Method for preparing manganese-copper-based catalyst for degrading VOCs (Volatile Organic Compounds)

A catalyst, manganese-copper technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of industrialization difficulty, increase investment cost, corrode equipment, etc., and achieve raw material economy and cost. Economical and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) the preparation method of the catalyst provided in embodiment 1, comprises the steps:

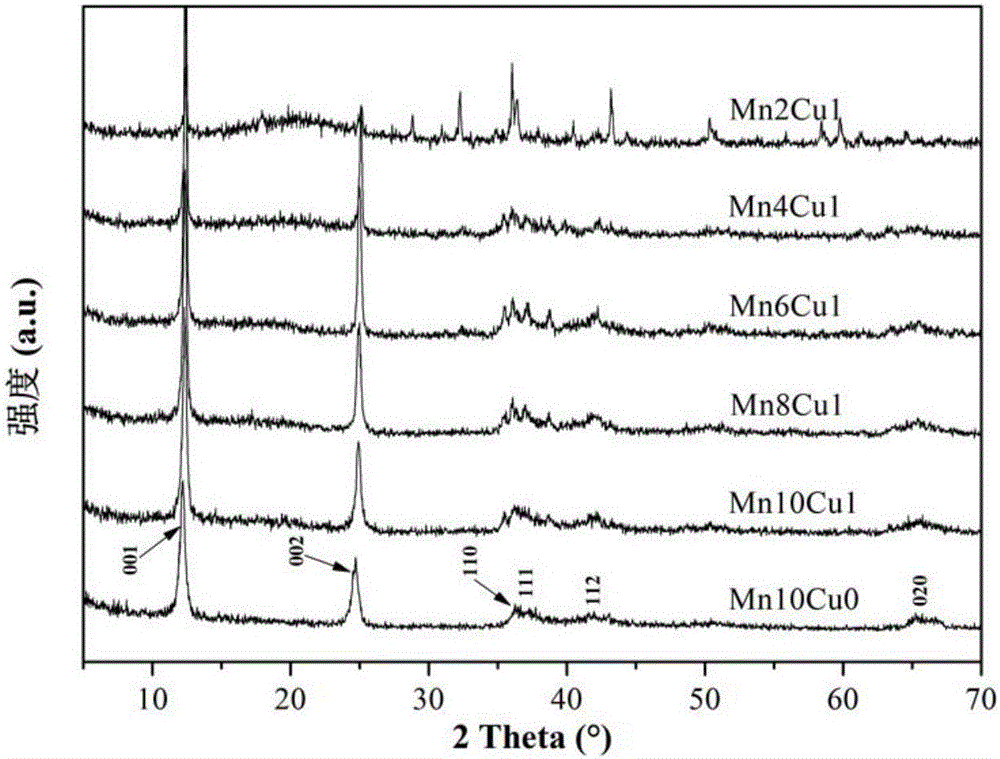

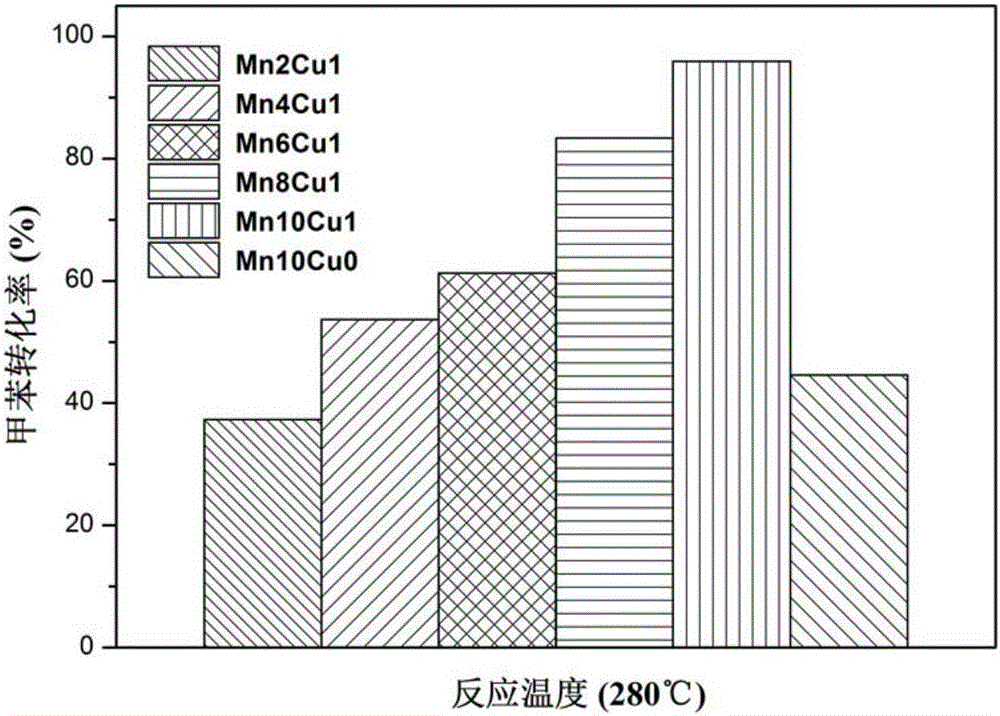

[0033] Mix potassium permanganate and copper acetate evenly in a dry powder mixer (the molar ratio: Mn:Cu=4:1), then spread the mixture on a glass plate, ignite it with an electronic igniter, and react for a few seconds , to obtain a black manganese-copper-based catalyst, and then the appeal black powder was washed with water and filtered to obtain a pure manganese-copper-based (Mn4Cu1) catalyst.

[0034] (2) Catalytic activity test: toluene concentration 1000ppm, gas space velocity 30000ml g catalyst -1 h-1 . Gas chromatography TCD detection reaction tail gas CO 2 And CO, FID detects the content in toluene and other organic matter. The catalyst obtained in Example 1 catalytically burns toluene (90% conversion of toluene) at a temperature of 330°C, and the 50% degradation rate of toluene is 276°C. In the catalytic degradation reaction of toluene, the products are only toluene...

Embodiment 2

[0036] (1) the preparation method of the above-mentioned catalyst provided in embodiment 2, comprises the steps:

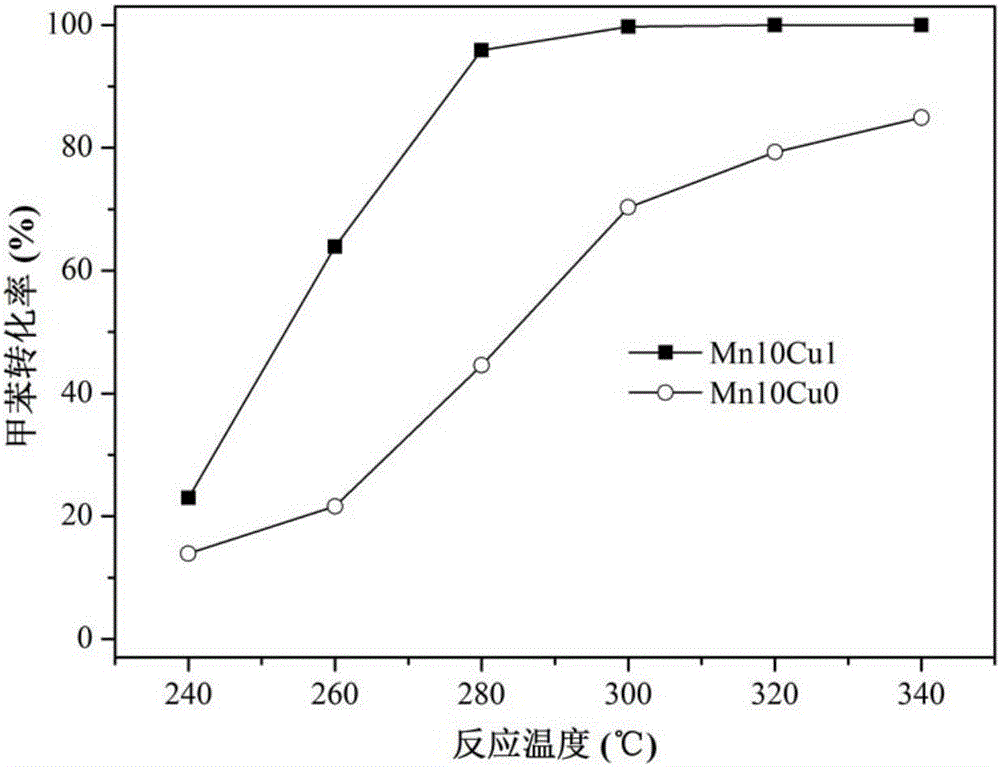

[0037] Mix potassium permanganate and copper acetate evenly in a dry powder mixer (molar ratio: Mn:Cu=10:1), then spread the mixture on a glass plate, ignite it with an electronic igniter, and react for a few seconds , to obtain a black manganese-copper-based catalyst, and then the appeal black powder was washed with water and filtered to obtain a pure manganin-copper-based (Mn10Cu1) catalyst.

[0038] (2) Catalytic activity test: toluene concentration 1000ppm, gas space velocity 30000ml g catalyst -1 h -1 . Gas chromatography TCD detection reaction tail gas CO 2 And CO, FID detects the content in toluene and other organic matter. The catalyst obtained in Example 2 of the present invention completely catalytically burns toluene (100% conversion of toluene) at a temperature of 303°C, 90% conversion of toluene is 276°C, and 50% conversion of toluene is at 254°C...

Embodiment 3

[0040] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0041] Mix potassium permanganate and copper acetate evenly in a dry powder mixer (molar ratio: Mn:Cu=2:1), then spread the mixture on a glass plate, ignite it with an electronic igniter, and react for a few seconds , to obtain a black manganese-copper-based catalyst, and then the appeal black powder was washed with water and filtered to obtain a pure manganese-copper-based (Mn2Cu1) catalyst.

[0042] (2) Catalytic activity test: toluene concentration 1000ppm, gas space velocity 30000ml g catalyst -1 h -1 . Gas chromatography TCD detection reaction tail gas CO 2 And CO, FID detects the content in toluene and other organic matter. The catalyst prepared in Example 3 of the present invention catalytically burns toluene (50% conversion of toluene) at a temperature of 291°C. In the catalytic degradation reaction of toluene, the products are only toluene, car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com