Structure of landing door of elevator

A technology of landing doors and elevators, applied in elevators, lifts, transportation and packaging in buildings, etc., can solve problems such as difficult cleaning, and achieve the effects of high speed, reduced power burden, and short travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

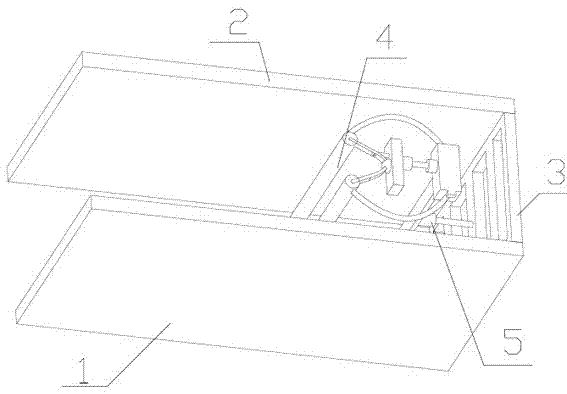

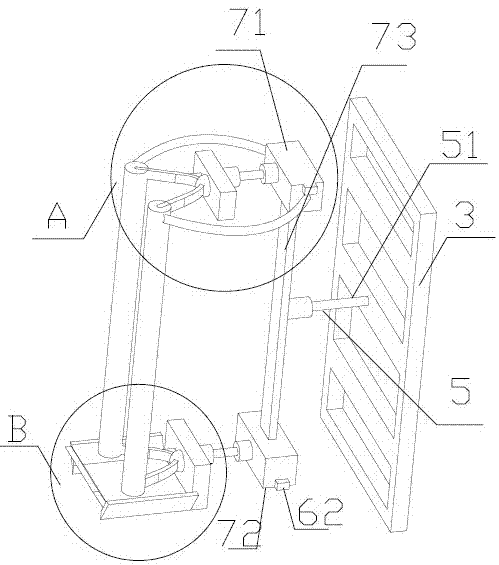

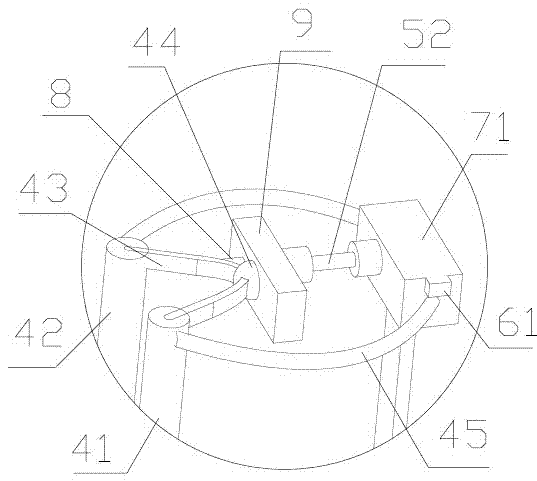

[0033] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 Shown: an elevator floor door structure, including a lift box, an inner door 1 and an outer door 2, and also includes a connecting frame 3 connected to the lift box and located between the inner door 1 and the outer door 2 for cleaning the inner door 1 The cleaning device 4 of the outer door 2 and the driving device 5 that drives the cleaning device 4 to move relative to the inner door 1 and the outer door 2, the driving device includes a main drive 51 connected to the connecting frame 3 at one end and connected to the cleaning device 4 at the other end, The cleaning device 4 includes an inner door barrel 41 for cleaning the inner door 1, an outer door barrel 42 for cleaning the outer door 2, which is U-shaped, and a U-shaped frame 43 connecting the inner door barrel 41 and the outer door barrel 42 at both ends. It is connected with the hinged seat 44 at the middle position of the U-shaped frame 43, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com