High-adhesion conductive copper colloid and screen printing application method thereof

A technology of screen printing and application method, which is applied in printing, conductive adhesives, adhesives, etc., and can solve problems such as poor durability of solar cells, conductive copper glue falling off and short circuit, and affecting the production yield of copper glue conductive substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

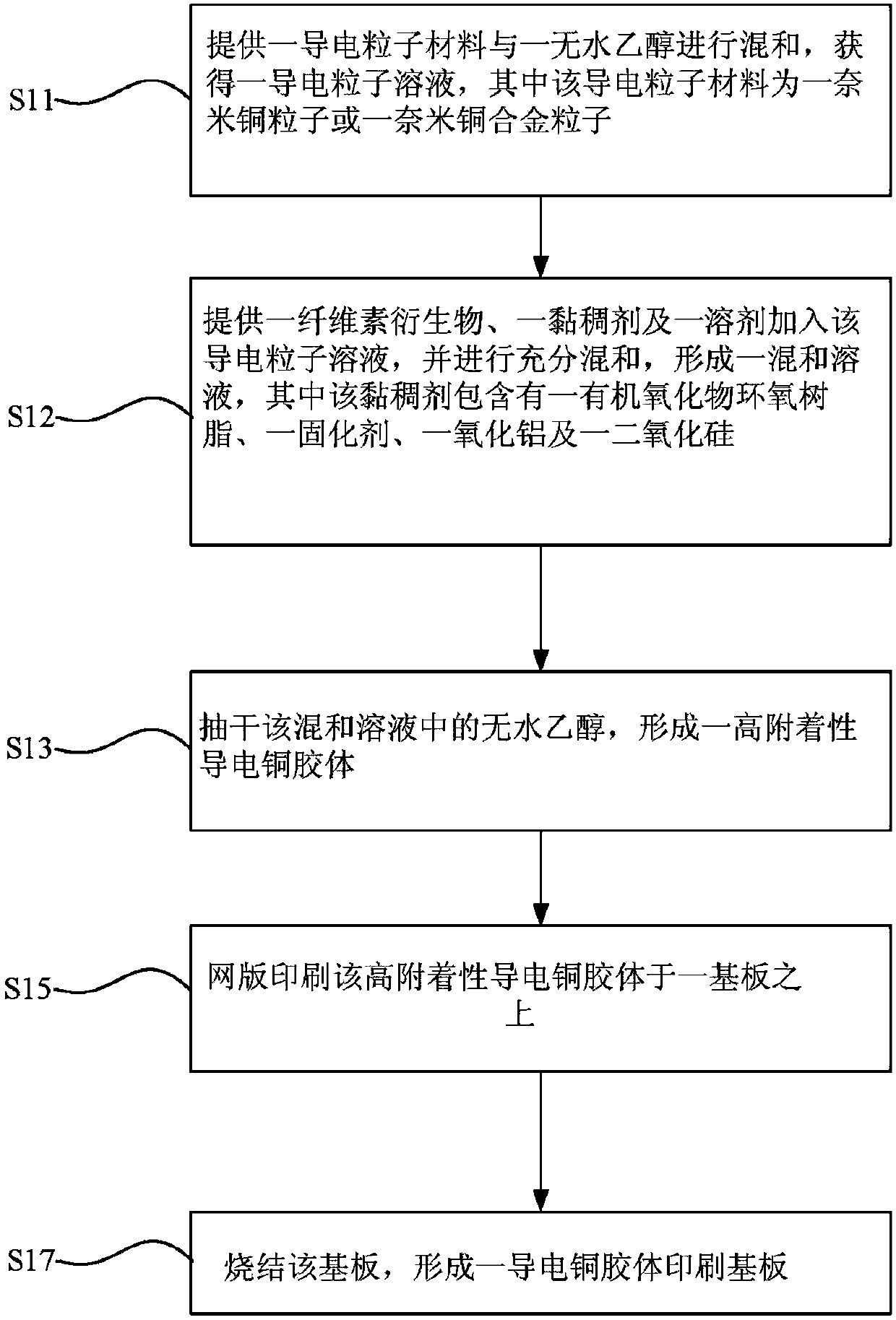

[0047] Next, the following collocation invention diagram figure 1 The screen printing application method step flow chart of the high adhesion conductive copper colloid of the present invention illustrates the screen printing application method of the high adhesion conductive copper colloid provided by the present invention and the preparation method of the copper glue conductive substrate, and its steps are as follows:

[0048] Step S11: providing a conductive particle material and mixing it with an anhydrous ethanol to obtain a conductive particle solution, wherein the conductive particle material is a nano-copper particle or a nano-copper alloy particle;

[0049] Step S12: Provide a cellulose derivative, a viscous agent and a solvent to add to the conductive particle solution, and fully mix to form a mixed solution, wherein the viscous agent includes an organic oxide epoxy resin, a curing agent, a Aluminum oxide and silicon dioxide;

[0050] Step S13: Drain the absolute eth...

Embodiment 1

[0075] Preparation of Highly Adhesive Conductive Copper Colloid

[0076] Take 45 grams of anti-oxidation nano-copper particles and disperse them in some absolute ethanol to form the conductive copper particle solution, then add a viscous agent mixture comprising organic oxide epoxy resin, silicon dioxide, aluminum oxide and curing agent Add 10 grams and 2 grams of cellulose in the conductive copper particle solution, then perform ultrasonic homogeneous vibration for 2 minutes, then add 16 grams of terpineol, and ultrasonic homogeneous vibration for 2 minutes to complete the mixed solution preparation. Then drain the anhydrous ethanol in the mixed solution at 80 mbar (mbar) and 40°C, and finally use a roller to disperse the conductive copper colloid that has been drained of the solvent in the previous steps to remove the internal air bubbles, and complete the process. The preparation of the high adhesion conductive copper colloid.

Embodiment 2

[0078] Screen printing method of highly adhesive conductive copper colloid

[0079] Get 5 grams of the high-adhesion conductive copper colloid prepared in Example 1, place it on the screen plate with 320 meshes and 28 units of tension, and under the condition of printing pressure 2 pascals (bar), the high-adhesion Adhesive conductive copper colloids are screen printed on glass substrate materials, ceramic substrate materials, silicon substrate materials and flexible polyimide substrates (Polyimide, PI), as shown in the illustration of the invention Figure 2A to Figure 2D shown. Among them, the copper glue conductive substrate printed under the above conditions can print a line width of about 150 microns (um), as shown in the illustration of the invention Figure 2A shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com