Interlayer bonding sheet for multilayer board as well as preparation method and application of interlayer bonding sheet

A multi-layer board and bonding sheet technology, applied in the direction of multi-layer circuit manufacturing, coating, printed circuit manufacturing, etc., can solve the problem of poor heat resistance reliability of PTFE multi-layer board bonding, and poor bonding performance between fluororesin and film materials. It can meet the needs of high frequency signals, as well as good stability, fluidity and bonding performance, and low dielectric constant and dielectric loss tangent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

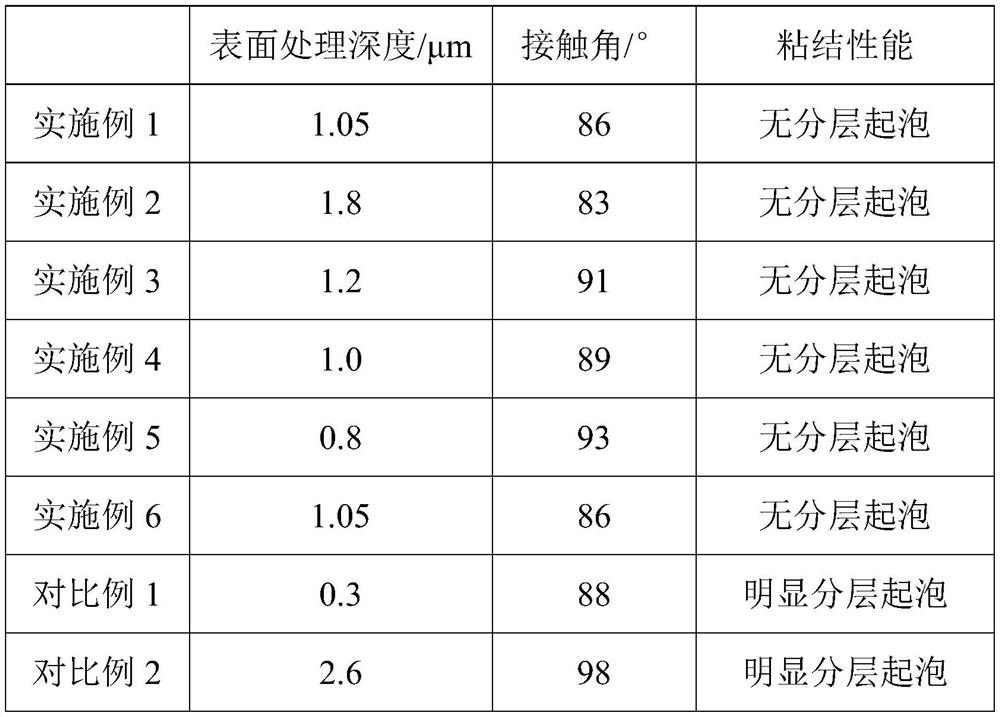

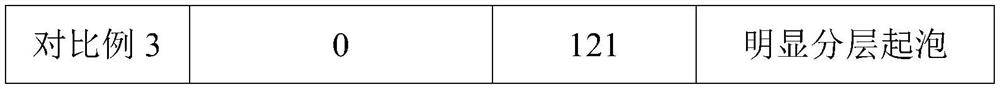

Examples

Embodiment 1

[0069] This embodiment provides an interlayer bonding sheet for a multilayer board, the preparation method of which is as follows:

[0070] (1) The PTFE substrate with a thickness of 0.5mm is cleaned with acetone, degreased, and dried; then it is soaked in the sodium naphthalene solution under the dry nitrogen protection atmosphere, and the concentration of the sodium naphthalene solution is 0.8mol / L, soaked Take it out after 280s, wash and dry with ethanol and distilled water respectively, and obtain the PTFE substrate after surface treatment;

[0071] (2) Roll-coat dielectric resin treatment solution I on the surface-treated PTFE substrate obtained in step (1) to obtain a dielectric resin layer with a thickness of 40 μm, and cure it at 210° C. for 2 hours to obtain the interlayer for the multilayer board. Adhesive sheet.

Embodiment 2

[0073] This embodiment provides an interlayer bonding sheet for a multilayer board, the preparation method of which is as follows:

[0074] (1) Clean the PTFE substrate with a thickness of 1.0mm with ethanol, remove oil stains, and dry it; then soak it in the sodium-naphthalene solution under the atmosphere of dry nitrogen protection, the concentration of the sodium-naphthalene solution is 3mol / L, soak for 100s After taking out, wash with acetone, distilled water respectively, dry, obtain the PTFE substrate after the surface treatment;

[0075] (2) Roll-coat dielectric resin treatment solution I on the surface-treated PTFE substrate obtained in step (1) to obtain a dielectric resin layer with a thickness of 35 μm, and cure at 230°C for 1.5h to obtain the layer for the multilayer board Adhesive sheet between.

Embodiment 3

[0077] This embodiment provides an interlayer bonding sheet for a multilayer board, the preparation method of which is as follows:

[0078] (1) The PTFE substrate with a thickness of 1.4mm is cleaned with ethanol, degreased, and dried; then it is soaked in the sodium naphthalene solution under a dry nitrogen protection atmosphere, the concentration of the sodium naphthalene solution is 8mol / L, and soaked for 60s After taking out, wash with ethanol, distilled water respectively, dry, obtain the PTFE substrate after the surface treatment;

[0079] (2) Roll-coat dielectric resin treatment solution I on the surface-treated PTFE substrate obtained in step (1) to obtain a dielectric resin layer with a thickness of 55 μm, and cure at 220°C for 1.5h to obtain the layer for the multilayer board Adhesive sheet between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com