Steel bar truss floor support plate with hanging ribs

A technology of reinforced trusses and floor decks, which is applied to floors, building components, buildings, etc. It can solve the problems of time-consuming and labor-intensive keel installation, high hardness of cement boards, and damage to cement boards. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

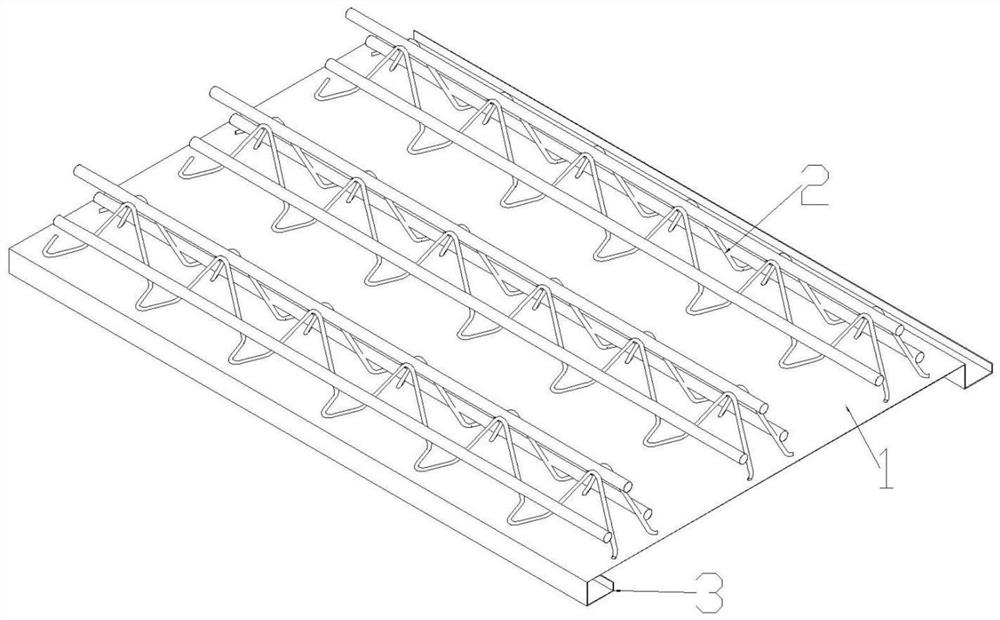

[0024] Such as figure 1 As shown, the present invention proposes a steel bar truss floor deck with suspension ribs, including a bottom plate 1 and a steel bar truss 2; the steel bar truss 2 is fixed on the bottom plate 1; There are at least two suspension ribs 3 .

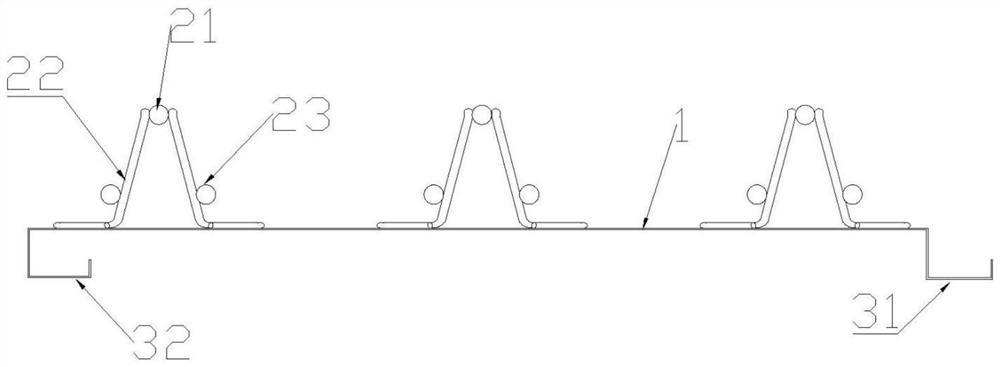

[0025] In this embodiment, the steel bar truss 2 of the present invention is a traditional steel bar truss structure, including a web bar 22, an upper chord bar 21 and a lower chord bar 23, two lower chord bars 23 and one upper chord bar 21 to form a triangular structure, and the upper chord The steel bars 21 and the two lower chord steel bars 23 are respectively fixedly connected by welding the web steel bars 22 .

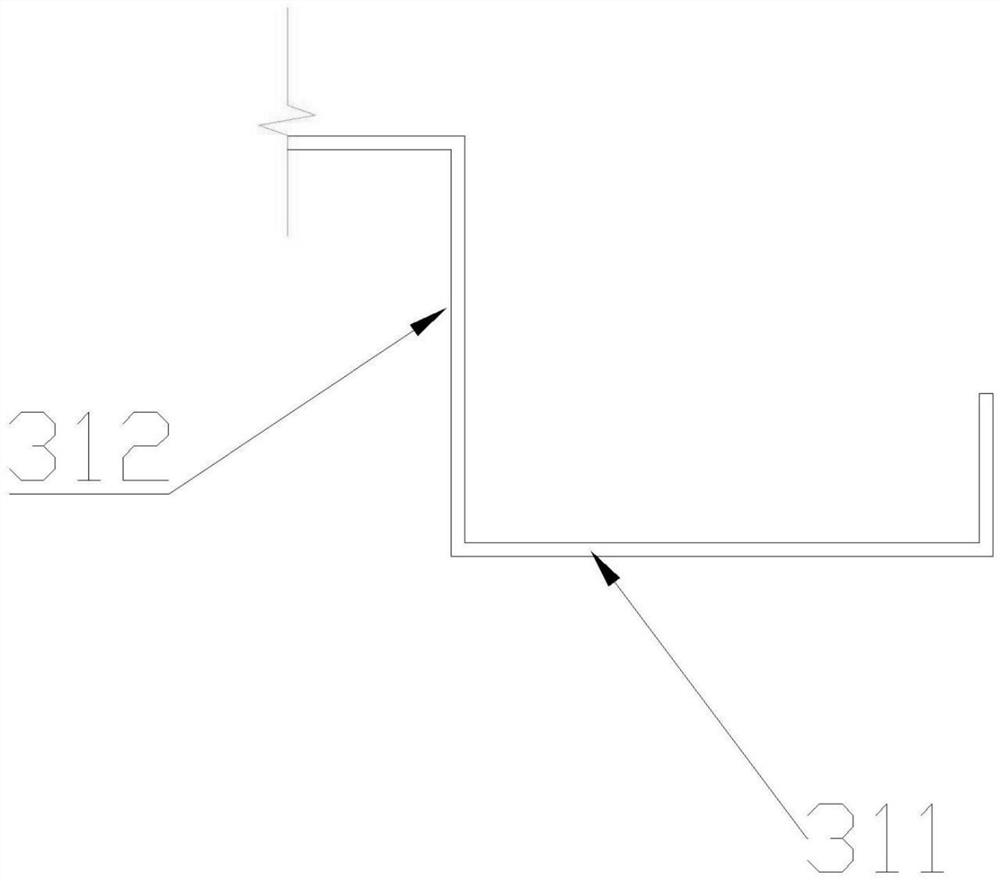

[0026] Such as figure 2 As shown, there are two suspension ribs in this embodiment, namely suspension rib 31 and suspension rib 32. Relatively parallel two sides; two hanging ribs 31 / 32 and the bottom plate 1 are integrally cast and formed, and can be combined with the truss forming equipment synch...

Embodiment 2

[0032] Such as Image 6 As shown, the overall structure of embodiment 2 is similar to that of embodiment 1, the difference is that the connection position between the suspension rib 3 and the bottom plate 1 is different, the suspension rib 3 is located near the middle of the bottom plate 1, the suspension rib 3 of this connection form is as Image 6 As shown, it can be integrally cast and formed with the base plate 1, or can be fixed at any position on the bottom of the base plate 1 by self-tapping screws and welding after the base plate is formed in the later stage. After prefabrication and fixing, even after pouring concrete at the construction site, it can Realize the connection between the suspended ceiling and the suspension rib 3 to ensure the integrity of the concrete, but it cannot realize the overlap between the adjacent bottom plates 1 . At the same time, the same as in embodiment 1, the suspension rib in embodiment 2 also has a horizontal section and a vertical sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com