Light-weight aluminum alloy carriage

An aluminum alloy, lightweight technology, applied in the direction of vehicle parts, superstructure of trucks, superstructure, etc., can solve the problems of unfavorable development and promotion of lightweight logistics vehicles, low efficiency of parts loading, unloading and replacement, and short service life, etc. Achieve the effect of excellent lightweight design effect, good lightweight design conditions, improved load capacity and anti-deformation and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

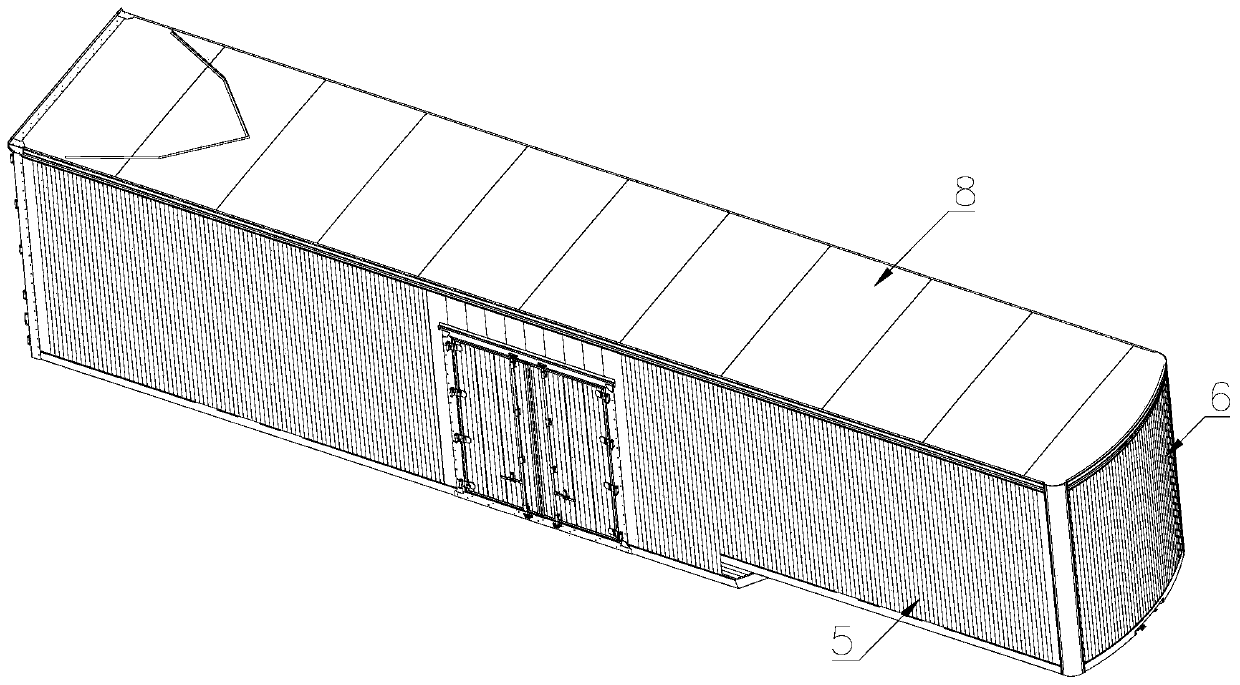

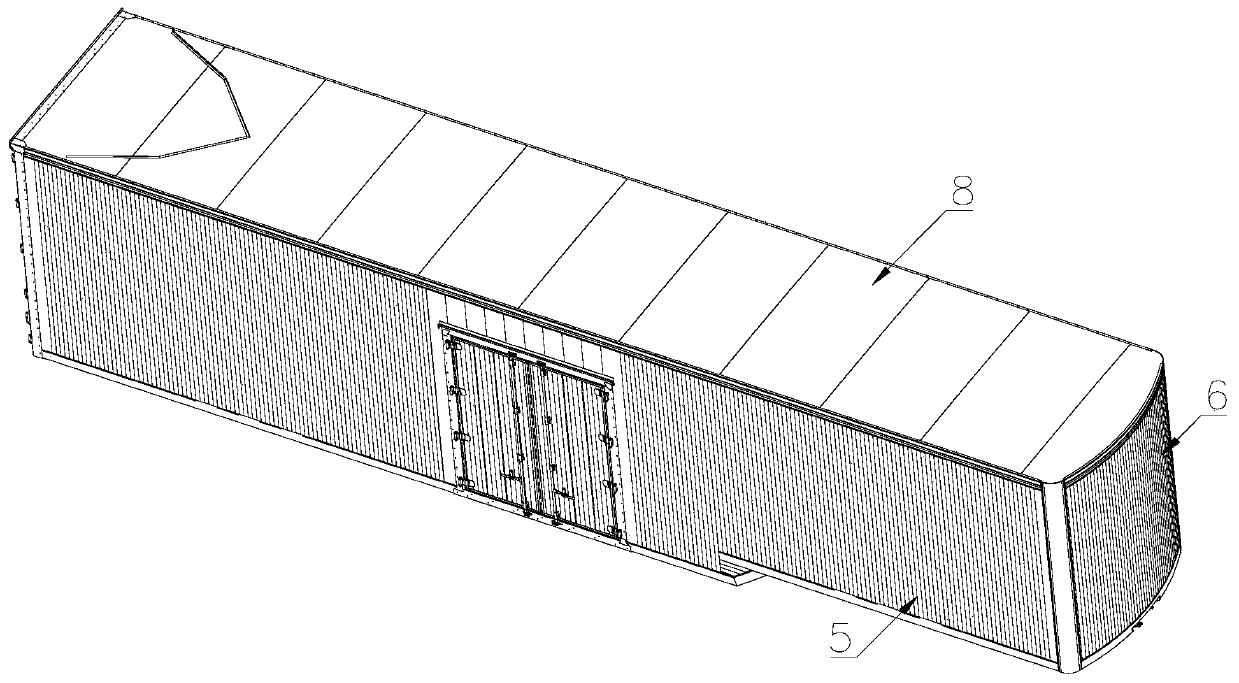

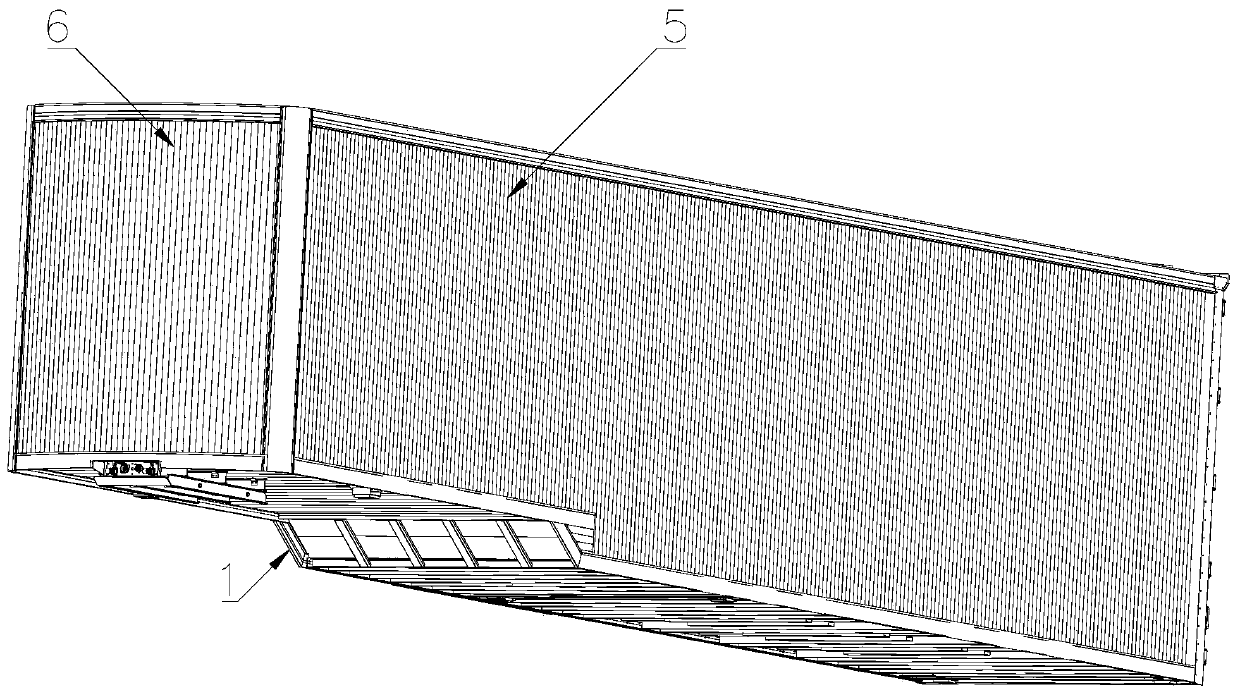

[0028] Please refer to Figure 1 to Figure 10 , a lightweight aluminum alloy carriage, comprising a floor assembly, the floor assembly including a front end and a rear end arranged front and rear on the axis;

[0029] The front end part includes a horizontally laid aluminum alloy profile bottom plate, and the extrusion direction of the horizontally laid aluminum alloy profile bottom plate is perpendicular to the axis of the bottom plate assembly;

[0030] The rear end part includes an aluminum alloy square tube beam and a longitudinally laid aluminum alloy profile base plate, the aluminum alloy square tube beam is perpendicular to the axis of the base plate assembly, and the extrusion direction of the longitudinally laid aluminum alloy profile base plate is para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com