Rotary hearth furnace

A technology for rotary hearth furnaces and furnace bodies, which is applied to furnaces, furnace components, descaling devices, etc. It can solve problems affecting the normal production of rotary hearth furnaces, furnace jams, and normal operation of furnace bodies, so as to save energy and reduce energy consumption. The effect of reducing consumption and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

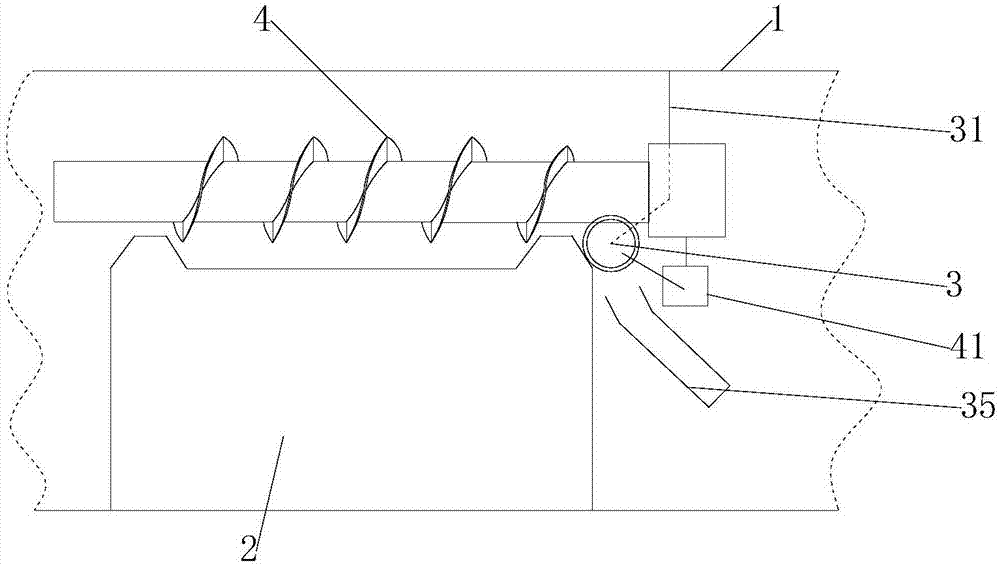

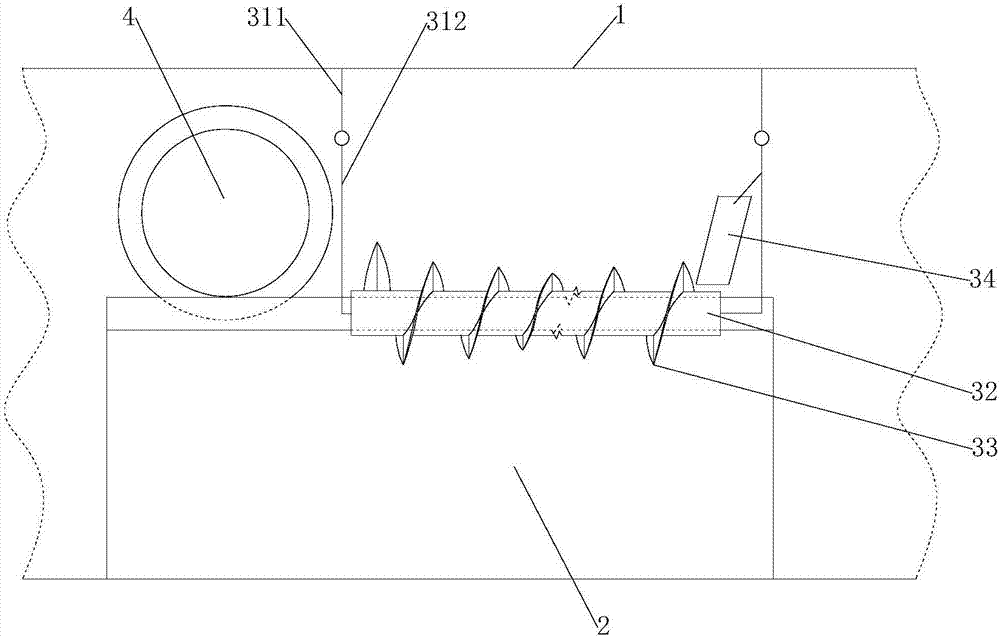

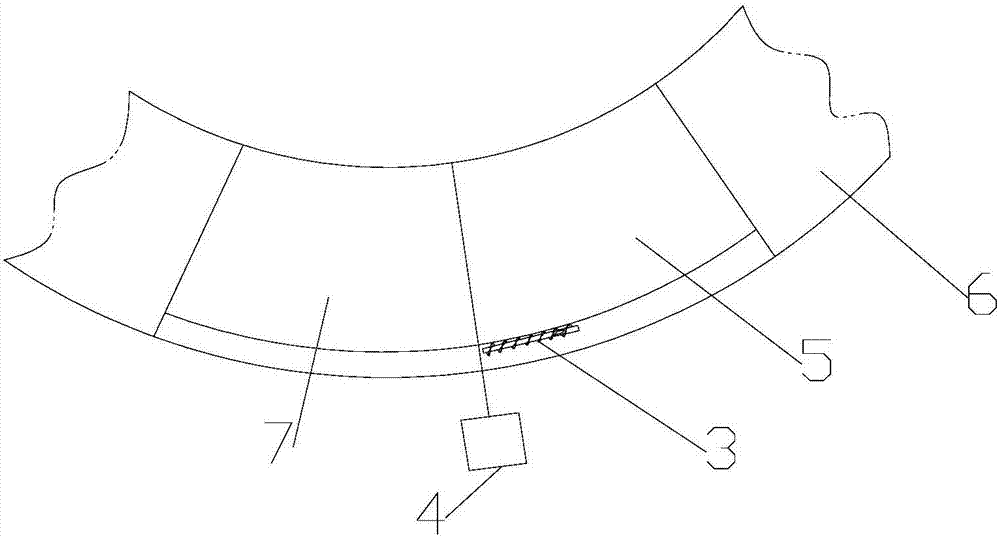

Embodiment 1

[0040] A tumor remover is arranged on the bottom side of the rotary hearth furnace, and the tumor remover is arranged in the material distribution area and fixed on the furnace roof. The tumor remover can remove the tumor body stuck on the furnace bottom through the rotation of the helical blade, and the tumor body moves with the helical blade to the end of the helical blade, or falls off a small amount during the movement. There is a scraper on the debulking device, which can remove the material on the spiral blade. The tumor-discharging groove provided directly under the spiral blade is used to receive the tumor body falling from the spiral blade, and the tumor body is discharged from the rotary hearth furnace through the tumor-discharging port.

[0041] The height at both ends of the spiral blade is greater than that in the middle, so that the shape of the spiral blade matches the circumference of the furnace bottom. In this embodiment, the length of the rotating shaft is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com