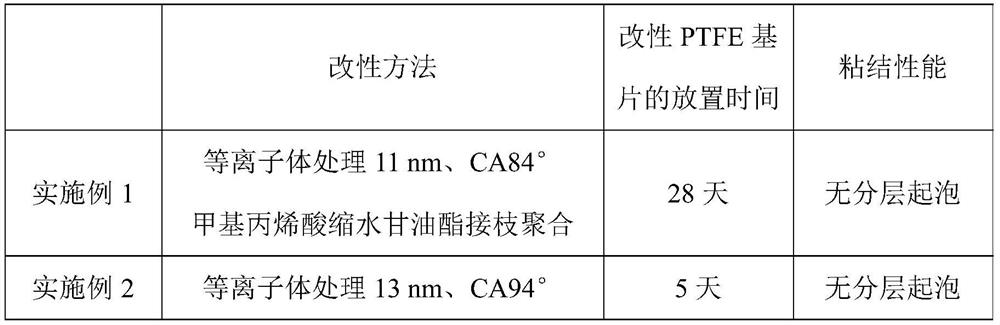

Inter-layer bonding sheet for multi-layer board and preparation method and application of inter-layer bonding sheet

ActiveCN112538186AMeet electrical performance requirementsExcellent dielectric propertiesPolyether coatingsMultilayer circuit manufactureDielectricPhysical chemistry

The invention provides an inter-layer bonding sheet for a multi-layer board and a preparation method and application of the inter-layer bonding sheet. The inter-layer bonding sheet for the multi-layerboard comprises a modified PTFE substrate and a dielectric resin layer bonded to the surface of the modified PTFE substrate. The modified PTFE substrate is a modified PTFE substrate of which the surface is subjected to plasmon and monomer graft polymerization treatment. A long-time-efficiency activation layer is formed on the PTFE substrate through the synergistic cooperation of plasma treatmentand monomer graft polymerization treatment, the activation property of the activation layer can be kept for 30 days, and the requirements of a manufacturing process and the requirements on product performance are fully met. According to the inter-layer bonding sheet for the multi-layer board provided by the invention, through the synergistic cooperation of the modified PTFE substrate and the dielectric resin layer, the dielectric property, the bonding strength, the mechanical property and the resistance are good, the bonding stability of the multi-layer board containing the inter-layer bondingsheet for the multi-layer board at high temperature is high, and the requirements of the multi-layer board for high frequency of signals, stability and reliability can be fully met.

Owner:GUANGDONG SHENGYI SCI TECH

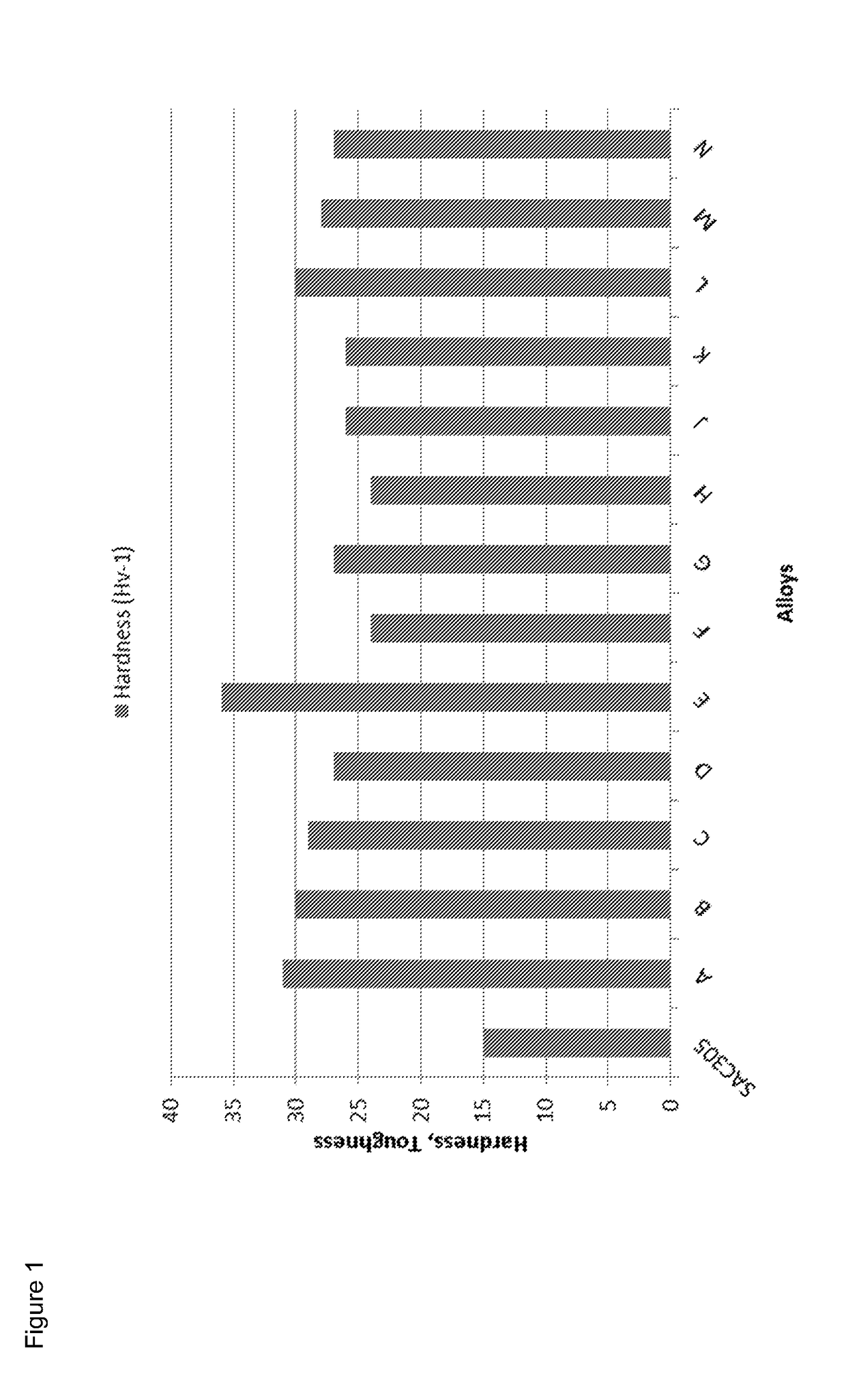

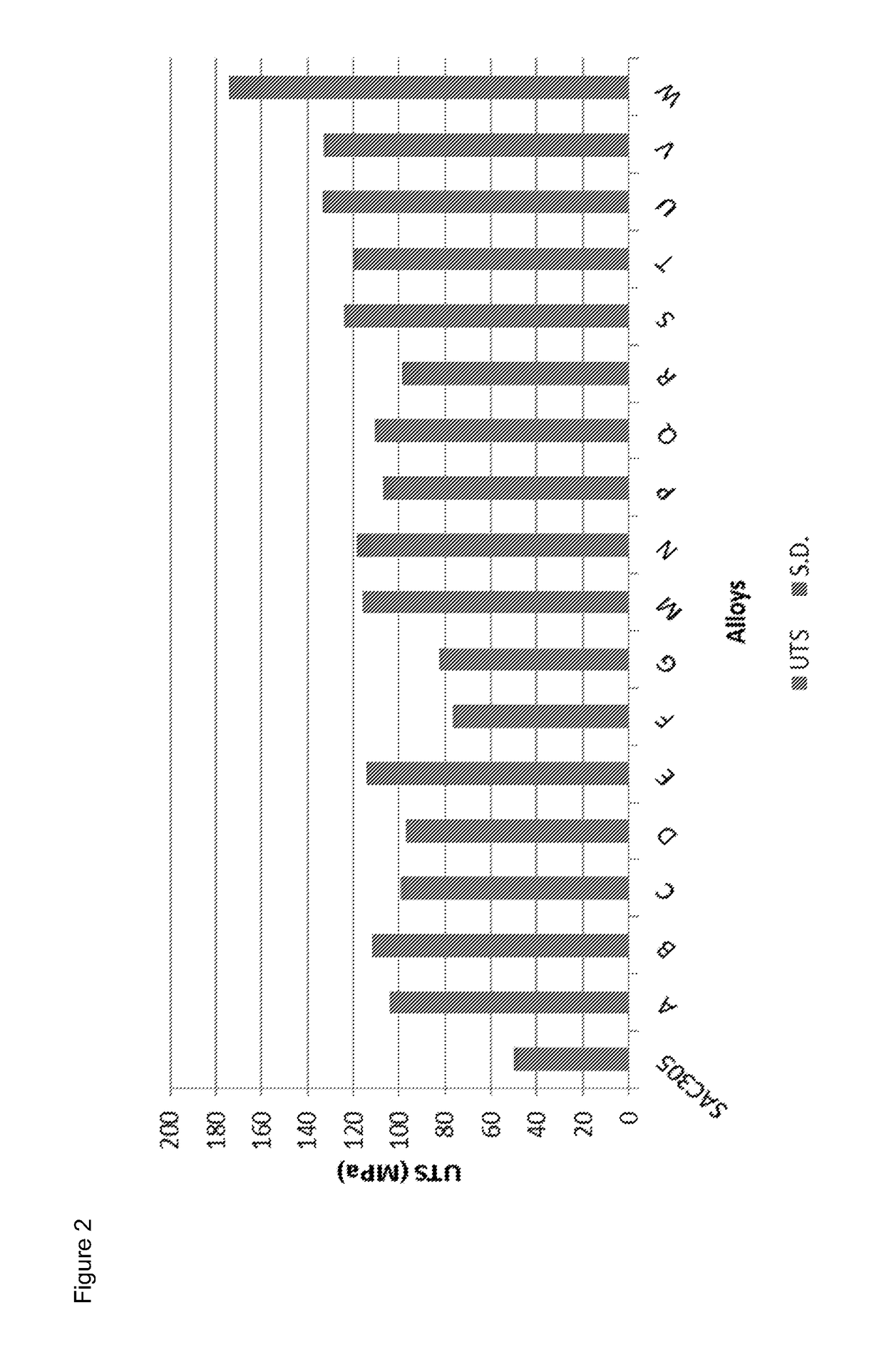

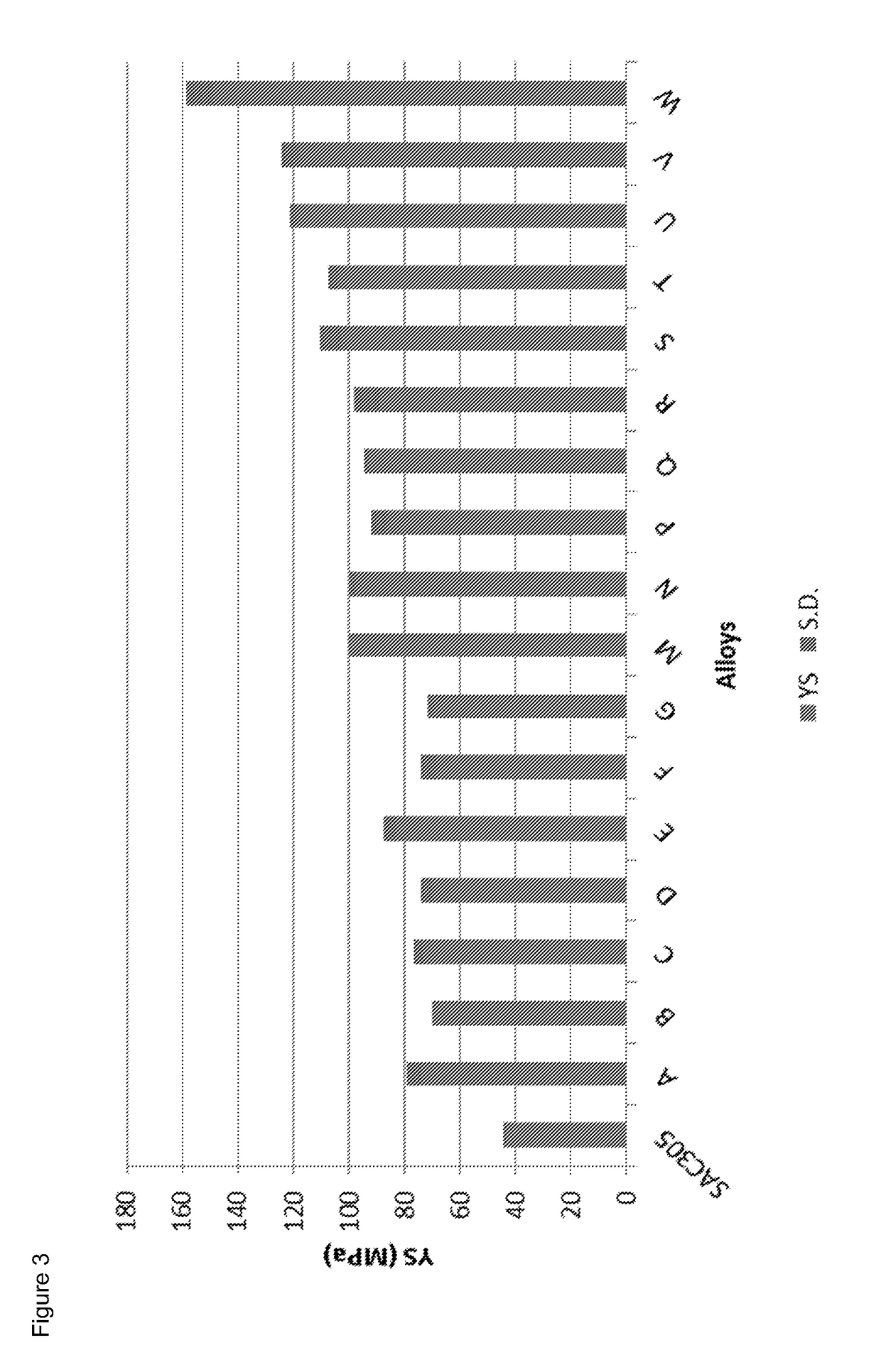

Low Temperature High Reliability Alloy for Solder Hierarchy

ActiveUS20170197281A1Improve high temperature reliabilityLow liquidus temperatureSemiconductor/solid-state device detailsSolid-state devicesIndiumCopper

A lead-free, antimony-free solder alloy_suitable for use in electronic soldering applications. The solder alloy comprises (a) from 1 to 4 wt. % silver; (b) from 0.5 to 6 wt. % bismuth; (c) from 3.55 to 15 wt. % indium, (d) 3 wt. % or less of copper; (e) one or more optional elements and the balance tin, together with any unavoidable impurities.

Owner:FRY S METALS INC

Interlayer bonding sheet for multilayer board as well as preparation method and application of interlayer bonding sheet

ActiveCN112442202AMeet electrical performance requirementsExcellent dielectric propertiesPolyether coatingsMultilayer circuit manufactureBonding strengthNaphthalene

The invention provides an interlayer bonding sheet for a multilayer board and a preparation method and application of the interlayer bonding sheet. The interlayer bonding sheet for the multilayer board comprises a PTFE substrate and a dielectric resin layer bonded to the surface of the PTFE substrate; the PTFE substrate is a PTFE substrate of which the surface is treated by a sodium naphthalene solution, and the surface treatment depth of the PTFE substrate is 0.5-2 microns; after the surface of the PTFE substrate is treated by a sodium naphthalene solution, the wettability is remarkably improved, and the PTFE substrate can be stably bonded with the dielectric resin layer in a high-strength manner. The interlayer bonding sheet for the multilayer board has excellent dielectric property, flowability and bonding strength through the synergistic cooperation of the PTFE substrate with the surface treated by the sodium naphthalene solution and the dielectric resin layer, is high in bonding stability, can fully meet the signal high-frequency requirement and the stability and reliability requirements of the multilayer board, and has bright application prospect.

Owner:GUANGDONG SHENGYI SCI TECH

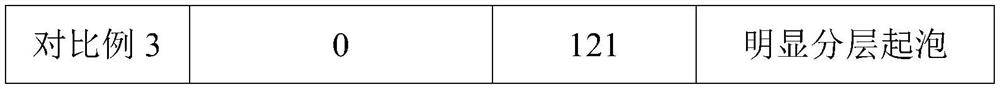

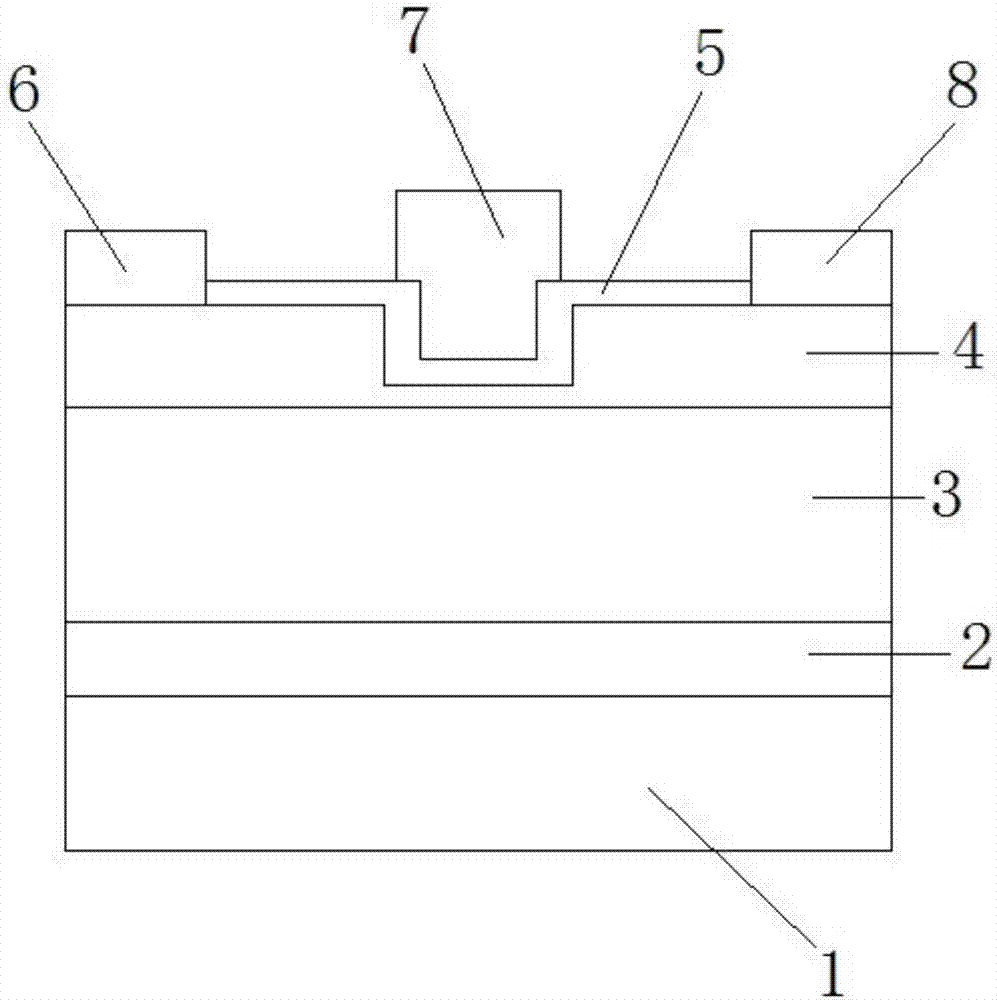

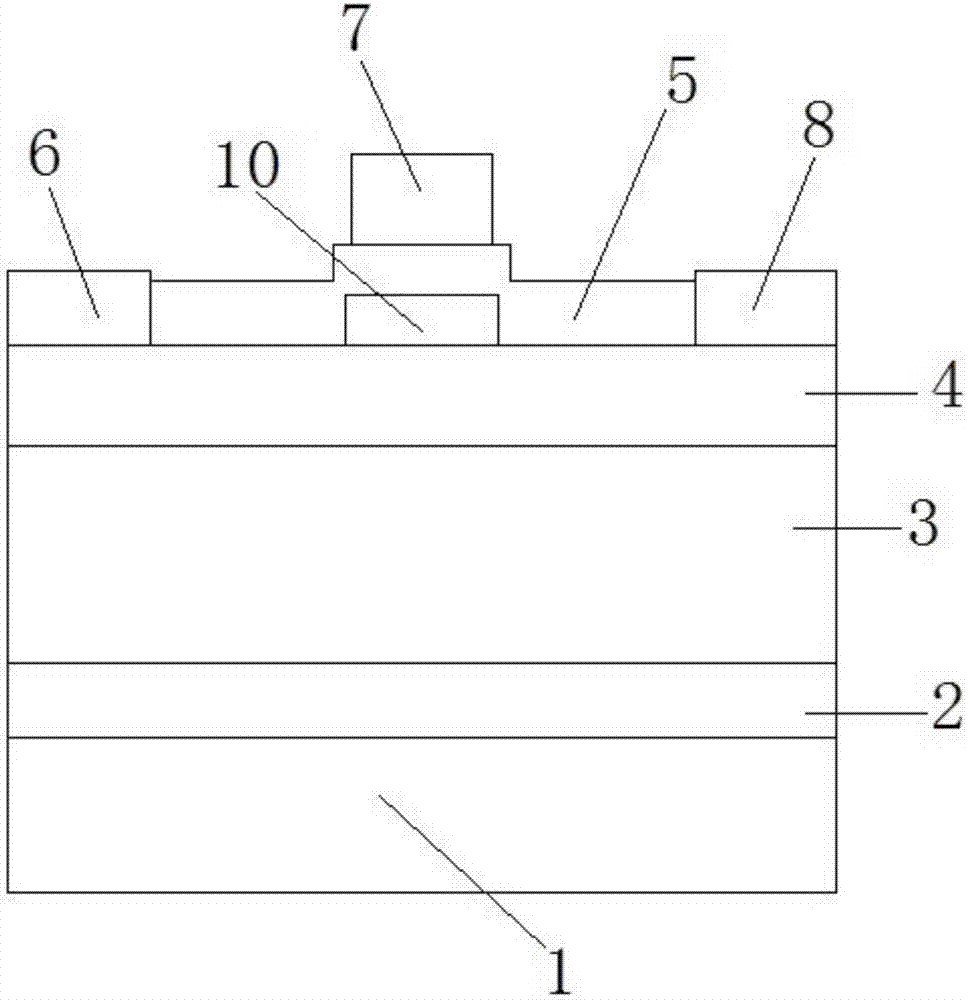

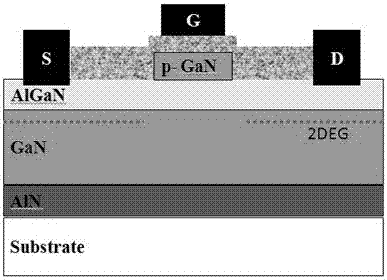

Graphene buried heat radiation layer and vertical channel GaN MISFET cellular structure and preparation method

PendingCN107393890ALower on-resistanceGood uniformity and repeatabilitySemiconductor/solid-state device detailsSolid-state devicesPhysicsVoltage

The invention discloses a graphene buried heat radiation layer and vertical channel GaN MISFET cellular structure and a preparation method; the cellular structure comprises a substrate, an AIN isolation layer, a graphene buried heat radiation layer, an AIN nucleating layer, a GaN buffer layer, a n type heavy doping GaN layer, a n type GaN layer, a P type GaN electronic stop layer, a non-doping GaN layer and an AlGaN barrier layer arranged from bottom to top; a cellular structure grating groove hole extends from the cellular structure top to the n type GaN layer; the gating groove hole side wall and bottom are respectively provided with a gate medium layer. An existing normally off GaN MISFET device cannot simultaneously have even and stable large threshold-voltage, low device conductive resistance and high switching rate; aiming at the normally off type GaN base III-V family material power device, the normally off GaN MISFET cellular structure with the vertical grid structure and the preparation method are provided so as to solve said problems, thus realizing GaN MISFET device stable large threshold-voltage normally off operations, and effectively reducing the device starting conduction resistance.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

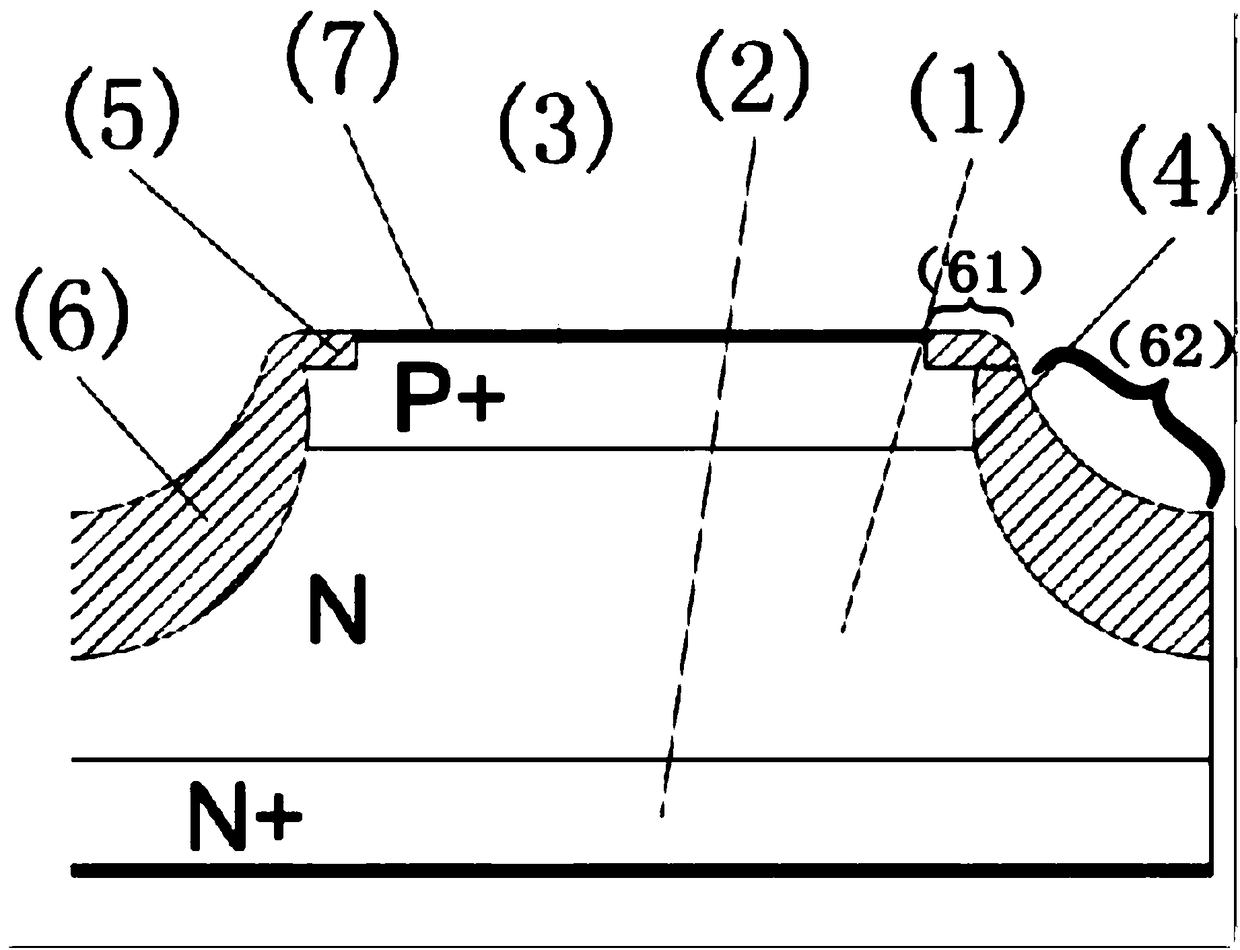

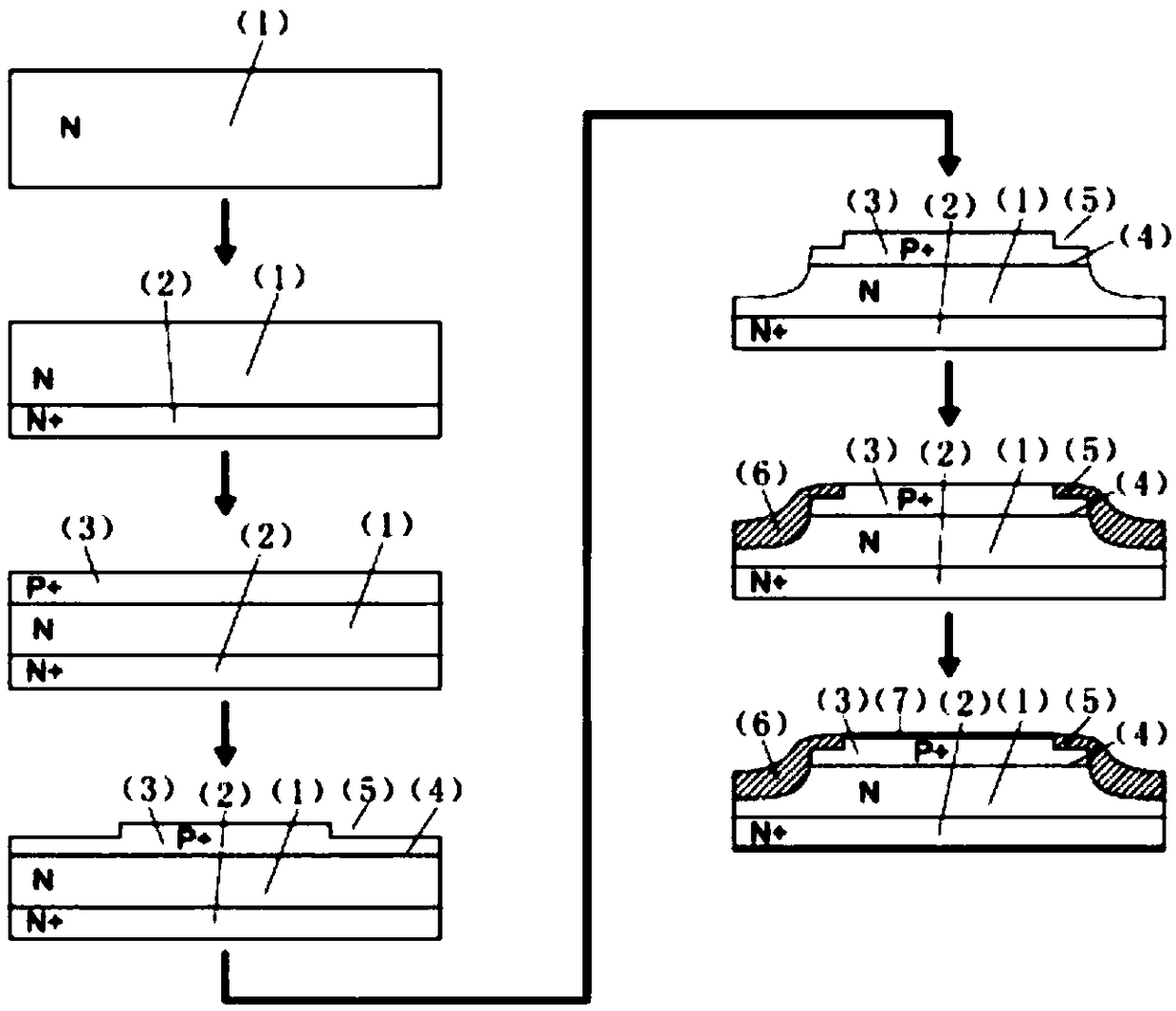

Semiconductor diode chip and manufacturing method thereof

InactiveCN108365015AIncreasing the thicknessIncrease the effective use areaSemiconductor/solid-state device detailsSolid-state devicesBeak shapeSand blasting

The invention belongs to the technical field of semiconductors, and relates to a diode chip, in particular to a semiconductor diode chip and a manufacturing method thereof. The semiconductor diode chip comprises a silicon chip substrate, wherein the bottom part of the silicon chip substrate is provided with a phosphorus diffusion layer, the upper part is provided with a boron diffusion layer, metal electrodes are arranged on the upper part of the boron diffusion layer and the bottom part of the phosphorus diffusion layer, a novel passivation layer is arranged at the outer side of the peripheryof the silicon chip substrate, and the novel passivation layer comprises a transition portion and a 'beak' portion. The manufacturing method comprises the steps of original sheet cleaning, diffusion,sand blasting, cleaning, primary photoetching, stepped corrosion, secondary photoetching, grooving corrosion, cleaning, passivation, third-time photoetching, metallization, electrical performance testing and scribing. The semiconductor diode chip has the advantages that the 'beak' portion of the semiconductor diode chip is protected by glass, the glass is not higher than the table board of the chip, ignition is not caused, the manufacturing cost is low (higher than that of a knife scraping manufacturing process, and lower than that of a photoresist manufacturing process), the effective use area of the chip is large, the VF is lower, the glass is thick, the pressure endurance capability is high, the service life is long, the high temperature reliability is high and the like.

Owner:济南兰星电子有限公司

Liquid crystal composition and liquid crystal display device thereof

ActiveUS20180119011A1Large maximum absolute transmittanceHigh voltage retentionLiquid crystal compositionsCrystallographyDielectric anisotropy

Provided is a liquid crystal composition, comprising: 1-30% of one or more compounds of general formula I; 1-50% of one or more compounds of general formula II; 1-20% of one or more compounds of general formula III; 20-70% of one or more compounds of general formula IV; and 1-30% of one or more compounds of general formula V. The liquid crystal composition has properties such as a large maximum absolute transmittance, a high voltage holding ratio, better anti-UV properties, and high temperature reliability, and has a suitable optical anisotropy, a suitable dielectric anisotropy, and a relatively high clearing point, and is environmentally friendly. The liquid crystal composition is suitable for use in a liquid crystal display device, especially a transmissive liquid crystal display element, enabling the liquid crystal display device to have properties such as a high maximum absolute transmittance, a high voltage holding ratio, good anti-UV properties and high temperature reliability, and to be energy-saving and environmentally-friendly.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Dielectric composition, and multilayered ceramic capacitor including the same as dielectric layer

InactiveUS20140177130A1Improve high temperature reliabilityLittle changeFixed capacitor electrodesFixed capacitor dielectricMaterials scienceDielectric layer

Disclosed herein are a dielectric composition including a compound represented by the following Chemical Formula A5-xB10O30-x (A necessarily includes Ba, and a portion of Ba is substituted by at least one selected from Sr and Ca; B necessarily includes Nb, and a portion of Nb is substituted by at least one selected from Ta and V; and x satisfies the following equation: 1<x<5) as a main component and a multilayered ceramic capacitor including the same as a dielectric layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

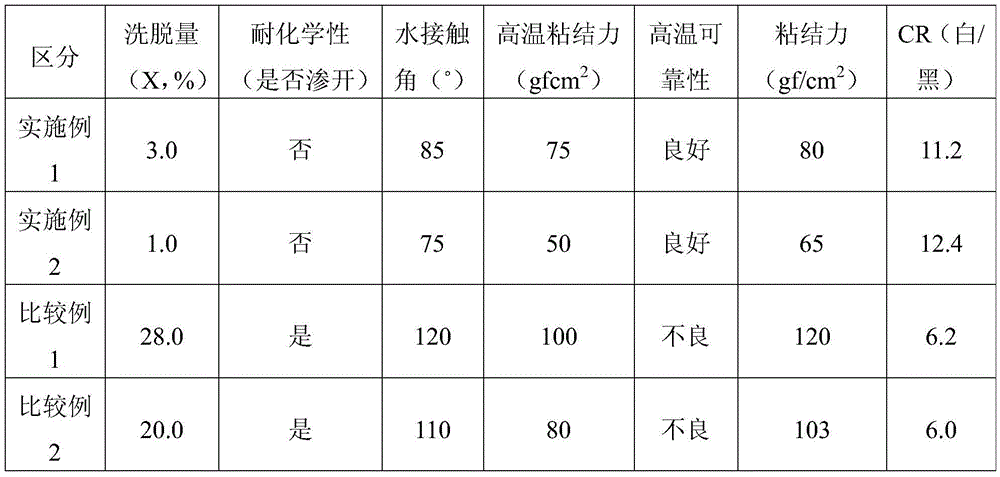

Composition for forming adhesive film, adhesive film for processing prior to photo-curing, adhesive film, and electronic paper display device

ActiveCN105579547AGood chemical resistanceImprove high temperature reliabilityFilm/foil adhesivesEpoxy resin adhesivesEpoxyDisplay device

Provided is a composition for forming an adhesive film, comprising: a phenoxy-based thermosetting resin; a cyclic epoxy-based photo-curable compound; an isocyanate-based heat hardening agent; and a cationic photoinitiator.

Owner:LG CHEM LTD

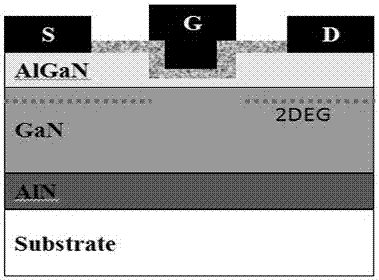

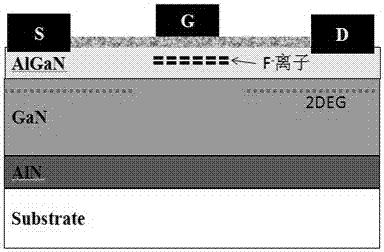

GaNHEMT cell structure with graphene buried source and longitudinal gate and preparation method

PendingCN107195674ALower turn-on resistanceIncrease the areaSemiconductor/solid-state device manufacturingSemiconductor devicesHigh densityGraphite

The invention discloses a GaNHEMT cell structure with a graphene buried source and a longitudinal gate. The source is connected with a graphene buried cooling layer through a metal material; the device adopts a longitudinal gate structure, a long transverse channel opening mode in the traditional HEMT device is turned to a short longitudinal channel opening mode, a long transverse current control channel is turned to a short longitudinal current control channel for the gate, the device uses a short gate side wall channel to realize switch control, and the on resistance of the device can be effectively reduced. A high-density cell structure can be realized, and the effective using area and the unit area power density of the device are improved; and by using the excellent thermal conductivity of the graphene, heat generated in an active area of the device can be conducted rapidly, the high-power GaNHEMT device can be realized, and the high-temperature reliability of the device can be enhanced.

Owner:BEIJING HUAJINCHUANGWEI ELECTRONICS CO LTD

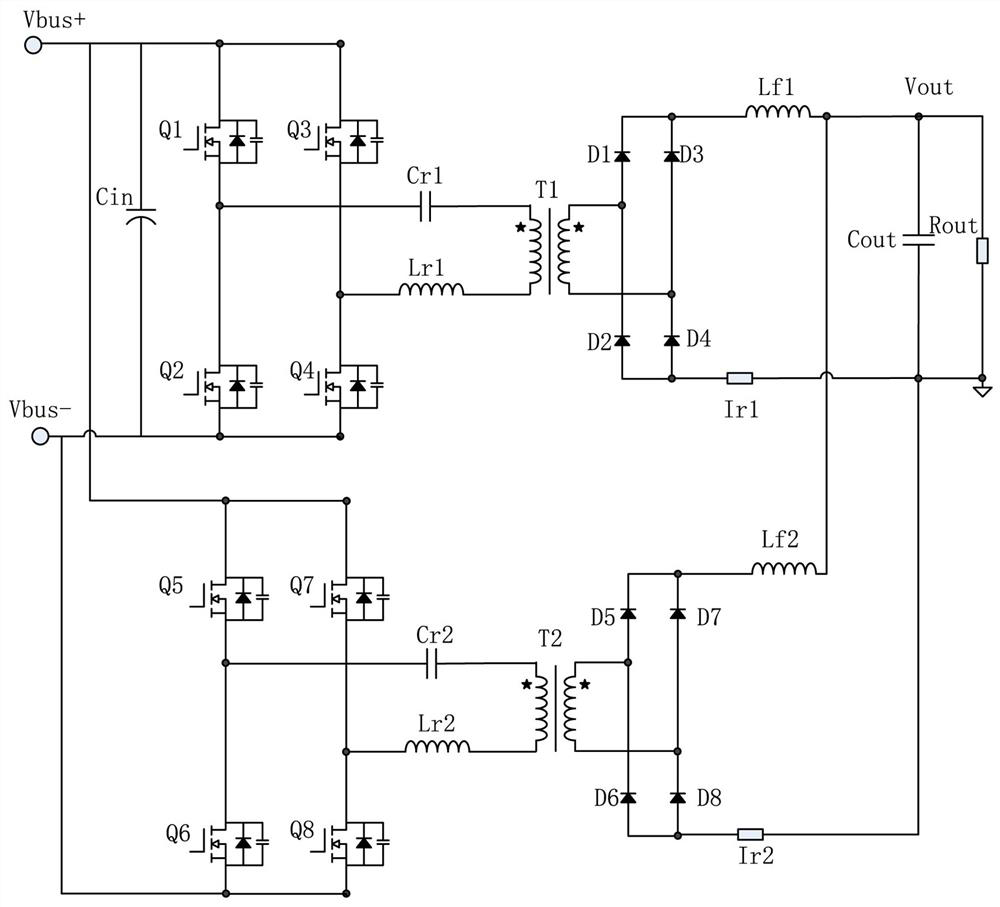

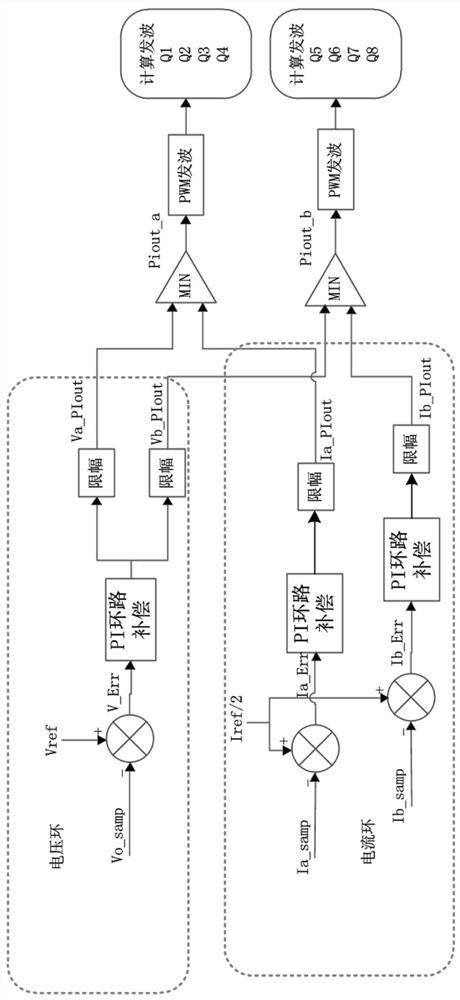

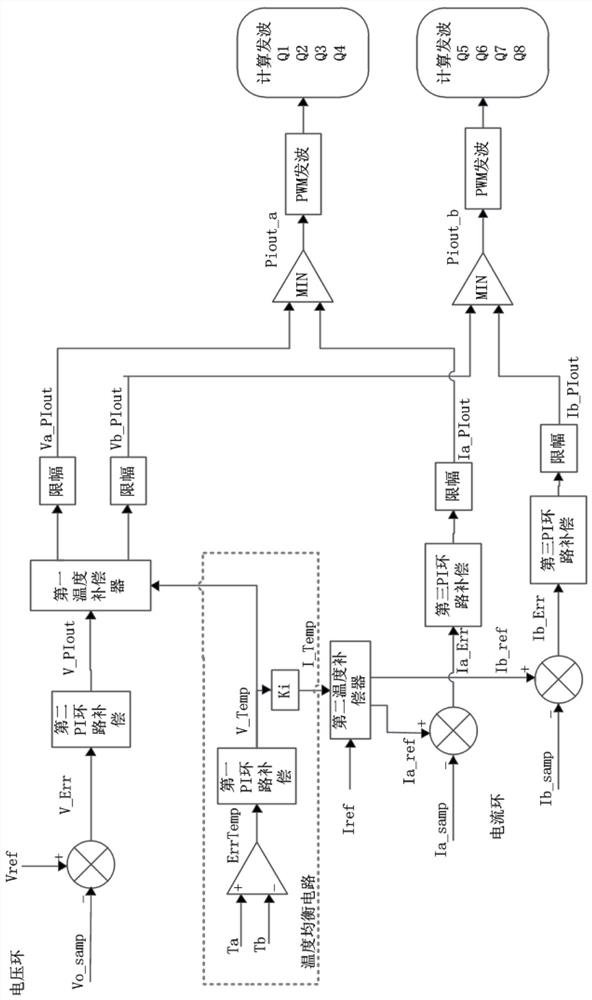

Automatic thermal equalization control device and method for interleaved parallel circuit

ActiveCN112467994ALifetime wear levelingSolve the technical problem of sharp decline in lifeApparatus with intermediate ac conversionElectric variable regulationControl signalControl engineering

The invention discloses an automatic thermal equalization control device and method for an interleaved parallel circuit, and the device comprises a temperature equalization circuit and acontrol loop;the temperature equalization circuit is used for generating a temperature compensation signal based on a temperature signal corresponding to each power circuit of the interleaved parallel circuit, andthe temperature compensation signal is used for compensating the temperature difference between the power circuits; and the control loop is connected with the temperature equalization circuit and isused for generating a driving control signal based on the output sampling signal of each power supply circuit and the temperature compensation signal, and the driving control signal is used for controlling a control signal generator for controlling a switching element of each power supply circuit.

Owner:SHENZHEN WINLINE TECH

Multilayer ceramic capacitor

ActiveUS20220102076A1Improve propertiesImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricRare-earth elementLutetium

A multilayer ceramic capacitor includes a base body including first and second main surfaces, first and second side surfaces, first and second end surfaces, and dielectric layers and internal electrode layers, and external electrodes at the first and second end surfaces, and electrically connected to the internal electrode layers. The base body includes an inner layer, first and second outer layers, first and second side margin portions. The dielectric layers in the inner layer and the first and second outer layers include main crystal grains including barium and titanium, and with respect to 100 parts by mol of titanium, nickel in an amount of about 0.2 to about 3.0 parts by mol, and at least one rare earth element selected from yttrium, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium in an amount of about 0.6 parts to about 2.0 parts by mol.

Owner:MURATA MFG CO LTD

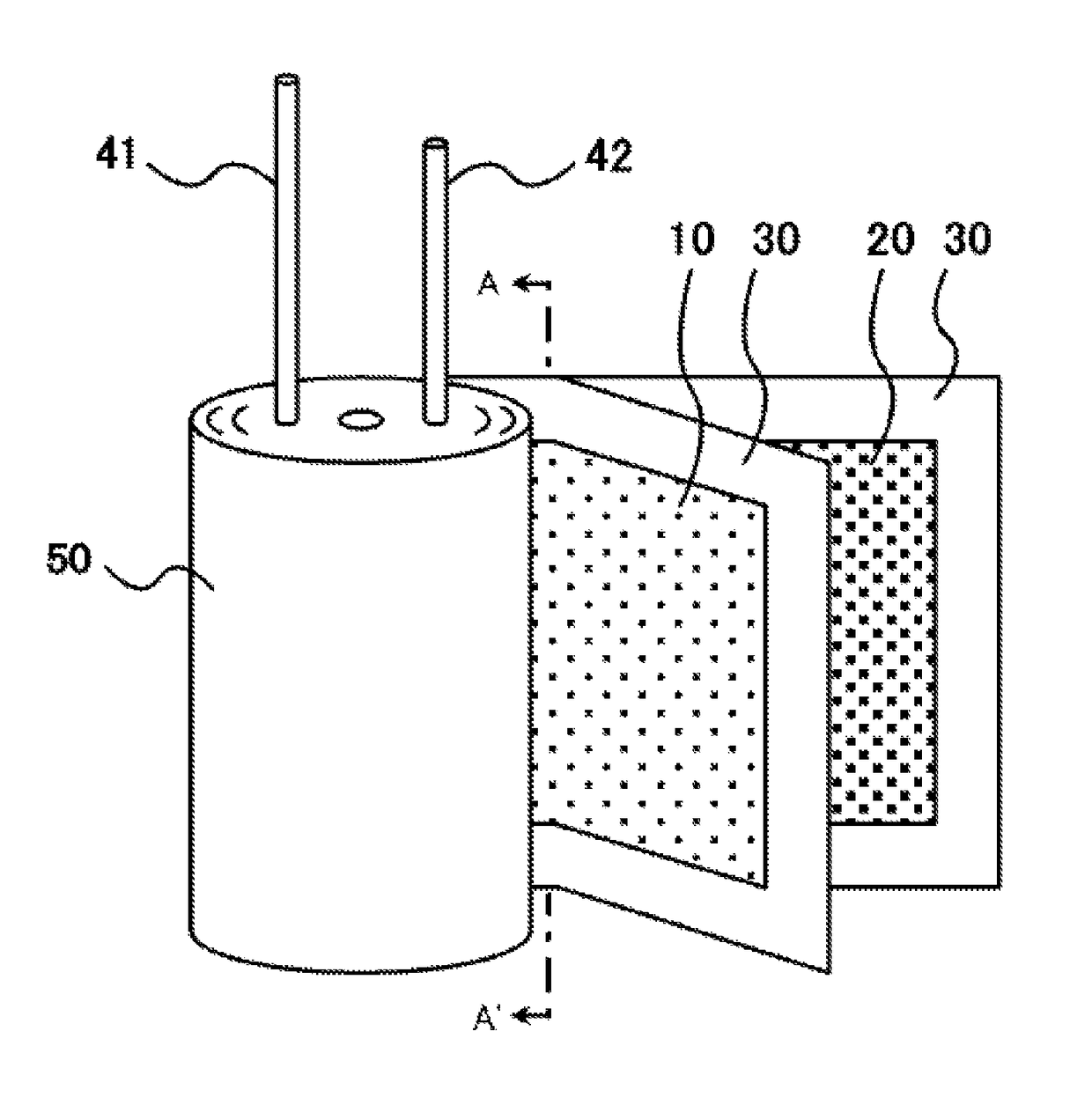

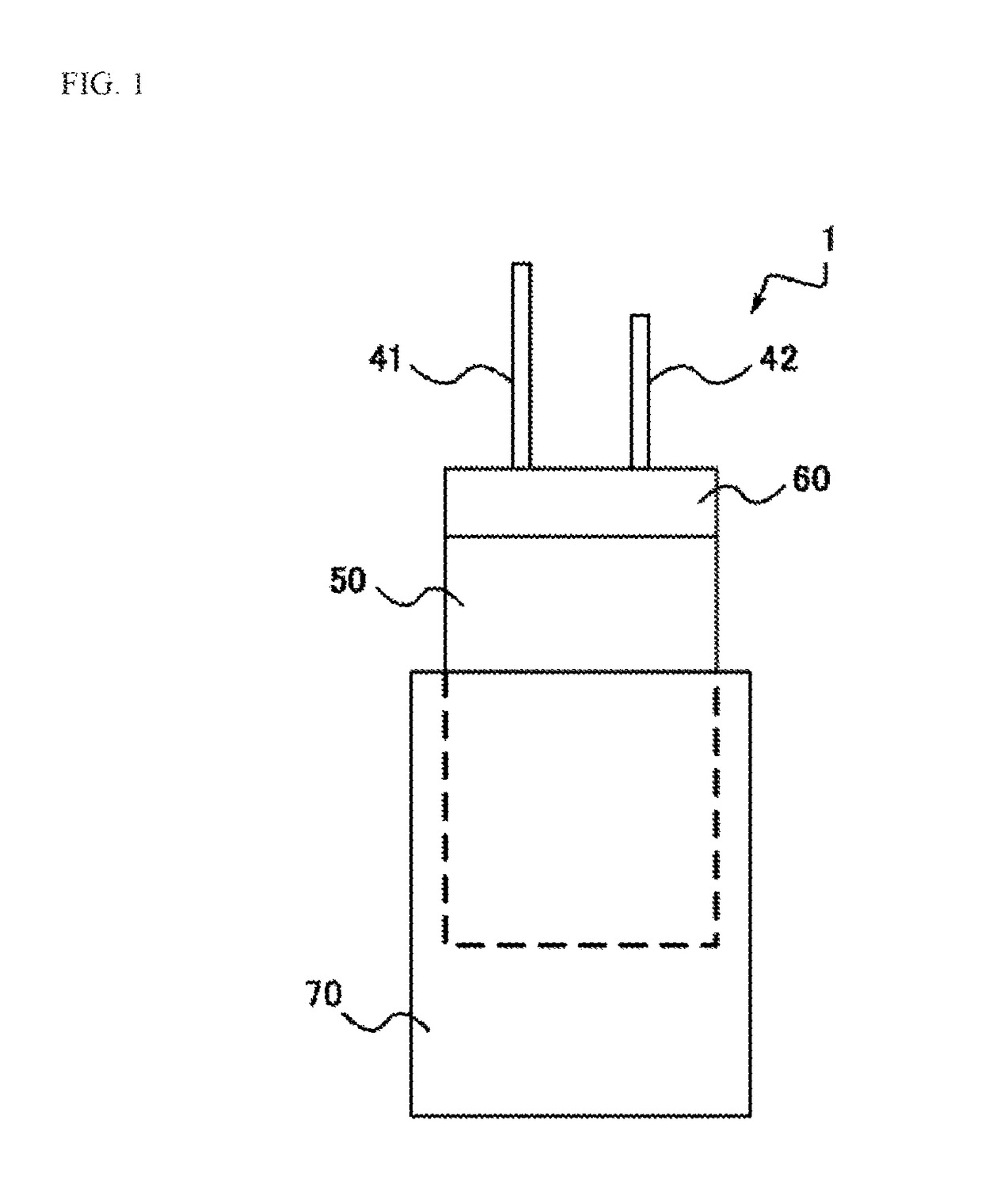

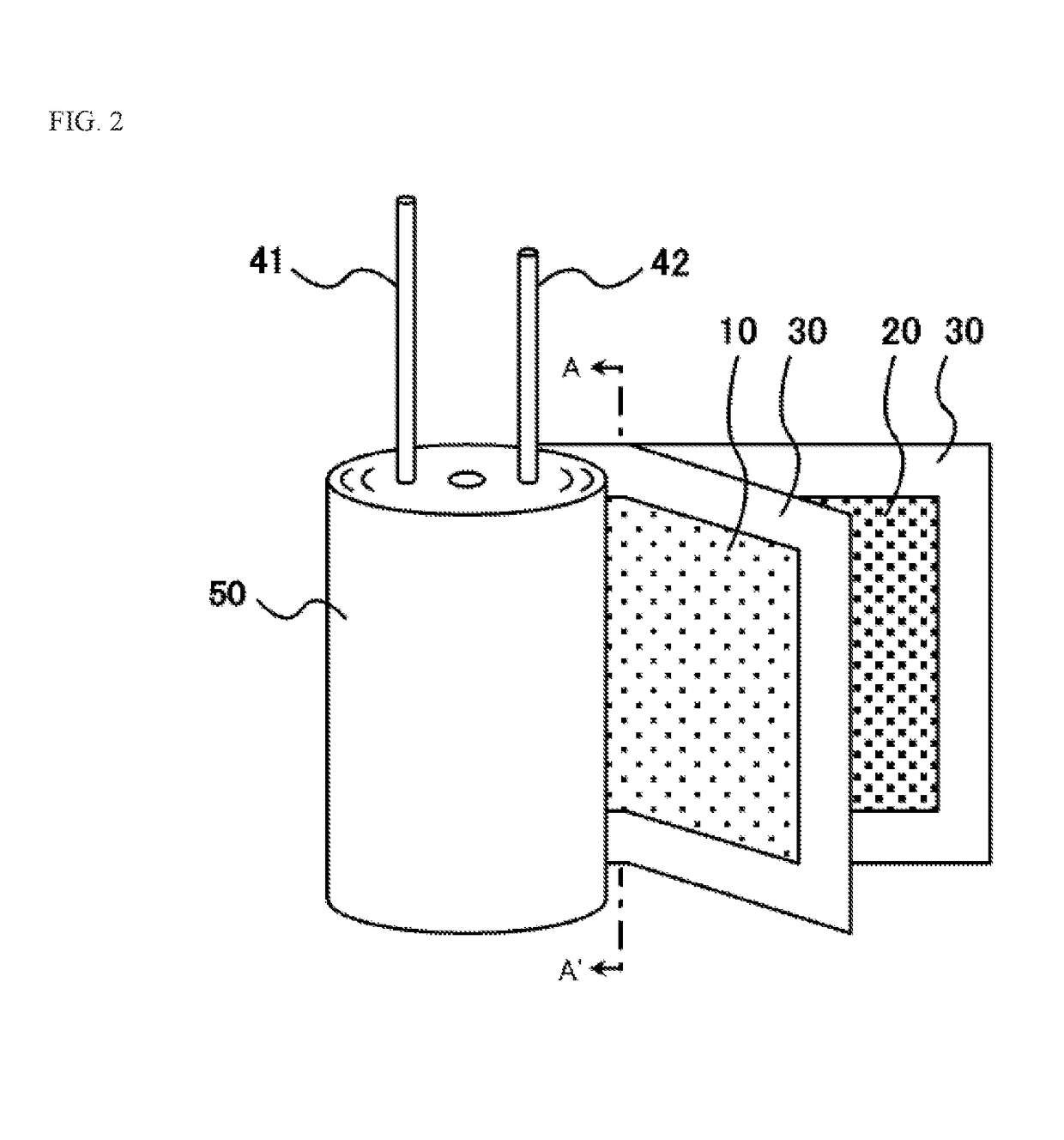

Electric storage device

ActiveUS10115535B2Improve featuresImprove high temperature reliabilityHybrid capacitor electrolytesSulfonateLithium

In an embodiment, an electric storage device 1 includes: an electric storage element 50 having a positive electrode and a negative electrode; a non-aqueous electrolytic solution constituted by a non-aqueous solvent primarily containing cyclic ester and cyclic carbonate ester, in which an electrolyte containing lithium salt is dissolved and to which a sulfonate ester derivative whose reduction potential is higher than that of the cyclic ester and cyclic carbonate ester is added; and an outer container 70 that stores the electric storage element 50 and non-aqueous electrolytic solution. The electric storage device can offer both good low-temperature characteristics and good high-temperature reliability.

Owner:TAIYO YUDEN KK

Preparation method of high thermal conductivity phase change temperature control composite packaging substrate

InactiveCN108831837AHighly integratedLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesComposite substrateAlloy

The invention discloses a preparation method of a high thermal conductivity phase change temperature control composite packaging substrate, wherein, a low-melting-point alloy solid phase change material is integrated directly into an LTCC-ALN composite substrate and a phase change temperature control device with high integration and high thermal conductivity is formed. The invention is realized bythe following technical scheme: a phase change temperature control cavity is produced on the middle AlN green ceramic plate of the multi-layer AlN green ceramic plate, and then the aluminum nitride AlN substrate embedded with the sandwich of the phase change temperature control cavity is formed by laminated isostatic pressing and co-firing; matrix-distributed electronic component mounting cavities are fabricated on the LTCC green ceramic substrate, and then the AlN substrate and the LTCC green ceramic substrate are laminated and co-fired to form the LTCC-AlN composite substrate in which an electronic active device can be embedded. At last, solid phase change material of the low melting point alloy is heated and melted into the liquid state and poured into the phase change temperature control cavity of the composite substrate, and the phase change temperature control composite substrate with high thermal conductivity is prepared by sealing a cover plate.

Owner:10TH RES INST OF CETC

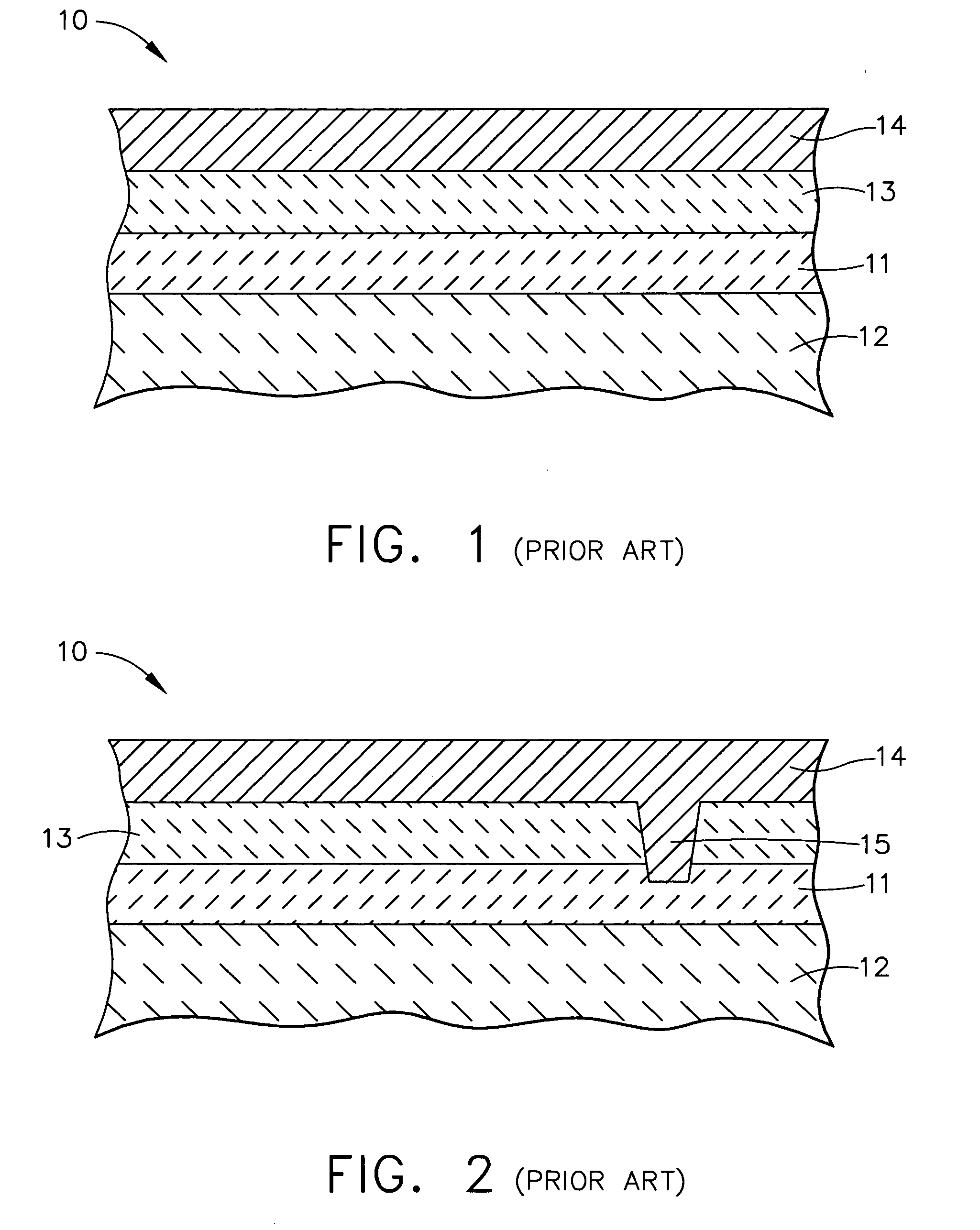

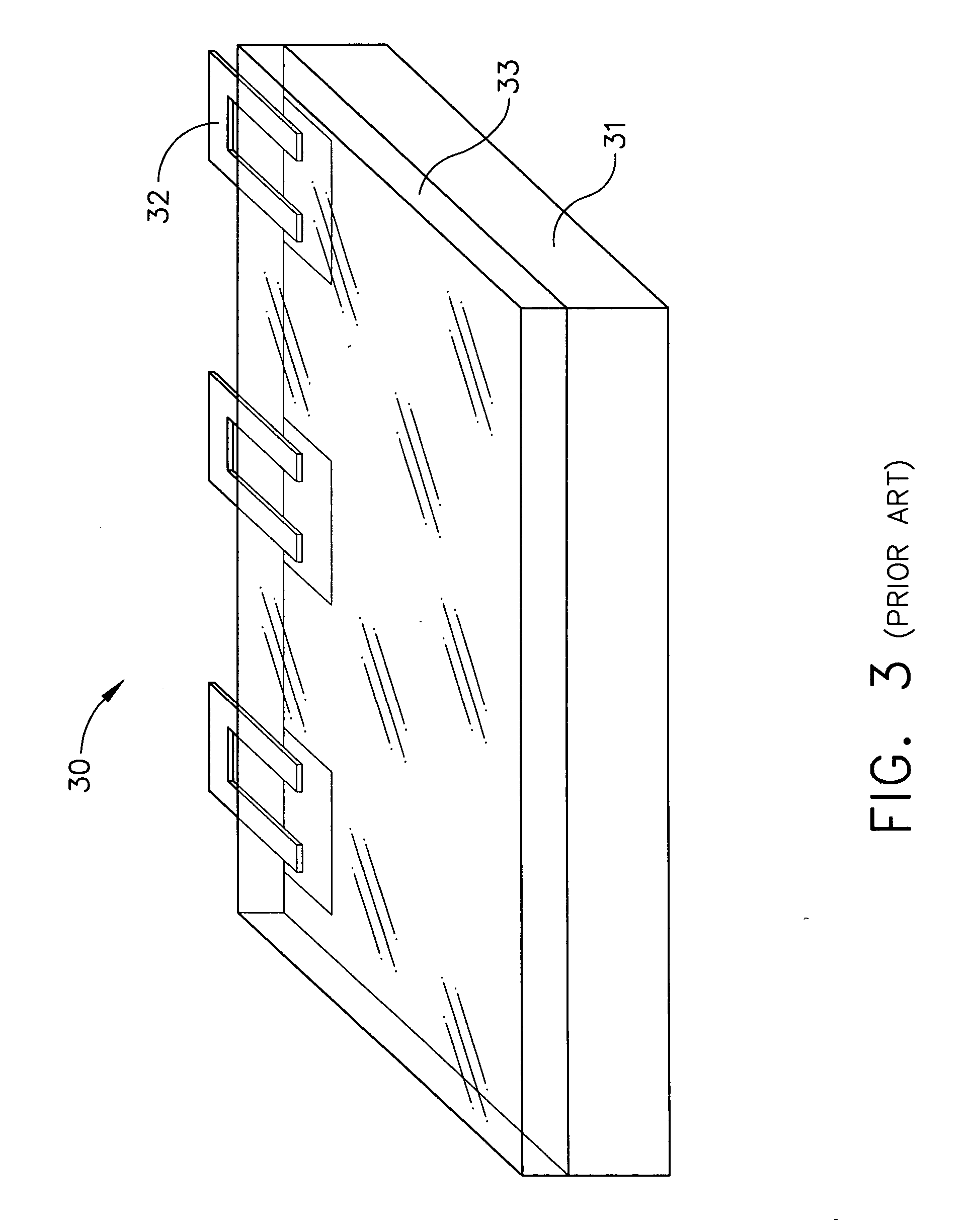

Semiconductor structure with metal migration semiconductor barrier layers and method of forming the same

ActiveUS20050133919A1Improve high temperature reliabilityImproving performance and high-temperature reliability and stabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureContact layer

A semiconductor structure includes a semiconductor substrate, a semiconductor active region, a semiconductor contact layer, at least one metal migration semiconductor barrier layer, and a metal contact. The metal migration semiconductor barrier layer may be embedded within the semiconductor contact layer. Furthermore, the metal migration semiconductor barrier layer may be located underneath or above and in intimate contact with the semiconductor contact layer. The metal migration semiconductor barrier layer and the semiconductor contact layer form a contact structure that prevents metals from migrating from the metal contact into the semiconductor active layer during long-term exposure to high temperatures. By providing a robust contact structure that may be used in semiconductor structures, for example in solar cells that power spacecraft or terrestrial solar cells used under concentrated sunlight, the high temperature reliability of the semiconductor structure will be improved and the operation time will be prolonged.

Owner:THE BOEING CO

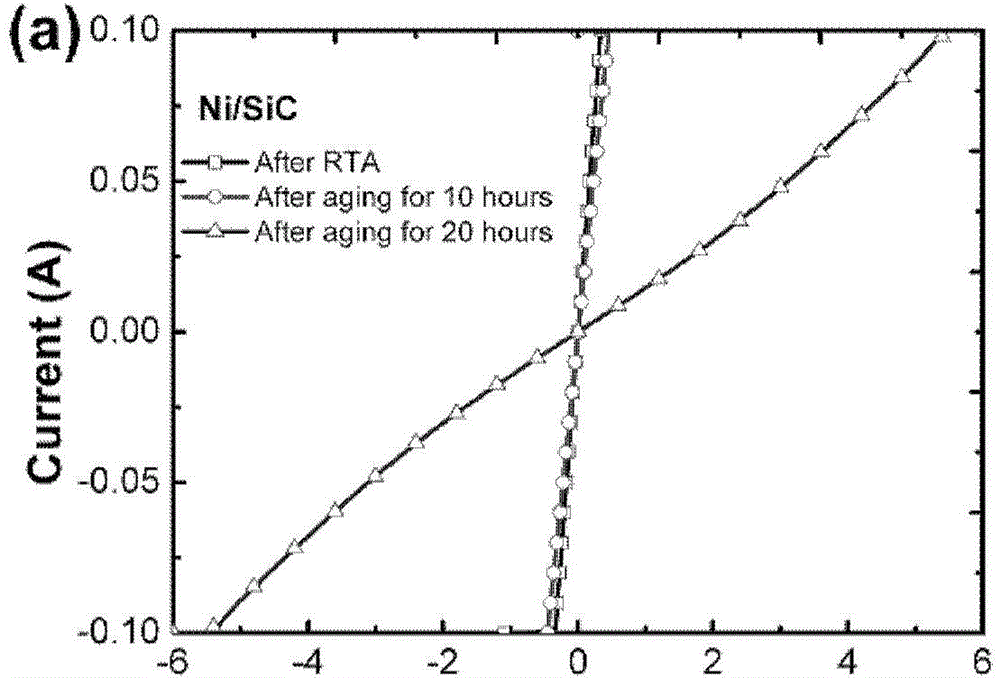

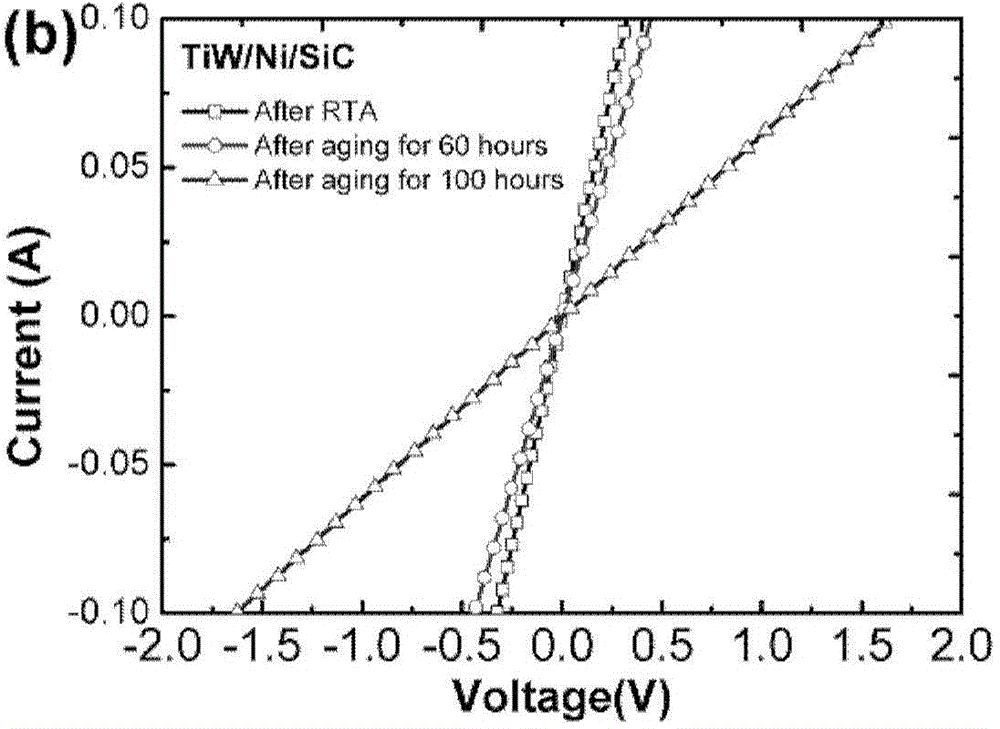

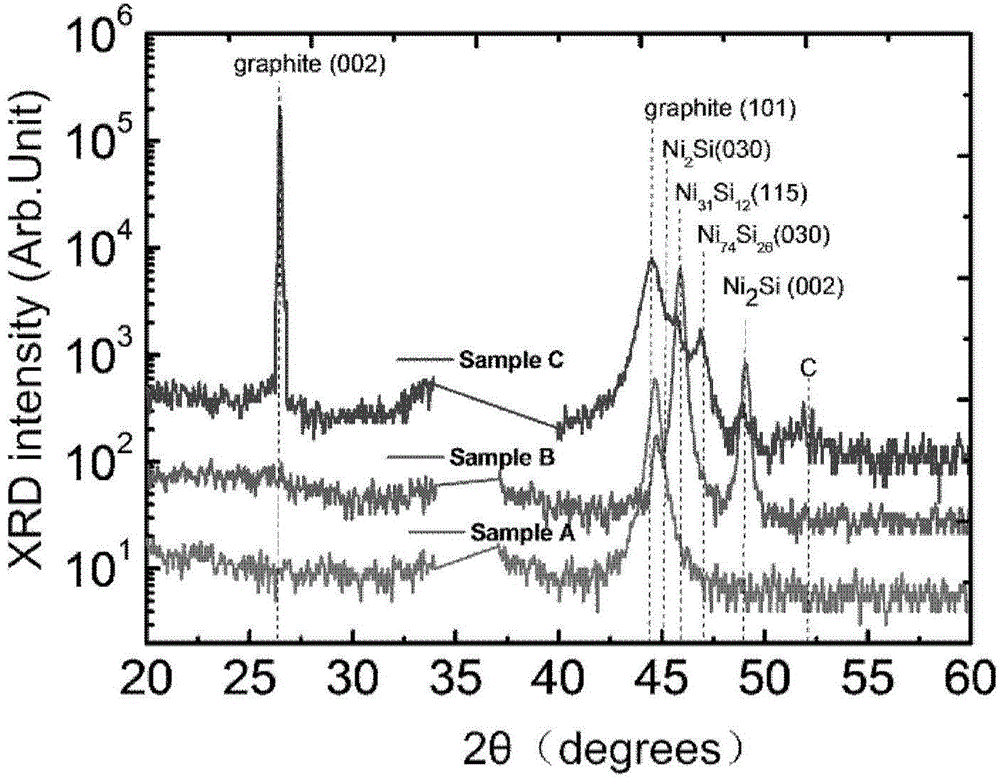

Silicon carbide ohmic contact electrode and manufacturing method of silicon carbide ohmic contact electrode

InactiveCN104538294APrevent oxidation failureImprove reliabilitySemiconductor devicesPartial oxidationOhmic contact

The invention discloses a silicon carbide ohmic contact electrode and a manufacturing method of the silicon carbide ohmic contact electrode. The manufacturing method includes the steps of providing a SiC wafer material, and cleaning the surface of a SiC wafer; depositing ohmic contact metal Ni on the surface of the SiC wafer; depositing TiW alloy on the ohmic contact metal Ni; conducting high-temperature annealing on ohmic contacts, and completing manufacturing of SiCohmic contact structures. According to the silicon carbide ohmic contact electrode and the manufacturing method, as the TiW alloy has certain oxidation resistance, ohmic contact partial oxidation efficacy losing in the ohmic contact annealing and follow-up technological process can be prevented; the ohmic contacts of TiW / Ni / SiC structures have the better reliability compared with ohmic contacts of Ni / SiC structures.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

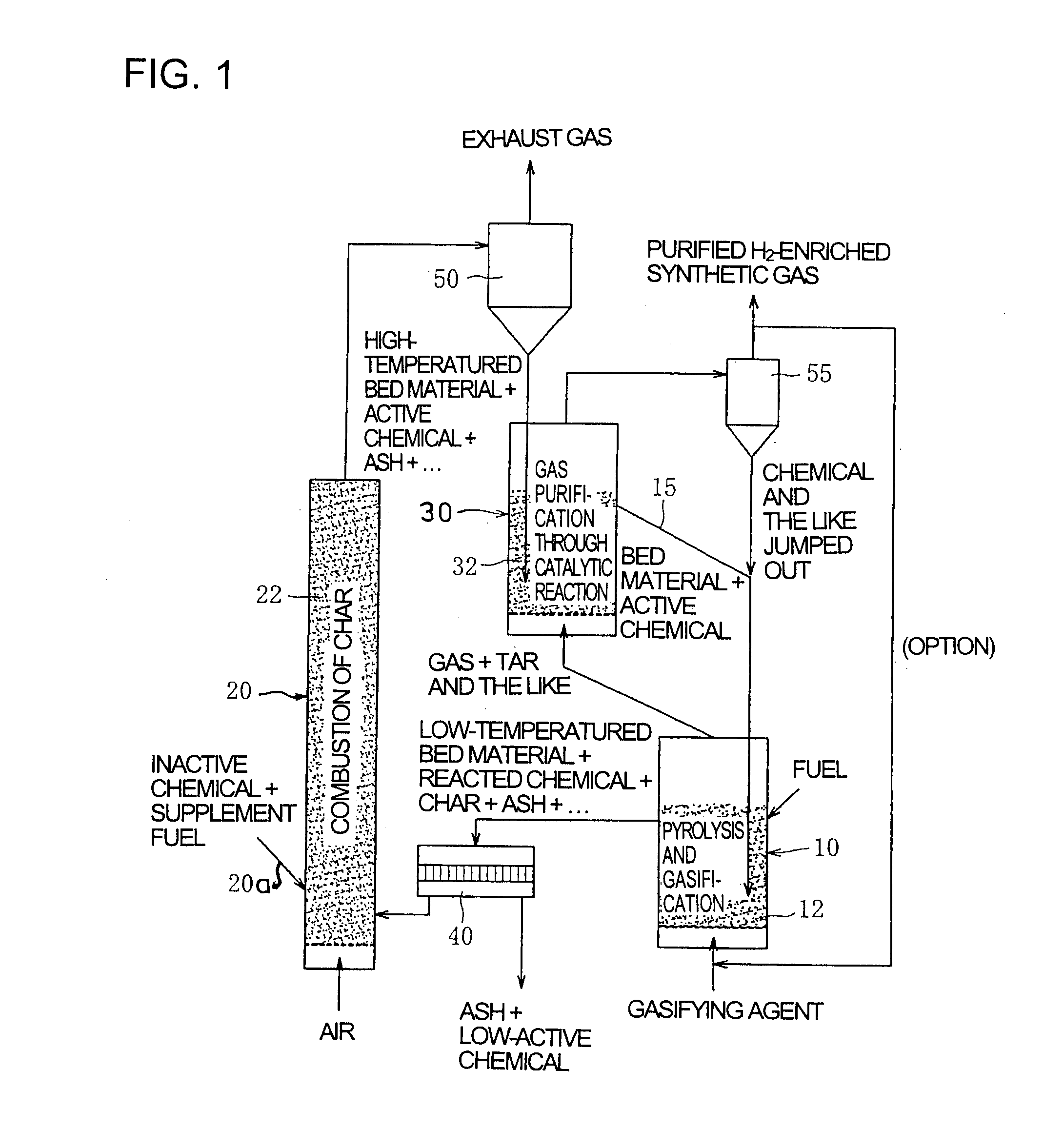

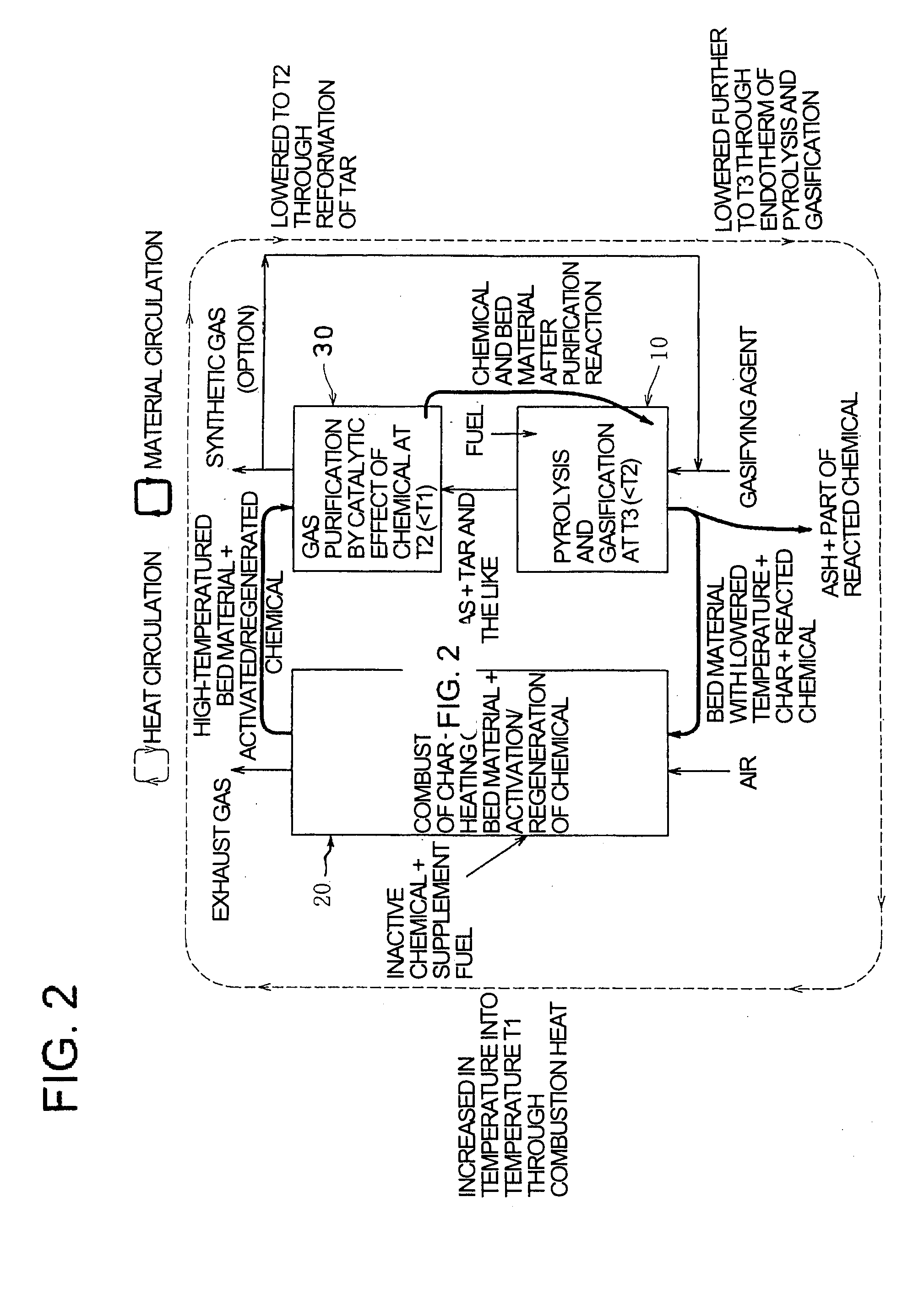

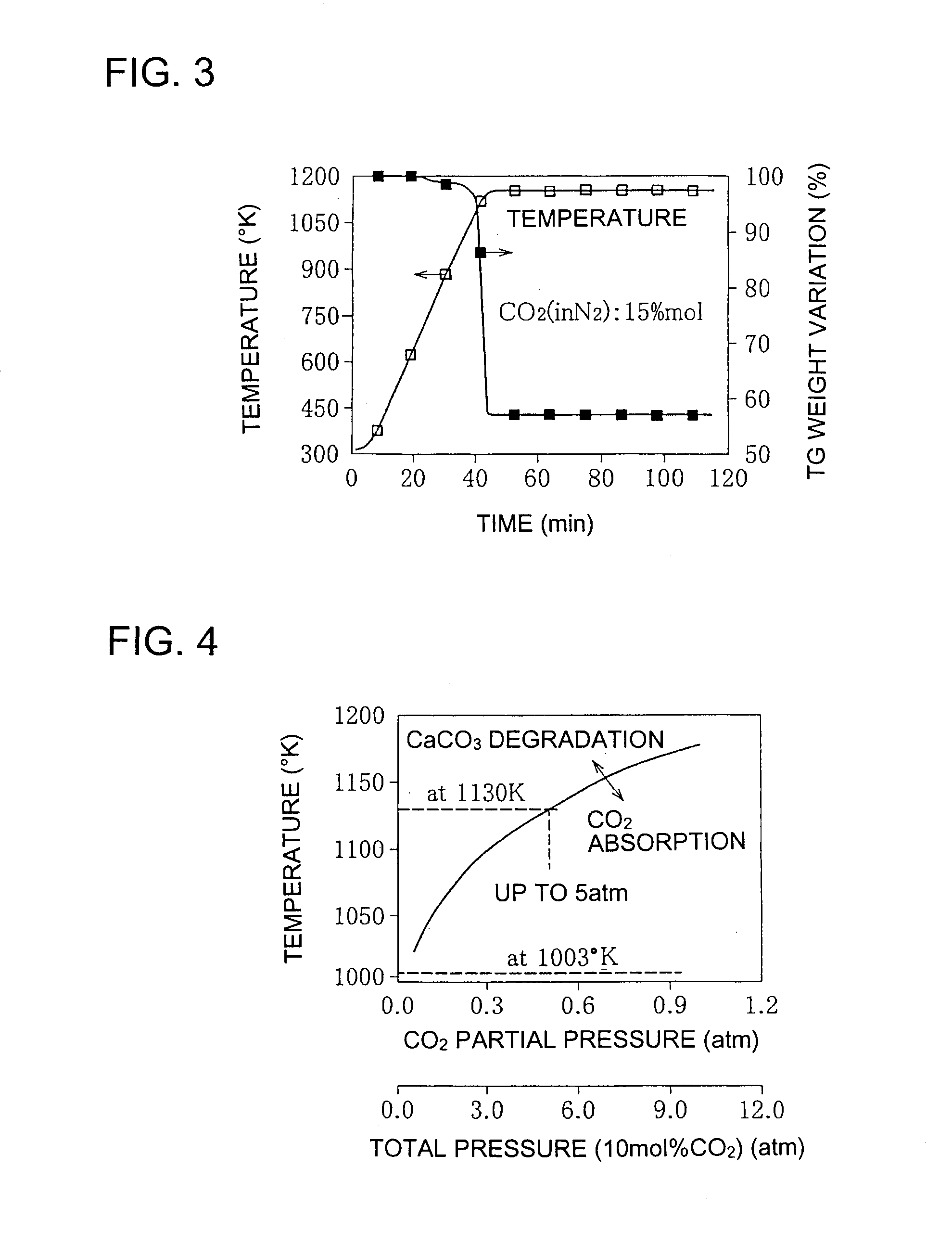

Method for gasifying solid fuel with unified gas purification and gasifier using said method

ActiveUS20120167467A1Quality improvementFully absorbedHydrogenCombustible gas catalytic treatmentChemical reactionHeat transmission

A gasification process is divided into three processes: a gasification furnace for carrying out gasification process by pyrolysis and gasification (pyrolysis gasification phase, first process), a combustion furnace for burning char to obtain calcined active chemical (char combustion phase, second process) and a gas purification furnace for purifying gasified gas (gasified gas purification phase, third process). Through heat transmission by the fluid heat medium and chemical reactions in respective phases by the chemical, the gasification furnace is independently controlled to a low or medium temperature (773-1073 K) which is required for gasification and which enables absorption of CO2; and the gas purification furnace is controlled to a high temperature (1073 K or more) required for gas purification.

Owner:IHI CORP

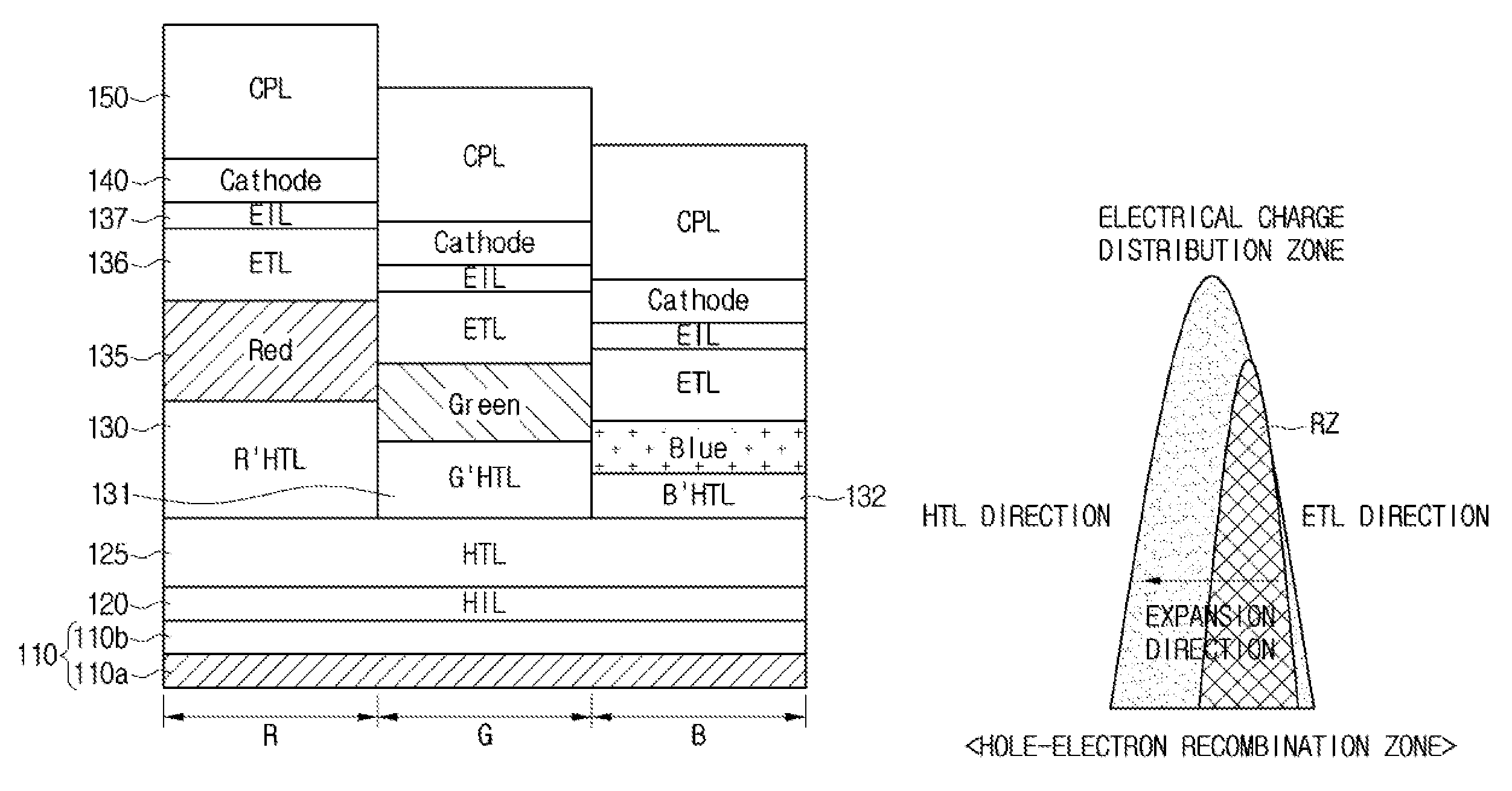

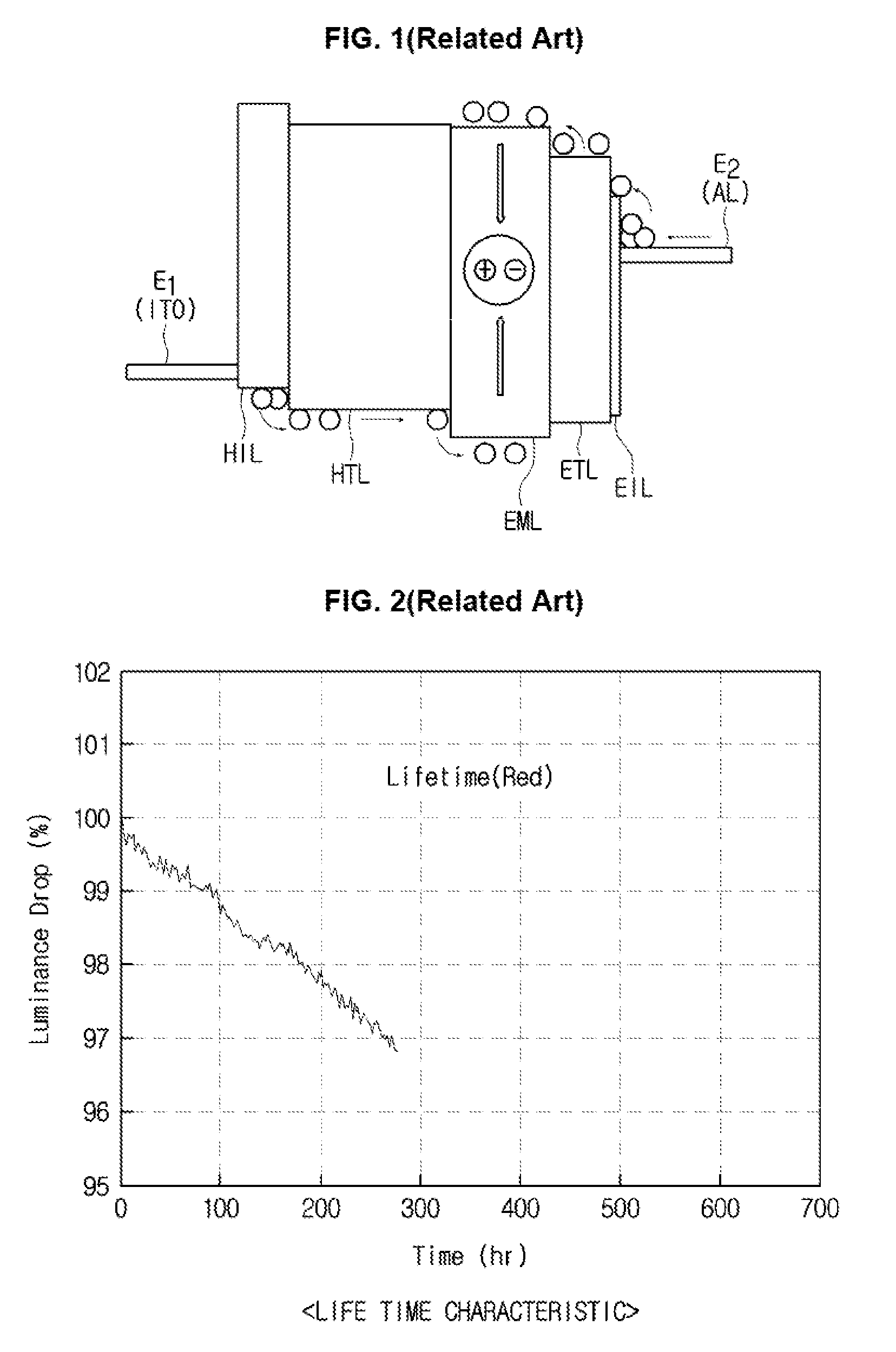

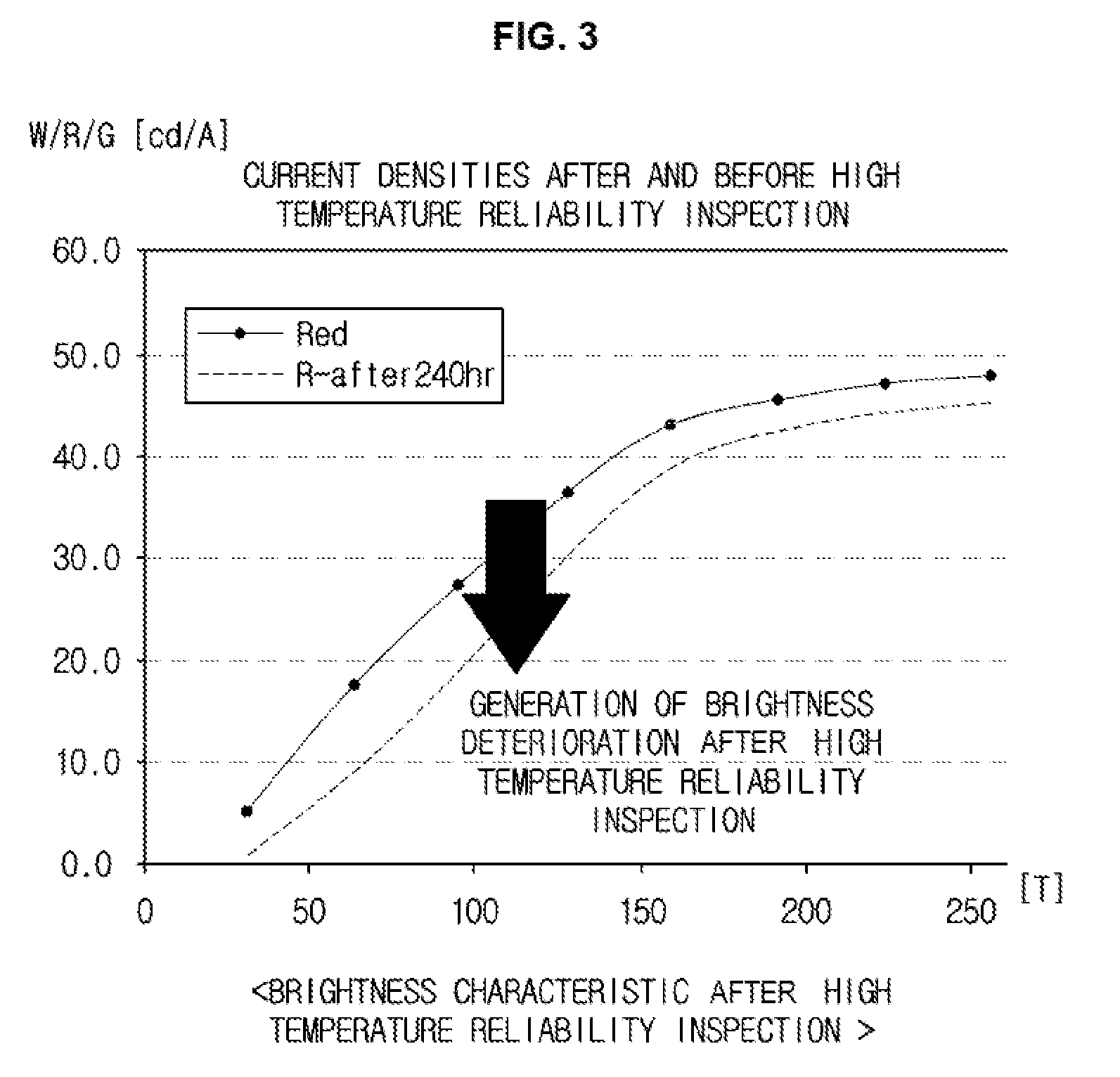

Organic light emitting display device

ActiveUS9324963B2Improve lighting efficiencyExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerTransport layer

An organic light emitting display device is disclosed which includes: a first electrode including red, green and blue sub-pixel regions; a first hole injection layer disposed on the first electrode; a first hole transport layer disposed on the hole injection layer; second, third and fourth hole transport layers arranged on the first hole transport layer corresponding to the red, green and blue regions, respectively; an organic emission layer disposed on the second, third and fourth hole transport layers; an electron transport layer disposed on the organic emission layer; and a second electrode disposed on the electron transport layer, the second, third and fourth hole transport layers each having a hole mobility different from an electron mobility of the electron transport layer.

Owner:LG DISPLAY CO LTD

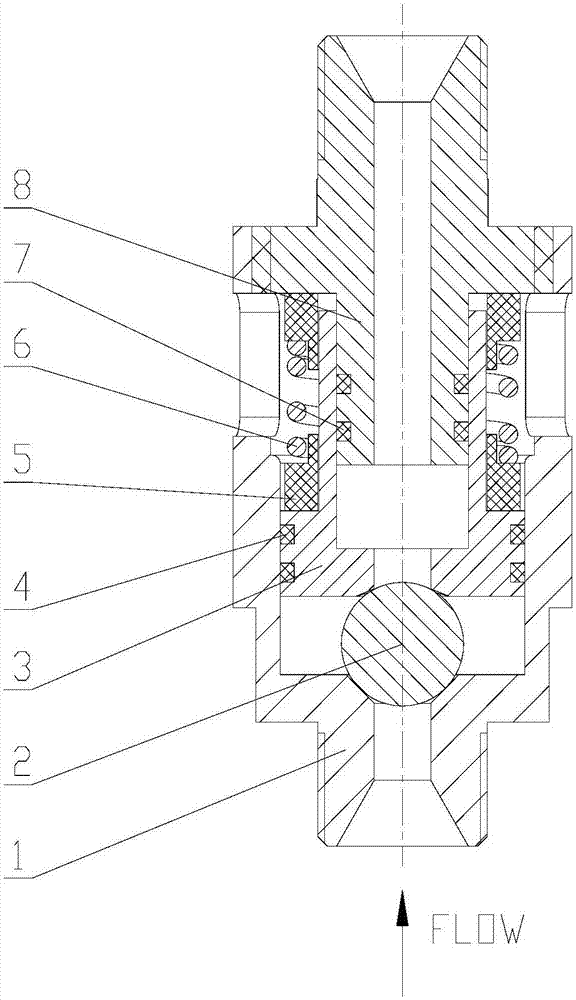

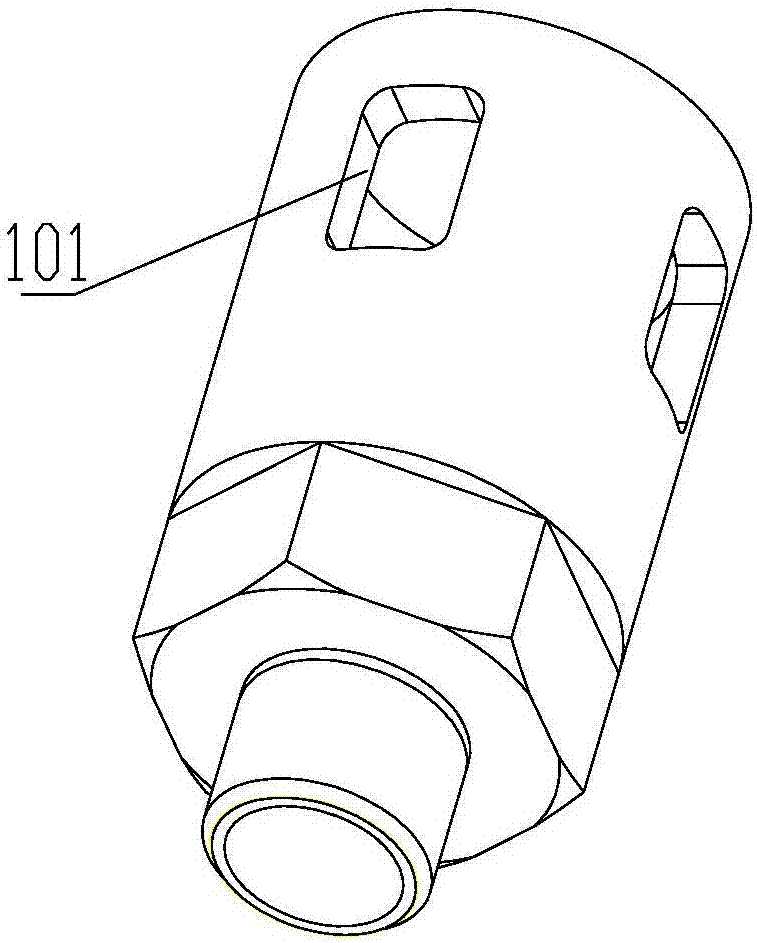

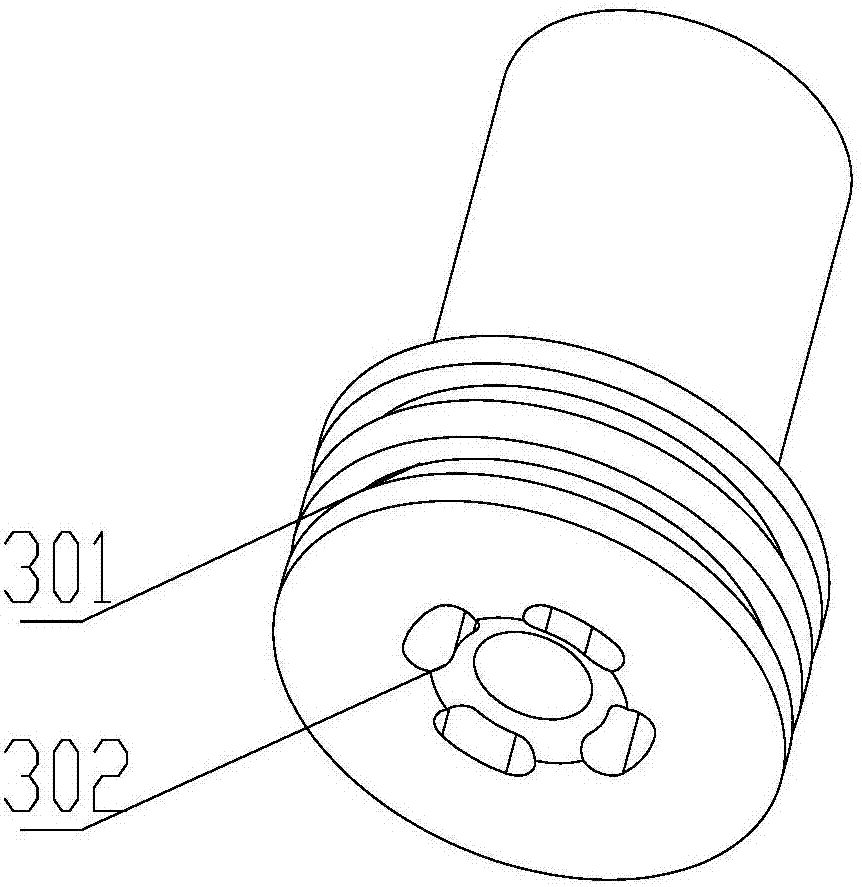

High-temperature one-way valve

ActiveCN107420591ASmall flow resistanceImprove high temperature reliabilityThermal insulationValve members for heating/coolingEngineeringPiston

The invention discloses a high-temperature one-way valve which comprises a valve body (1), a sealing ceramic ball (2), a piston (3), a sealing gasket I (4), a sealing gasket II (7) and a valve deck (8), wherein an external thread is formed in the outer side of the lower end of the valve body (1); a taper hole is formed in the inner side of the lower end of the valve body (1); a taper sealing valve seat and a cylindrical cavity are sequentially arranged upwards along an air inlet; the piston (3) takes the shape of a step shaft; two annular grooves (301) are formed in the excircle of the large end; a deeper inner hole is formed in the small end; and two annular grooves (301) are formed in a cylinder at one end of the valve deck (8). The high-temperature one-way valve has the characteristics of being compact in structure and small in flow resistance of a direct connection passageway; in addition, the heat insulation and heat dissipation design enables the high-temperature one-way valve to have higher high temperature reliability; and the high-temperature one-way valve has the advantage of practical engineering application, can be widely applied to industrial control and other industries and is suitable for fuel gas and other high-temperature media.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com