Hollow wind power generation tower foundation

A basic and hollow technology, applied in the field of hollow wind power tower foundation, can solve the problems of wind power tower threat, non-replacement of anchor bolts, repair, hidden safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

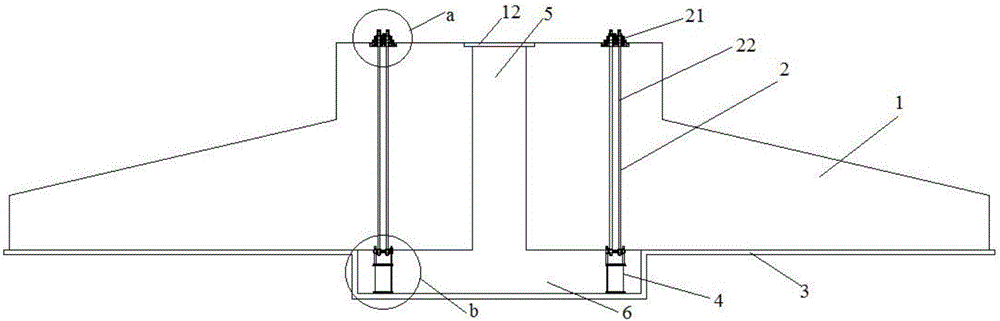

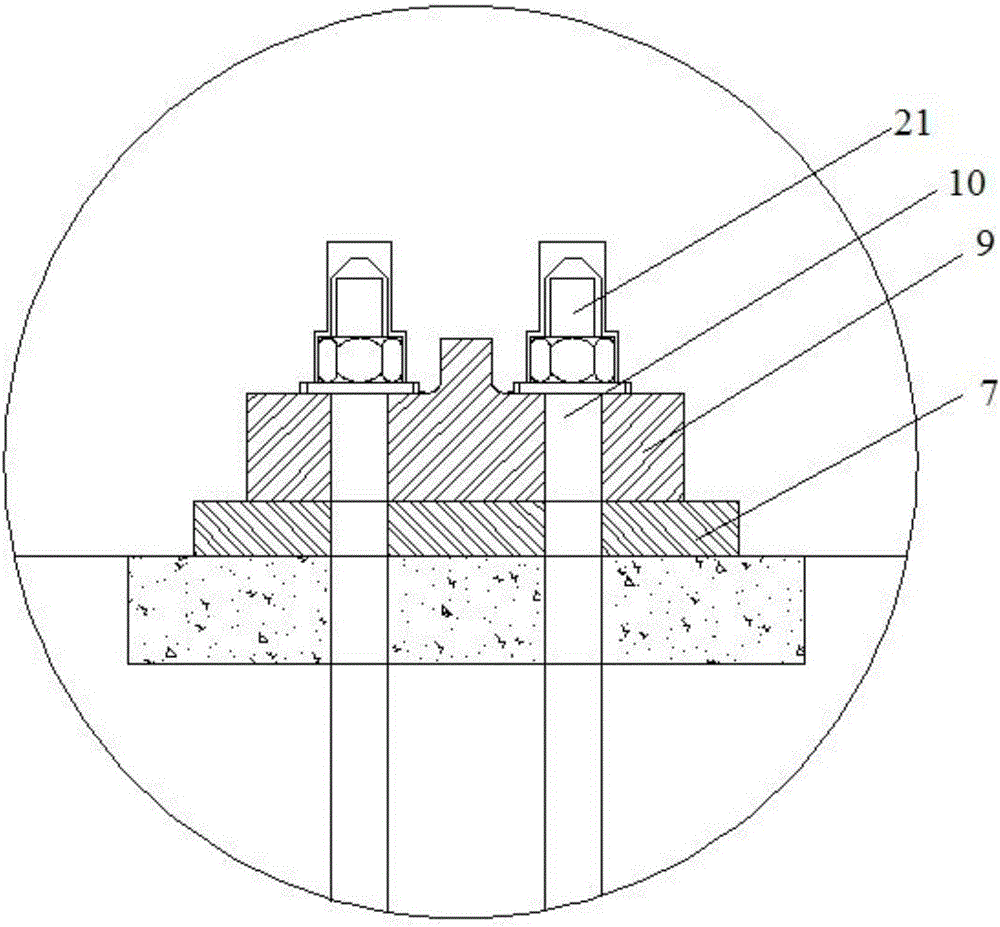

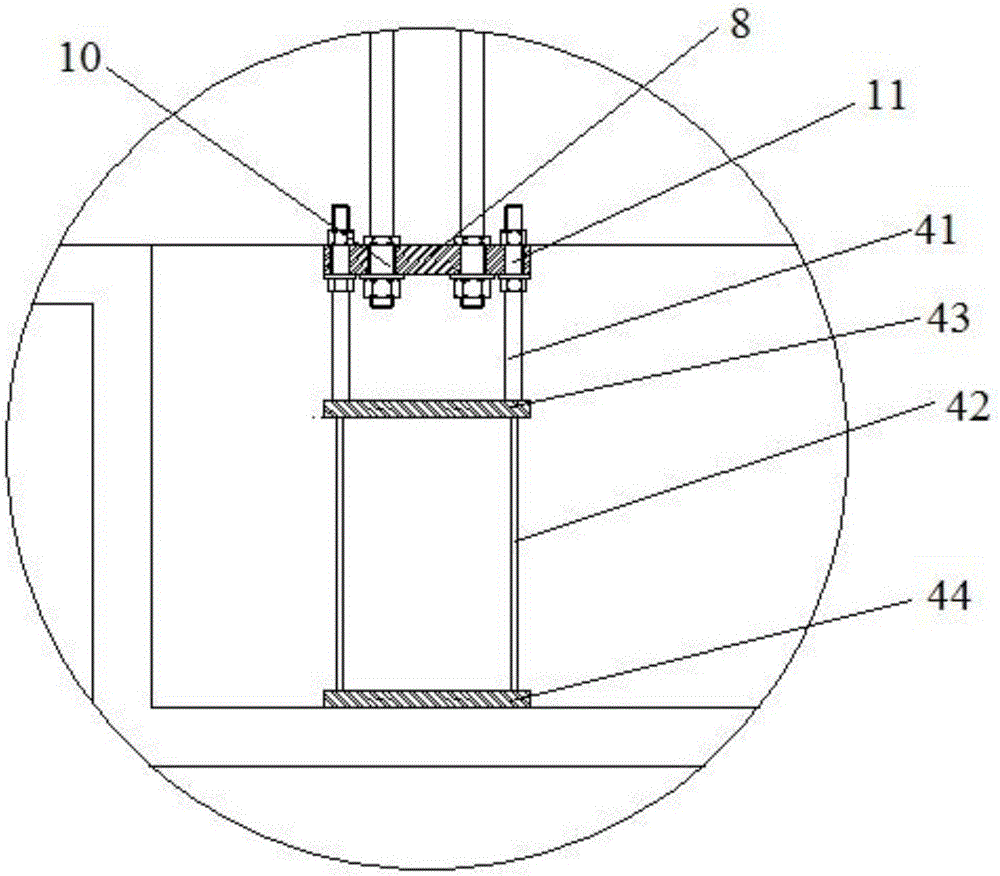

[0028] Such as figure 1 , figure 2 with image 3 As shown, a hollow wind power tower foundation includes a wind power tower base body 1, a ground anchor cage 2, a cushion layer 3, and a ground anchor cage bracket 4; the ground anchor cage 2 is vertically embedded in a wind power generator casted by concrete In the tower foundation body 1, the cushion layer 3 is arranged under the ground anchor cage 2 and the wind power tower foundation body 1. The wind power tower foundation body 1 is provided with a hollow cavity 5 through up and down, and the cushion layer 3 is in the wind power tower foundation body. 1 The center position of the lower surface is recessed downward to form a recessed cavity 6 that is convenient for man or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com