Machine tool driving type retractable cutter and method for machining differential mechanism shell by using same

A driving and cutting tool technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low processing accuracy, high price, and expensive structure, so as to reduce positional accuracy deviation and improve product processing accuracy. , the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

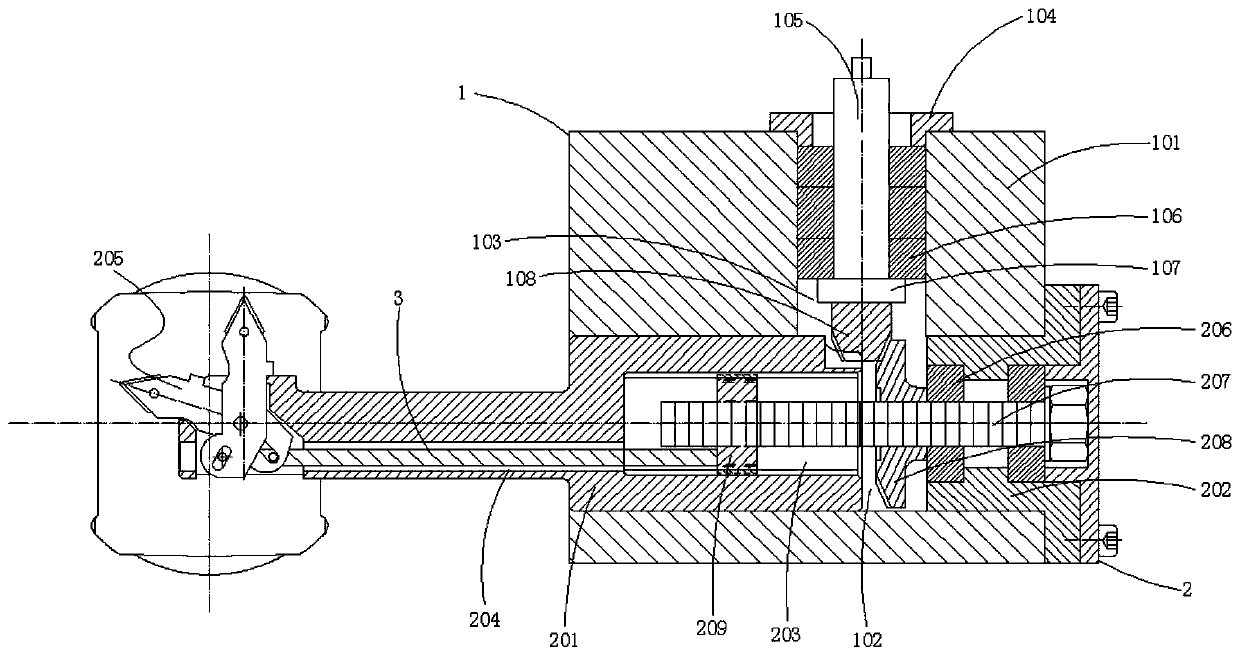

[0030] see figure 1 , 2 , a machine-driven telescopic tool, comprising a power turret 1 and a power tool holder 2, characterized in that: the inside of the power turret 1 is connected to the outside of the power tool holder 2;

[0031] The power turret 1 includes a turret housing 101, an installation port 102, a power port 103, a mounting ring 104, a worm 105, a first bearing 106 and a limit ring 107, and the exterior of the power turret 1 is provided with The turret housing 101, the bottom of the turret housing 101 is provided with a left and right through installation port 102, and the upper end of the turret housing 101 is provided with a vertical power port 103, the power port 103 communicates with the installation port 102, the upper opening position of the power port 103 is fixedly installed with a mounting ring 104, and a worm 105 is rotatably connected inside the mounting ring 104, and the bottom end of the worm 105 is a transmission gear part, Three first bearings 1...

Embodiment 2

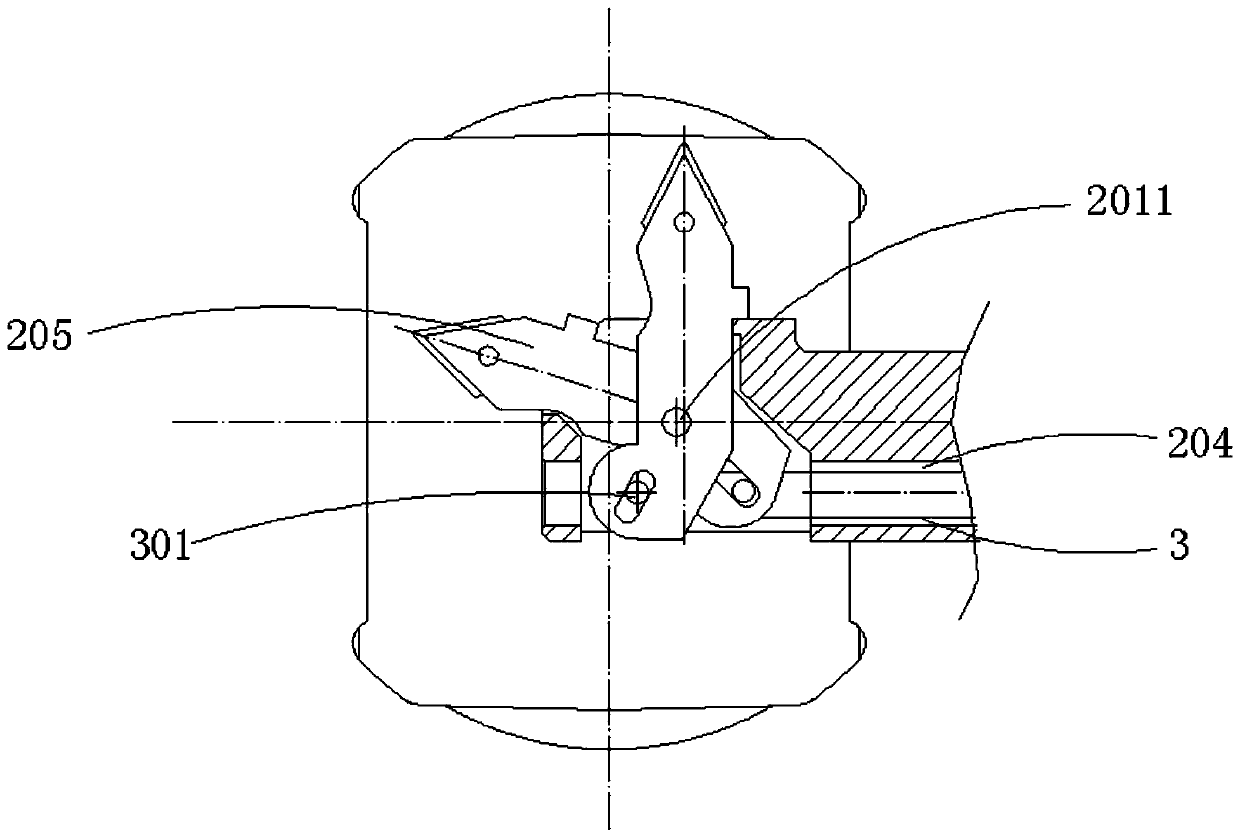

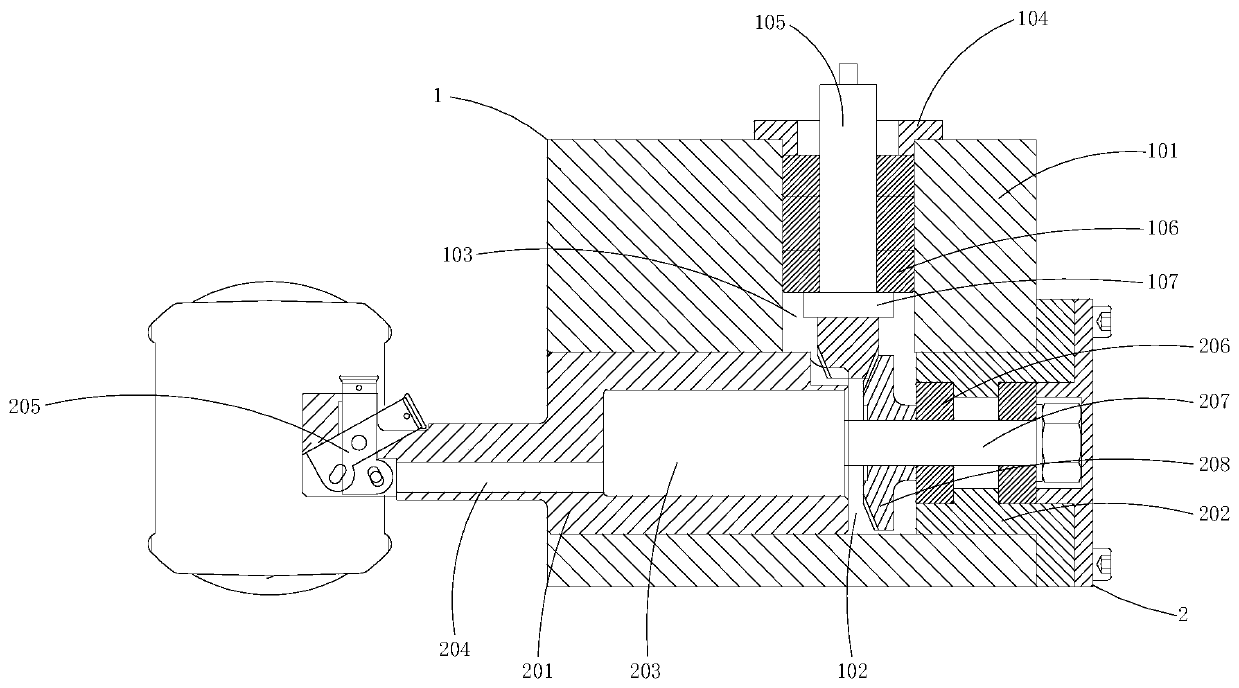

[0034] see Figure 3-5 , a machine tool driven retractable tool, comprising a power turret 1 and a power tool holder 2, characterized in that: the inside of the power turret 1 is connected to the outside of the power tool holder 2;

[0035] The power turret 1 includes a turret housing 101, an installation port 102, a power port 103, a mounting ring 104, a worm 105, a first bearing 106 and a limit ring 107, and the exterior of the power turret 1 is provided with The turret housing 101, the bottom of the turret housing 101 is provided with a left and right through installation port 102, and the upper end of the turret housing 101 is provided with a vertical power port 103, the power port 103 communicates with the installation port 102, and the upper opening position of the power port 103 is fixedly installed with a mounting ring 104, and a worm 105 is rotatably connected inside the mounting ring 104, and the bottom end of the worm 105 is a transmission gear part, Three first be...

Embodiment 3

[0039] see Figure 3-5 , a machine tool driven retractable tool, comprising a power turret 1 and a power tool holder 2, characterized in that: the inside of the power turret 1 is connected to the outside of the power tool holder 2;

[0040] The power turret 1 includes a turret housing 101, an installation port 102, a power port 103, a mounting ring 104, a worm 105, a first bearing 106 and a limit ring 107, and the exterior of the power turret 1 is provided with The turret housing 101, the bottom of the turret housing 101 is provided with a left and right through installation port 102, and the upper end of the turret housing 101 is provided with a vertical power port 103, the power port 103 communicates with the installation port 102, and the upper opening position of the power port 103 is fixedly installed with a mounting ring 104, and a worm 105 is rotatably connected inside the mounting ring 104, and the bottom end of the worm 105 is a transmission gear part, Three first be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com