Method for calculating optimum preparing and adding proportion of iron ore sintering

A calculation method and iron ore technology, applied in the field of iron and steel metallurgy, can solve the problem of inaccurate quantitative ore mixing plan and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

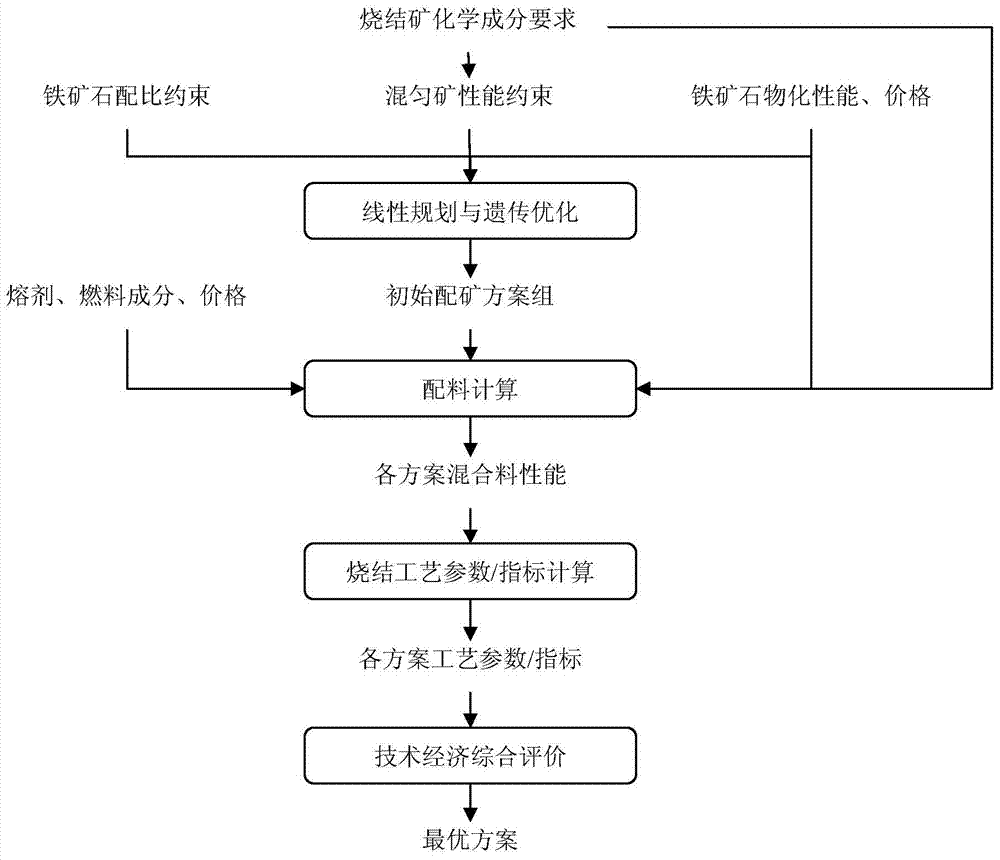

[0042] A method for calculating the optimal proportion of iron ore sintering, the calculation process is as follows figure 1 As shown in the figure, under the determined application environment, according to its sintering production requirements, gradually increase the proportion of a certain iron ore, and determine a group of ore blending plans with low ore blending cost and excellent sintering index. Carry out a comprehensive evaluation of the proportioned ore blending plan, and determine the proportion of iron ore with the highest technical and economic comprehensive evaluation index in this application environment and the corresponding ore blending plan.

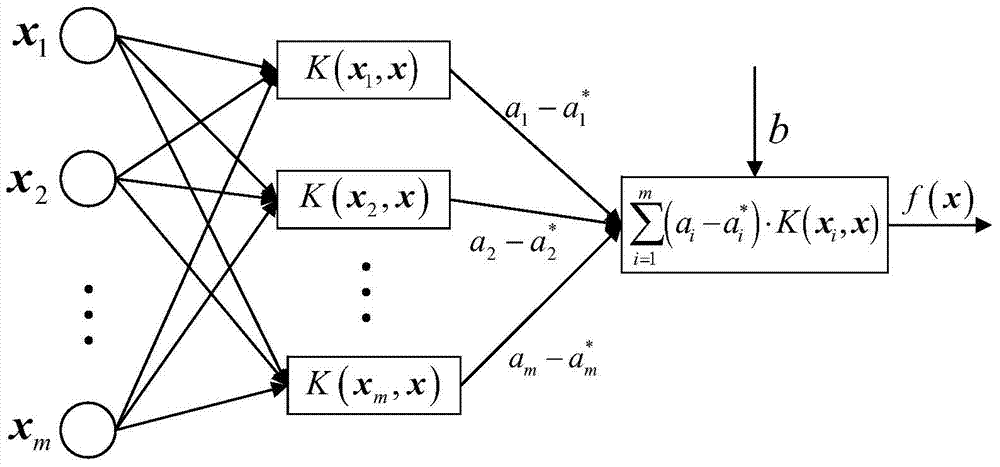

[0043] The sintering process parameters and product quality index model structure are as follows: figure 2 As shown, in the model, a represents the Lagrange multiplier; b represents the deviation, which are the optimal solutions obtained by minimizing the error between the training sample and the optimal classification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com