Buffer reaction storage tank

A storage tank and reaction technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of fast continuous production speed, difficult operation of the next step process, high viscosity, etc., and achieve improvement Shelf life and quality, facilitate installation and maintenance, and reduce power burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

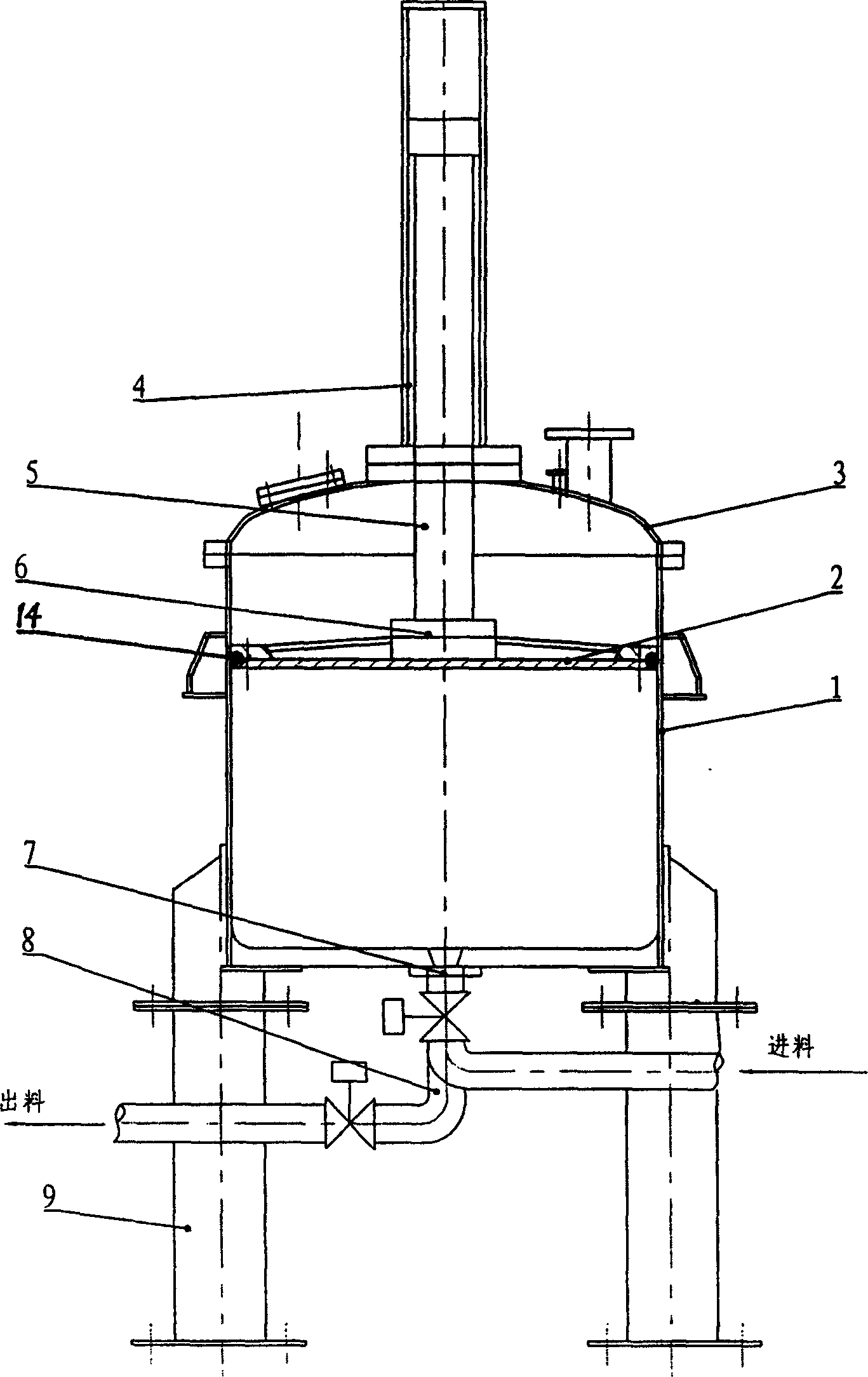

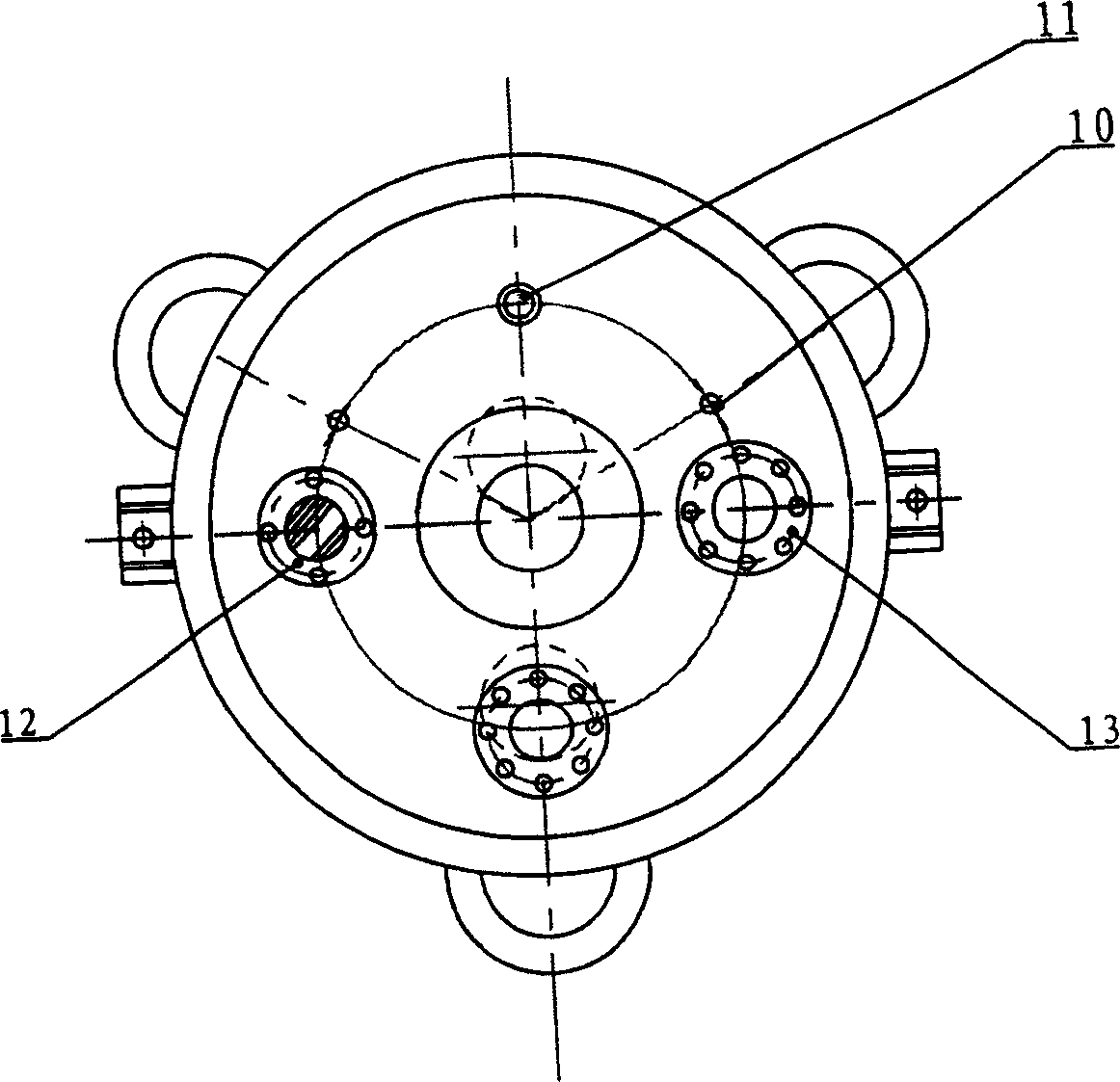

[0017] Such as figure 1 , 2 As shown, the buffer reaction storage tank of the present invention includes a cylindrical storage tank body 1 , and the storage tank body 1 is provided with a foot 9 . The upper part of the storage tank body 1 is provided with a head gland 3, and the storage tank body 1 and the head gland 3 form a closed space. A protective gas input port 10 , an ultrasonic probe 11 , a camera probe 13 and a sight glass 12 are respectively arranged on the head gland 3 . The bottom of the tank body 1 is provided with a material inlet 7 and a material outlet 8 . There is a pressure plate 2 inside the storage tank body 1, the size of the pressure plate 2 is equivalent to the inner diameter of the storage tank body 1, and it is sealed with an O-shaped sealing ring 14. The pressure plate 2 is connected with a pressure plate seat 6 and the pressure plate 2 and the pressure plate Seats 6 are separable. A hydraulic cylinder 4 is arranged on the top of the head gland 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com