Automatic fire extinguishing battery capacity grading cabinet

A technology of automatic fire extinguishing and capacity separation cabinets, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte storage batteries, etc., can solve problems such as difficult to extinguish fires in time, fires in separation cabinets and batteries, battery factories and personnel losses, etc. Achieve the effect of simple structure, low cost and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

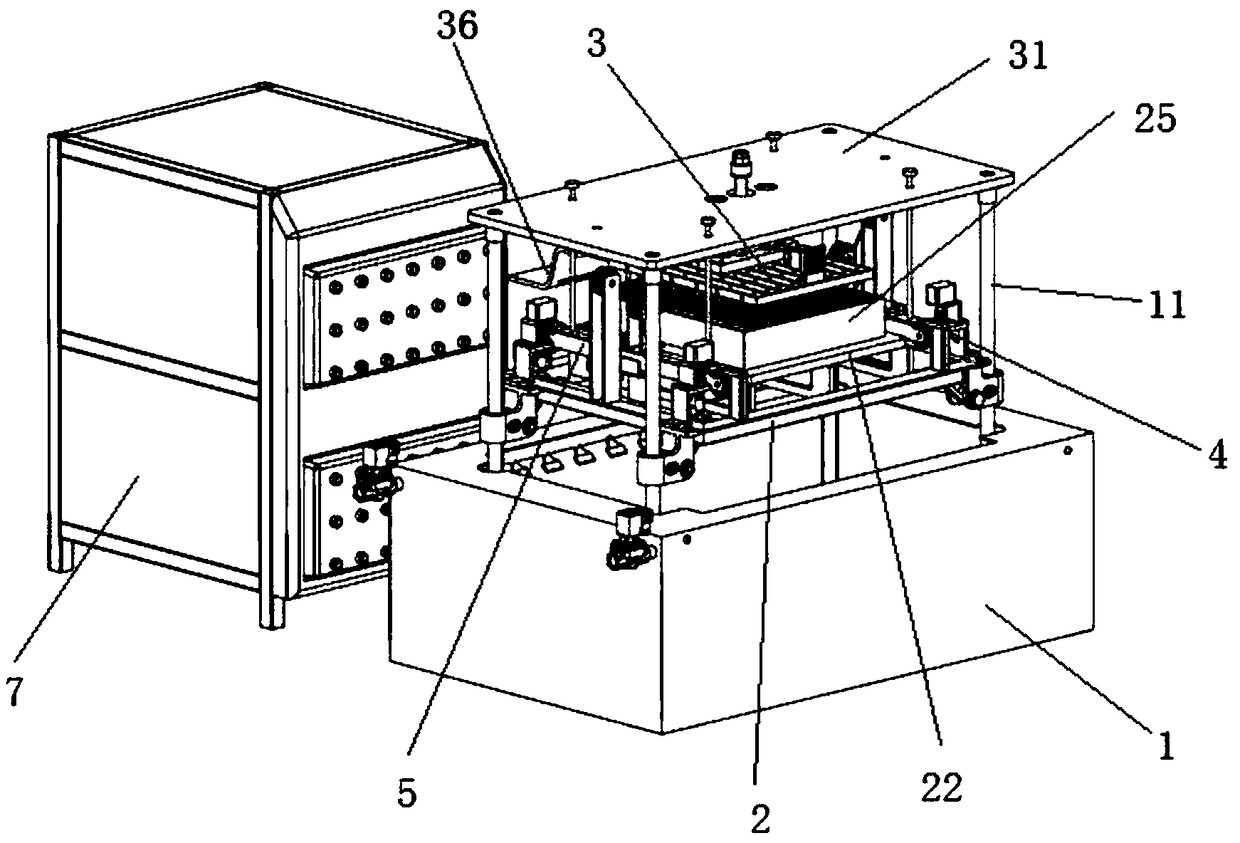

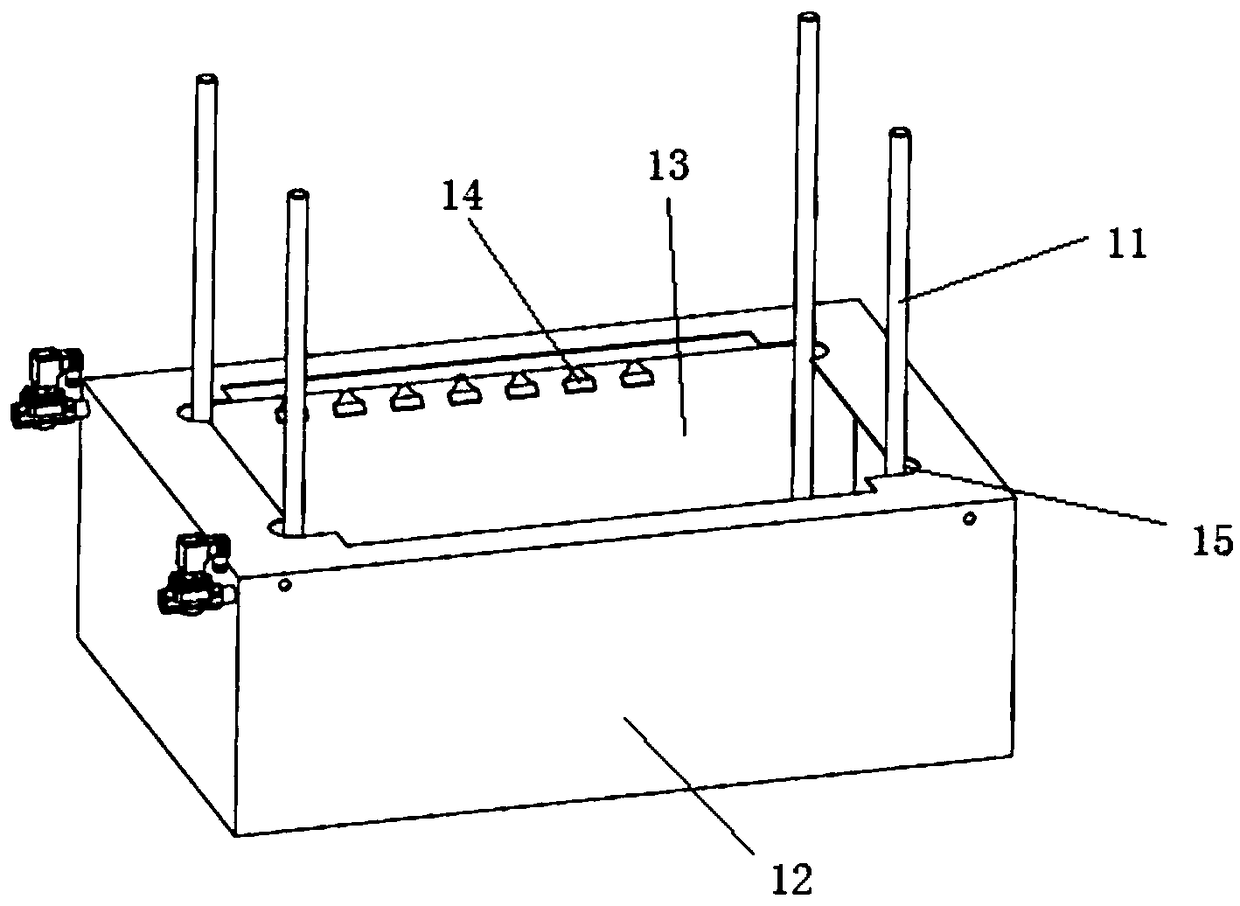

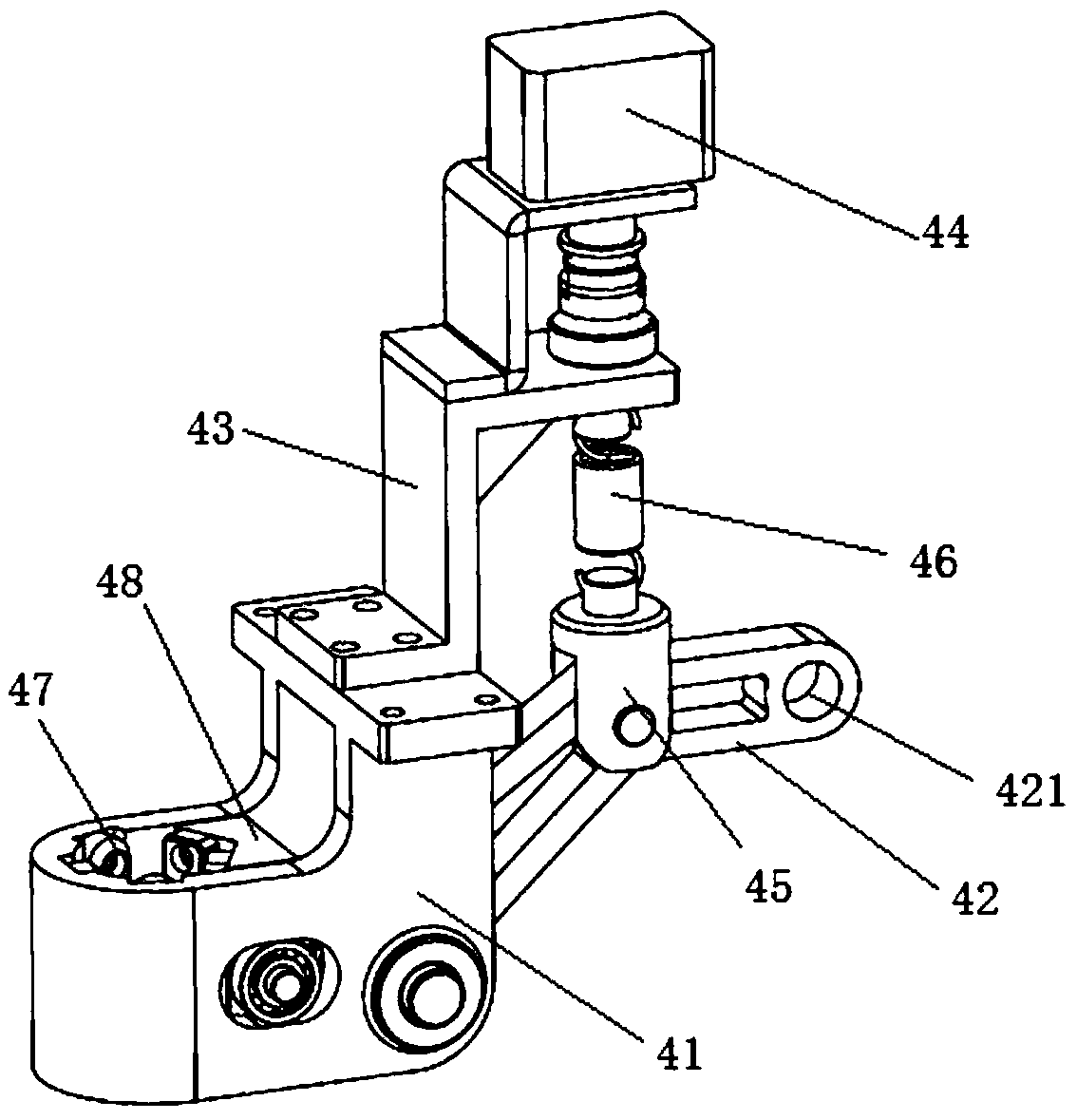

[0027] like figure 1 As shown, the automatic fire extinguishing battery sub-container of the present embodiment includes a sprinkler tank 1, a battery tray mechanism 2 and an electrified probe mechanism 3, the sprinkler tank 1 is provided with a guide rod 11, and the guide rod 11 is provided with a The brake guide shoe 4 slidingly matched with it, the battery tray mechanism 2 is arranged on the brake guide shoe 4, through the sliding cooperation of the brake guide shoe 4 and the guide rod 11, the battery tray mechanism 2 slides into the sprinkler tank 1, A weight mechanism 5 is provided above the battery tray mechanism 2, and the weight mechanism 5 is suspended above the battery tray mechanism 2 through a tension mechanism 6. The electrified probe mechanism 3 is arranged above the battery tray mechanism 2 and slides with the guide rod 11 connected, the weight mechanism 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com