Device and method for arraying and combining screw, spring pad and flat pad

A screw and spring washer technology, applied in the field of auxiliary devices, can solve the problems of high price, high cost, vibration and noise, etc., and achieve the effect of convenient operation, simple structure and low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be further described in conjunction with the embodiments and accompanying drawings:

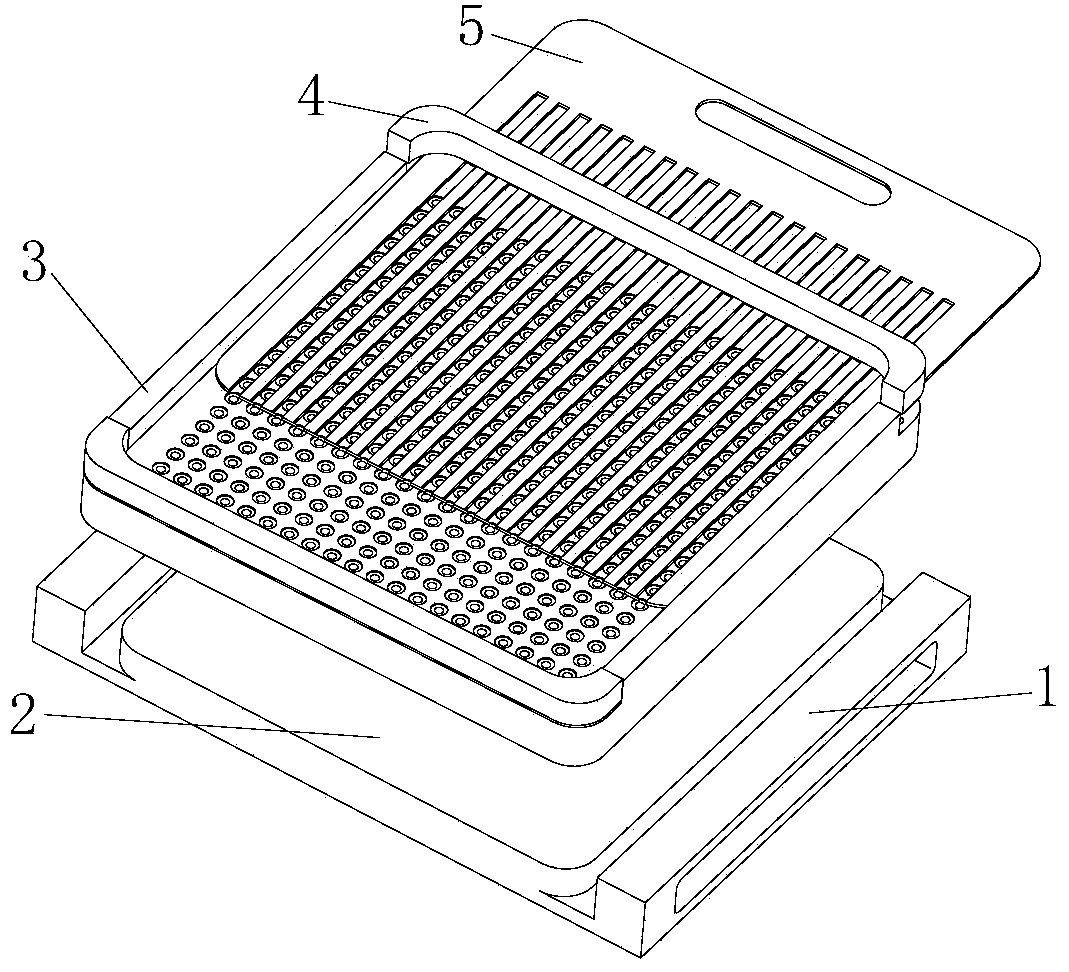

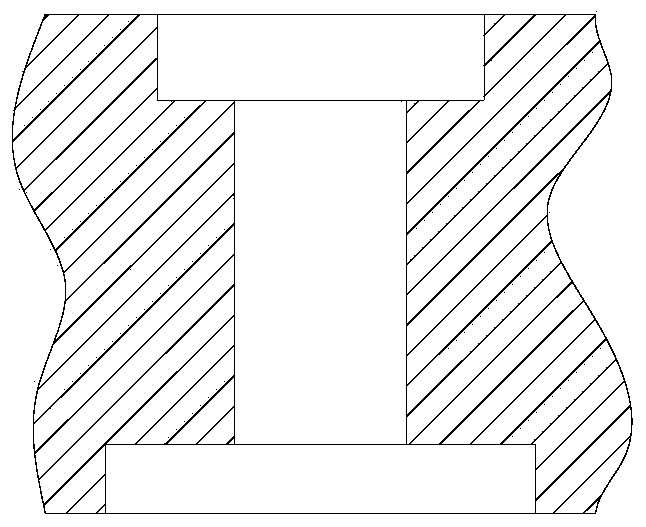

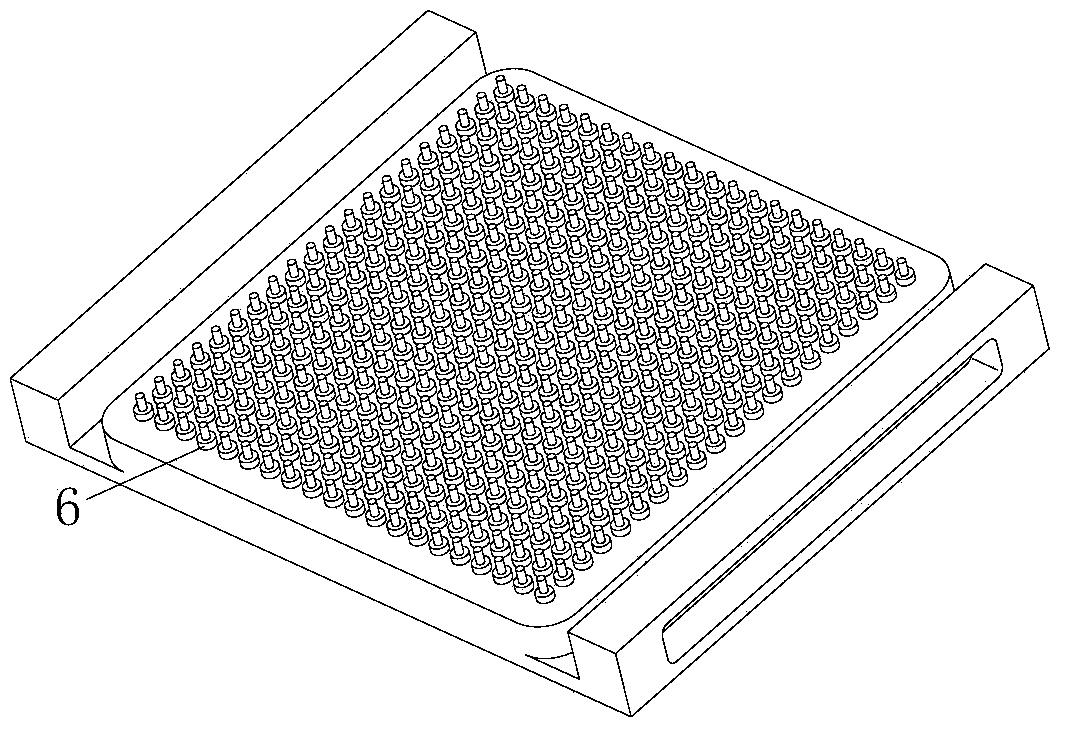

[0031] This embodiment includes bottom plate 1, double-sided adhesive cloth 2, sieve plate 3 and comb plate 5; bottom plate 1 has a concave structure, and the shape of sieve plate 3 matches the concave structure of bottom plate 1; the double-sided adhesive cloth 2 is placed between the sieve plate 3 and the bottom plate 1; the sieve plate 3 is provided with an array of double-faced holes consisting of several double-faced holes, and the comb plate 5 is located above the sieve plate 3; the structure of the double-faced holes is three steps The through hole, the diameter of the through hole in the middle section and the diameter of the through hole at one end match the size of the screening screw, and the diameter of the through hole at the other end matches the size of the elastic washer or flat pad; The dimensions of the double-sided hole arrays on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com