Quick track slab replacing system and method for slab-type ballastless track

A technology of ballastless track and replacement method, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of large rail damage, inconvenient construction, and long time consumption, and achieve the effect of low cost and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

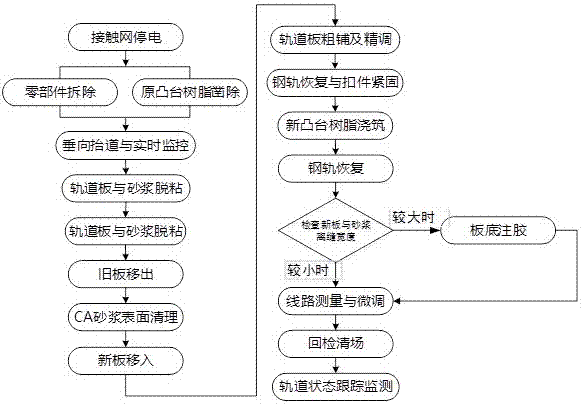

[0027] Embodiment 1 of the present invention provides a system and method for quick replacement of track slabs of CRTS I type slab ballastless track for double-line straight sections. The process flow is shown in figure 1 , the replacement system and method specifically include the following:

[0028] (1) According to the ESC order, carry out catenary power outages, power inspections, ground wires, and take relevant protective measures; use ink lines, rulers, steel rulers, strings, etc. to check the plane and elevation positions of the original track slabs Measure and mark, and make data records, mainly measure the relative position between the original track slab and the adjacent track slab, including horizontal position, distance between plates, height difference between plates, boss clearance and parameters for positioning the state of track slabs;

[0029] (2) Remove all spare parts on the track plate that need to be replaced, remove the bolts and gauge blocks within the r...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a system and method for quick replacement of track slabs of CRTSⅡ type slab ballastless track for double-line straight sections. The process flow is shown in Figure 4 , the replacement system and method specifically include the following:

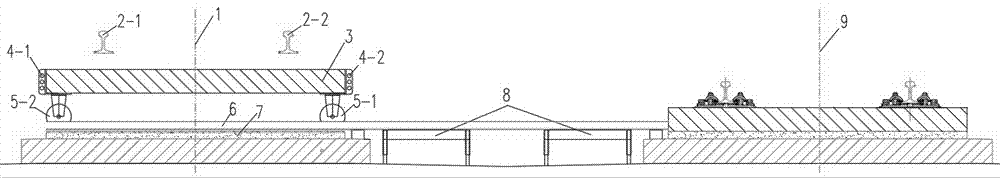

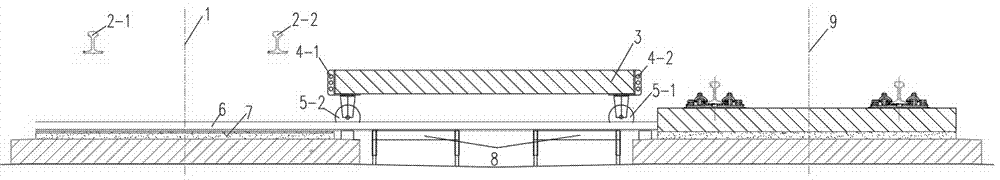

[0042] (1) On the track plate 3 to be replaced ( figure 2 As shown) the adjacent track slabs on both sides shall be planted and anchored, the concrete at the wide and narrow joints at both ends shall be chiseled, and the tension locks at both ends shall be unlocked;

[0043] (2) Carry out catenary power outages, power inspections, and ground wires in accordance with the ESC order, and take relevant protective measures; use ink lines, rulers, steel rulers, strings, etc. to check the plane and elevation positions of the original track slabs Measure and mark, and make data records, mainly measure the relative position between the original track slab and the adjacent track slab, including...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com