Automobile chassis lining matching method based on rigidity matrix

A technology of stiffness matrix and matching method, applied in vehicle components, special data processing applications, instruments, etc., can solve the problems of unsatisfactory development methods, time-consuming and labor-intensive, etc., to meet the development trend of virtual prototyping, reduce testing, and optimize The effect of the matching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

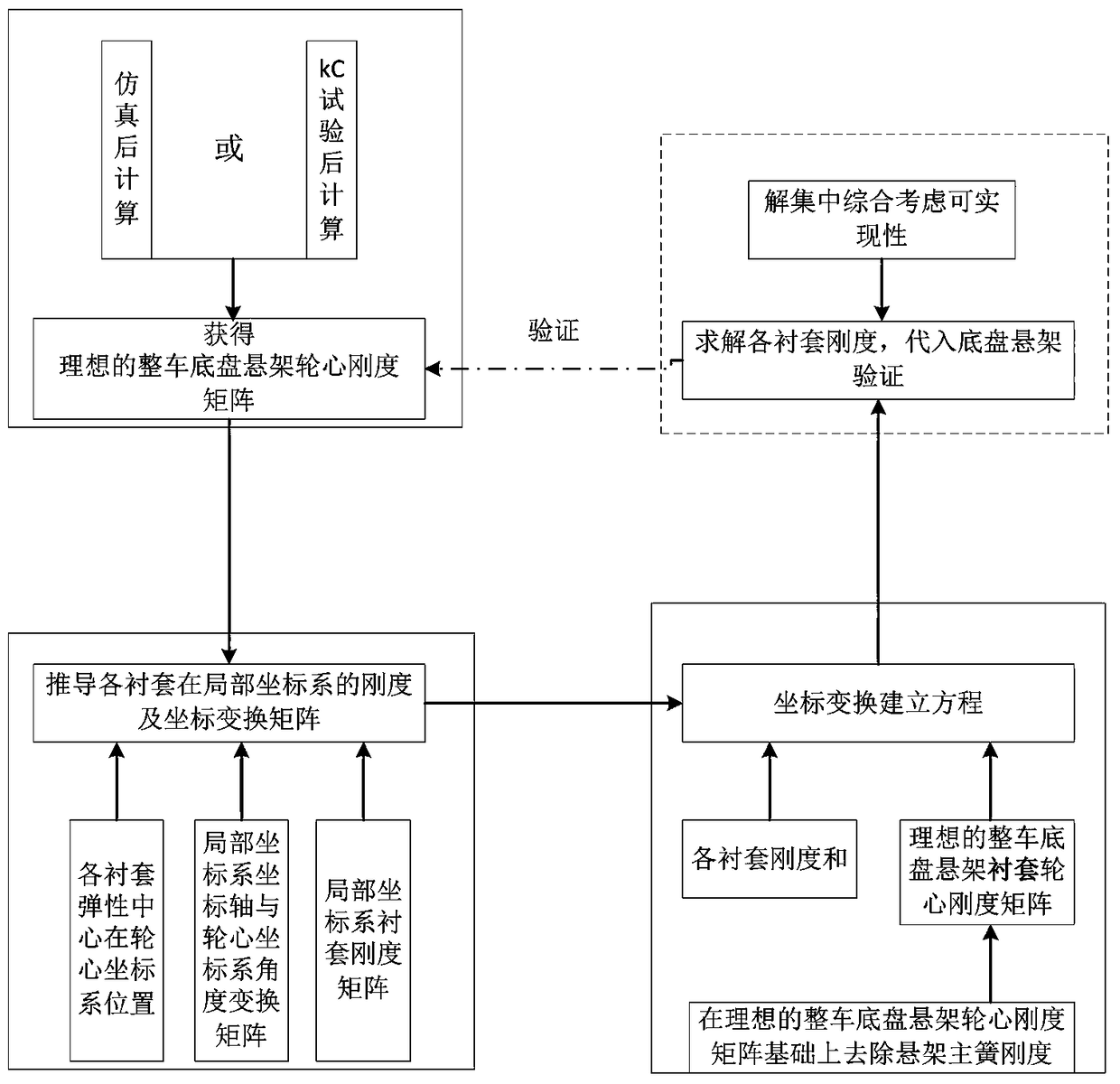

[0022] The automobile chassis liner matching method based on stiffness matrix in the present embodiment, its flow process is as follows figure 1 shown, including the following steps:

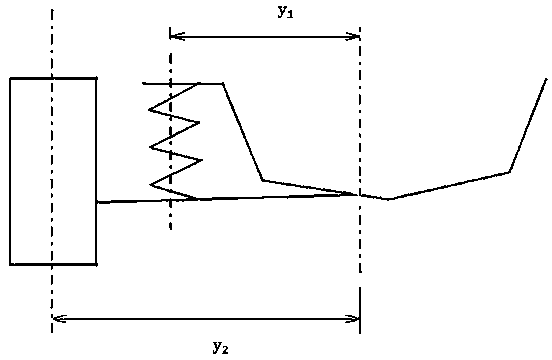

[0023] Step 101, select a car as a standard model, and obtain the stiffness of the chassis system of the standard model. In this embodiment, the wheel center stiffness matrix of the chassis suspension of the vehicle is obtained by obtaining the selected vehicle type. Due to the symmetry of the chassis suspension, this matrix considers all the bushings on one side of the suspension to obtain the selected vehicle The chassis suspension wheel center stiffness matrix, the specific process is:

[0024] First of all, according to the previous market research, the performance index that the chassis bushing to be matched needs to meet is proposed, and on this basis, the target model of the elastic kinematic performance of the chassis is selected, and the elastic kinematic performance of the suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com