Preparation method of high thermal conductivity phase change temperature control composite packaging substrate

A technology with high thermal conductivity and packaging substrates, which is applied in many fields, can solve the problems of large thermal resistance, difficulty in further reducing volume and weight, and achieve the effects of low dielectric constant, excellent high-temperature reliability, and low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

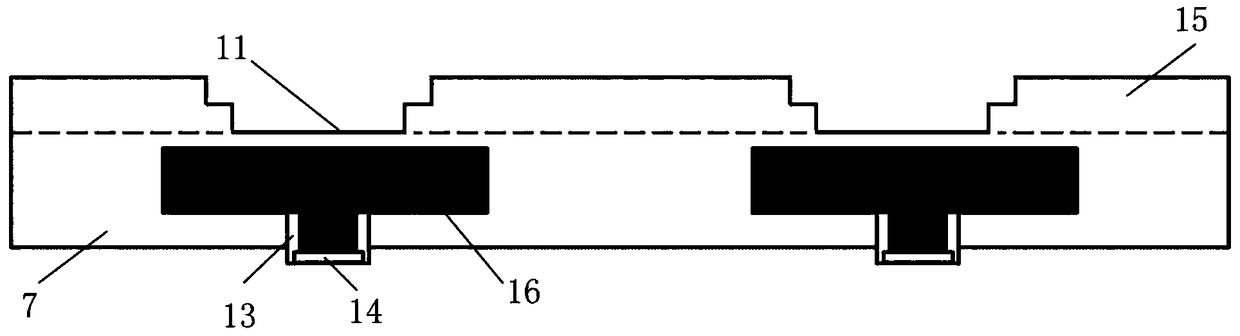

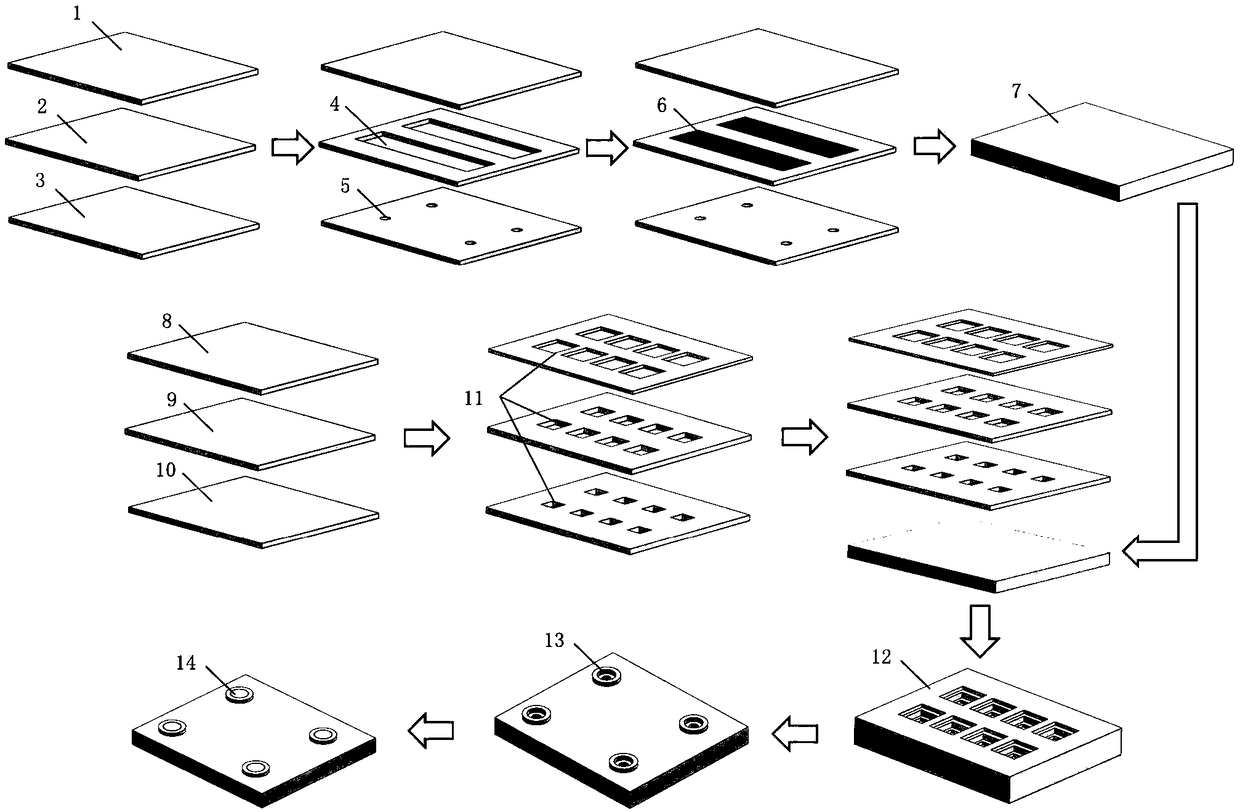

[0013] refer to figure 1 . In a preferred embodiment described below, the high thermal conductivity phase change temperature control composite packaging substrate mainly includes LTCC green ceramic substrate 15, AlN substrate 7, low melting point alloy solid phase change material 16, potting joint 13, sealing cover plate 14. The phase change temperature control cavity 4 is at least two cavities arranged in parallel on the middle layer of AlN green ceramic sheet 2, the upper layer of AlN green ceramic sheet 1 and the lower layer of AlN green ceramic sheet 3 are formed by laminating and sealing the middle layer of AlN green ceramic sheet 2 An AlN substrate 7 embedded with a phase change temperature control cavity 4 . The LTCC green ceramic substrate 15 is inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com