Flat blade wiper

A non-bracket, wiper technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as poor structure, increased fatigue, jitter, etc., to reduce assembly costs and improve mass production. The effect of productivity and power burden reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

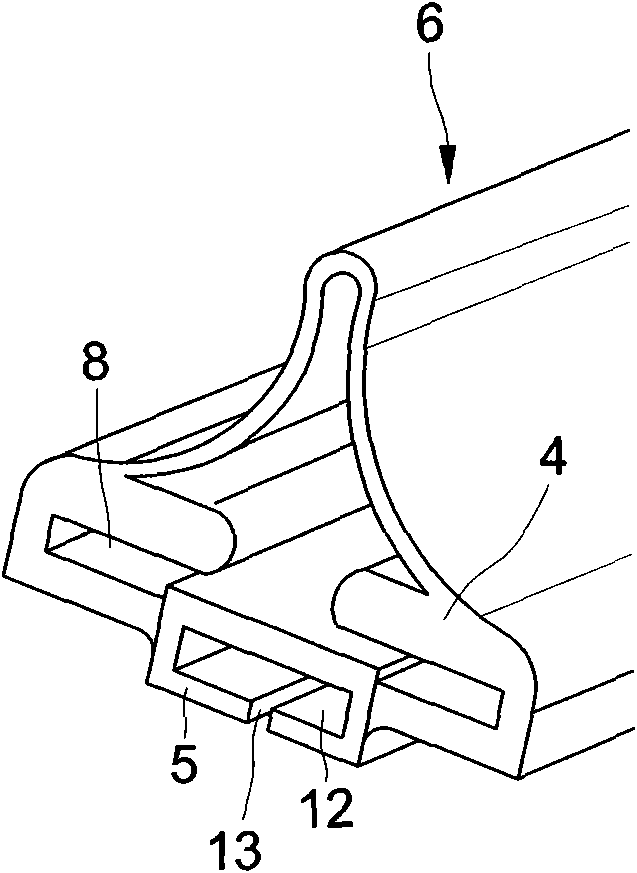

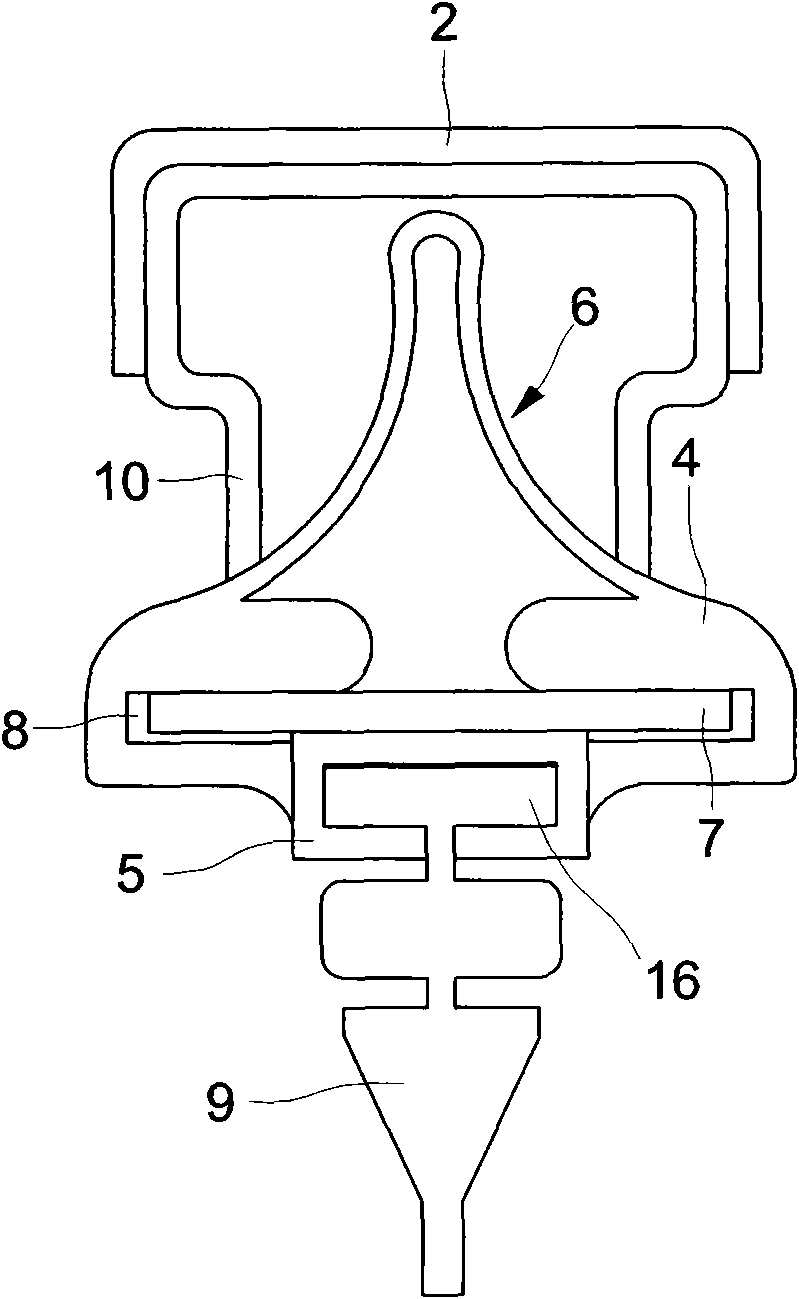

[0108] Please refer to Figure 8 , Figure 9 to Figure 9-d and Figure 10 to Figure 11 As shown in -e, the structure of the non-support type wiper of the present invention includes:

[0109] A metal shrapnel body 20 is a flat strip body made of metal material and has the flexibility to bend downwards. On the two long sides 23 of 21, each recess is provided with a pair of symmetrical and inward grooves 24;

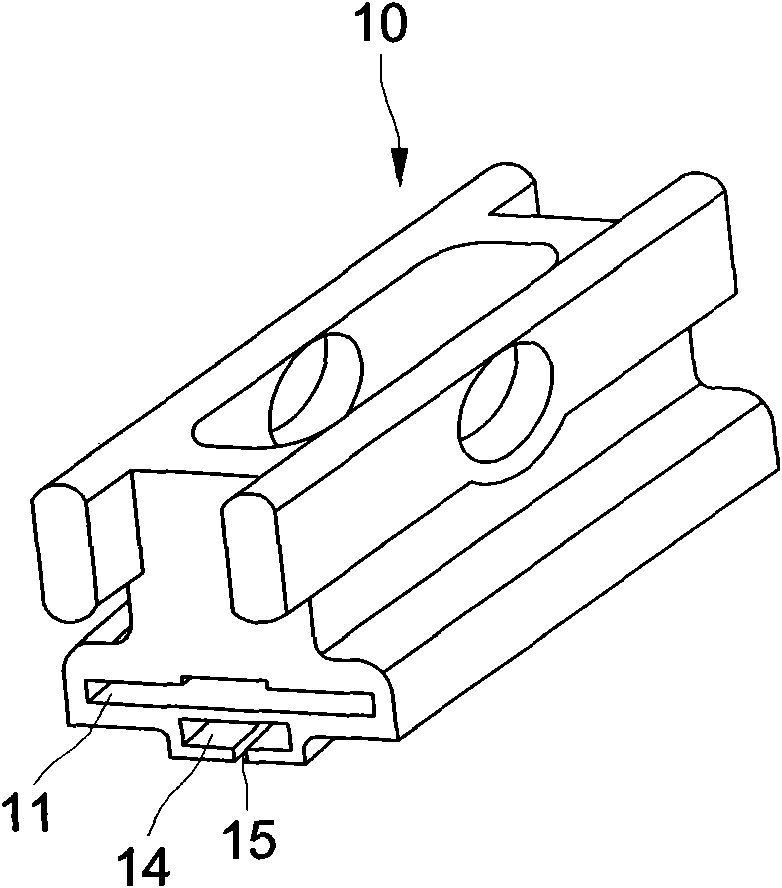

[0110] A connector holder 30 is a cuboid formed by integral injection molding of plastic material, and has a top surface 31, a bottom surface 32, two long sides 33 and two short sides 34, and the top surfaces 31 close to the two long sides 33 are protruding respectively There is a vertical surface 311, and a support shaft 312 is indirectly provided between the two vertical surfaces 311, which can be used for a wiper connector 70 to be fit and fixed, and then be connected and fixed on the end of the wiper rocker arm 2 (such as Figure 17 As shown), in addition, between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com