Solid acid catalyst for selective catalystic reduction of NOx by methane and preparation method thereof

A solid acid catalyst and catalyst technology, which is used in industrial catalysis, environmental pollution control technology, automobile industry, and gas purification fields. It can solve problems such as high ozone concentration, greenhouse effect, and corrosion, and achieve high catalytic combustion activity and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

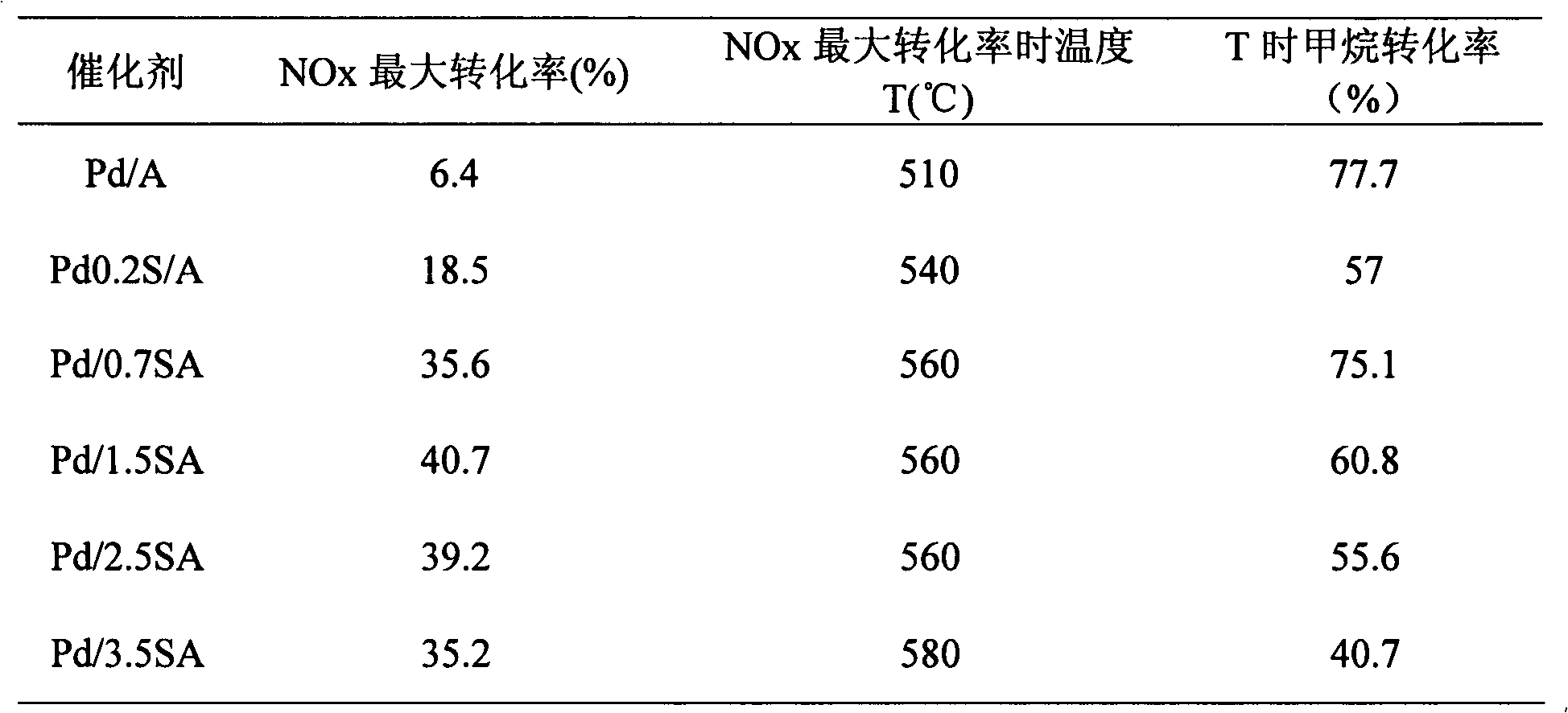

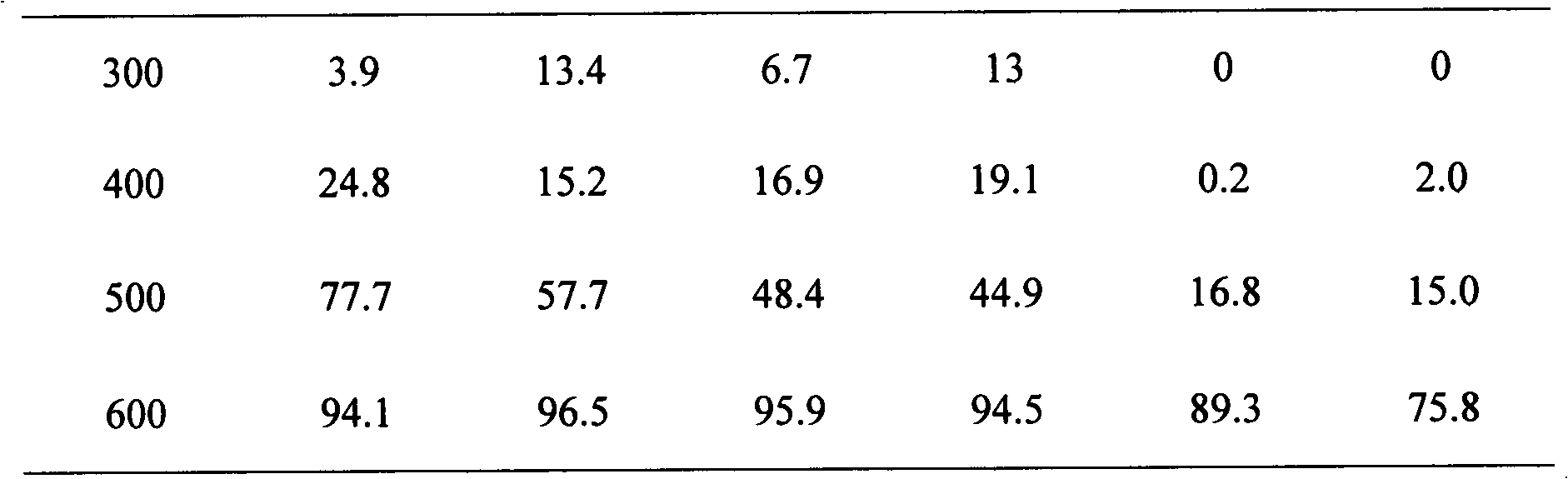

Embodiment 1

[0029] Take 6 parts of 20-60 mesh γ-Al 2 o 3 Carrier, each 5g, one of which is left untreated, marked as A. The rest were impregnated in H 2 SO 4Concentrations of 0.2, 0.7, 1.5, 2.5, 3.5M / L solution, the volume of each sulfuric acid solution is 6ml, and then soaked at room temperature for 30min, stirring once every ten minutes during the soaking process, put it into 110 Dry in an oven at ℃ for 12 hours, take it out, put it into a muffle furnace and bake at 600℃ for 4 hours, the heating rate of the furnace is 5℃ / min, and the carrier A, 0.2SA, 0.7SA, 1.5SA, 2.5SA, 3.5SA are obtained.

Embodiment 2

[0031] Take 0.5ml of a solution with a Pd content of 12mg / ml, dilute it to 7.5ml with water, immerse 3g of carrier A in it for 30min, then evaporate to dryness with a rotary evaporator, the condition is 55°C for 1h, take it out, and put it in the muffle Calcined in the furnace at 600°C for 4h, and the heating rate of the furnace was 5°C / min, to prepare the catalyst Pd / A.

Embodiment 3

[0033] Take 0.5ml of solution with Pd content of 12mg / ml, dilute it to 7.5ml with water, immerse 3g carrier 0.2SA in it, immerse in it for 30min, then evaporate to dryness with rotary evaporator, the condition is 55℃ for 1h, take it out, and put it in the horse The catalyst Pd / 0.2SA was prepared by calcining at 600°C for 4h in a Furnace with a heating rate of 5°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com