Manufacturing method for anti-ultraviolet and anti-static composite film layer

A composite film layer and anti-ultraviolet technology, which is applied in the field of anti-ultraviolet and anti-static composite film layer, can solve the problems of strengthening the anti-ultraviolet and anti-static functions of glass panels, and achieve the effect of cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment.

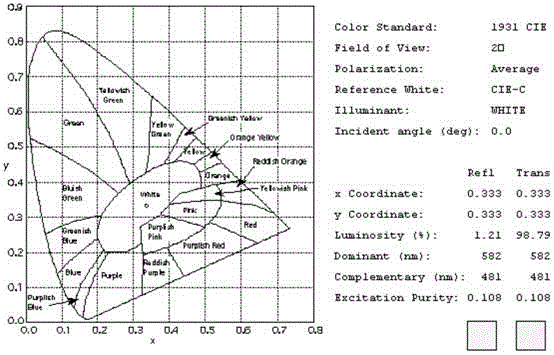

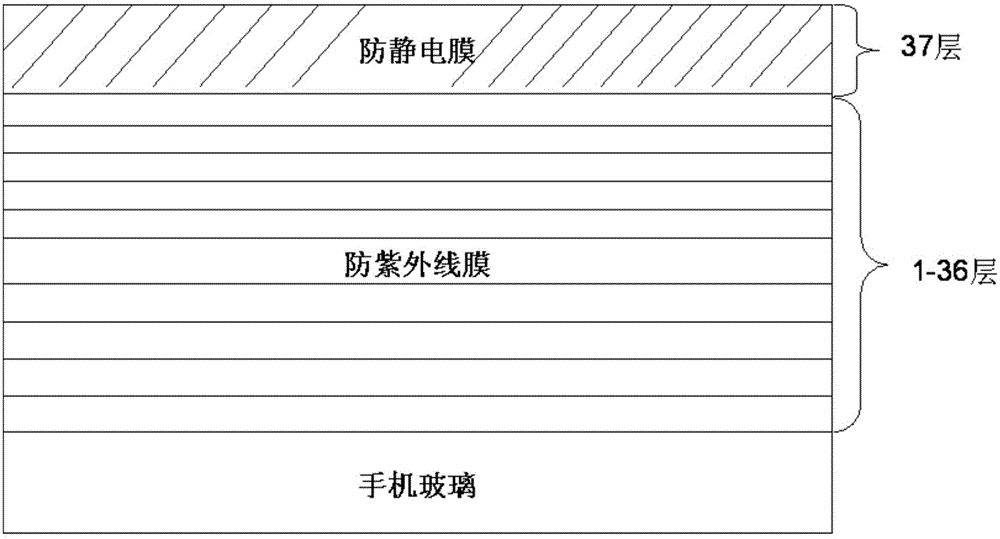

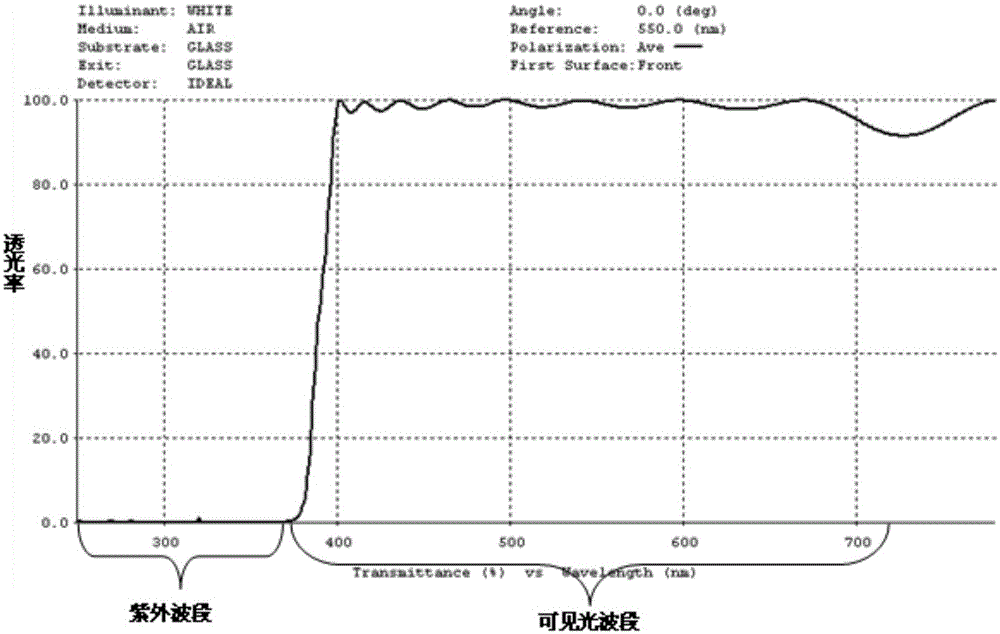

[0013] Select the coating material with a purity of 99.99% and a particle size of 1-2mmSiO 2 and TiO 2 And the powdered tin antimony oxide with a purity of 99.9% is ready for use. Coating with Hanyi 2050 coating machine, the diameter of the equipment is 2050mm, using quartz crystal control, monitoring the coating thickness through the change of the vibration frequency of the quartz plate, and installing 4 correction baffles before coating to ensure the uniformity of the coating thickness of the equipment; The coating adopts the evaporation method, the electron gun (E-Beam) is coated with anti-ultraviolet film, the electrode is coated with tin antimony oxide, and the equipment has a built-in Hall ion source. Before coating, ion beams are emitted to bombard the glass surface to enhance the bond between the glass and the electroplating film layer. Adhesion; take SiO 2 and TiO 2 Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com