Analytical design method of camber and surface shape of automobile plate spring

A technology of leaf springs and design methods, applied in springs/shock absorbers, leaf springs, mechanical equipment, etc., can solve problems such as failure to meet design requirements, avoid repeated tests and revisions, design accurate and reliable, and meet precise design requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the following examples of the design of the arc height and curved shape of the two leaf springs without auxiliary spring and with auxiliary spring will further describe the present invention in detail. The specific steps are as follows.

[0023] (1) Design of arc height and curved shape of leaf spring without auxiliary spring

[0024] Design value of equivalent thickness of required stiffness for a certain automobile leaf spring h =19mm, width b =40mm, the length of the leaf spring l =1400mm, the maximum load that the single-wheel leaf spring can bear = N, the elastic modulus of the leaf spring material . According to the above parameters, the design value of the arc height of the leaf spring is determined

[0025] =122.5mm;

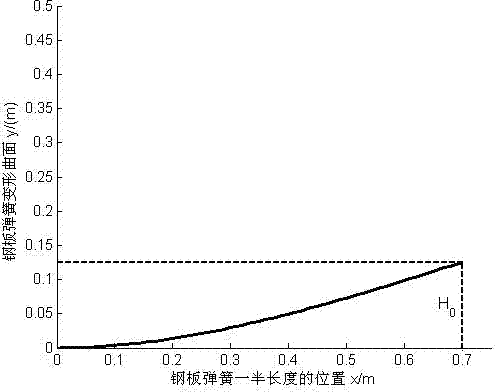

[0026] According to the formula Determine the curved surface shape of the leaf spring, such as figure 1 Shown.

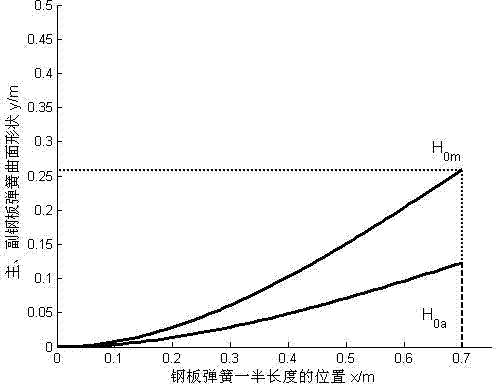

[0027] (2) Design of arc height and curved shape of leaf spring with auxiliary spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com