Patents

Literature

35results about How to "Cost economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

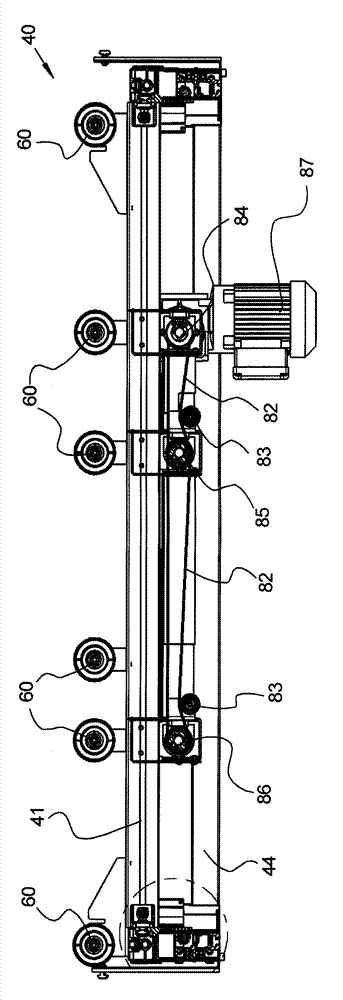

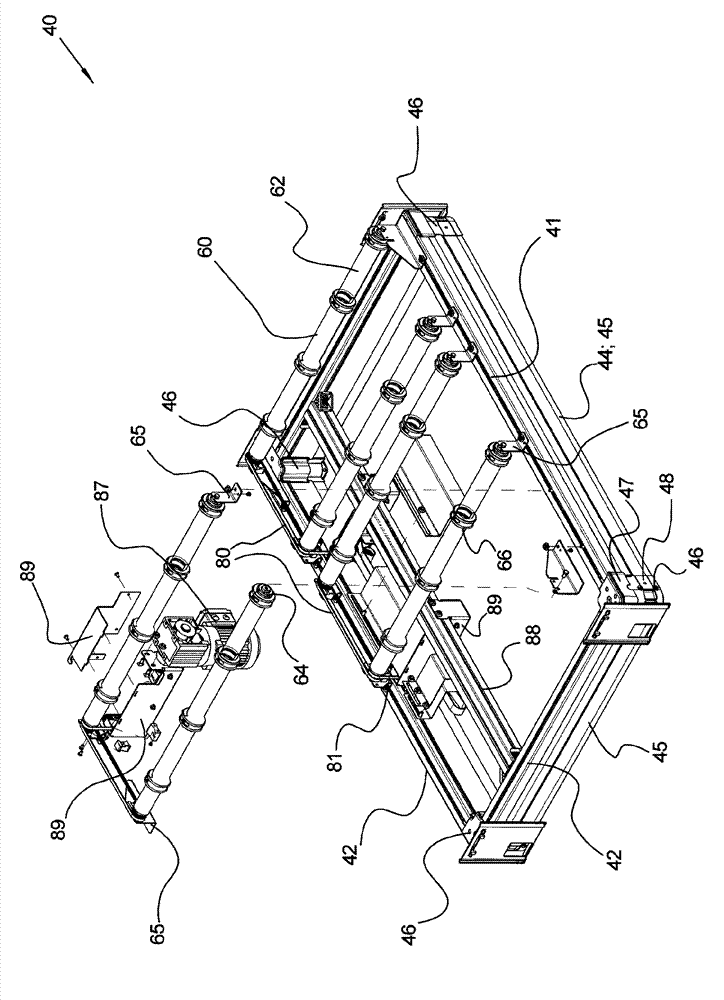

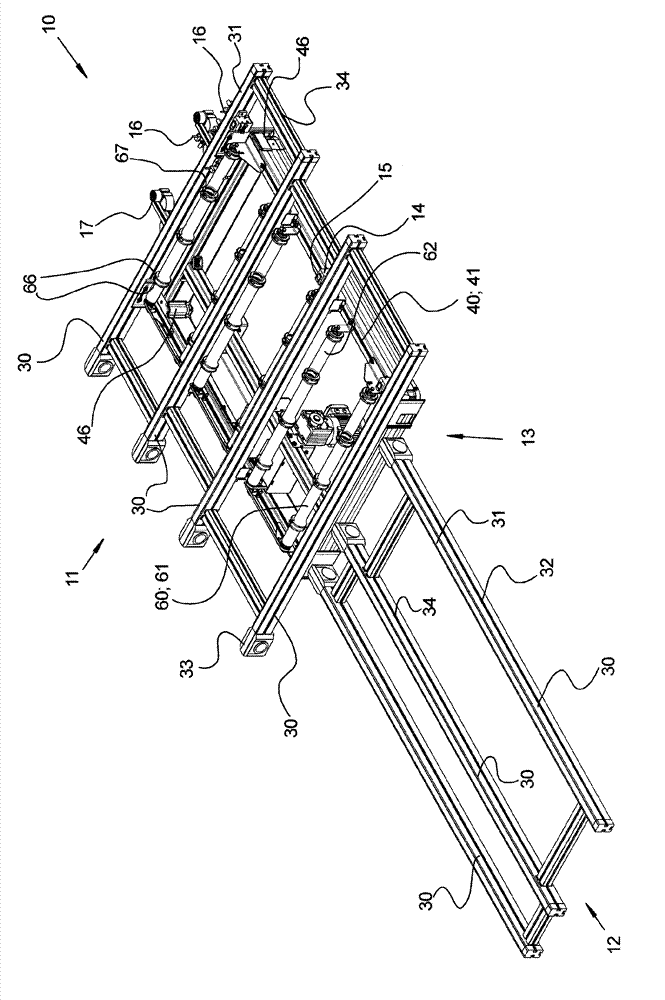

Transport device comprising a transverse lifting unit with transport rollers

Owner:ROBERT BOSCH GMBH

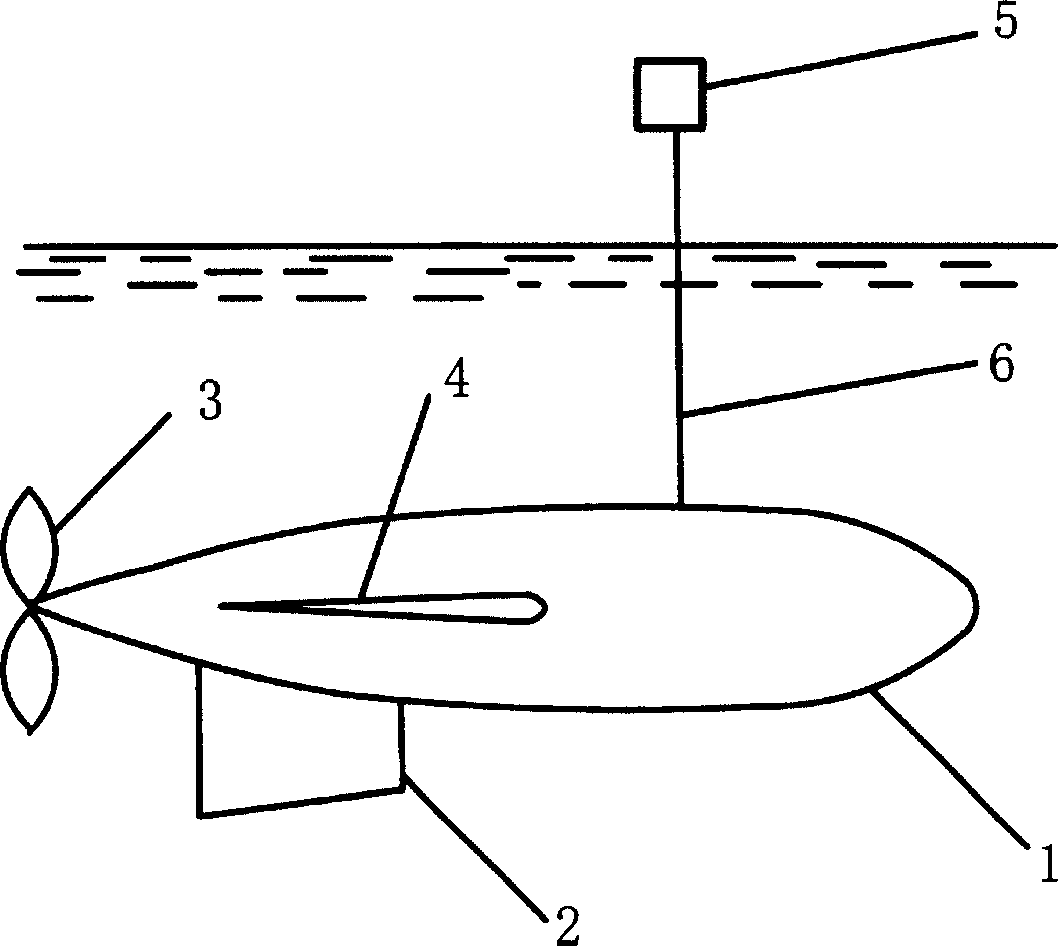

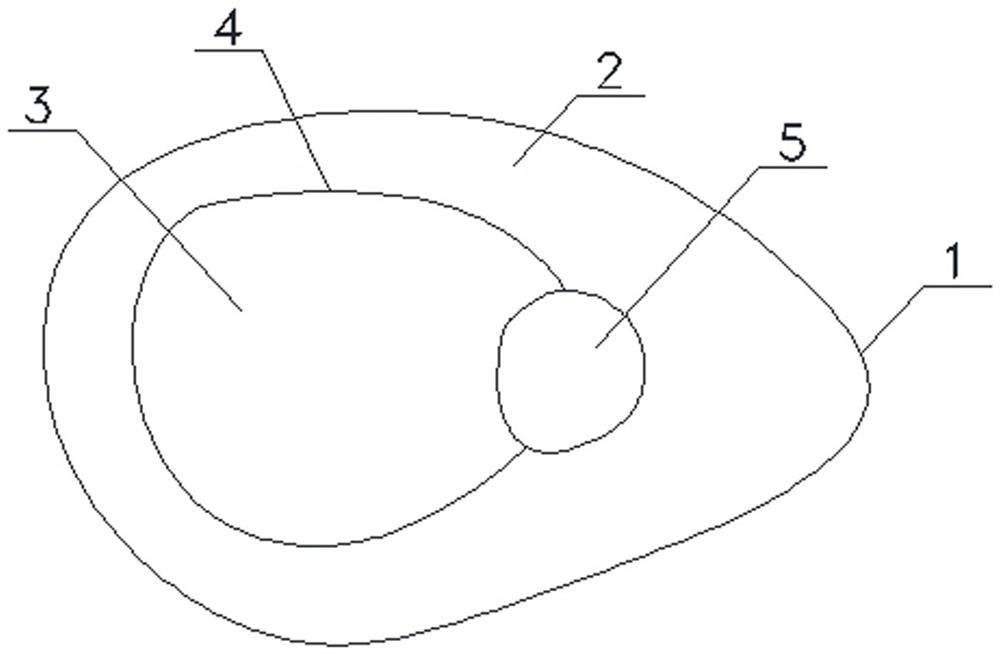

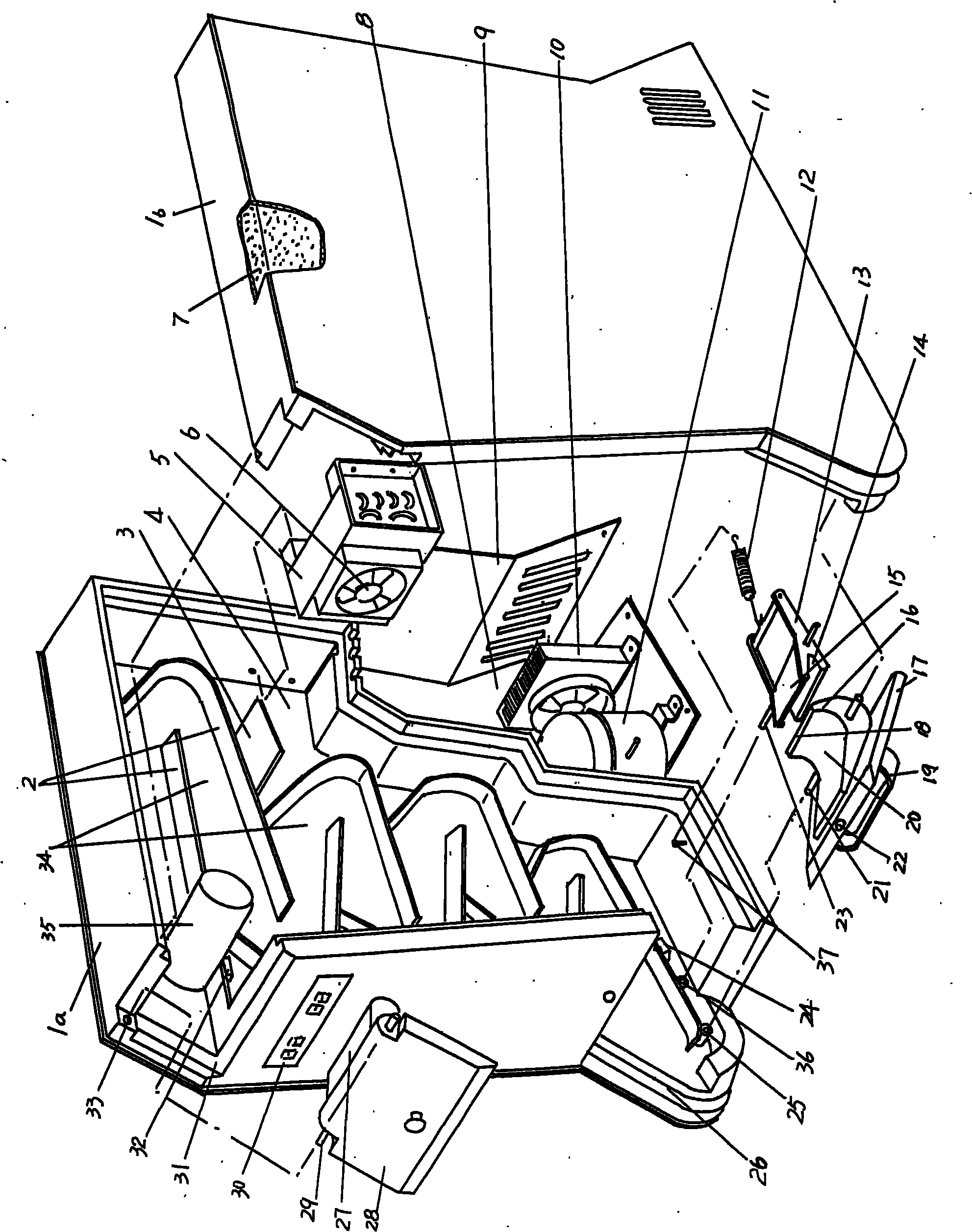

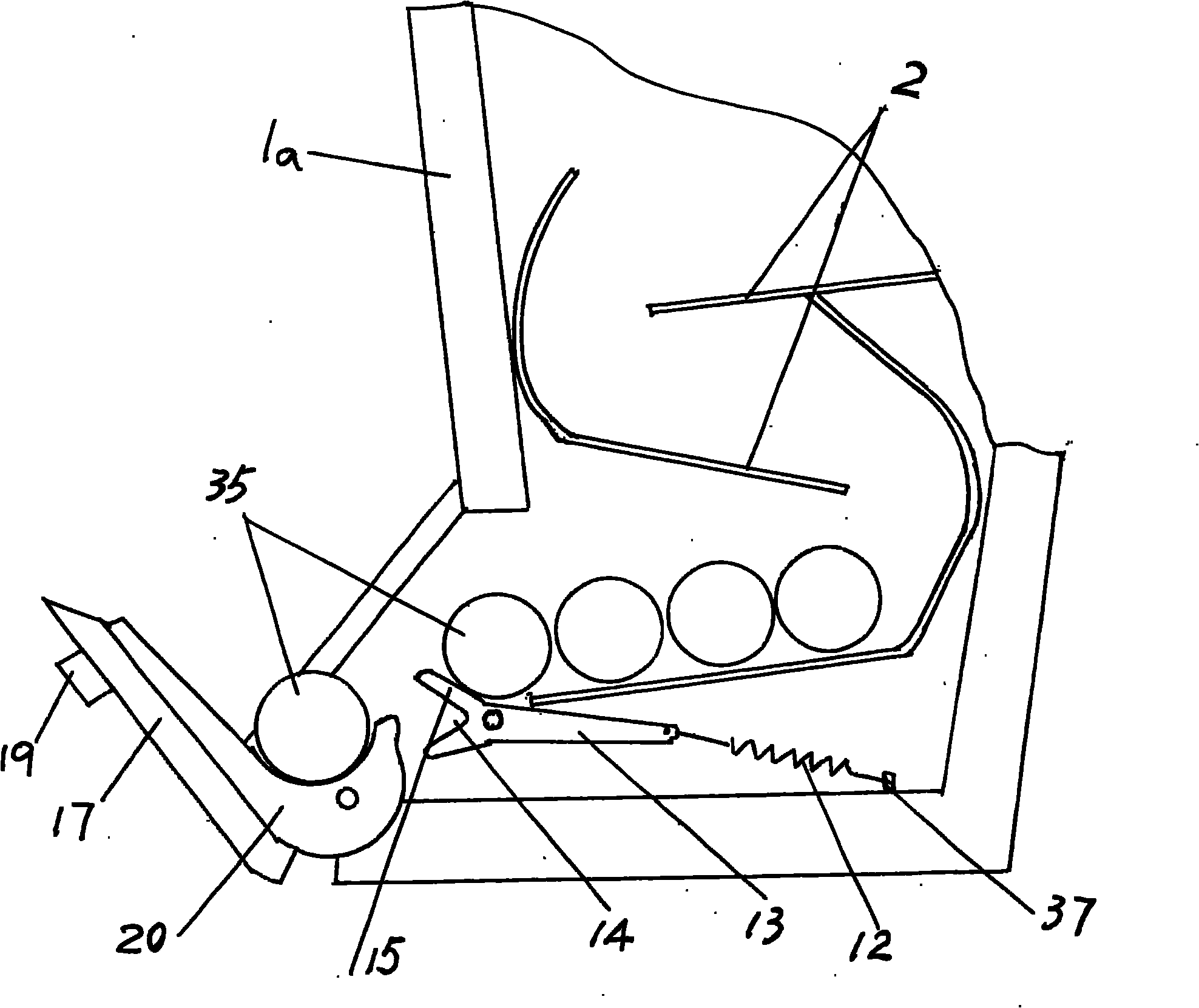

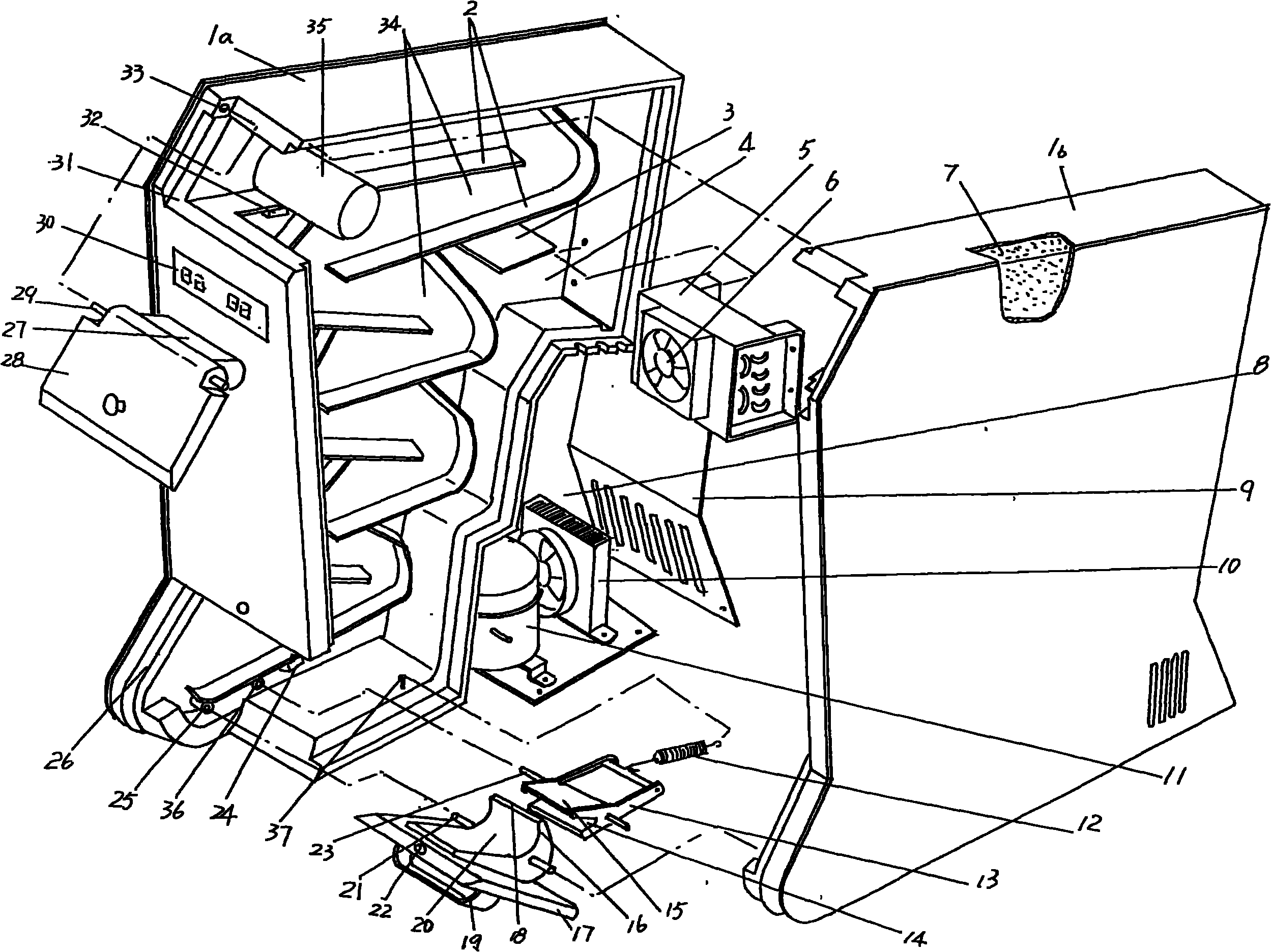

Shallow water type continuous unmanned submersible vehicle

InactiveCN1594030ASmall sizeCost economyUnderwater vesselsUnderwater equipmentPropellerAttitude control

This invention is a kind of continual shallow-water unmanned submerged machine including the shell, vertical fins, reversible propeller, tail plane , the cabane, connecting tubes, navigation system , communication system, underwater detection system, water detection system, water-pressure sensor , dynamical system, tail plane actuator, vertical fin actuator, engine scavenging port, navigation system receiver and control system. The speed of the submerged machine can be achieved by the turning speed of the reversible propeller, the course-changing can be achieved by changing the vertical angle of the vertical fins, the posture control and regulation of the submerged machine can be completed by the coordinated action of the tail plane and vertical fins. This invention can navigate itself according to the scheduled or temporary order under the totally pilotless condition, and it can give a steady performance when there are fierce wind and waves. It doesn't need any special expensive energy system and gas supply system and it has a cabinet build, the economy of making cost and cheap operation. With carrying enough routine fuel only, it can finish the strategic task ceaselessly.

Owner:SHANGHAI JIAO TONG UNIV

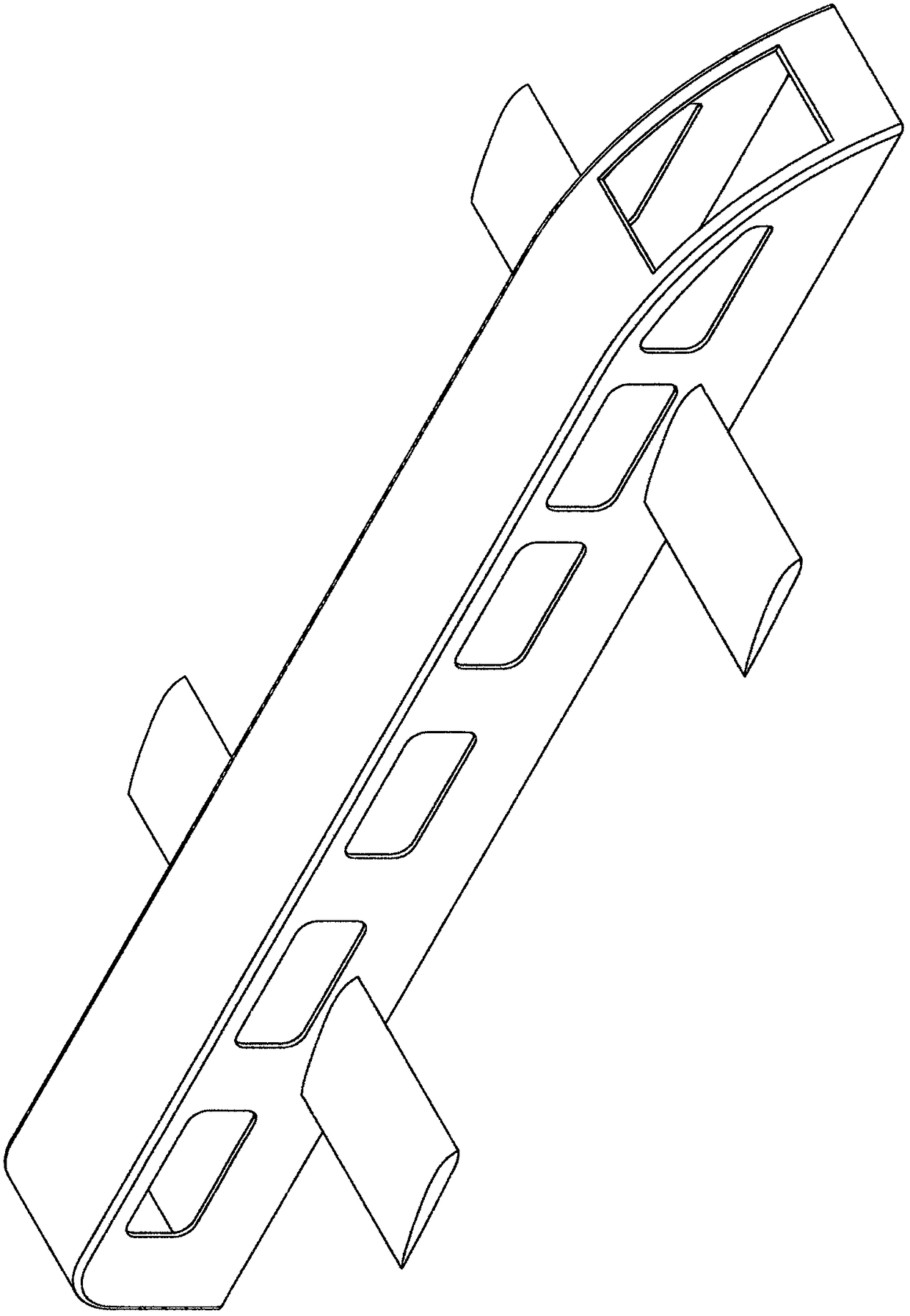

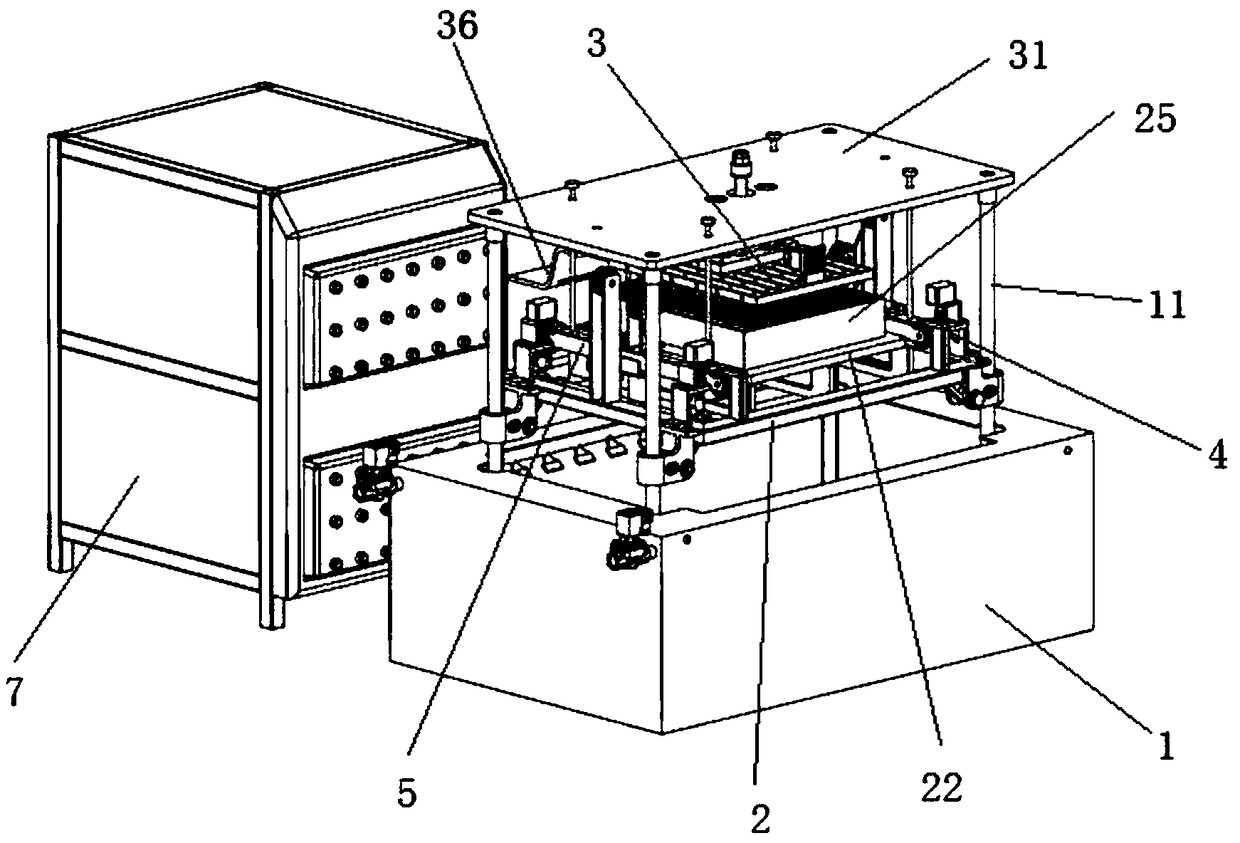

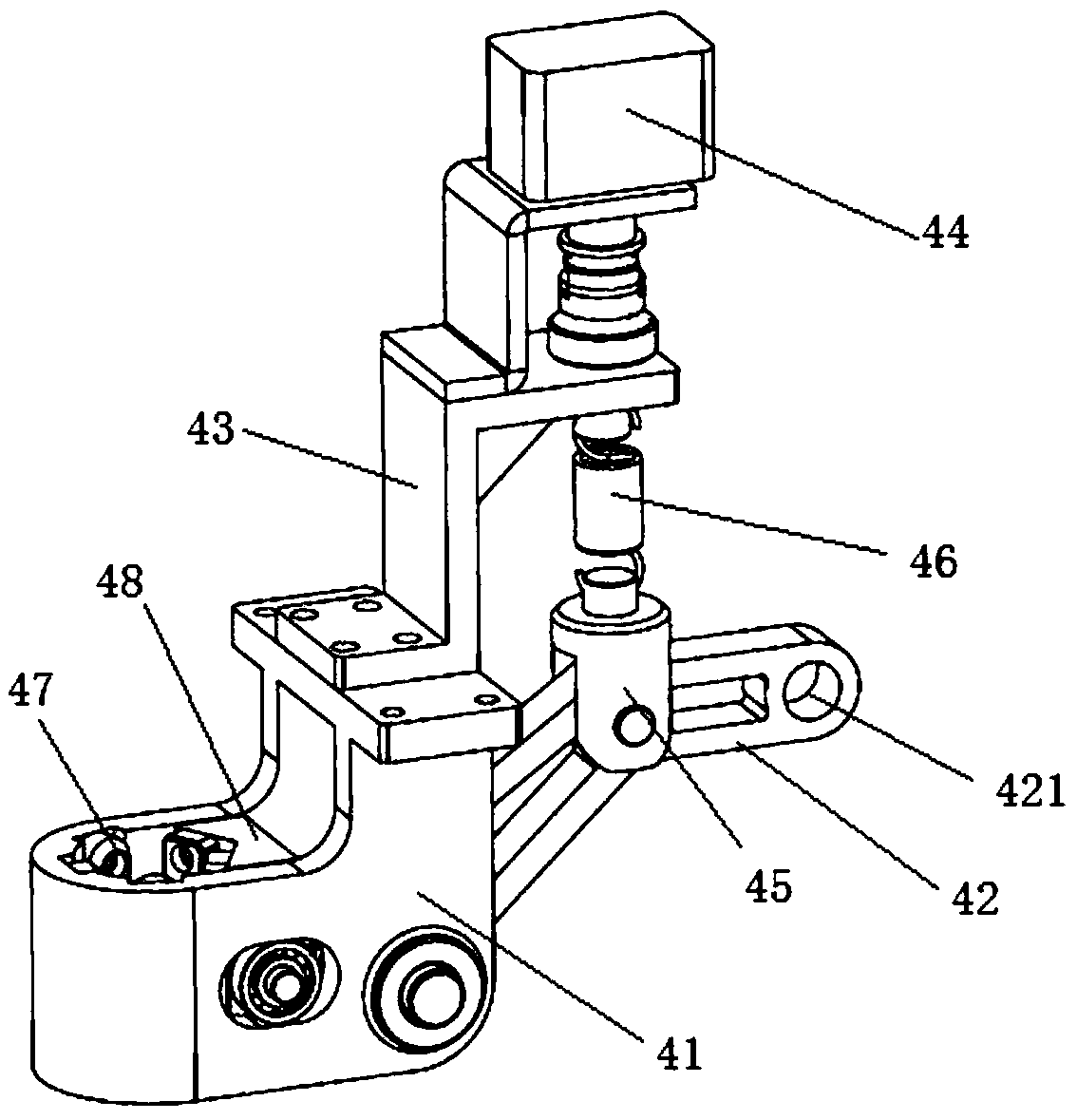

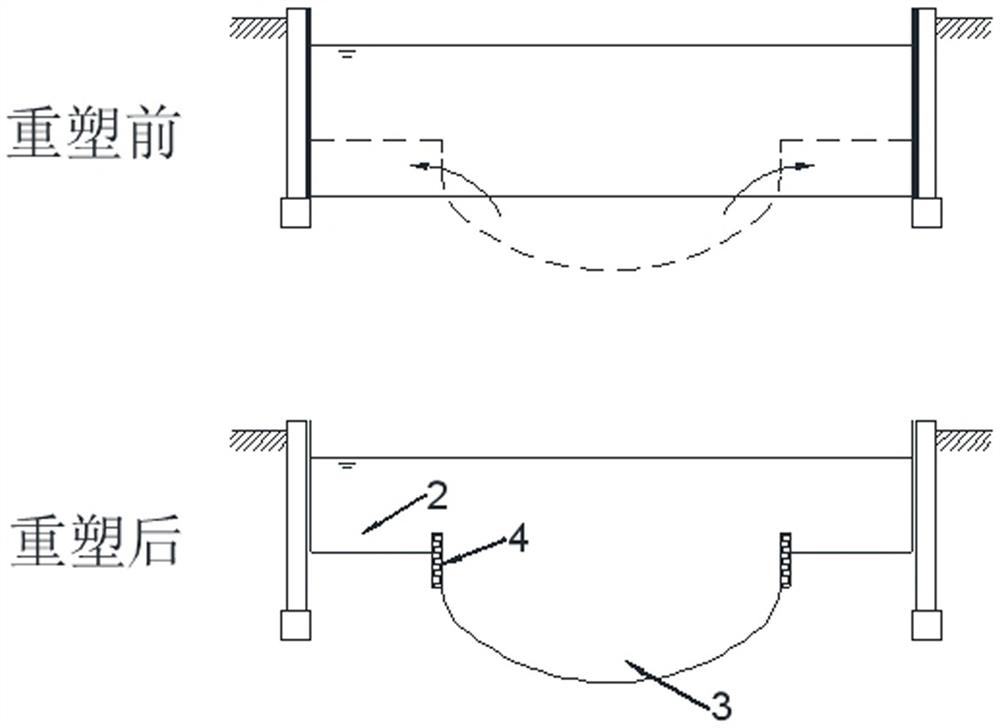

Quick track slab replacing system and method for slab-type ballastless track

ActiveCN106948228AFast constructionCost economyRailway track constructionEngineeringReplacement method

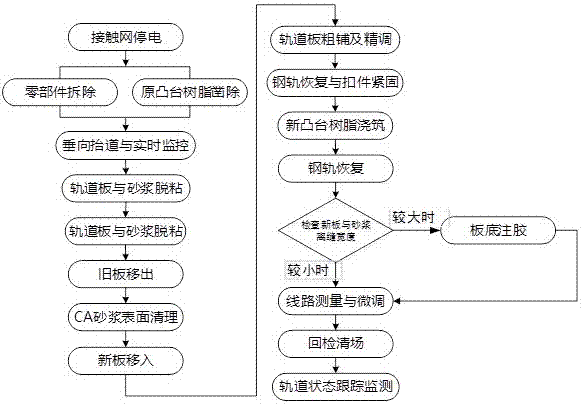

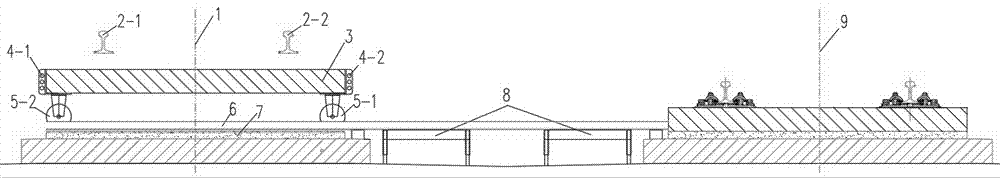

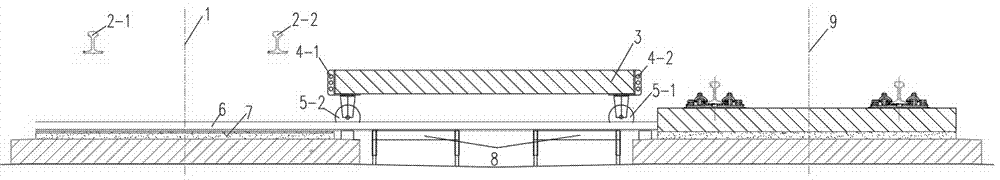

The invention discloses a quick track slab replacing system for a slab-type ballastless track and a quick track slab replacing method for the slab-type ballastless track. The replacing system comprises a steel rail jacking device, a track slab jacking device, a track slab translation device, a track slab placement tray, track slab transportation equipment and track slab hoisting equipment. The replacing method comprises the following steps of jacking an upper steel rail of a to-be-replaced track slab to a certain height, jacking the track slab by utilization of a span jacking device, moving the track slab out of a steel rail range and placing the track slab on the tray by utilization of the track slab translation device, moving the to-be-replaced track slab away, placing a new track slab on the tray and moving the new track slab into the original track slab position in place by utilization of the hoisting equipment, and finally restoring the limitation of the track slab and the bonding between the track slab and a filling layer. The replacing system and the replacing method disclosed by the invention are used for replacing the track slab for maintenance of a high speed railway, have the advantages of adoption of light and convenient tooling, simplicity in operation and high construction efficiency without damaging the steel rail, and are especially suitable for construction in a high-speed railway skylight period.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

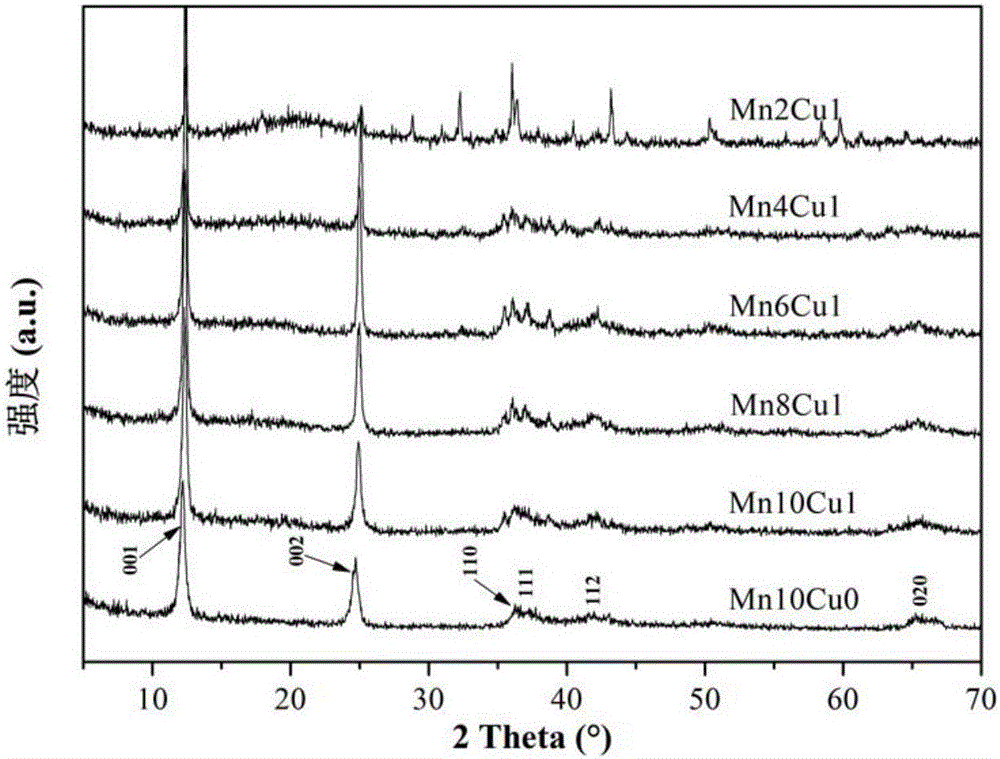

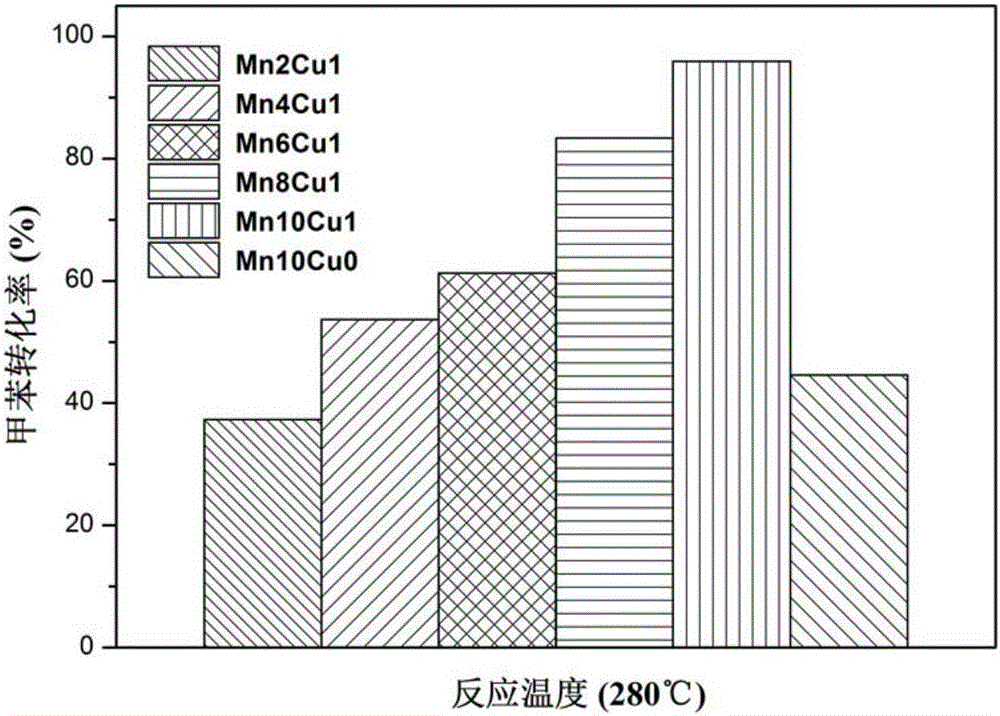

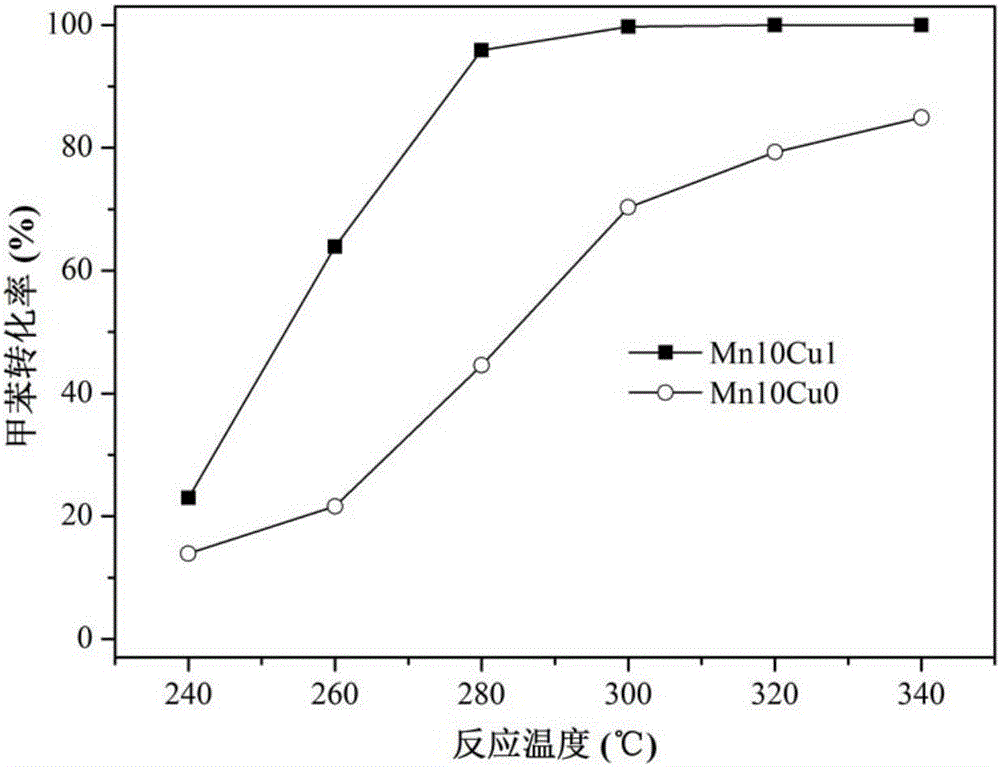

Method for preparing manganese-copper-based catalyst for degrading VOCs (Volatile Organic Compounds)

ActiveCN106179393AHigh catalytic combustion activityCost economyCatalyst activation/preparationIncinerator apparatusVolatile organic compoundPotassium permanganate

The invention discloses a method for preparing a manganese-copper-based catalyst for degrading VOCs (Volatile Organic Compounds). According to the method, the manganese-copper-based catalyst capable of catalytically degrading toluene is prepared rapidly by using a self-propagating reaction between potassium permanganate and cupric acetate; the catalytic activity of the manganese-copper-based catalyst is regulated and controlled through changing the mole ratio of Mn to Cu, and the catalyst can be used for completely (100%) converting a 1000ppm gas mixture of toluene and air into CO2 and H2O at the reaction temperature range of 303 DEG C to 340 DEG C at normal pressure at the air speed of 30,000ml gcatalyst<1>h<1>; and the raw materials used by the catalyst are low in price, the preparation process is simple and efficient and is high in practicability, and toxic and harmful gases such as NOx cannot be produced in the preparation process. The manganese-copper-based catalyst prepared by using the method shows excellent catalytic combustion activity and can be used for completely eliminating low-concentration VOCs.

Owner:SICHUAN UNIV

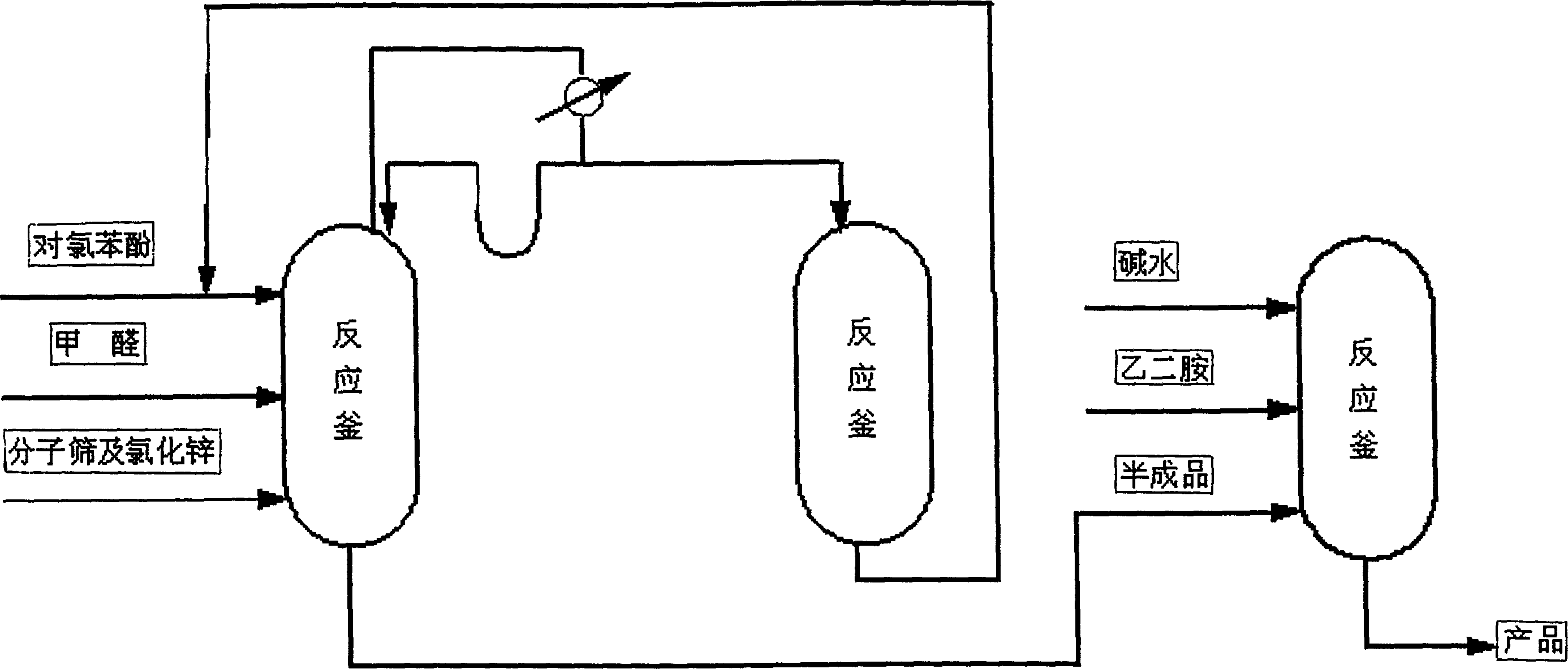

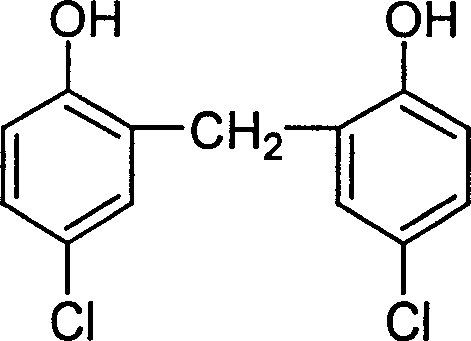

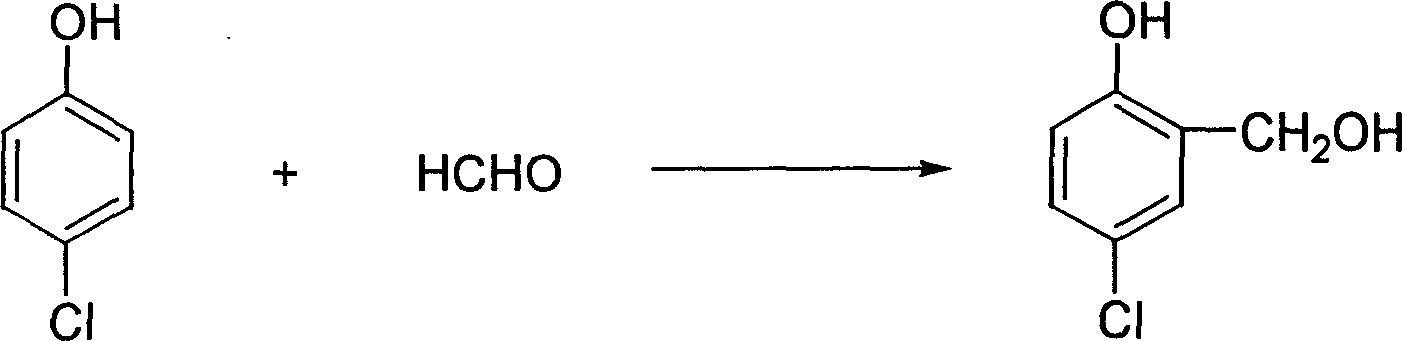

Sterilization algae removal anti-fungus agent and preparation method thereof

The invention relates to a sterilization, algae removal and anti-fungus agent, and its preparing method. It is made of dichlorophen, ethanediamine, caustic soda and water.Wherein, the dichlorophen is made by precommising and heating the chlorophenol, methyl aldehyde, molecular screen and catalyser zinc chloride, as well as backflowing and steaming the p-chlorophenol. The invention has the projecting function of suppressing the microorganism such as mould, fungus, bacteria and algae growing in the organic medium, and the advantages of small dosage, economic cost, long sterilization duration, large pH applicability, convenient processing method and safe usage. It can be used in industry cycle sterilization in water of the departments as fertilizer, chemical fiber, petrochemical plant, oil refining and metallurgy. It is also a merit anti-fungus agent, can be used to sterilize in leather, textile, paper pulp, coating material, wood and organic material.

Owner:南京台硝化工有限公司

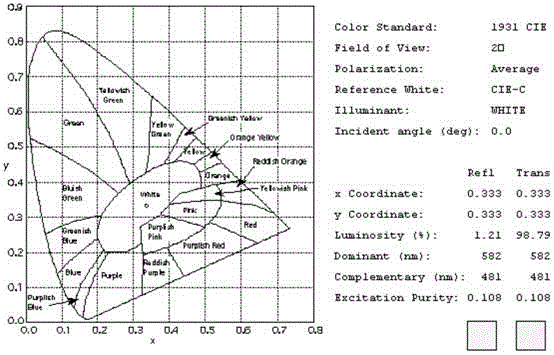

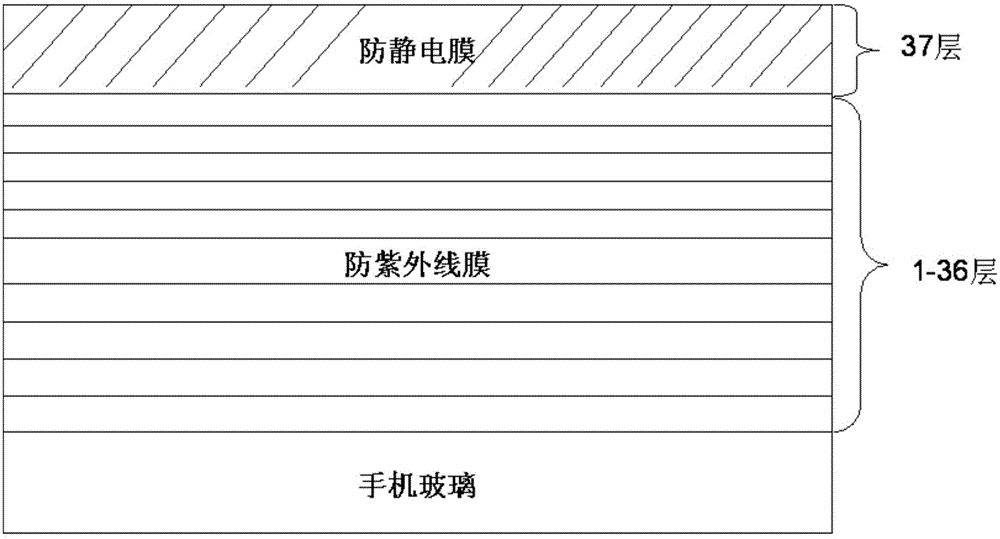

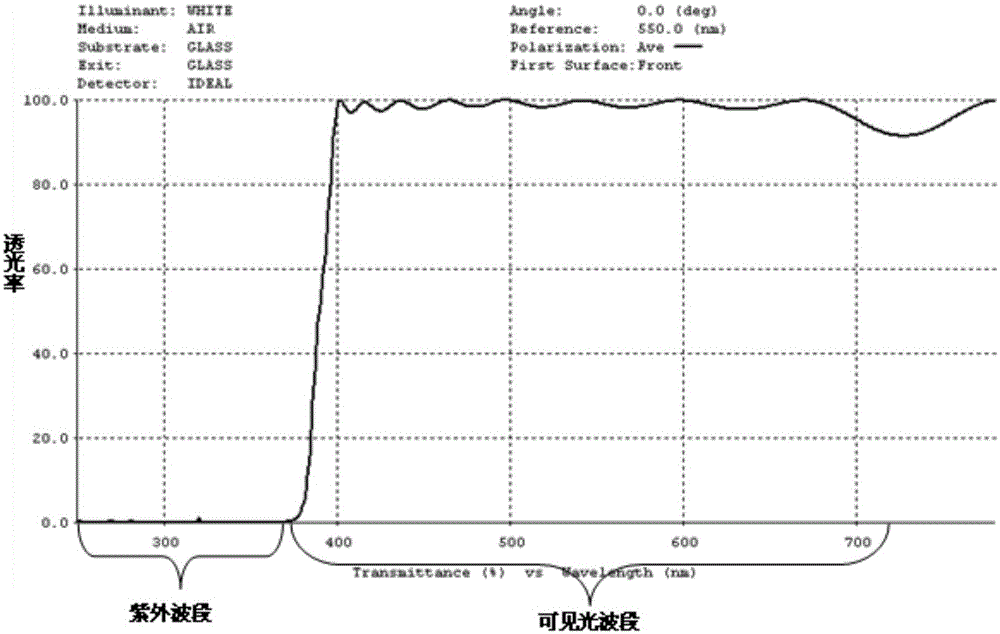

Manufacturing method for anti-ultraviolet and anti-static composite film layer

The invention discloses a manufacturing method for an anti-ultraviolet and anti-static composite film layer. The method is characterized in that: plating an anti-ultraviolet composite film layer on a to-be-plated glass surface, then plating an ATO film layer; and the anti-ultraviolet composite film layer is formed by alternating superimposition of 18 SiO2 film layers and 18 TiO2 film layers in order, and each layer of film has different thickness and is in thick-thin alternate distribution. Compared with the prior art, by plating the anti-ultraviolet composite film layer and the ATO film layer, the method provided by the invention enhances the anti-ultraviolet and anti-static functions of the to-be-plated glass on the basis of retaining the colourless and transparent characteristics of the glass itself.

Owner:WINTEK CHINA TECH LTD

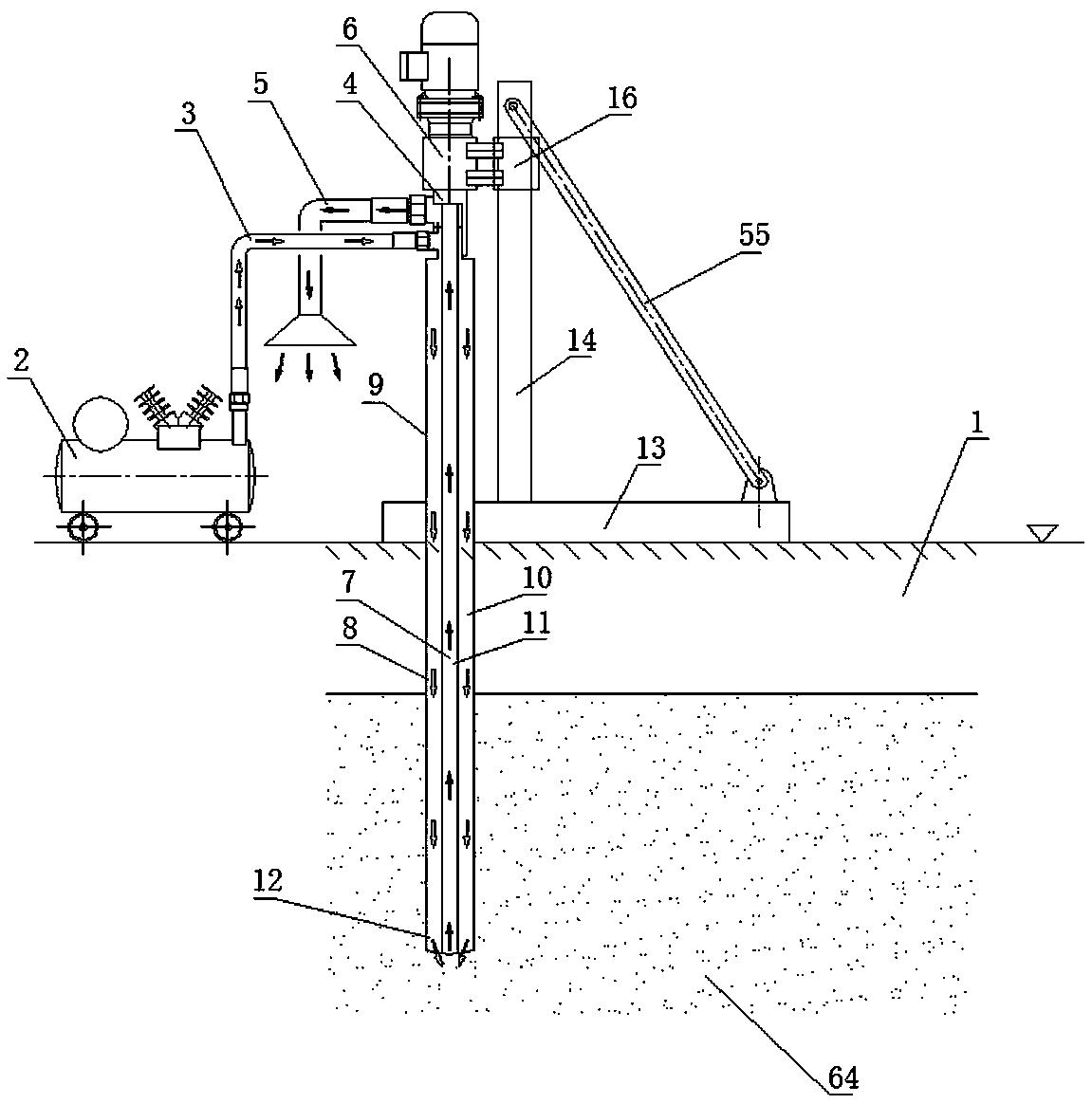

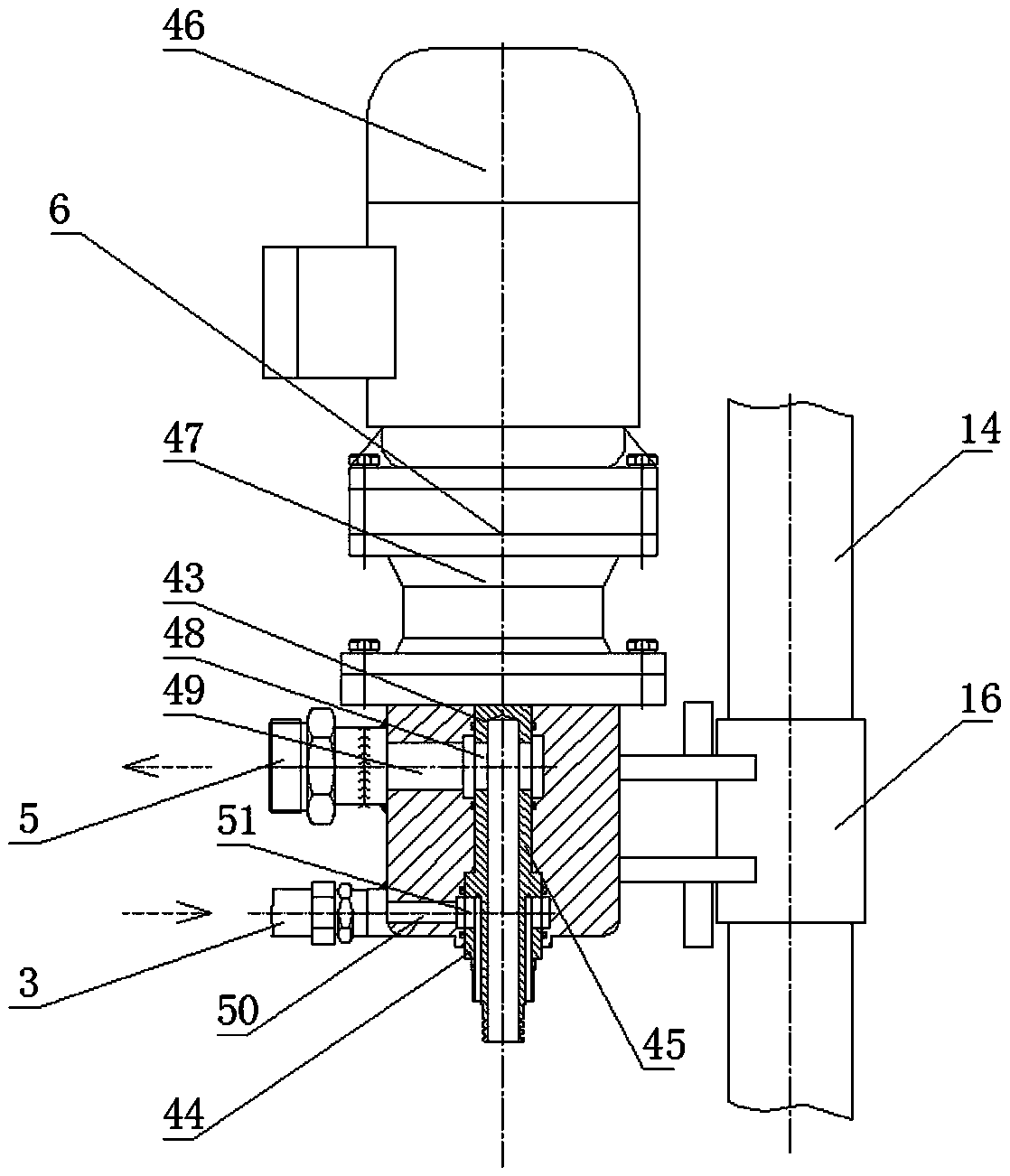

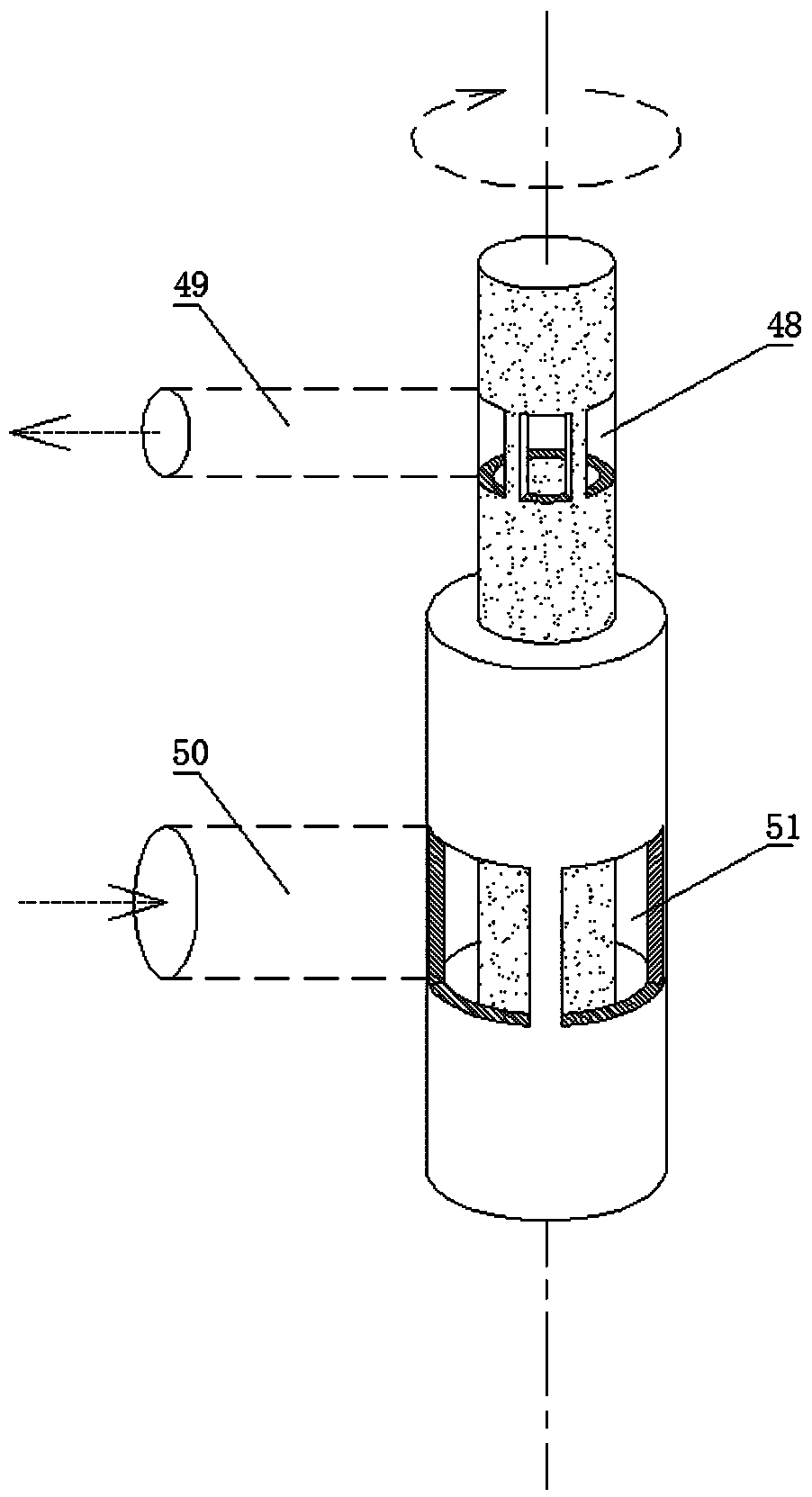

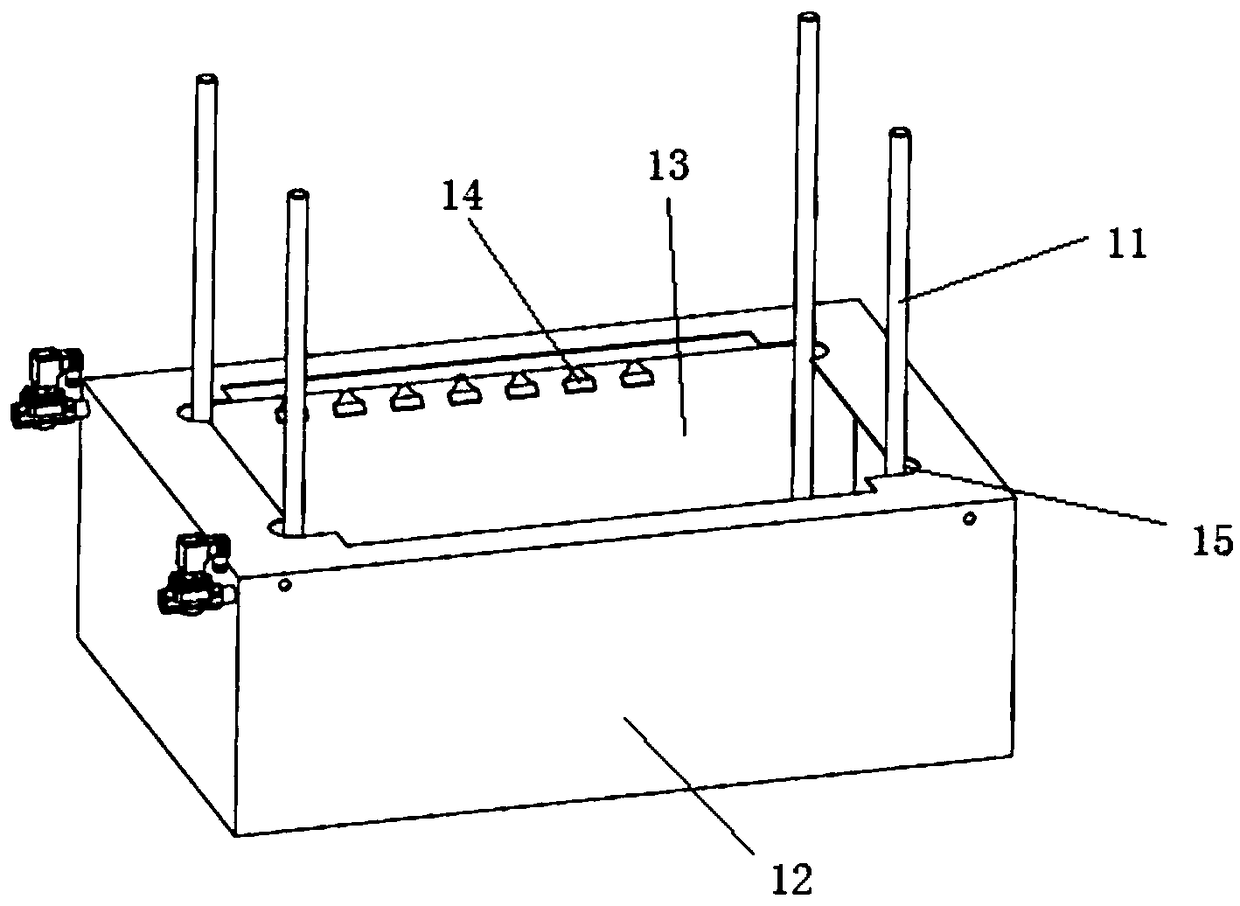

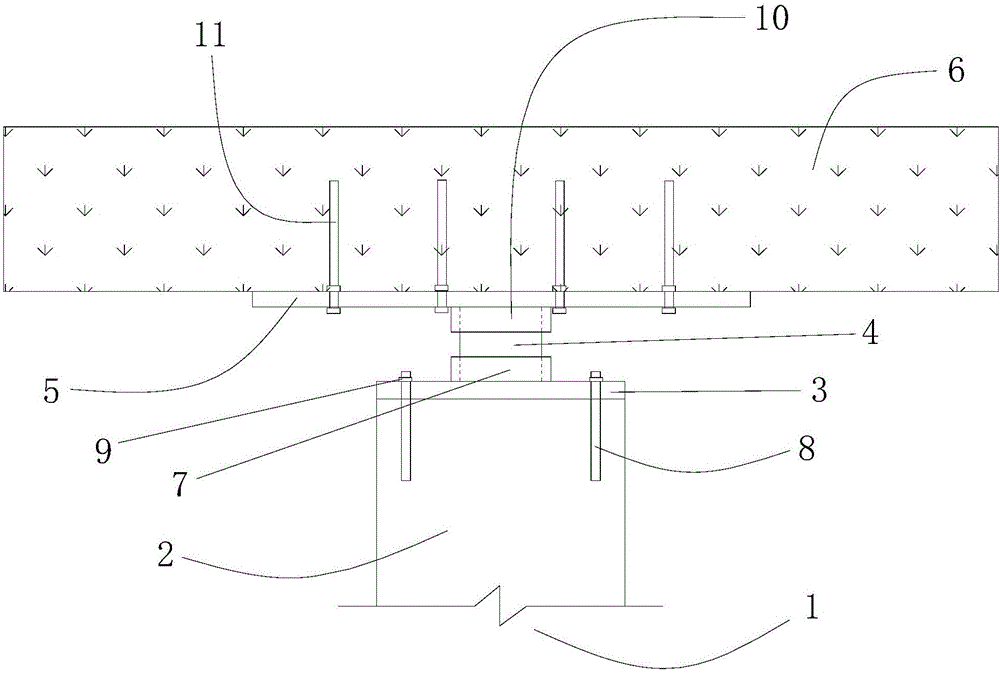

Airflow sampling method and device for grain in grain depot

The invention provides an airflow sampling method and device for grain in a grain depot, and belongs to the technical field of agricultural product inspection. As for the airflow sampling method and device, on the outside world of the grain depot, high-pressure airflow is used for being introduced into a grain heap through an airflow conveying pipeline, the high-pressure airflow and backflow of the high-pressure airflow are integrated on a sampling tube being composed by sleeving an inner tube and an outer tube, the shell side of a circular gap space between the outer wall of the inner tube and the inner wall of the outer tube of the sampling tube is used as a channel for inputting the high-pressure airflow, the tube side of an inner tube cavity is used as a channel for backflow of the high-pressure airflow, the high-pressure airflow flows back to the tube side of the inner tube at the tail end of the shell side, backflow air in the tube side of the inner tube carries grain particles to flow back to the outside world of the grain depot to obtain a sample. According to the airflow sampling method and device for the grain in the grain depot, high-pressure air is combined with the special device to solve the problem of grain sampling in the deep grain depot, meanwhile, the damage and pollution of the high-pressure air to the grain is minimal, the method is effective, the cost is economical, and the sampling effect is good.

Owner:山东省地质矿产勘查开发局第一地质大队

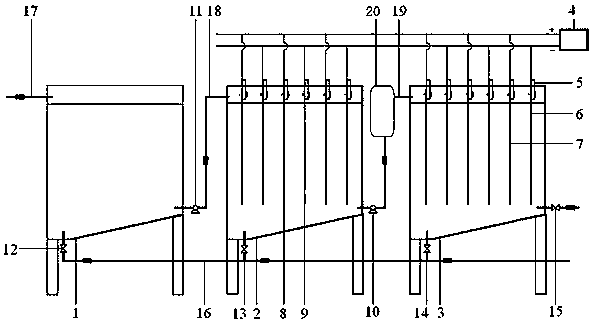

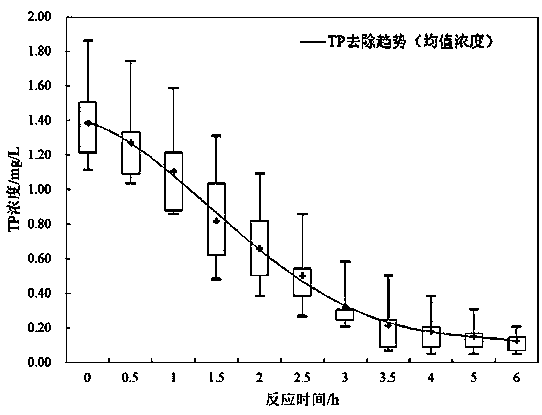

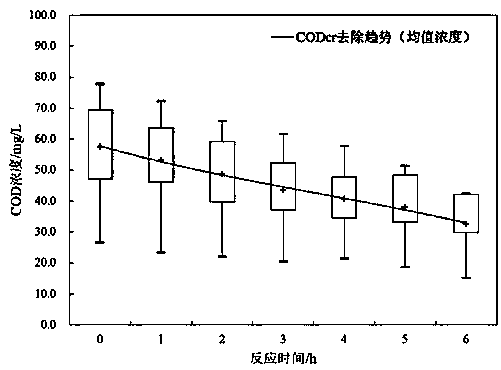

Wastewater electrochemical enhanced treatment device and method

PendingCN109231608AOvercoming the low efficiency of biological treatmentCost economyAlkali orthophosphate fertiliserWater contaminantsFertilizerElectrochemistry

The invention relates to a wastewater electrochemical enhanced treatment device and method. The device comprises a settling pool, a first electrolysis pool, a second electrolysis pool and a direct current power supply, wherein the settling pool is provided with a water inlet, the settling pool, the first electrolysis pool and the second electrolysis pool are sequentially connected through water flowing pipelines, and the second electrolysis pool is provided with a water outlet capable of being opened and closed; at least one pair of electrodes are arranged in the first electrolysis pool, and positive poles of all the pairs of the electrodes in the first electrolysis pool are made of magnesium or magnesium alloy materials; at least one pair of electrodes are arranged in the second electrolysis pool; and positive poles and negative poles of all the pair of the electrodes are electrically connected with an anode and a cathode of the direct current power supply respectively. The device iseasy to operate and has a good removal effect on nitrogen and phosphorus and organics; the device has good adaptability on treatment of various kinds of wastewater, and is not affected by fluctuationof the water quality and the water amount, and the biological activity; magnesium ammonium phosphate sediment generated in the treatment process can be recycled and serve as agricultural sustained release fertilizer, the pollution problem of nitrogen and phosphorus in the wastewater is solved, and meanwhile, waste recycling is facilitated.

Owner:CHONGQING UNIV

Formula for manufacturing wood-plastic composite section

The invention discloses a formula for manufacturing a wood-plastic composite section. The formula comprises the following materials in percentage by weight: 33.23 percent of wood fiber powder, 36.93 percent of polyvinyl chloride resin, 18.46 percent of filler, 1.48 percent of chlorinated polyethylene, 1.11 percent of acrylate copolymer, 0.45 percent of lubricant, 2.95 percent of stabilizer, 3.18 percent of plasticizer, 0.96 percent of foaming agent and 1.25 percent of toughening agent. The wood-plastic composite section manufactured by the invention has the characteristics of raw material recycling, product plasticizing, environmentally-friendly application, economic cost and renewable recovery.

Owner:李雪连

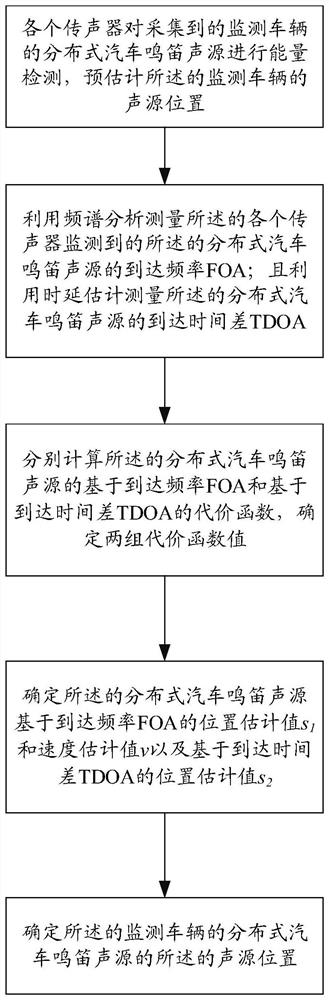

Distributed automobile whistling sound source real-time rapid positioning method, system and device capable of adapting to moving sound source, processor and storage medium

PendingCN112649788AReduce the number of microphones and computing resourcesCost economyPosition fixationMicrophoneEngineering

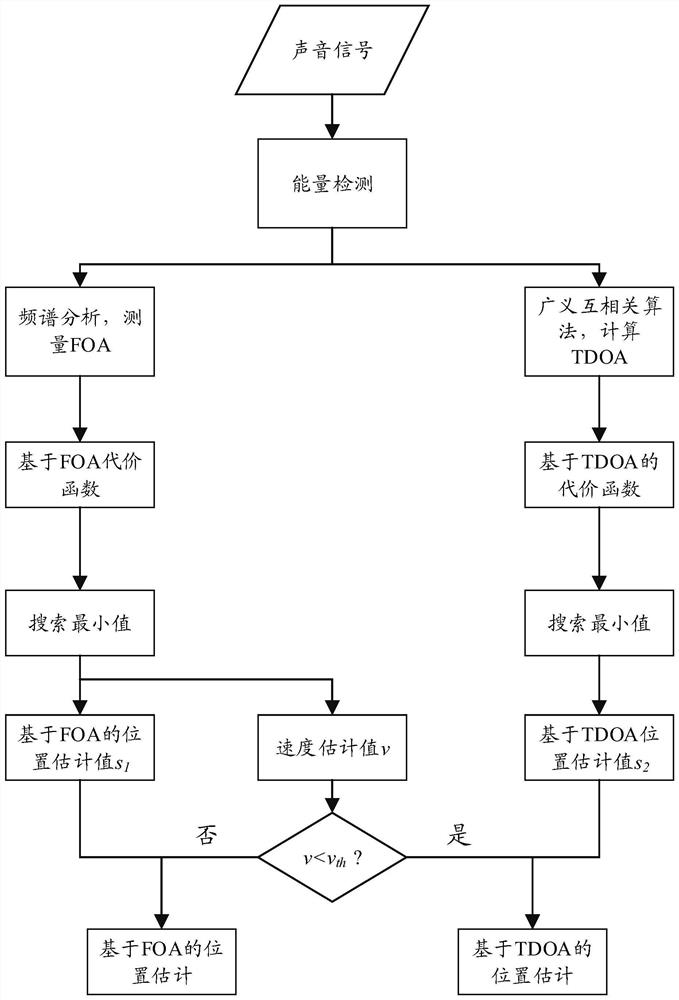

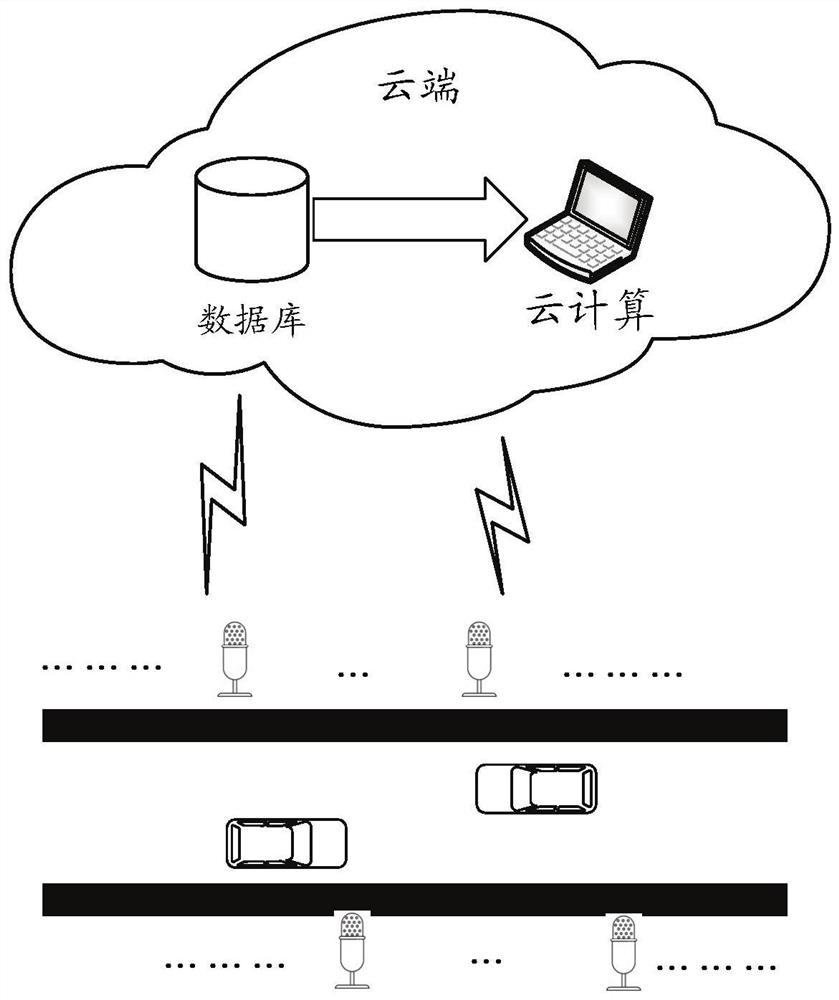

The invention relates to a TDOA-FOA-based distributed automobile whistling sound source real-time rapid positioning method capable of adapting to a moving sound source. According to the method, a distributed automobile whistling sound source of a monitored vehicle is detected through a plurality of microphones. The method specifically comprises five steps of energy detection, TDOA and FOA measurement, cost function calculation, position estimation and speed estimation and sound source position determination. The invention further relates to a corresponding system and device, a processor and a computer readable storage medium. By adopting the method, the system, the device, the processor and the computer readable storage medium provided by the invention, the bottleneck that a time difference of arrival method is difficult to adapt to a moving sound source is overcome by fully utilizing Doppler information difference among distributed microphones, and compared with a beam forming method, the method can greatly reduce the number of the microphones and operation resources; the method has the advantages of being economical in cost and flexible in deployment; and compared with other methods based on TDOA, the method has the advantages of being low in operation complexity and capable of adapting to a sound source moving at a high speed.

Owner:EAST CHINA UNIV OF SCI & TECH

Ground-effect suspended rail train

PendingCN108621858ACost economyBrakes for specific applicationsSliding/levitation railway systemsPantographEngineering

The invention provides a ground-effect suspended rail train. The ground-effect suspended rail train generates the suspension effect by utilizing the general aerodynamic principle which wings obtain lifting force and the ground effect principle; and the ground-effect suspended rail train comprises the following key parts of a wing assembly, a linear motor driving system, a guiding system, a train body supporting assembly and a train body. When the linear motor driving system is arranged on the side face of the train body, the guiding effect is achieved due to the characteristics of magnetic coupling, and at the time, the linear motor driving system and the guiding system are combined into a whole. A linear motor can be used for regenerative braking, reverse connection braking or energy consumption braking; and a linear magnetic retarder can be additionally mounted on the ground-effect suspended rail train for braking. When an armature winding, used for being connected with an external power supply, of the linear motor of the ground-effect suspended rail train is arranged on the train body, the train body needs to be additionally provided with a pantograph to be connected with an external power transmission line; and when the armature winding, used for being connected with the external power supply, of the linear motor is arranged on a rail, segmented power supplying can be achieved. The ground-effect suspended rail train can be designed to meet the freight transportation or passenger transportation demands.

Owner:李启飞

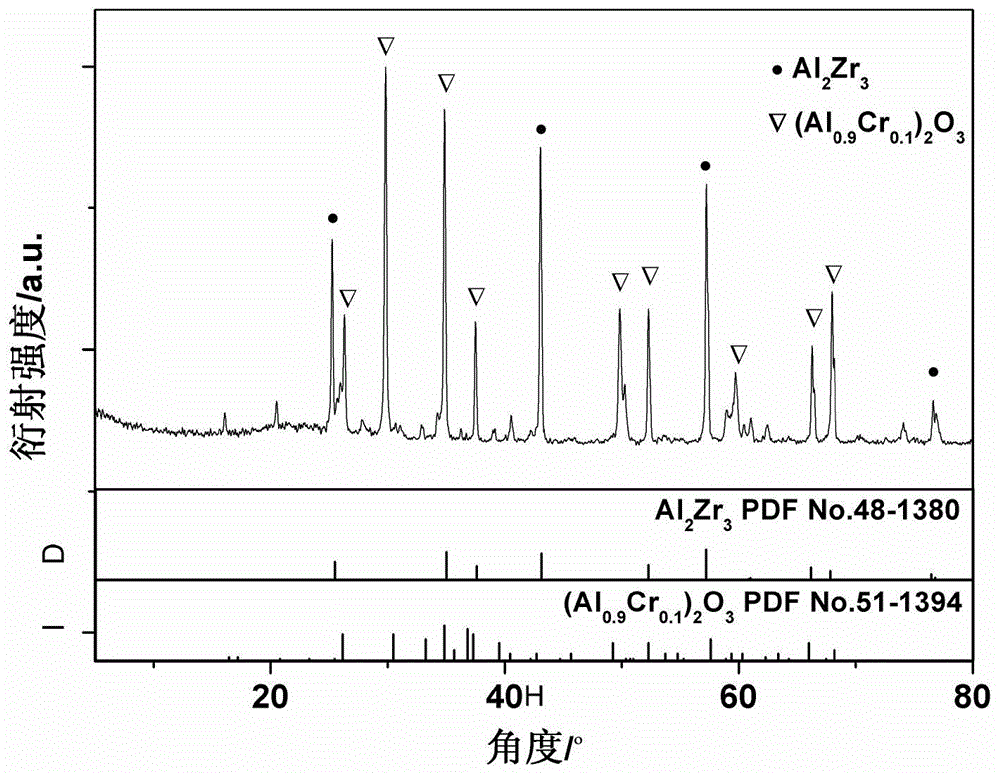

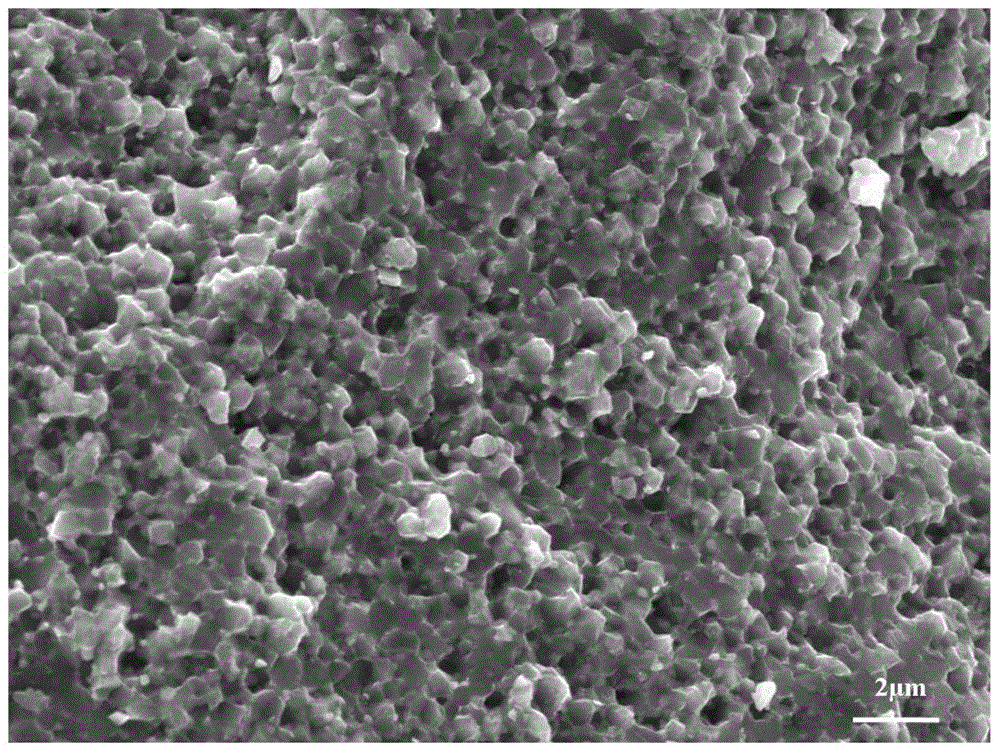

Manufacturing method of composite oxide ceramic chopper

The invention provides a manufacturing method of a composite oxide ceramic chopper. The method includes the steps of dissolving organic monomers, cross-linking agents and dispersing agents in distilled water to prepare premixed liquid, adding aluminum oxide ceramic powder, adding zirconium oxide balls to conduct ball milling, adding initiating agents and defoaming agents, conducting uniform ball milling to obtain sizing agents, pouring the sizing agents in a mold, covering the mold with a mold cover, standing still at the room temperature, polymerizing the organic monomers in the sizing agents to achieve the gelatinization process, taking the mixture out of the mold, and conducting drying and sintering in a vacuum oven, wherein steel needles with the diameter of 0.02 mm to 0.08 mm are arranged on the lower portion of the mold cover. The composite oxide ceramic chopper is manufactured through the gel casting process, the in-situ curing process of high-concentration suspensoid sol and the slip casting process of ceramic bodies are effectively combined, ceramic chopper green bodies which are high in density and strength and quite uniform in component and structure can be manufactured within a short time, the manufacturing method has the advantages of being simple in process, economical in cost, few in green body forming defect and the like, and the composite oxide ceramic chopper can be more easily produced in an industrialized mode.

Owner:SHAANXI UNIV OF SCI & TECH

SiC composite powder applied to infrared radiation energy-saving coating and preparation method of SiC composite powder

ActiveCN108276823AEasy to operateCost economyChemical industryCoatingsOxidation resistantTube furnace

The invention relates to SiC composite powder applied to an infrared radiation energy-saving coating and a preparation method of the SiC composite powder, and belongs to the technical field of functional materials. The SiC composite powder applied to the infrared radiation energy-saving coating is characterized by being coated with a mullite-phase antioxidant protective layer on the surfaces of particles, and the preparation method of the SiC composite powder applied to the infrared radiation energy-saving coating comprises the following steps: 1, ultrasonically dispersing SiC powder particlesto industrial aluminum sol; 2, adding industrial silica sol and uniformly stirring; 3, pouring into an open flat-bottomed utensil and drying in an oven to obtain slurry; 4, putting in a vacuum dryingbox to be dried in vacuum at room temperature; 5, grinding into fine powder particles; 6, placing the fine powder particles into a rotating tube furnace, calcining rotationally at a constant speed, and naturally cooling to obtain the SiC composite powder of which the surface is coated with the mullite-phase antioxidant protective layer. The SiC composite powder applied to the infrared radiation energy-saving coating disclosed by the invention has the advantages of excellent high-temperature oxidation resistance, low cost, simple and convenient technological process, high controllability, wideapplication prospects and the like.

Owner:天津中材工程研究中心有限公司

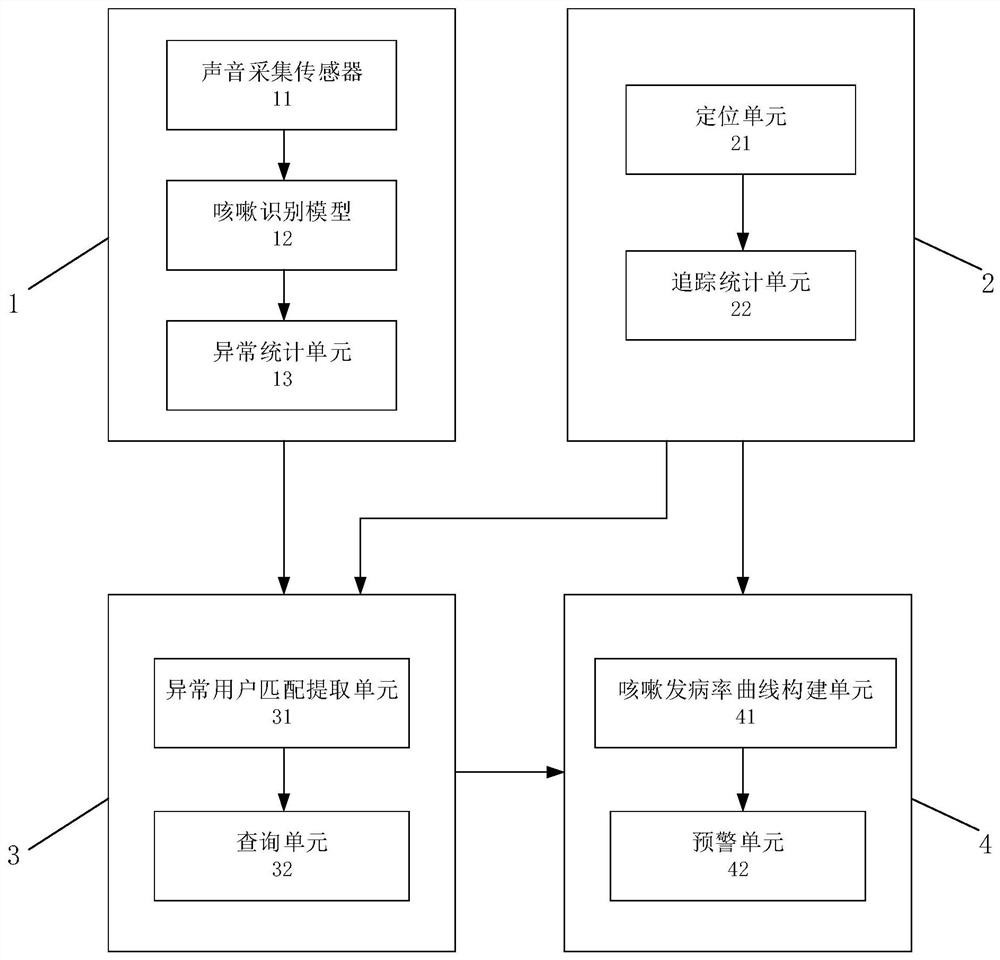

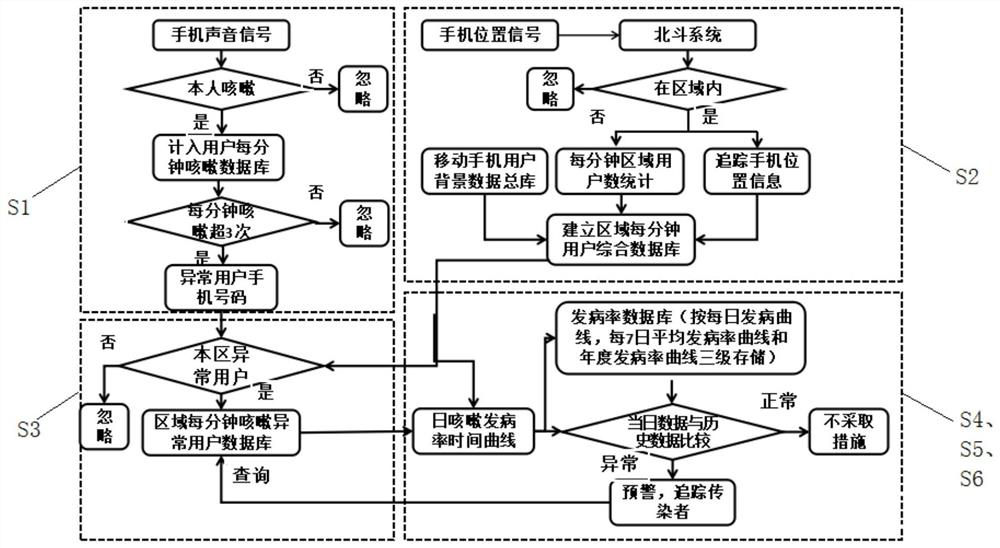

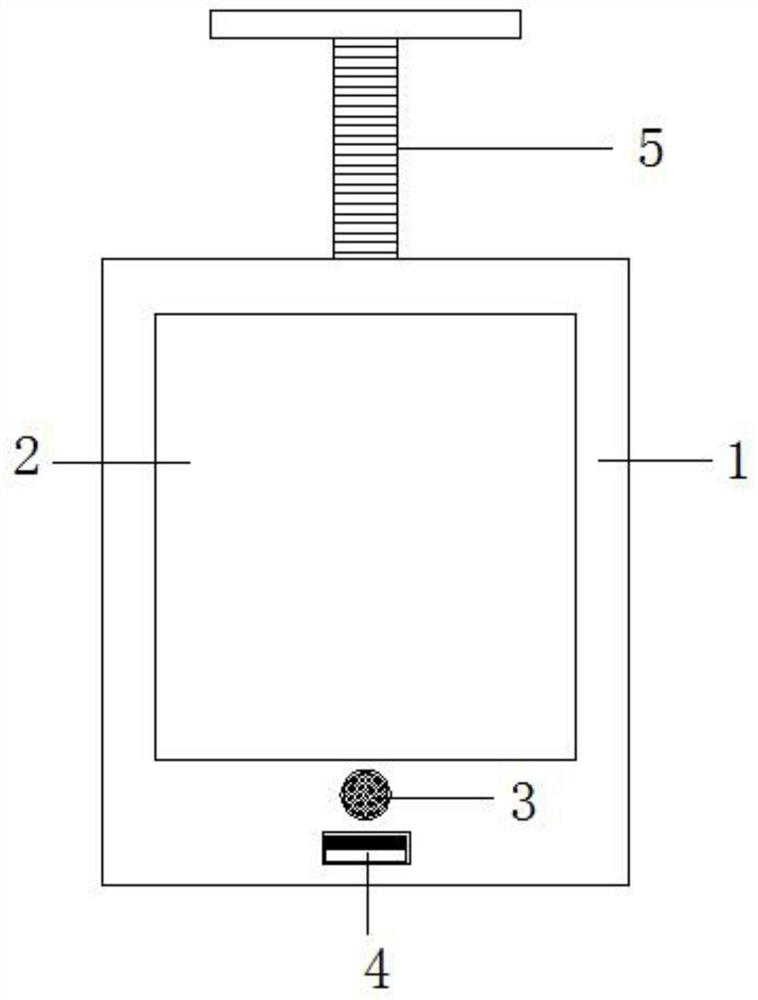

Respiratory infectious disease monitoring system and method based on cough symptoms

PendingCN111653367ACost economyEasy to useEpidemiological alert systemsPatient-specific dataMedical emergencyBackground information

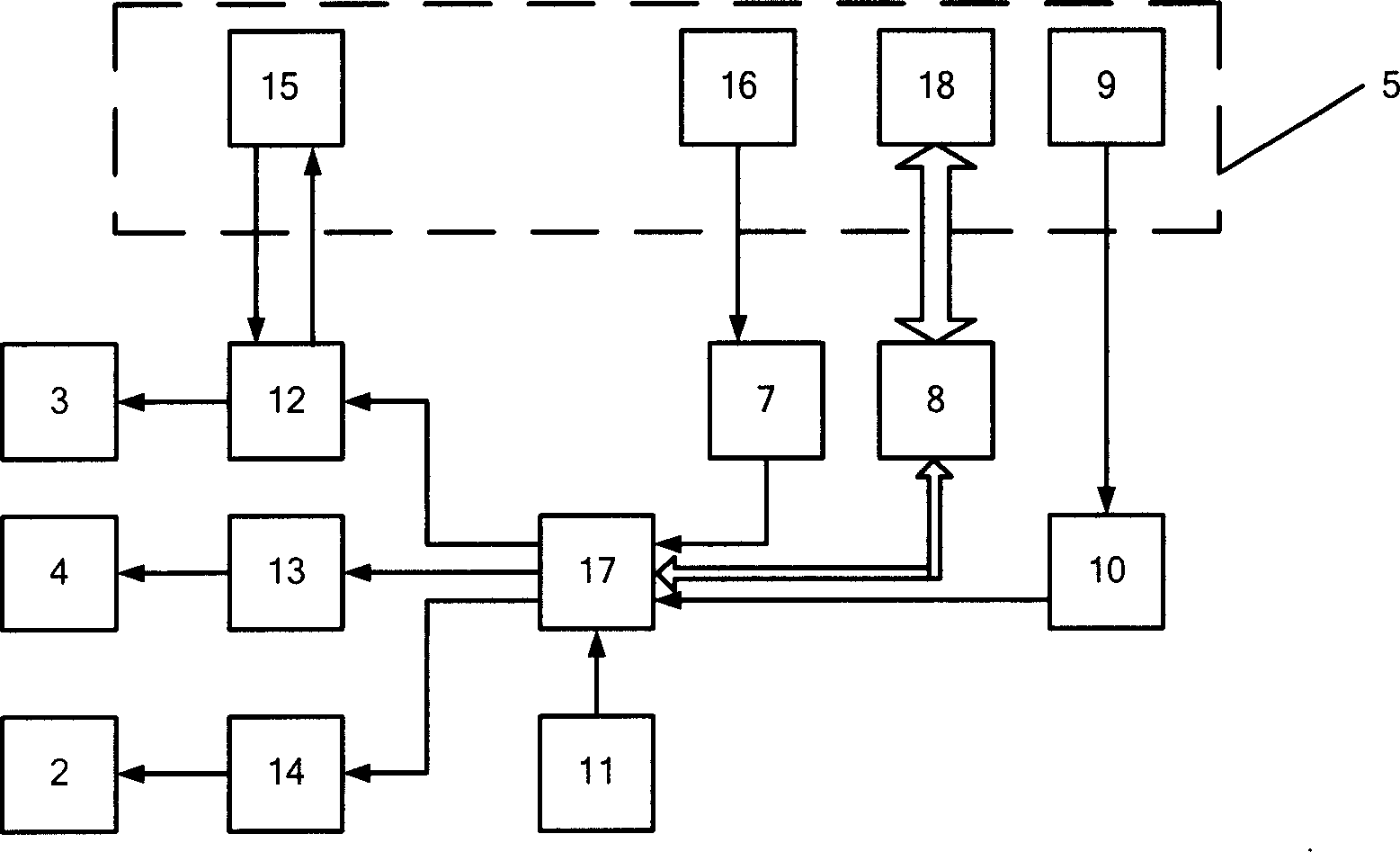

The invention relates to a respiratory infectious disease monitoring system and method based on cough symptoms. The system comprises: a cough detection and abnormality analysis module (1) for directionally recognizing the cough symptoms of a user based on user terminal equipment, judging whether the symptoms are abnormal, and uploading user detection abnormal information when the symptoms are abnormal; an intra-region user tracking and real-time statistics module (2) for establishing an intra-region real-time user database, wherein the intra-region real-time user database comprises intra-region user terminal quantity information, geographic position information and user background information; a cough user information screening and arranging module (3) for receiving user detection abnormalinformation and the real-time user database to form an abnormal user database; and a summarizing and early warning module (4) for receiving the abnormal user database and the real-time user database,calculating and storing a cough morbidity curve and carrying out early warning on infectious diseases according to the cough morbidity curve. Compared with the prior art, the system and the method ofthe invention have the characteristics that coverage rate of disease monitoring people is greatly improved, and the accuracy of infectious disease monitoring is high.

Owner:TONGJI UNIV

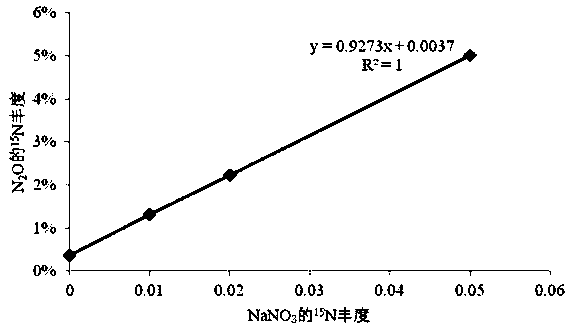

Method for preparing N2O with determined <15>N abundance and measuring nitrogen cycle based on <15>N isotope tracer technology

ActiveCN108300666AEasy to operateCost economyFungiMicrobiological testing/measurementPenicilliumNatural abundance

The invention relates to a method for preparing N2O with a determined <15>N abundance by using Penicillium janthinillum and measuring nitrogen cycle based on a <15>N isotope tracer technology, and belongs to the biotechnical field. The Penicillium janthinillum is preserved in China General Microbiological Culture Collection Center on August 7, 2017 with the storage number of CGMCC No. 14146. The method for preparing N2O with the determined <15>N abundance comprises the following steps: collecting a soil sample, diluting the soil sample, and carrying out culturing, gas measurement screening andidentification on the above strain; and preparing a Czapek Dox liquid medium by using NaNO3 with the determined <15>N abundance, inoculating the medium with the Penicillium janthinillum strain, performing shaking culture, collecting produced N2O, and adding an alkaline solution to absorb and remove CO2 in the N2O in order to obtain the N2O with the determined <15>N abundance. The method has the advantages of rapidness and accuracy in gas production, simplicity in operation and low cost; and the prepared gas achieves highly accurate and highly precise results when used in nitrogen cycle studying as a standard gas.

Owner:NINGBO URBAN ENVIRONMENT OBSERVATION & RES STATION NUEORS CHINESE ACADEMY OF SCI +1

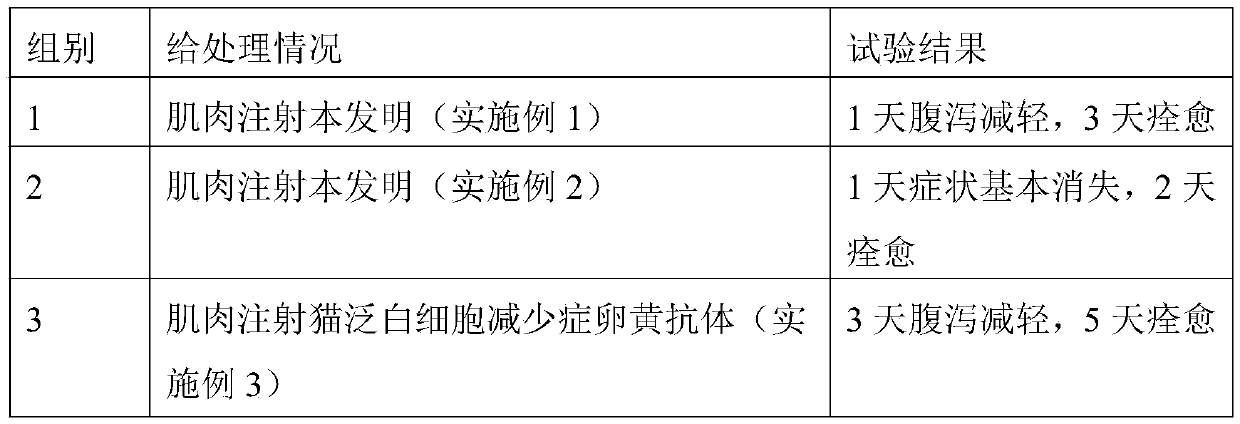

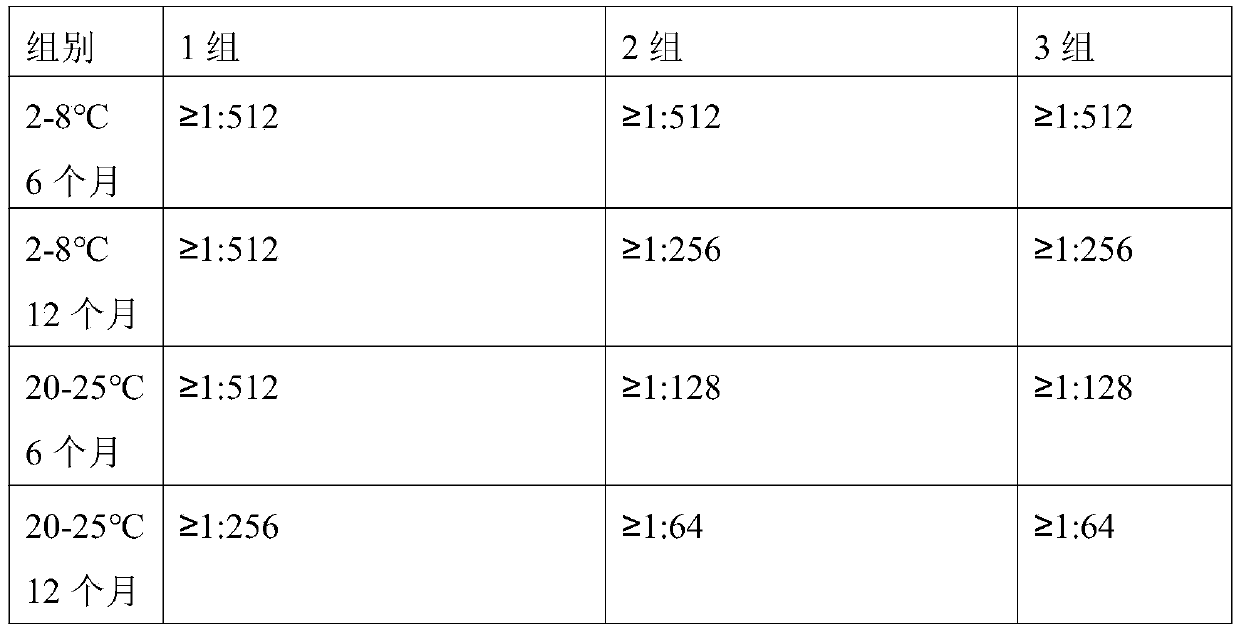

Preparation method of protective liquid containing feline panleukopenia yolk antibodies

InactiveCN111068050ASimple methodCost economyOrganic active ingredientsPharmaceutical delivery mechanismPhosphoric acidFeline panleucopenia

The invention provides a preparation method of a protective liquid containing feline panleukopenia yolk antibodies. The effective components and weight ratio of the protective liquid are respectivelyas follows: 20-40 parts of konjac gum; 20-30 parts of portulaca flavone; 10-30 parts of sucrose, 5-10 parts of Lactobacillus and 800-1000 parts of phosphoric acid buffer. According to the present invention, the excretion of toxins and garbage in cat body can be promoted by the natural plant effective ingredients and Lactobacillus in the protective liquid, and at the same time, the protective liquid has the effects of calming, reducing dryness, enhancing resistance, and avoiding the stress reaction of antibody immunity.

Owner:TIANJIN HLINTE BIOTECH CO LTD

Rock paint

The invention relates to the field of building paint, in particular to rock paint. The invention is characterized in that the rock paint comprises natural marble powder, paint, water, cellulose, thickening agents, defoaming agents, lubricating agents and corrosion agents. The invention has the advantages of good safety performance, water prevention, heat insulation, safe and simple operation and low cost.

Owner:郎叶龙

Universal mildew inhibitor

The invention discloses a universal mildew inhibitor. The universal mildew inhibitor comprises the following components by mass: 4 to 6 parts of silver chloride, 3 to 5 parts of fatty alcohol polyoxyethylene ether, 7 to 9 parts of aluminum hydroxide, 2 to 4 parts of an ethanol solution of propolis, 1 to 3 parts of an etherifying agent, 1 to 3 parts of an antiseptic, 8 to 12 parts of pine needle extract, 1 to 3 parts of bromogeramine and 1 to 2 parts of an adsorbent. The universal mildew inhibitor has the advantages of low dosage, cost performance, long-term fungicidal action, a wide pH application scope, convenience in feeding and safety in usage.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

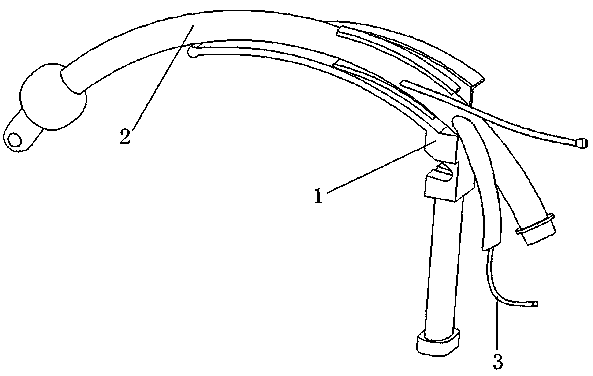

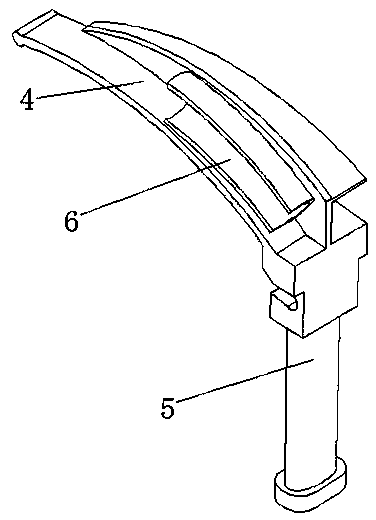

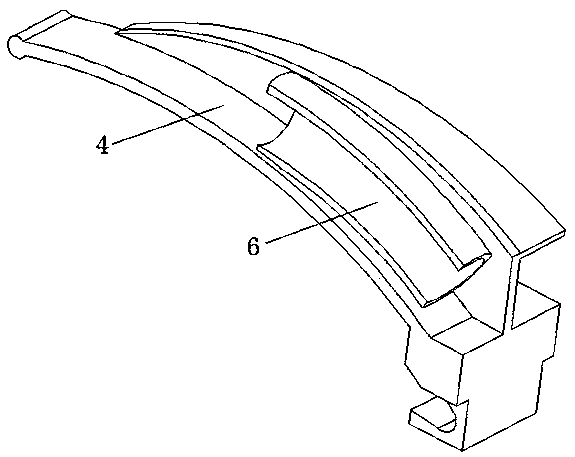

First-aid laryngoscope system integrating visualization and oxygen supply

The invention relates to a first-aid laryngoscope system integrating visualization and oxygen supply. The first-aid laryngoscope system comprises a laryngoscope, a working catheter and an endoscope, wherein the laryngoscope comprises a laryngoscope lens and a laryngoscope handle, the laryngoscope lens is clamped to the laryngoscope handle and provided with a catheter groove, the working catheter is arranged in the catheter groove, and the endoscope is arranged in the working catheter. The first-aid laryngoscope system has the advantages that the system is capable of being operated fast, low in cost, capable of saving rescue time, simple in structure, easy to manufacture, suitable for industrial production, popularization and application, and the like; first-aid staff can diagnose fast by observing the conditions in the trachea of a patient after opening the trachea, fast oxygen supply can be performed at the same time, and rescue time is saved.

Owner:云南省急救中心

Portable wearable RFID module

InactiveCN112115729ASimple structureCost economyMachine supportsCo-operative working arrangementsEmbedded systemRadio frequency

The invention discloses a portable wearable RFID module which comprises a main body, an RFID reader is arranged at the front end of the main body, a switch button and a USB charging port are arrangedbelow the RFID reader, a fastening screw is connected to the top of the rear end of the main body in a meshed mode, and a clamping block is connected to the end of the fastening screw through a bearing in a matched mode. A positioning groove is formed in the middle of the clamping block, a non-slip mat is fixed to the surface of the clamping block, a positioning groove is also formed in the middleof the bottom of the rear end of the main body, a non-slip mat is also fixed to the surface of the bottom of the rear end of the main body, and the interior of the main body is mainly composed of a control circuit board, a storage battery and a WiFi module. According to the portable wearable RFID module, the information in the RFID tag can be quickly identified and acquired by applying a radio frequency identification technology, and the portable wearable RFID module is simple in overall composition structure, economical in cost, small in size, convenient to carry, capable of being worn on agoods shelf, a counter and other objects, easy to operate and high in use flexibility.

Owner:QINGDAO YUNSHANG YUYI WULIAN TECH CO LTD

Biological mildew inhibitor

The invention discloses a biological mildew inhibitor, which is composed of the following components in parts by weight: 10 to 12 parts of polymer nano carrier, 4 to 6 parts of n-octyl, 2 to 3 parts of bromogeramine, 1 to 3 parts of chlorothalonil, 1 to 3 parts of propolis ethanol solution, 1 to 2 parts of water obstructing agent, 1 to 2 parts of antibacterial agent, 8 to 10 parts of natamycin, and 1 to 3 parts of emulsifier. The biological mildew inhibitor has a very good effect on inhibiting mildew, does not have any corrosive effect on clothes and furniture, and will not cause color fading or leave any spot on clothes and furniture.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

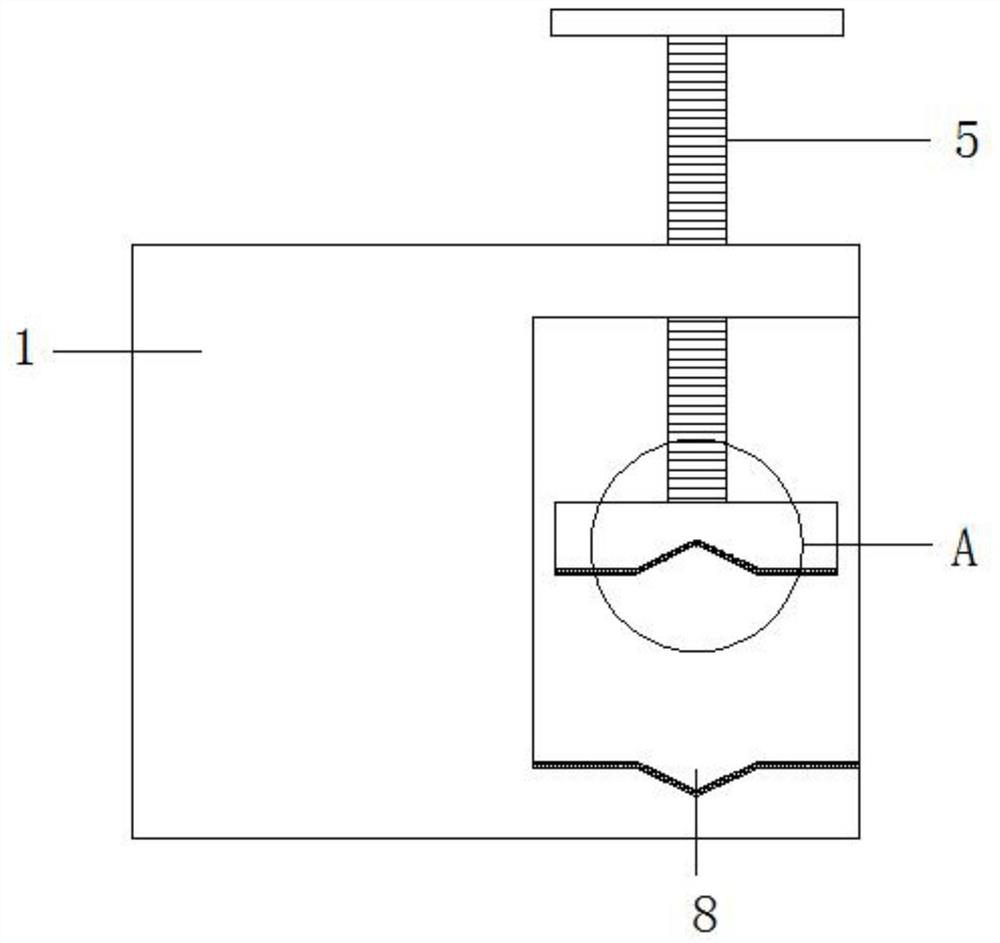

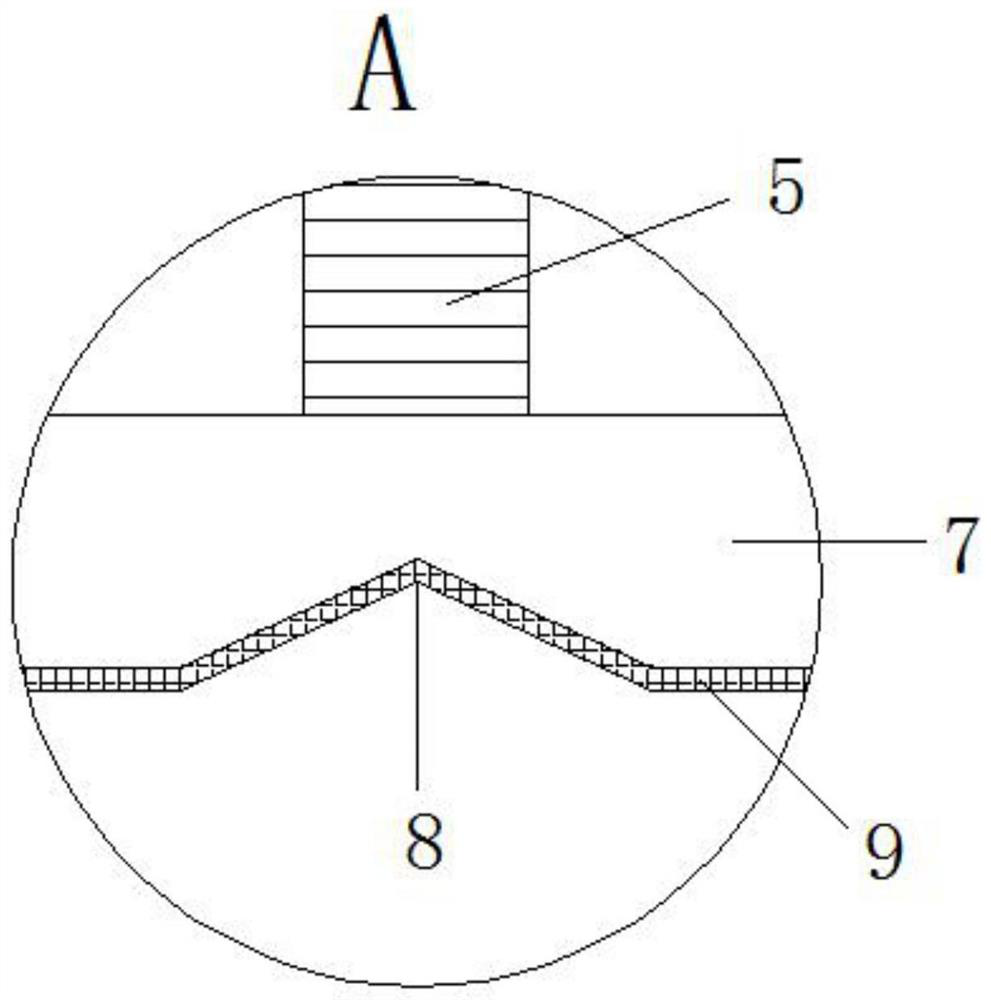

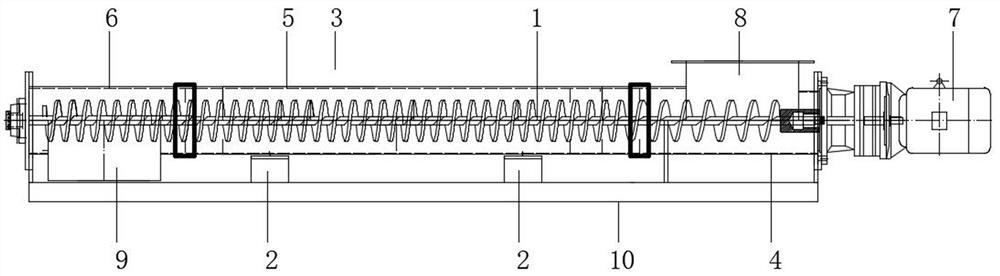

Spiral continuous weighing method for rock debris

PendingCN114061717ASave installation spaceCost economyConveyorsWeighing apparatus for materials with special property/formScrew conveyorGeotechnical engineering

The invention discloses a spiral continuous weighing method for rock debris, which comprises a spiral shaft, a weighing assembly and a conveying cylinder, the conveying cylinder comprises a feeding section, a metering section and a discharging section which are sequentially and flexibly connected in a sealed manner, the spiral shaft is rotatably arranged in the conveying cylinder, and two ends of the spiral shaft are respectively arranged in the feeding section and the discharging section through bearings. The weighing assembly is fixedly connected below the metering section; Therefore, during continuous weighing, 1, the transmission metering period of the rock debris passing through the metering section is calculated; 2, the weight of rock debris in the metering section in each transmission metering period is collected according to the transmission metering period; and 3, summing of the weights of the rock debris collected in each transmission metering period is carried out to obtain the total weight of the rock debris. An existing spiral conveyor is improved to be of a three-section type connecting structure comprising feeding, weighing and discharging, so that the impact of feeding and the adhesion of rock debris cannot affect the weighing of the rock debris, and the processing capacity of instantaneous mass feeding is improved while the weighing precision is guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Automatic fire extinguishing battery capacity grading cabinet

InactiveCN108630998ASimple structureCost economyFinal product manufactureSecondary cells manufactureOutbreakEngineering

The invention relates to an automatic fire extinguishing battery capacity grading cabinet, comprising a water-spray fire extinguishing water tank, a battery tray mechanism and an electrified probe mechanism, wherein the water-spray fire extinguishing water tank is provided with a guide rod; the guide rod is provided with a band-type brake guide shoe which is matched with the guide rod in a slidingway; the battery tray mechanism is arranged on the band-type brake guide shoe; the battery tray mechanism slides down towards the interior of the water-spray fire extinguishing water tank by means ofthe sliding fit between the band-type brake guide shoe and the guide rod; a heavy hammer mechanism is arranged above the battery tray mechanism; the heavy hammer mechanism is hung above the battery tray mechanism by means of a tensioning mechanism; the electrified probe mechanism is arranged above the battery tray mechanism and is connected with the guide rod in a sliding way; the heavy hammer mechanism is connected with the electrified probe mechanism in a sliding way by means of a sliding rod. The automatic fire extinguishing battery capacity grading cabinet is simple in structure; after outbreak of a fire, a mechanical control device also can rapidly isolate a fire source and put out the fire under the premise that electric control is burnt up, so that an effect of dual protection is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

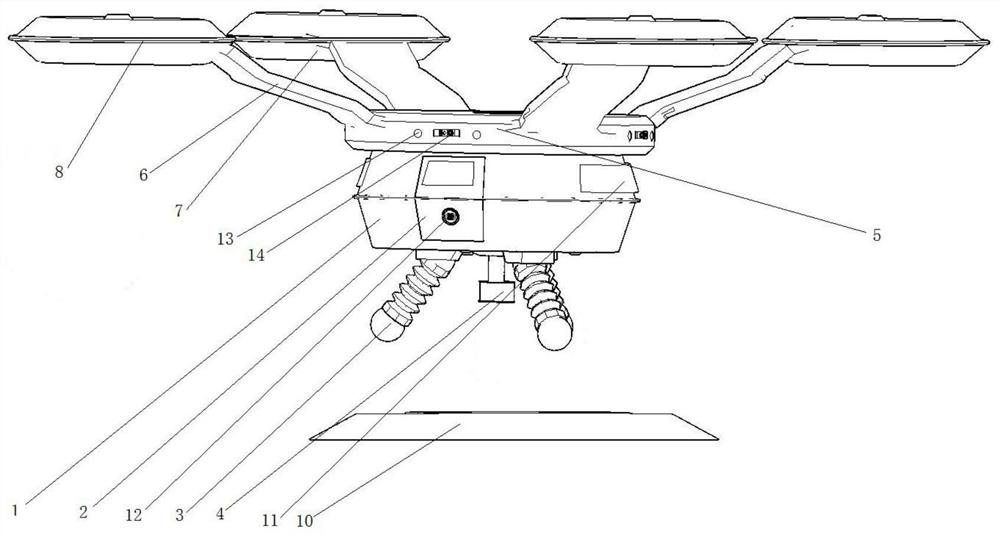

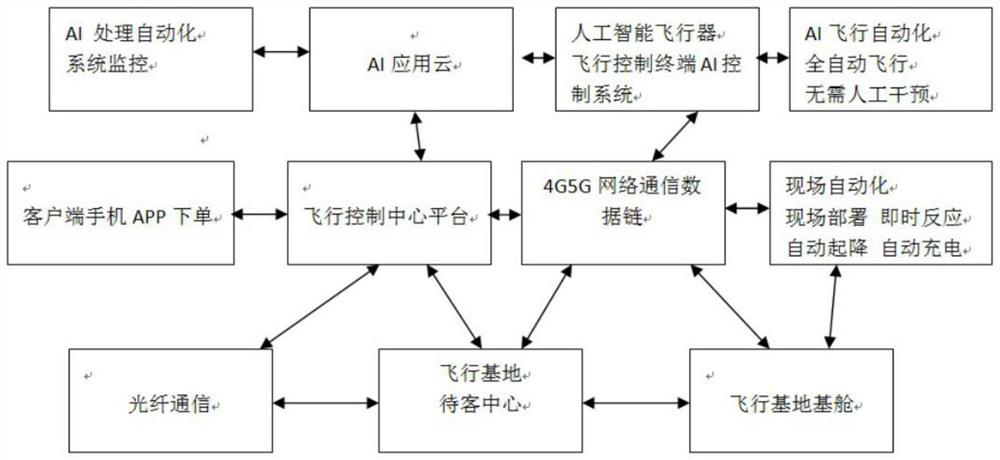

Artificial intelligence aircraft

InactiveCN111776220ACost economyReduce ground traffic pressureCharging stationsEfficient propulsion technologiesFlight vehicleElectric machinery

The invention discloses an artificial intelligence aircraft. The aircraft comprises an artificial intelligence aircraft body and a supporting system; the artificial intelligence aircraft body comprises a cabin, a cabin door is arranged on the cabin, undercarriages are mounted at the bottom of the cabin, radars are installed between the undercarriages, a power battery pack is installed at the top of the cabin and arranged in the cabin, a connecting arm is installed at the top of the exterior of the cabin, a power assembly motor and blades are installed on the connecting arm, the supporting system comprises a flight base, the flight base is provided with a charging base, and a control platform is further arranged in the flight base. Compared with the prior art, the artificial intelligence aircraft has the advantages that passengers can reserve travel in real time through mobile phones, the cost is low, an electric power device is adopted, environmental protection and no pollution are achieved, the ground traffic pressure is reduced, the problem of inter-city travel is solved, precious travel time of people is saved, and wider development space is provided for future city development.

Owner:丁志峰

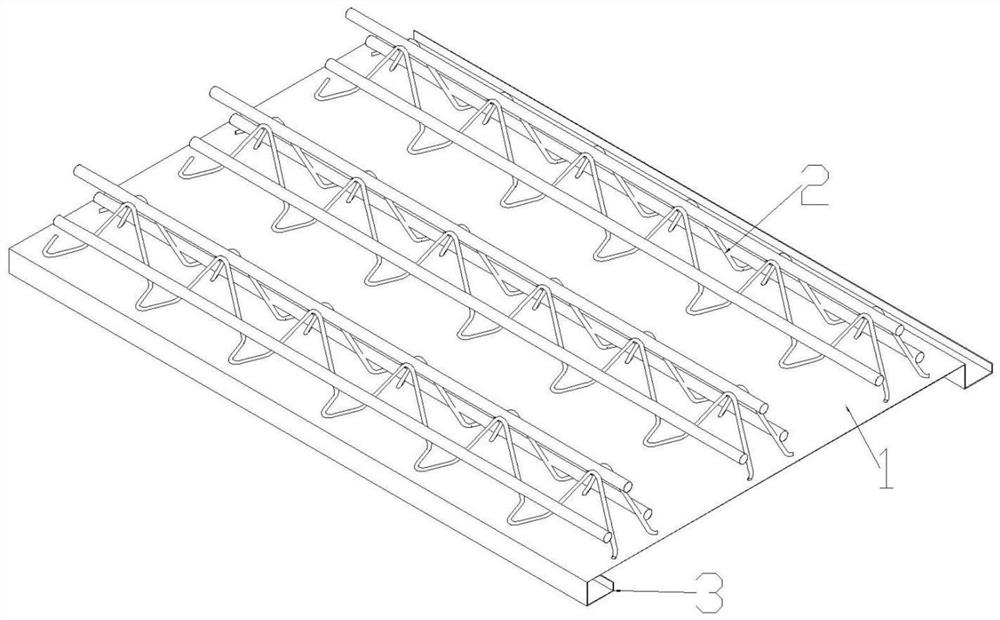

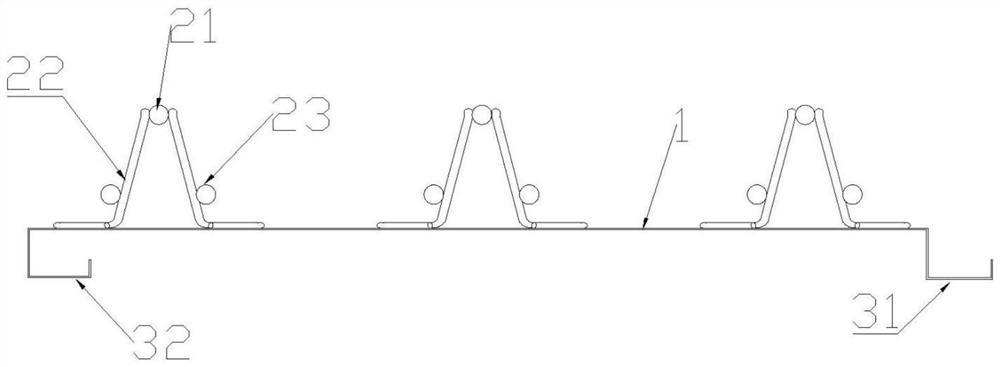

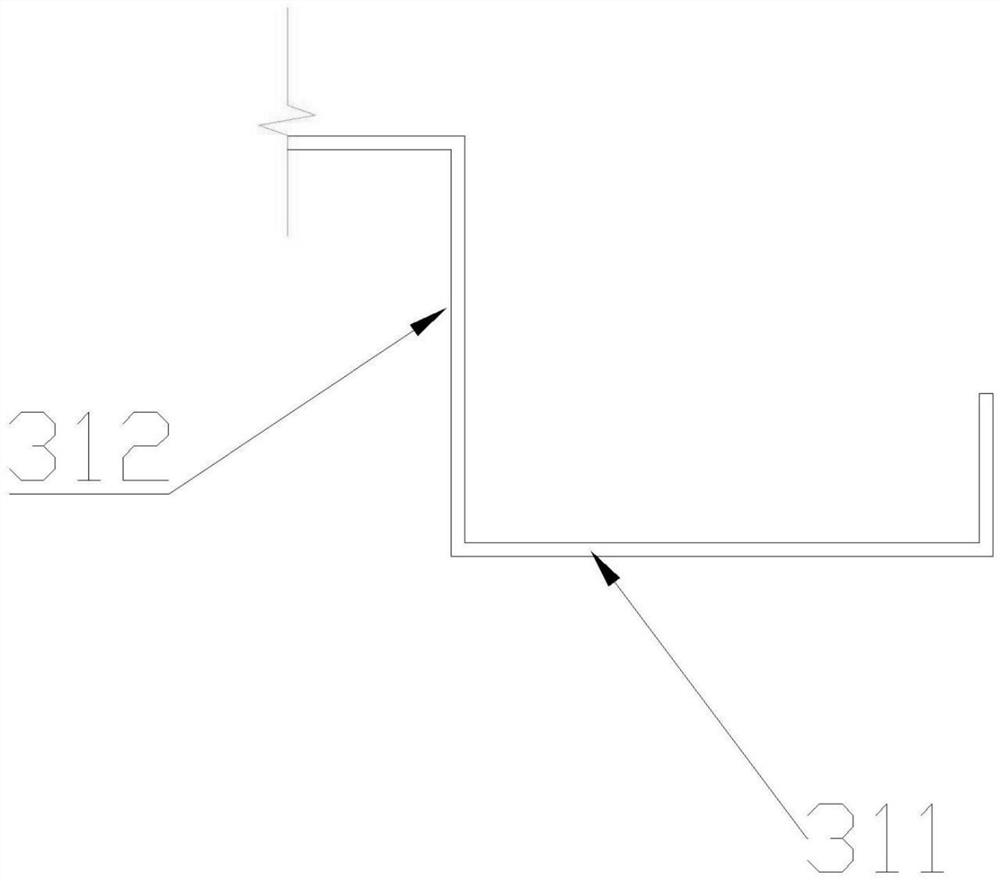

Steel bar truss floor support plate with hanging ribs

The invention provides a steel bar truss floor support plate with hanging ribs. The steel bar truss floor support plate comprises a bottom plate and a steel bar truss; the steel bar truss is fixed on the bottom plate; and at least two hanging ribs are arranged on the back face of the bottom plate, namely the side back to the steel bar truss. By arranging the hanging ribs, a gypsum board or other decorative boards can be conveniently connected with the bottom of the floor support plate through self-tapping screws to form a suspended ceiling, the construction difficulty is reduced, and the overall structure of the floor support plate is protected. If no hanging rib exists, the self-tapping screws are directly hit on a concrete slab, labor and work are wasted, and the structure of the concrete slab is damaged.

Owner:SHANGHAI OPEN STEEL JOIST

Degradable biomass fiber composite packaging product and preparation process thereof

The invention belongs to the technical field of degradable packaging materials, and particularly relates to a degradable biomass fiber composite packaging product and a preparation process thereof. The degradable biomass fiber composite packaging product provided by the invention is prepared from the following components in parts by weight: 100 parts of straw powder; 30-50 parts of hemp fiber powder; 10 to 20 parts of starch; 6 to 12 parts of gamma-chloropropyl methyl diethoxy silane; 10 to 20 parts of polylactic acid; 20-40 parts of methacrylic acid epoxy resin; 4 to 10 parts of triethylene tetramine; 4-8 parts of ammonium bicarbonate; 3-6 parts of sodium abietate; the total amount of other auxiliaries is not more than 12 parts. The degradable biomass fiber composite packaging product is economical in cost, wide in raw material source and good in degradability, the degradation period in a conventional natural environment is 8-20 months, the packaging strength requirement is met, and long-term harm to the environment is not caused after the degradable biomass fiber composite packaging product is abandoned. The preparation process of the degradable biomass fiber composite packaging product provided by the invention has the advantages of simple steps, convenience in manufacturing and convenience in automatic batch production.

Owner:太仓缤克新材料有限公司

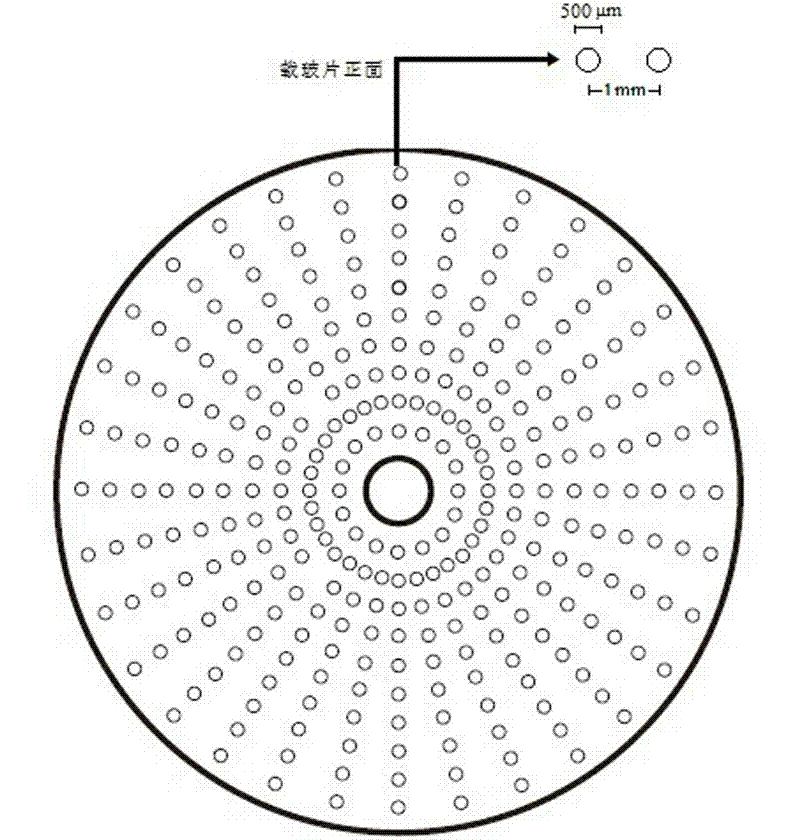

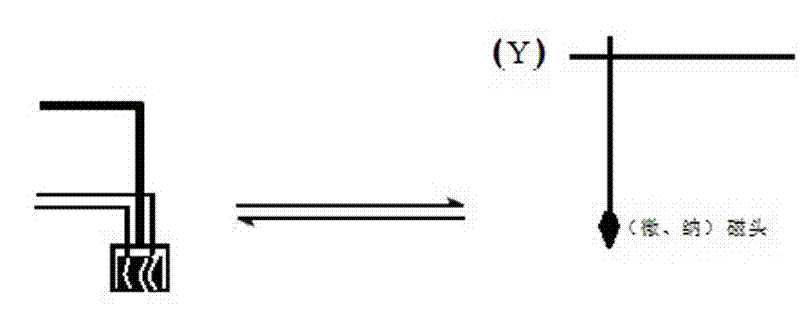

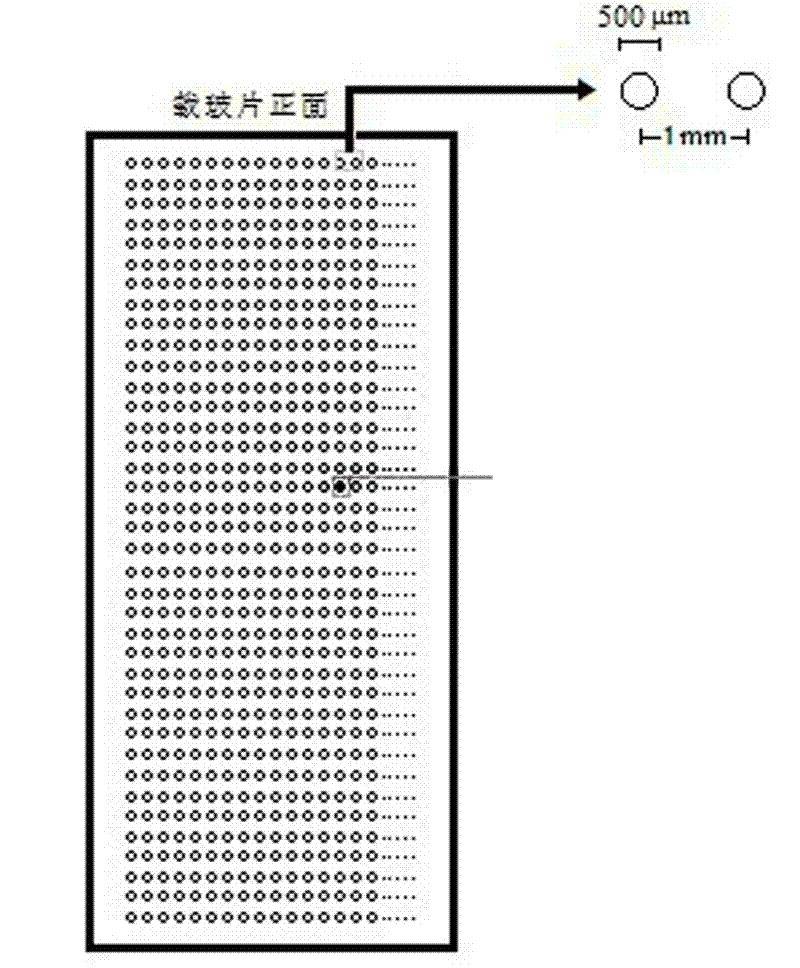

Gene chip detection method on basis of micro and nano magnetic heads

InactiveCN102653788ASimple detection routeCost economyMicrobiological testing/measurementMagnetoNuclear magnetic resonance

The invention discloses a gene chip detection method on the basis of micro and nano magnetic heads. The gene chip detection method adopts a detection principle similar to the working mode of a hard disc, and the micro and nano magnetic heads formed by GMR (Giant Magneto Resistive) sensors such as a spin valve (SV) or MTJ (Magnetic Tunnel Junction) slide on the surface of a gene chip to read magnetic markers rapidly and with high flux and to provide relevant biological information further. Compared with the prior art, the method greatly changes a magnetic particle marking process, remarkably improves the maximum saturation magnetization of magnetic particles and decreases the requirements on a magnetic detection device through developing a specific palladium marker magnetism dying technology, thus having a wide potential application prospect.

Owner:SOUTHEAST UNIV

Force measurement pile cap

The invention discloses a force measurement pile cap. The force measurement pile cap is fixed to a pile located in a supporting layer and comprises a bottom board, a loadometer, a top board and a pile cap body which are distributed from bottom to top; the lower side surface of the bottom board is fixed to the pile; the bottom of the loadometer is fixed to the upper side surface of the bottom board, and the top of the loadometer is fixed to the lower side surface of the top board; the pile cap body is arranged on the upper side surface of the top board; the force measurement pile cap further comprises a vibration string, a cable and a reading device; and the loadometer is connected with the reading device sequentially through the vibration string and the cable. By means of the force measurement pile cap, load transmitted to a single pile can be accurately measured, and therefore, the accurate bearing load of earth among piles is obtained; the single-pile bearing load in a rigid pile or flexile pile composite foundation can be monitored, the reliable actual measurement basis is provided for study of a design theory of the pile-foundation composite foundation, and accordingly, the pile-foundation composite foundation optimal design which is technically reliable and low in construction cost can be obtained; and the security and stability of the pile-foundation composite foundation can be guaranteed by monitoring the change rule of the single-pile load in the construction process.

Owner:广东舍卫工程技术咨询有限公司

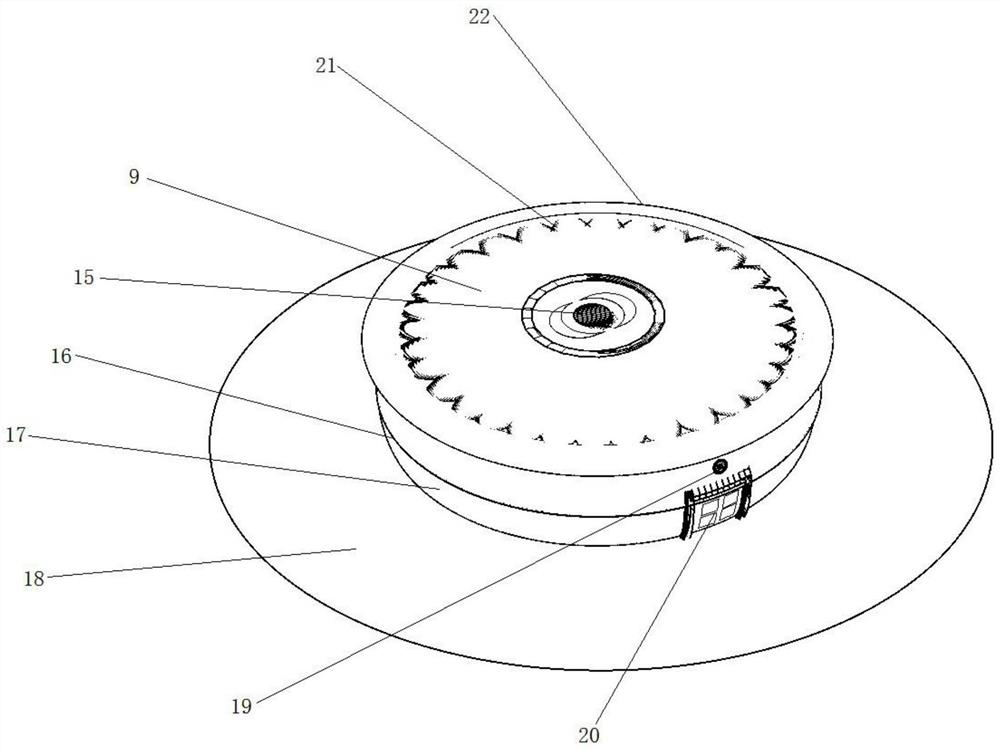

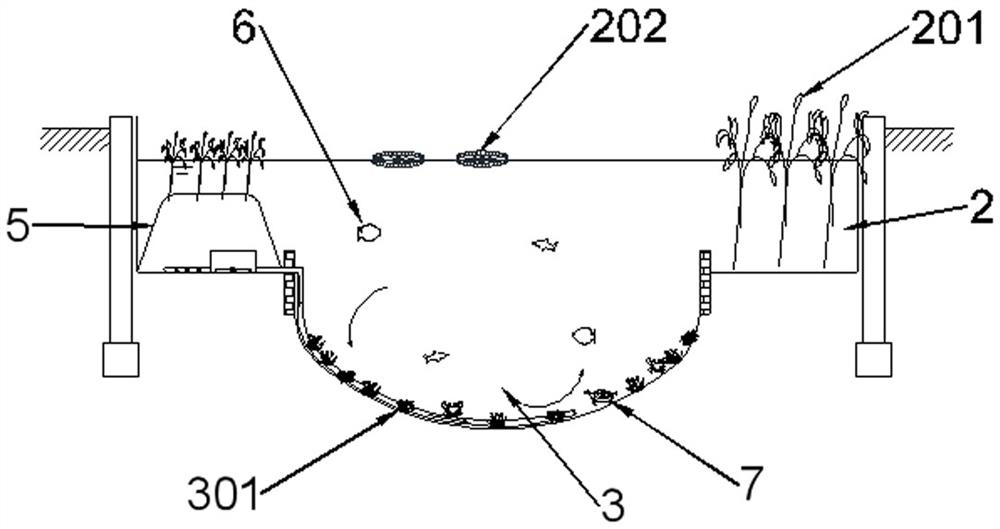

Ecological submerged island device and ecological algae control system

PendingCN112607867ACost economyReduce in quantityWater/sewage treatment apparatusBiological water/sewage treatmentAlgaeEcosystem

The invention relates to an ecological submerged island device and an ecological algae control system. The invention aims to provide the ecological submerged island device and the ecological algae control system which can treat both symptoms and root causes, are durable and effective, are low in cost and are environment-friendly, so that the water quality of a water body is improved, the sensory effect is improved, and a healthy and stable water ecological system is constructed. According to the technical scheme, the ecological submerged island device is characterized in that the ecological submerged island device is provided with an island-shaped structure formed by stacking and filling large-porosity filler underwater, and a pipe network and a water pump which are used for exchanging water inside and outside an island are arranged in the island-shaped structure. The device is suitable for the technical field of ecological environment engineering, and can be applied to planktonic algae control of closed or semi-closed water bodies such as various small and micro water bodies and landscape water bodies.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Automatic can taking device

InactiveCN102042730ASimple structureCost economyLighting and heating apparatusDomestic refrigeratorsEvaporatorEngineering

The invention provides an automatic can taking device and belongs to a feeding out device for storing a zip-top can in domestic appliances. The automatic can taking device comprises a left box body, a right box body, a group of rolling ways, caging and can taking door cavities, caging and can taking doors, caging and can taking counters, a baffle plate and a refrigerating device, wherein the left box body and the right box body are respectively provided with an accommodating cavity, the group of rolling ways are symmetrically arranged in the accommodating cavities from top to bottom in a rail mode, the caging and can taking door cavities are respectively arranged above and below the sides of the left and right box bodies, the caging and can taking doors are respectively pivoted on the caging and can taking door cavities, the caging and can taking counters are arranged at the starting part and terminating part of the rolling ways and are connected to a digital display element through circuits, the middle of the baffle plate is pivoted in the accommodating cavities and is positioned in the terminal part of the rolling ways, the front end of the baffle plate is matched with the can taking door, the rear end of the baffle plate is connected with one end of a spring, the other end of the spring is connected with the inner wall of the box body, a compression box and a condenser of the refrigerating device are arranged at the outer bottoms of the left and right box bodies, and an evaporator with a fan is arranged at the upper part of the accommodating cavity. The automatic can taking device has the following advantages: the zip-top can is taken out without feeding coins each time, and the number of cans can be reflected by a digital display file; and the automatic can taking device is simple in structure and economical in construction cost.

Owner:CHANGSHU YONGXIANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com