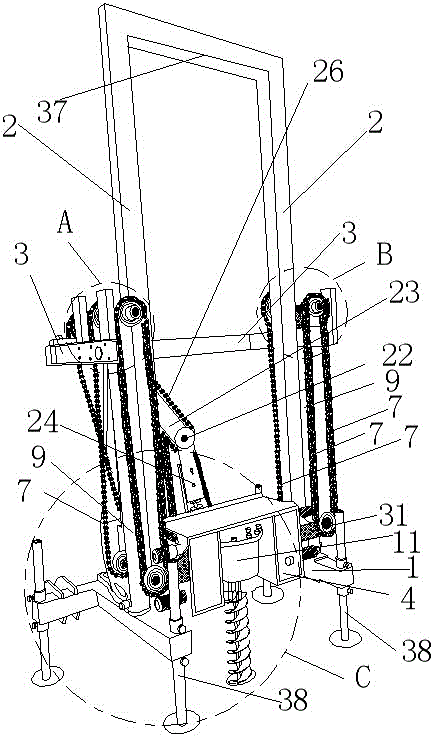

Pit drilling machine

A technology for drilling and excavating pits, which is applied in the directions of earth movers/shovels, construction, etc., can solve the problems of low efficiency of manual pit excavation, and achieve the effects of simple structure, low price and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

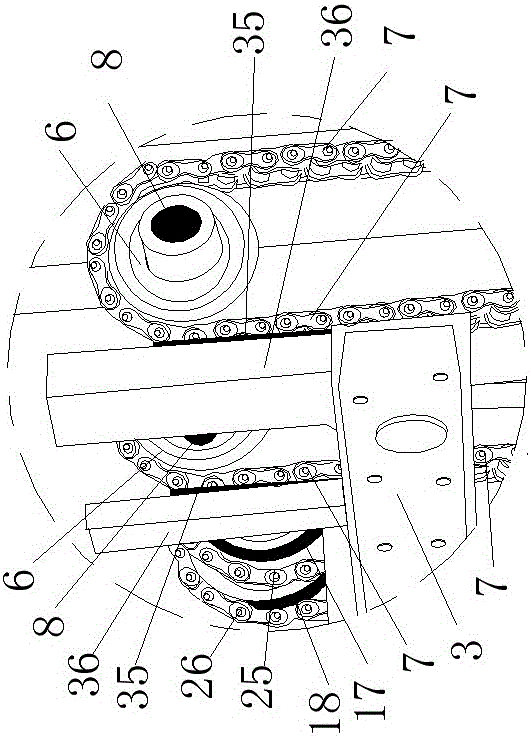

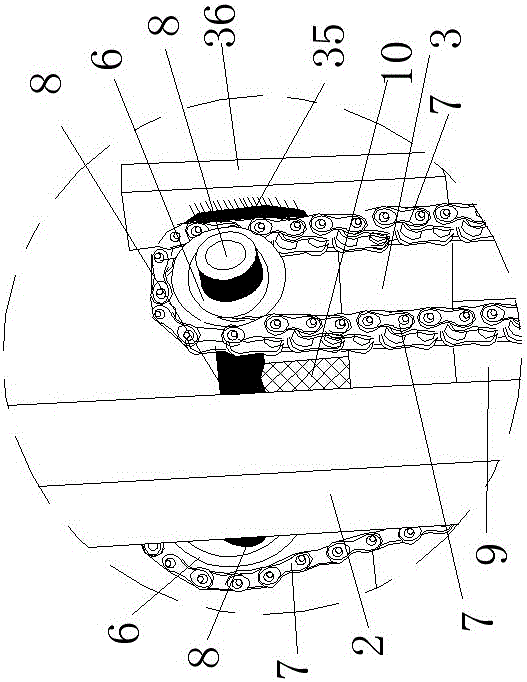

[0050] Example 2, such as Figure 8 to Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the first endless belt 25, the second endless belt 26, and the third endless belt 27 are belts, and the first transmission wheel 16, the second transmission wheel 17, the Three transmission pulleys 18, the fourth transmission pulley 19, and the fifth transmission pulley 20 are belt pulleys. The vertical circulation strip 7 is a belt, and the bottom wheel 5 and the top wheel 6 are pulleys. The outer side of the vertical circulation strip 7 is welded to the vertical plate 36 arranged on the middle horizontal frame 3 . The movable power output mechanism is a tractor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com