System and method for designing aerial fog jug forming and punching mold

A technology for designing systems and stamping dies, applied in computing, special data processing applications, instruments, etc., can solve problems such as low efficiency and high cost, and achieve the effect of optimizing the die structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

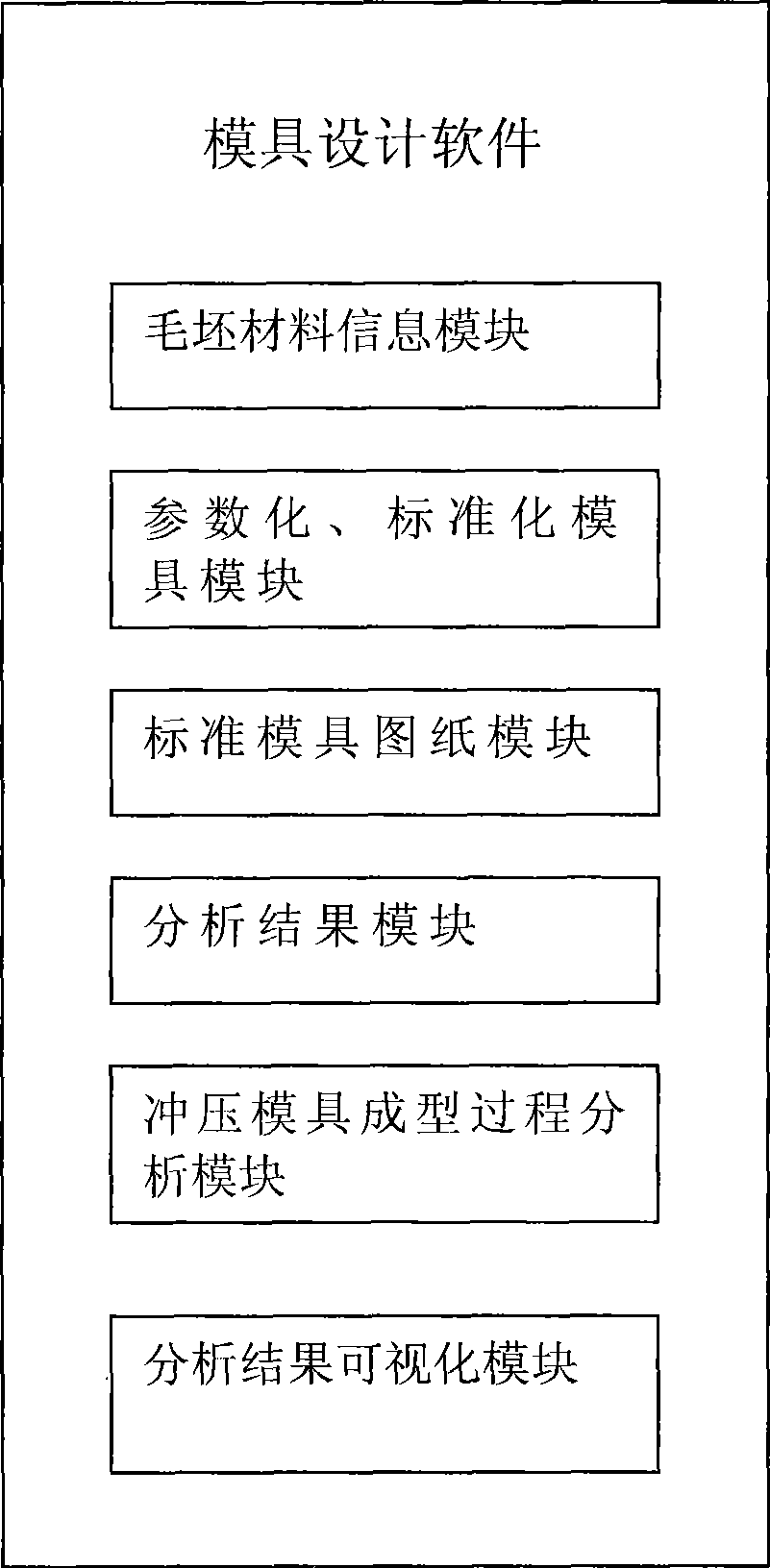

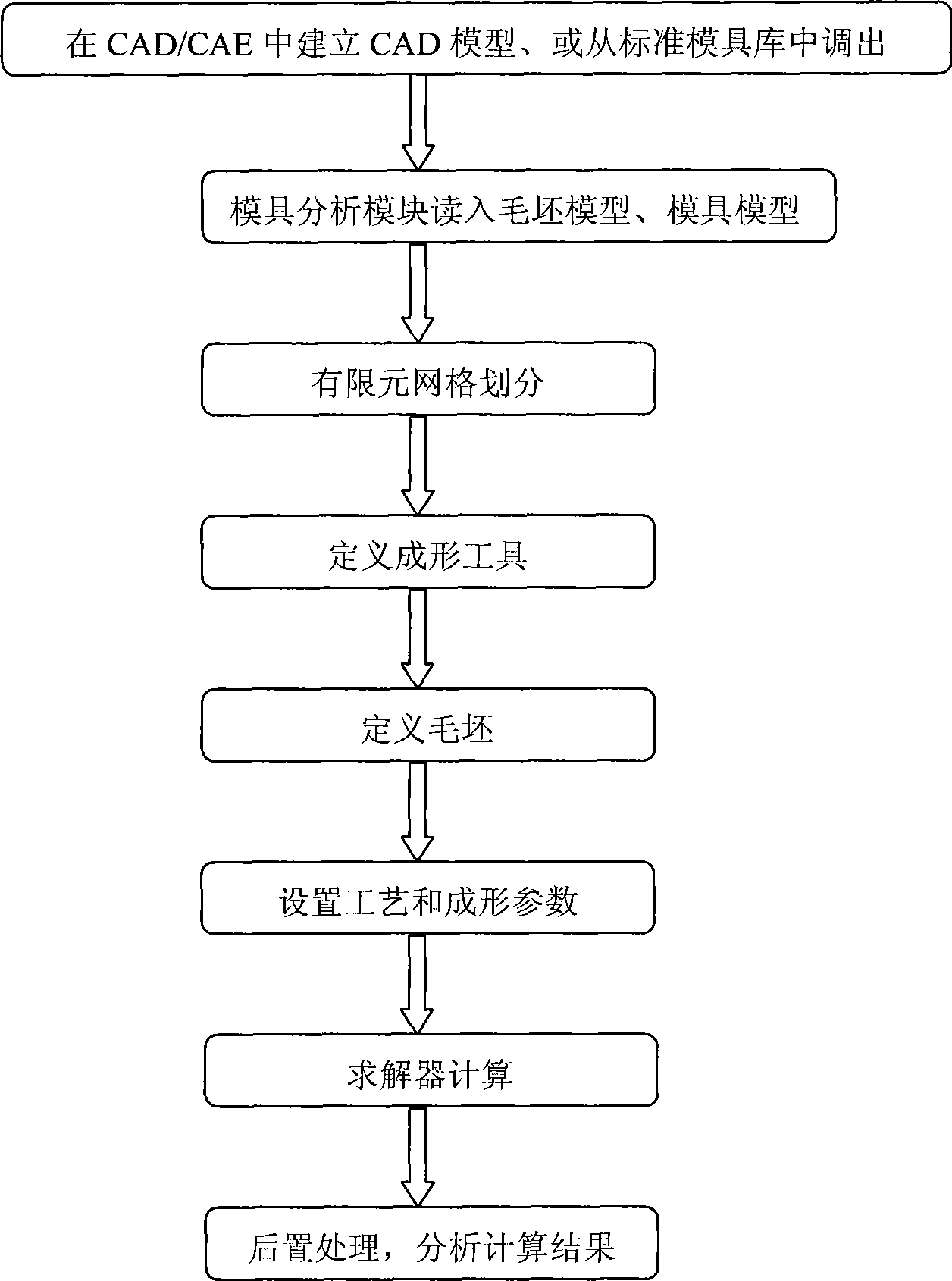

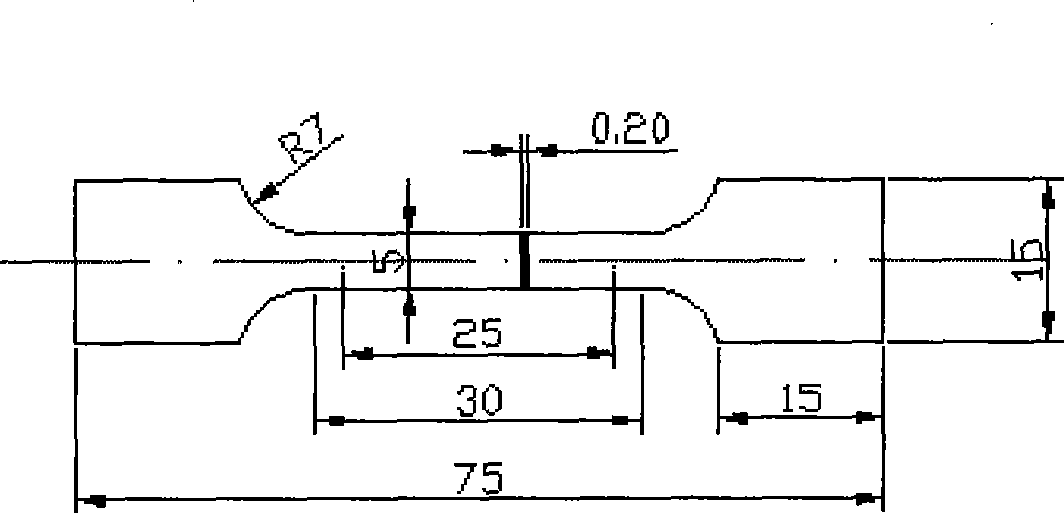

[0027] refer to Figure 1 to Figure 15 , an aerosol can forming stamping die design system, the design system includes: a blank material information module for storing various blank material related information, the blank material related information includes mechanical property data of common raw materials for aerosol cans, True stress transformation algorithm and specification size information; used to store the parameterized and standardized mold modules of the three-dimensional and two-dimensional mold diagrams of various parts for manufacturing aerosol cans. Three-dimensional and two-dimensional mold drawings and three-dimensional and two-dimensional mold drawings of each process of the bottom cover; standard molds used to store the three-dimensional and two-dimensional mold drawings and production assembly drawings of the molds in the actual production process of the various parts of the aerosol can Drawing module: used to store the original mold structure design drawing...

Embodiment 2

[0071] refer to Figure 1 to Figure 15 , a method for designing stamping dies for forming aerosol cans, in the design method, a blank material information module that stores various blank material-related information, the blank material-related information includes mechanical performance data, true Stress transformation algorithm and specification size information, store the parameterized and standardized mold modules of the three-dimensional and two-dimensional mold diagrams of various parts for manufacturing aerosol cans, and the three-dimensional and two-dimensional mold diagrams include the three-dimensional and two-dimensional 3D and 2D mold diagrams of each process of the bottom cover; store the 3D and 2D mold diagrams and production assembly diagrams of the molds in the actual production process of the various parts of the manufacturing process of the aerosol can; and store the manufacturing of different types of gas The original mold structure design drawing and corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com