Semiconductor diode chip and manufacturing method thereof

A diode and semiconductor technology, applied in the field of diode chips, semiconductor diode chips and their production, can solve the problems of large trench occupation area, easy discharge and ignition, short service life, etc., and achieve large effective use area and good high temperature reliability , the effect of strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

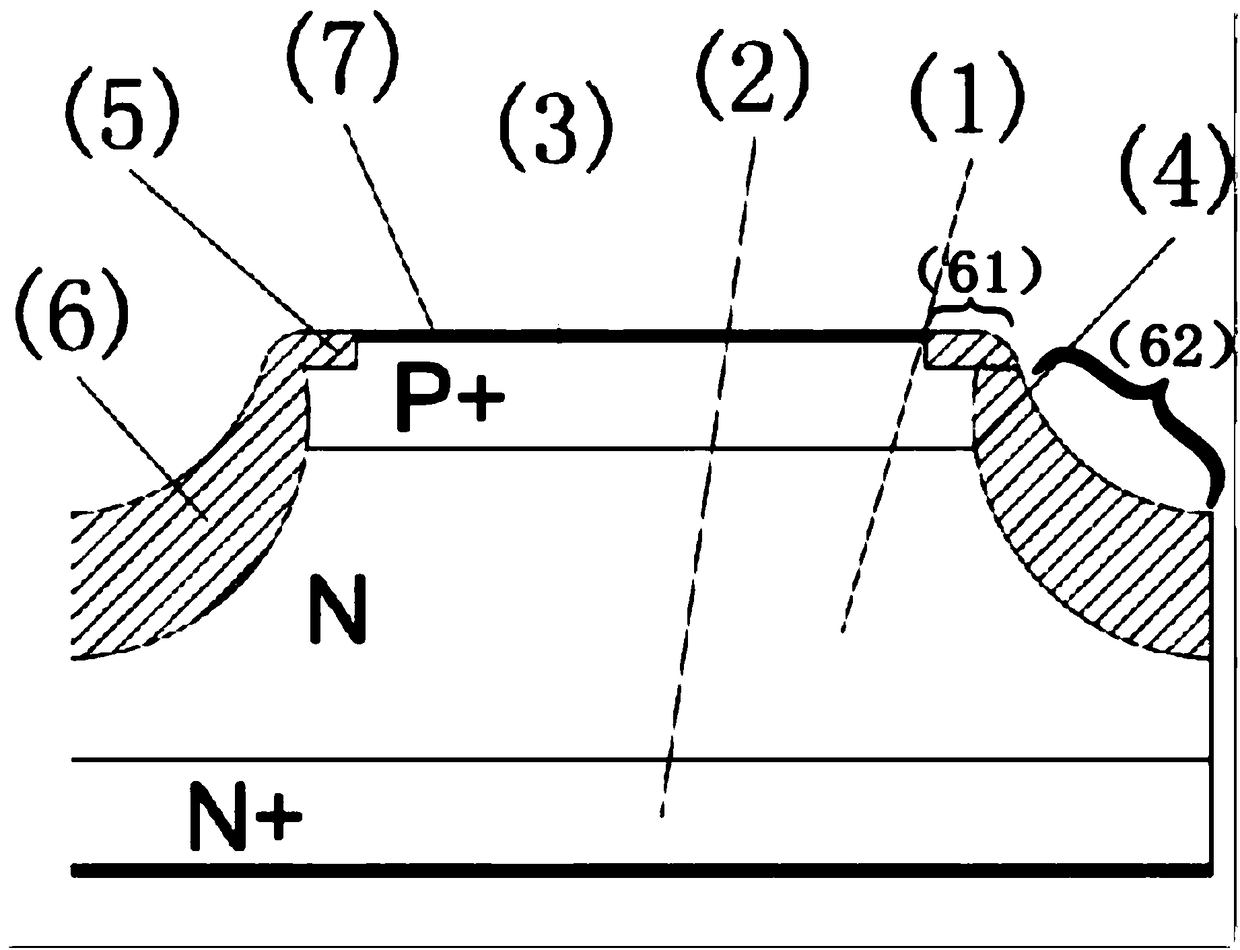

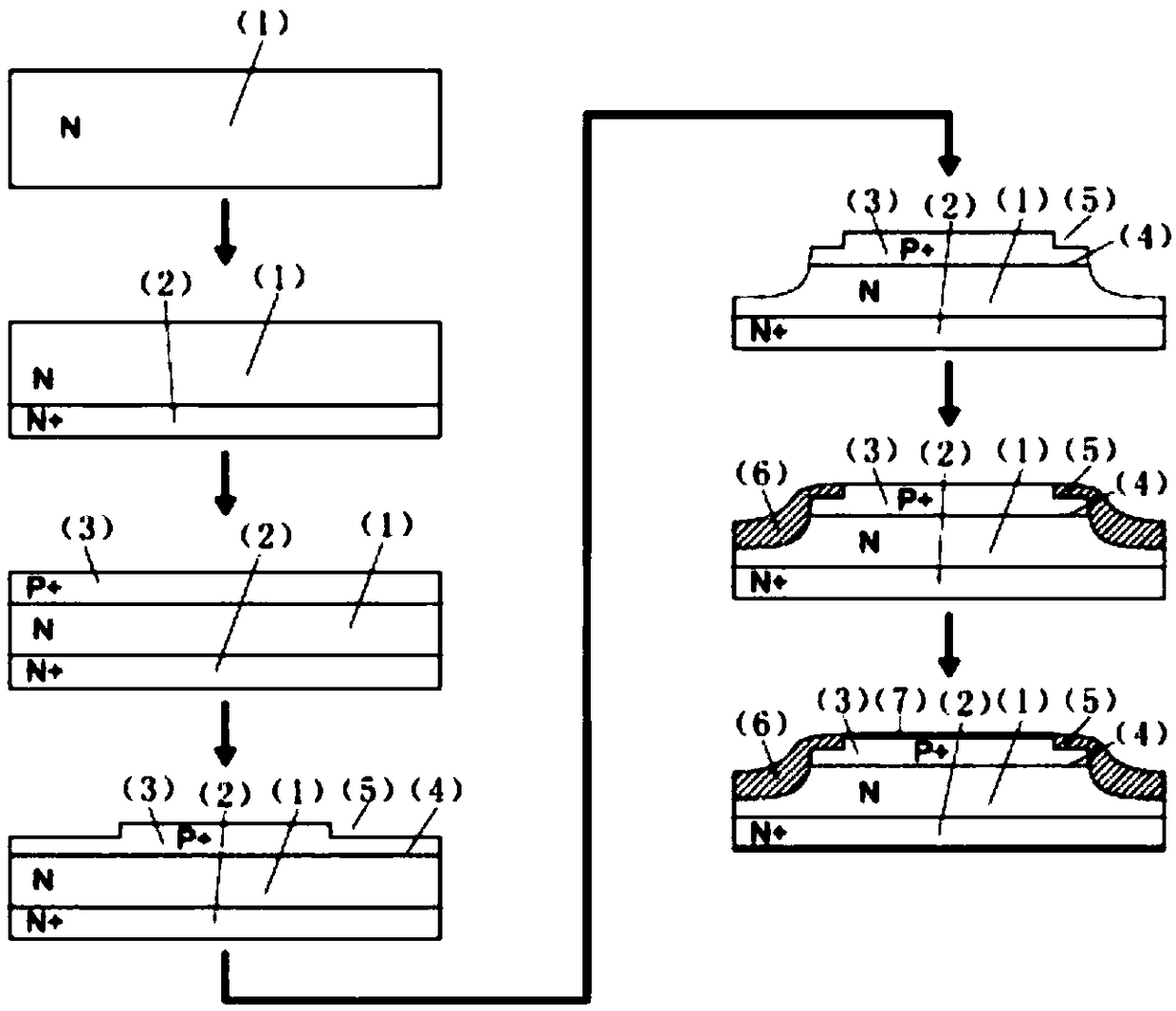

[0036] Example 1, such as figure 1 Shown, the present invention provides a kind of semiconductor diode chip, comprises silicon chip substrate, and the bottom of its silicon chip substrate is provided with phosphorus diffusion layer, and upper part is provided with boron diffusion layer, for the shape of silicon chip substrate and boron diffusion layer The design is also relatively simple, mainly depending on the design of the external passivation layer. In addition, the upper part of the boron diffusion layer and the bottom of the phosphorus diffusion layer are provided with metal electrodes. For welding, the inventor is provided with a novel passivation layer wrapping the silicon wafer substrate and the side of the boron diffusion layer on the outside of the silicon wafer substrate (chip), from figure 1 It can be seen from the figure that the new passivation layer includes the silicon wafer substrate and the surrounding sides of the boron diffusion layer. However, when the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com