Spiral continuous weighing method for rock debris

A spiral and cuttings technology, applied in the field of oil drilling, can solve problems such as poor wellbore cleaning, affecting downhole safety, and measurement errors, and achieve the effects of long-term dynamic measurement, avoiding weighing errors, and accurate measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

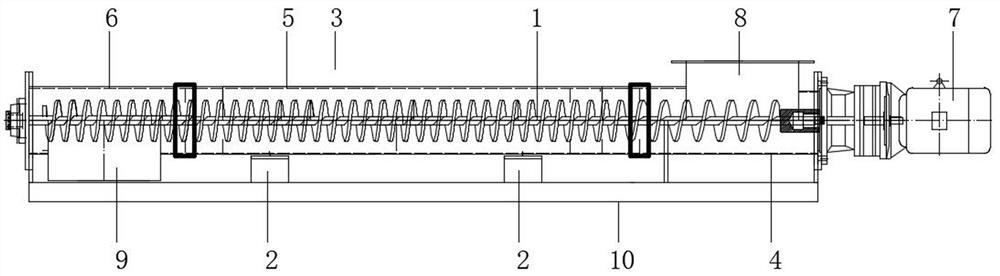

[0048] This embodiment discloses a spiral continuous weighing method for cuttings, which is realized based on a screw conveyor, such as figure 1 As shown, the screw conveyor includes a bracket 10, an explosion-proof motor 7, a screw shaft 1, a weighing assembly 2 and a delivery cylinder 3, and the delivery cylinder 3 includes a feeding section 4, a metering section 5 and a discharge section that are sequentially sealed and softly connected. Section 6, that is, between the feed section 4 and the metering section 5 and between the metering section 5 and the discharge section 6 are soft connection structures, and the joints are sealed. After the connection, the feed section 4, the metering section 5 and the discharge section Material segment 6 is relatively independent. In addition, the upper part of the feeding section 4 is provided with a feeding nozzle 8 , and the lower part of the discharging section 6 is provided with a discharging nozzle 9 , and the discharging nozzle 9 is ...

Embodiment 2

[0066] On the basis of Example 1, in order to further improve the accuracy of cuttings weighing and measuring, this embodiment further limits the connection mode of the feed section 4, the metering section 5 and the discharge section 6 in the delivery cylinder 3, as figure 1 As shown in the middle thick black line, the sealed soft connection refers to the sealed connection between the feed section 4 and the metering section 5 and between the metering section 5 and the discharge section 6, and the flexible rubber material is The rubber sleeve is made of oil-resistant, high-temperature-resistant hydrogenated nitrile rubber. When connecting, put the two ends of the rubber sleeve on the feeding section 4 and the metering section 5 or respectively put them on the metering section 5 and the outlet section 6, and then use the throat clamp to fix it. In this specific connection mode, the feeding impact of cuttings will not be transmitted to the weighing and measuring section 5 in the ...

Embodiment 3

[0068] On the basis of Embodiment 1 or Embodiment 2, in order to improve the instantaneous feeding capacity of cuttings, this embodiment further limits the pitch of the screw shaft 1 . Specifically, in this embodiment, the pitch of the screw shaft 1 in the feeding section 4 is set to be greater than the pitch of the screw shaft 1 in the metering section 5, and preferably the pitch of the screw shaft 1 in the feeding section 4 is set as the screw pitch in the metering section 5. 1.5 times the pitch of axis 1. Further, in actual use, the pitch of the screw shaft 1 in the metering section 5 can be set to 160 mm, and the pitch of the screw shaft 1 in the feeding section 4 is 240 mm. Under these conditions, the instantaneous feeding capacity of the screw conveyor can reach 24m³ / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com