Bending forming method, system and device and medium

A storage medium and relationship technology, applied in transportation and packaging, special data processing applications, instruments, etc., can solve problems such as iterative optimization methods, achieve strong versatility, and avoid repeated trials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

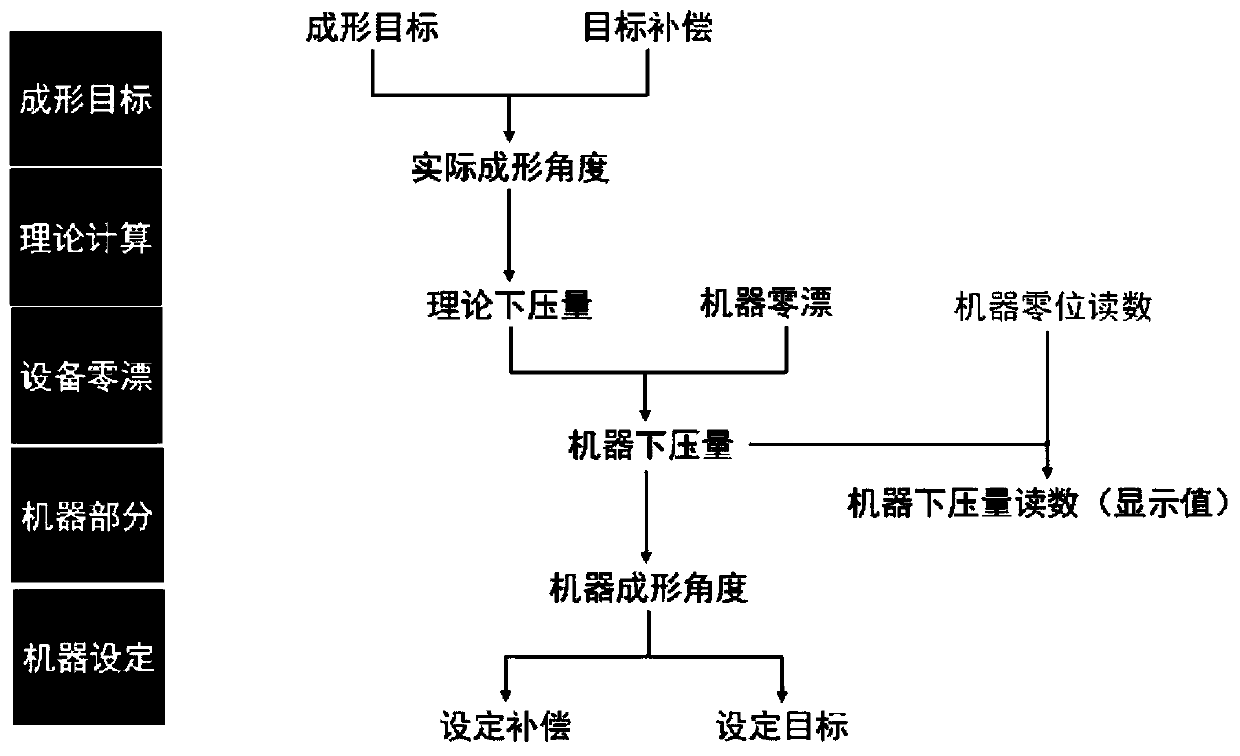

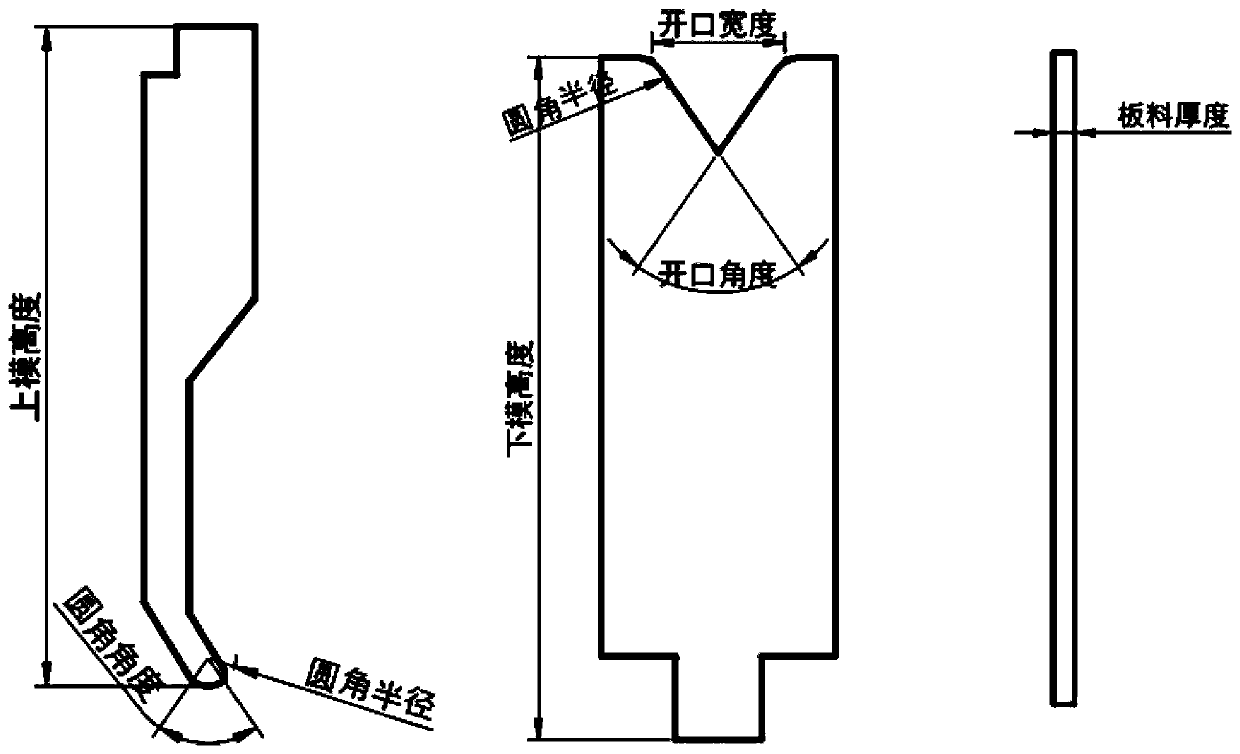

[0058] The basic process of the present invention is as figure 1 As shown, the specific implementation process of this method is illustrated by taking the bending of a high-strength steel hat shape as an example. The established bending simulation geometric model and important geometric parameters such as figure 2 As shown, from left to right are the upper die, lower die and sheet.

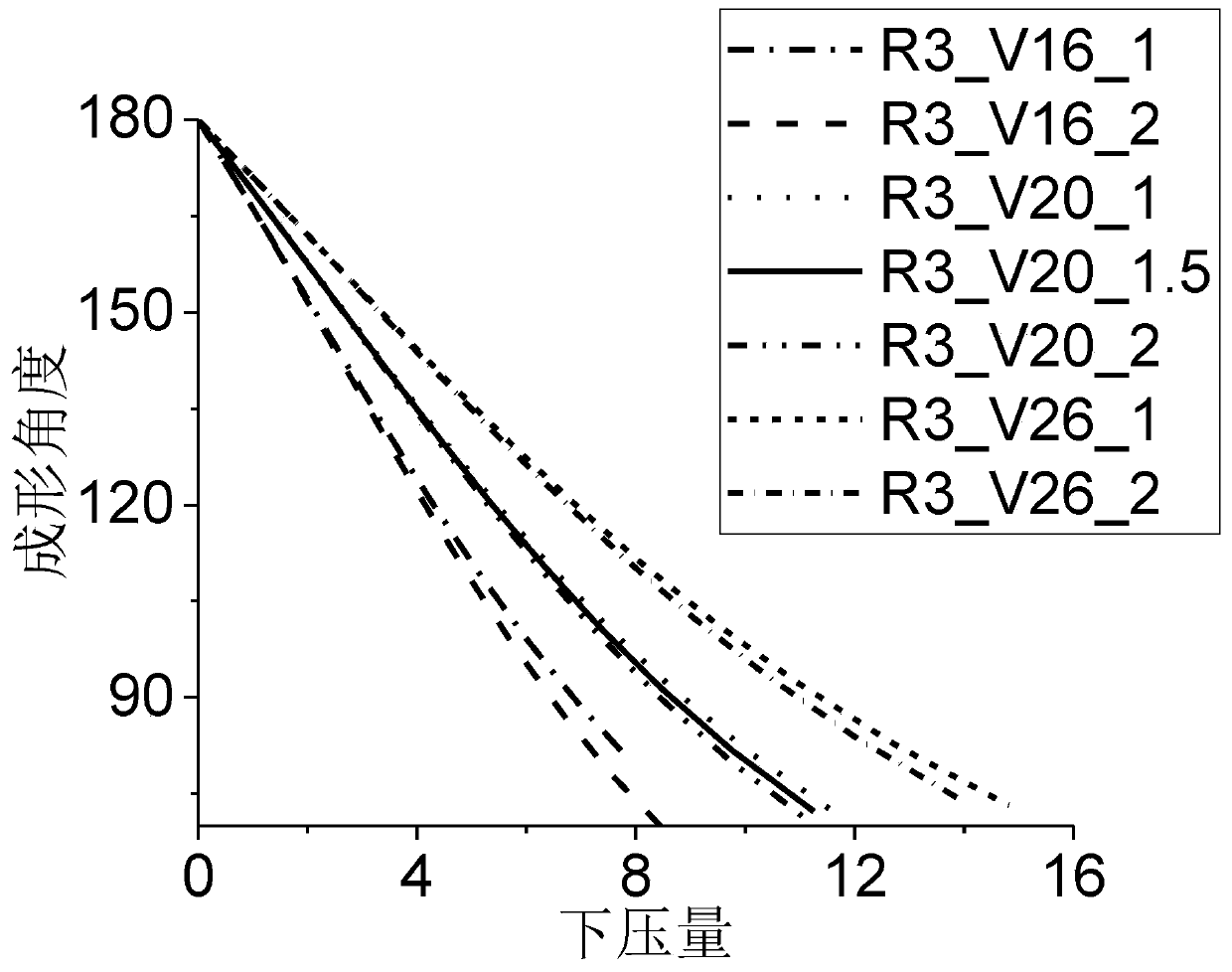

[0059] Through the secondary development and batch simulation of python, the forming process of the die surface and the plate with different geometric parameters is simulated, and the corresponding relationship between the pressing amount and the forming angle is obtained, such as image 3 As shown, the illustration in the figure, such as R3_V16_1, represents that the upper die fillet radius in the main geometric parameters is 3 mm, the lower die opening width is 16 mm, and the sheet thickness is 1 mm.

[0060] Set the target forming angle of the equipment to 0° or set the target pressing amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com