Composition for forming adhesive film, adhesive film for processing prior to photo-curing, adhesive film, and electronic paper display device

A technology for bonding films and compositions, applied in the direction of adhesive types, polyether adhesives, film/sheet adhesives, etc. performance degradation, etc., to achieve excellent high temperature reliability and excellent chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] The weight-average molecular weight is 52000g / mol, and glass transition temperature is that the phenoxy thermosetting resin of about 94 ℃ dissolves PKHH (trade name) of Inchem Company in methyl cellosolve with 30 weight percent concentration solution, and with 300 mesh The phenoxy solution (P1) was prepared by filtration. Stir and mix the above-mentioned phenoxy solution (P1) of 22.0 g (wherein PKHH content: 6.6 g), S-28 (bis-(3,4-ring Oxycyclohexyl) adipic acid), 0.06g of isocyanate curing agent MFA-75X produced by Asahi Kasei Co., Ltd. and 2.3g of cationic photoinitiator UVI-6974 (Momentive) are prepared by the company, including triarylsulfonium hexafluoroantimonite as the main component) to prepare a composition for forming an adhesive film.

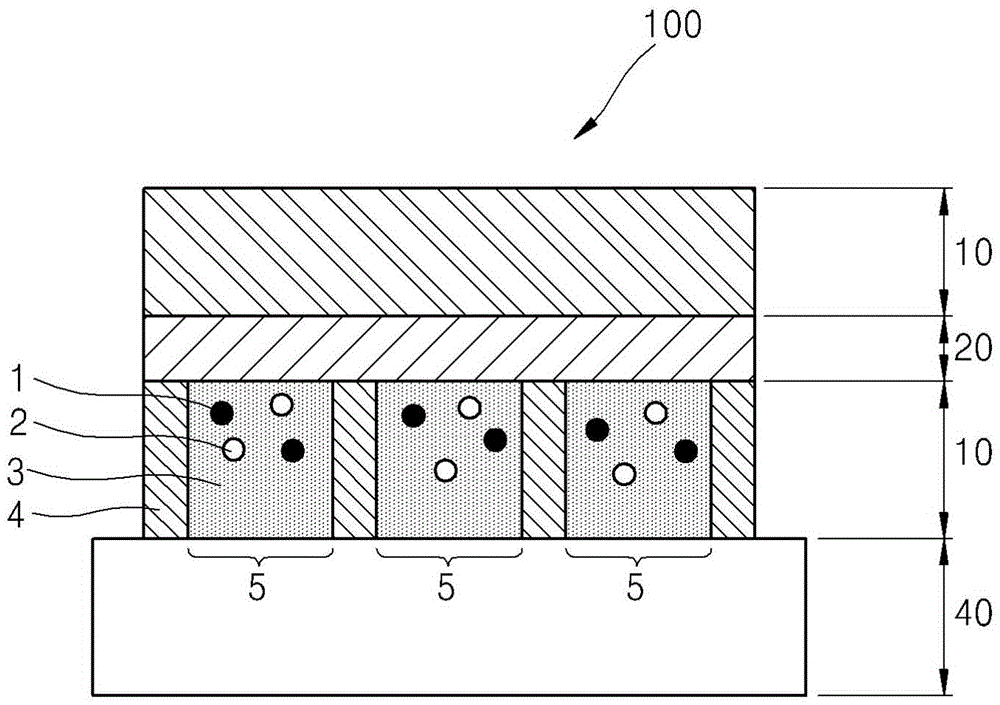

[0114] On the polyethylene terephthalate release film, the above composition is formed into a coating layer with a thickness of 10 μm, and then dried with hot air at 140°C for 3 minutes to prepare an adhesive for processing b...

Embodiment 2

[0117] In Example 2, an adhesive film was formed in the same manner as in Example 1, except that the glass transition temperature of the phenoxy resin was changed and used.

[0118]The weight-average molecular weight is 60000g / mol, glass transition temperature is that the phenoxy thermosetting resin of about 98 ℃ dissolves the PKFE (trade name) of Inchem company in methyl cellosolve with 30 weight percent concentration solution, and with 300 mesh Filter and prepare the phenoxy solution (P2). Stir and mix the above-mentioned phenoxy solution (P2) of 22.0 g (wherein PKHH content: 6.6 g), S-28 (bis-(3,4-ring Oxycyclohexyl) adipic acid), 0.06g of isocyanate curing agent MFA-75X produced by Asahi Kasei Co., Ltd. and 2.3g of cationic photoinitiator UVI-6974 (Momentive) are prepared by the company, including triarylsulfonium hexafluoroantimonite as the main component) to prepare a composition for forming an adhesive film.

[0119] On the polyethylene terephthalate release film, the...

experiment example 1

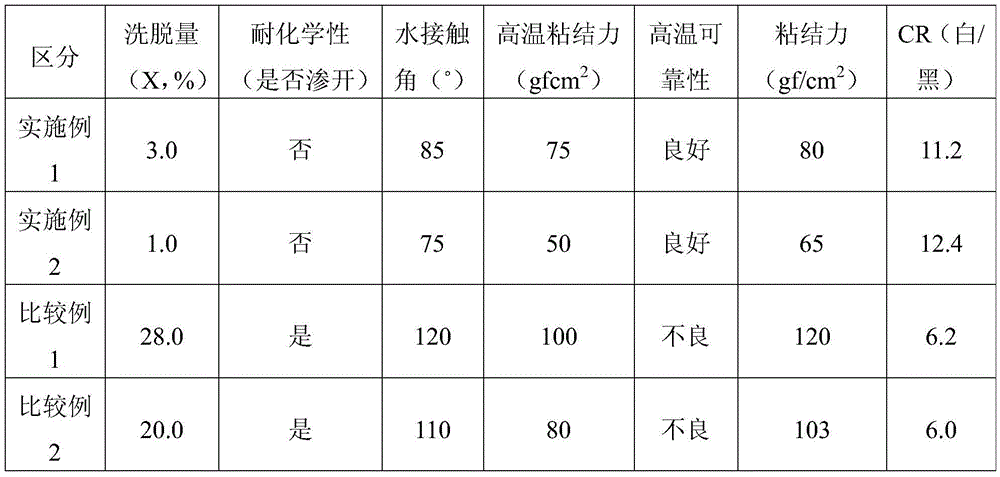

[0126] Experimental Example 1: Evaluation of Elution Amount

[0127] The adhesive film prepared in Examples 1-Example 2 and Comparative Example 1-Comparative Example 2 was mixed with a mixed solvent of halocarbon oil (Halocarbon Company halocarbon oil 0.8) and n-dodecane oil in a weight ratio of 3:7 After soaking in water for 12 hours, filter with a 300-mesh sieve, and dry at 110°C for 3 hours, measure the weight and measure the elution amount (X) [%] by the following calculation formula 2, and record it in Table 1 .

[0128] Calculation formula 2:

[0129] Elution amount (X) [%] = [(initial weight of adhesive film - weight of sealing film after immersion in solvent for a specified time) / initial weight of adhesive film] × 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com