Patents

Literature

45 results about "Electrochemical noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

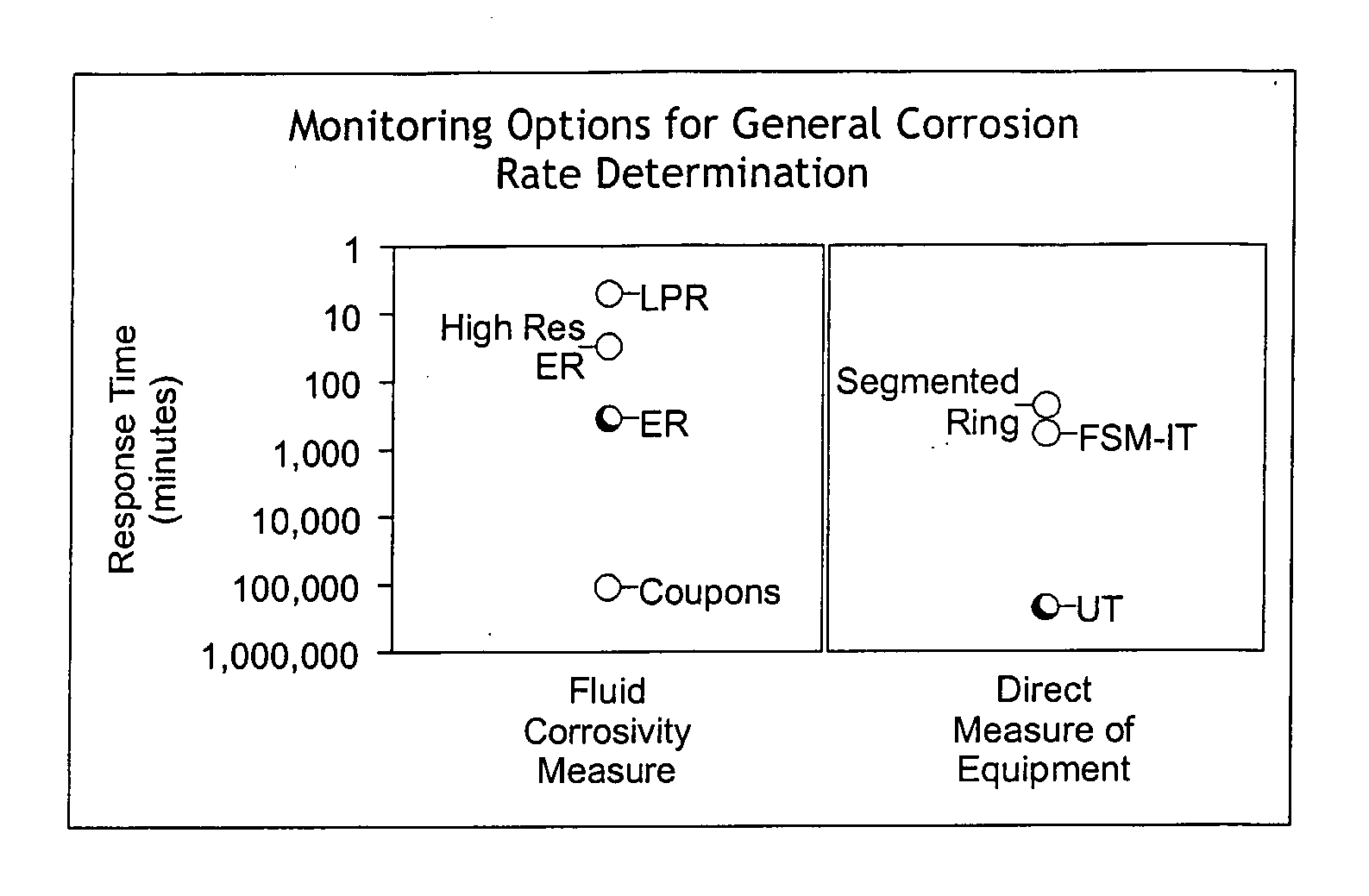

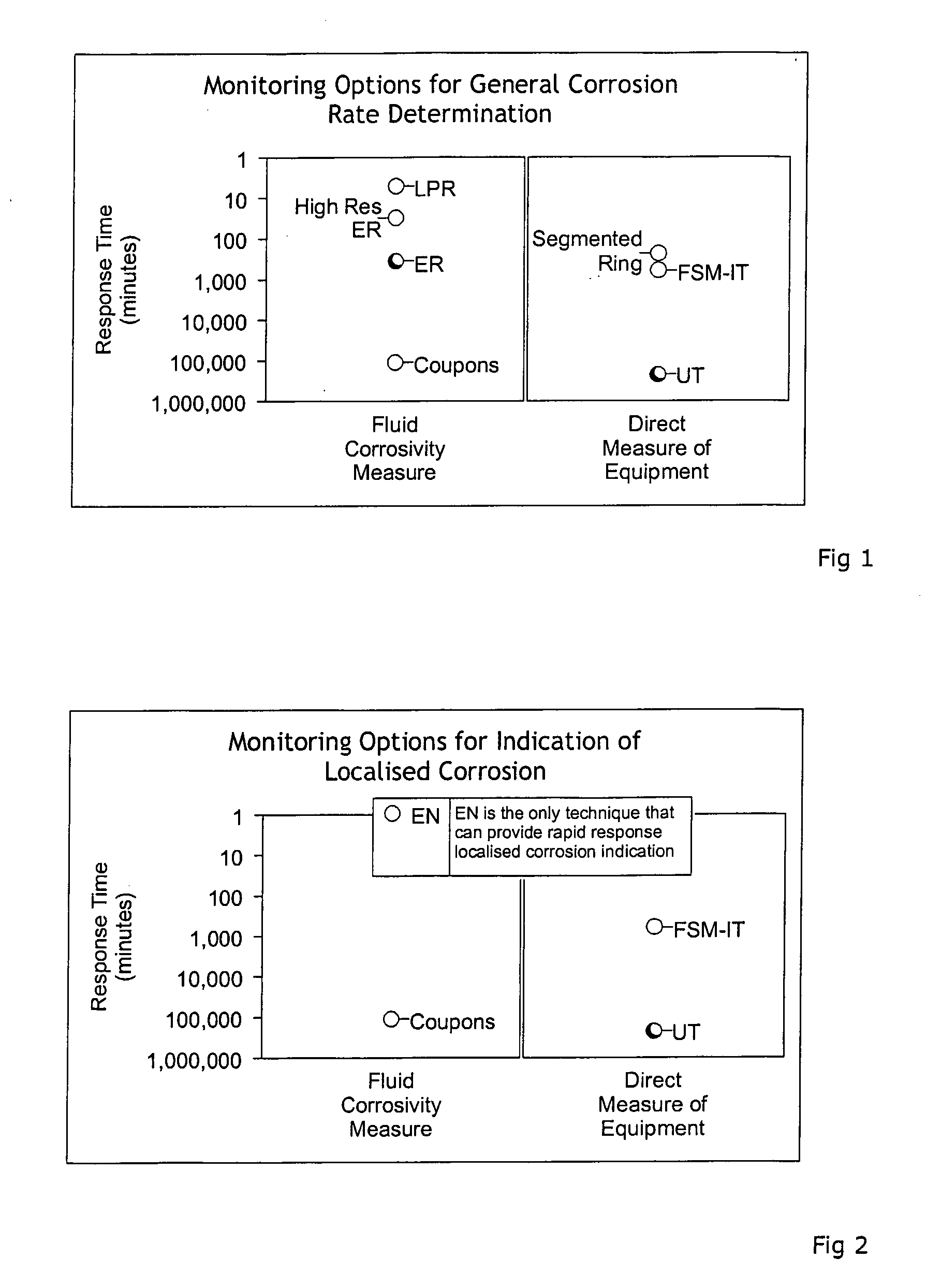

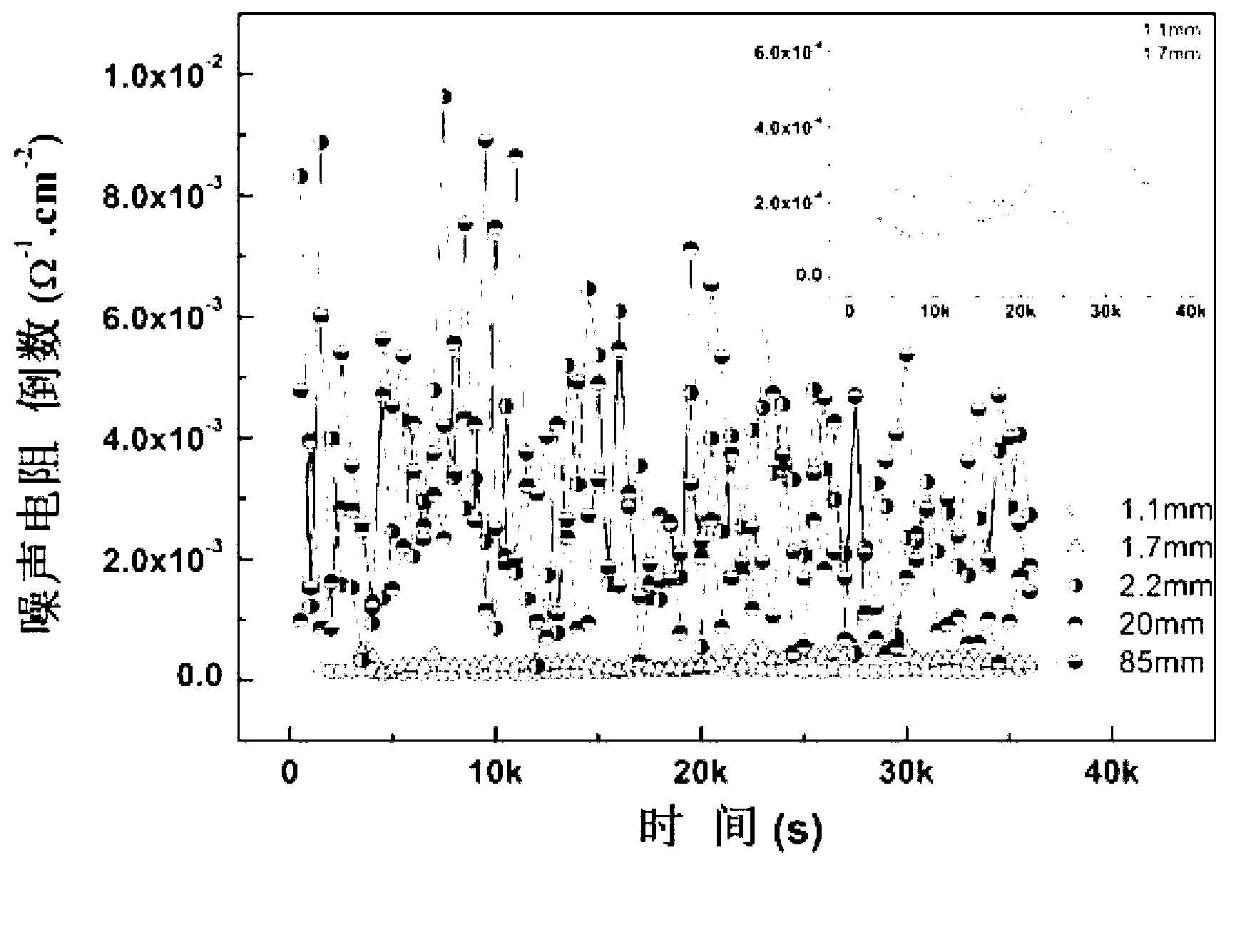

Electrochemical noise (ECN) is the generic term given to fluctuations of current and potential. When associated with corrosion, it is the result of stochastic pulses of current generated by sudden film rupture, crack propagation, discrete events involving metal dissolution and hydrogen discharge with gas bubble formation and detachment. The technique of measuring electrochemical noise uses no applied external signal for the collection of experimental data.

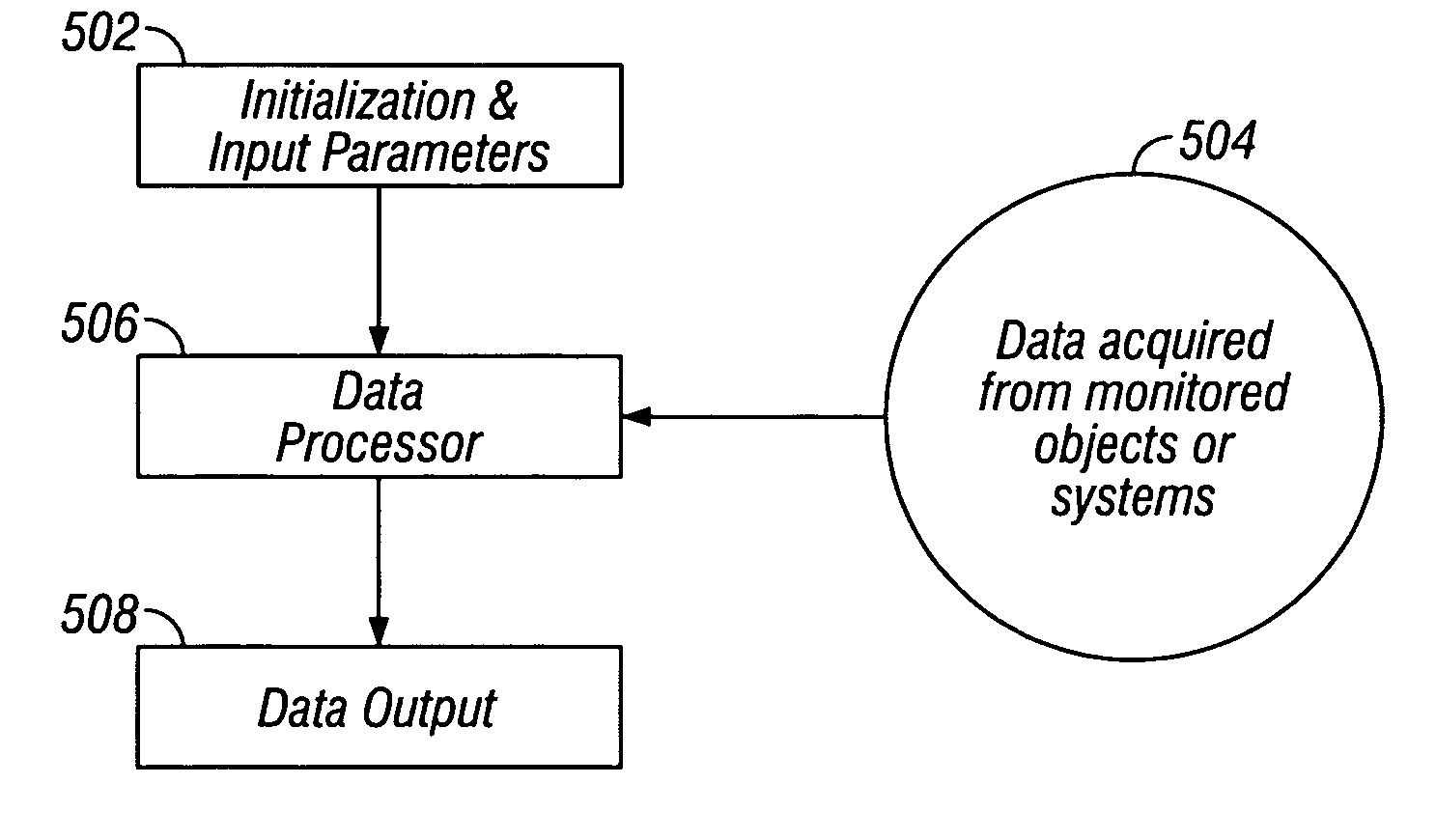

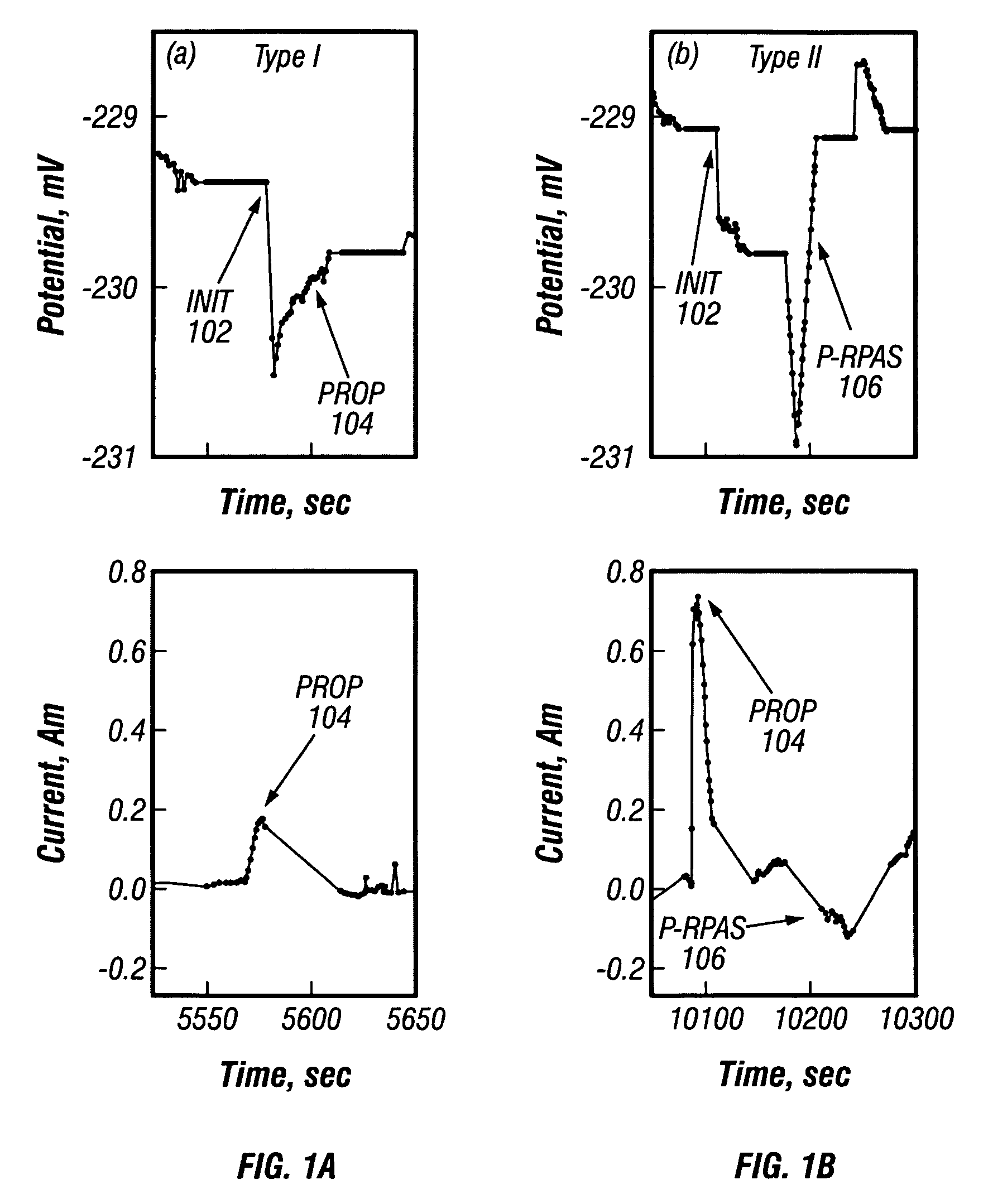

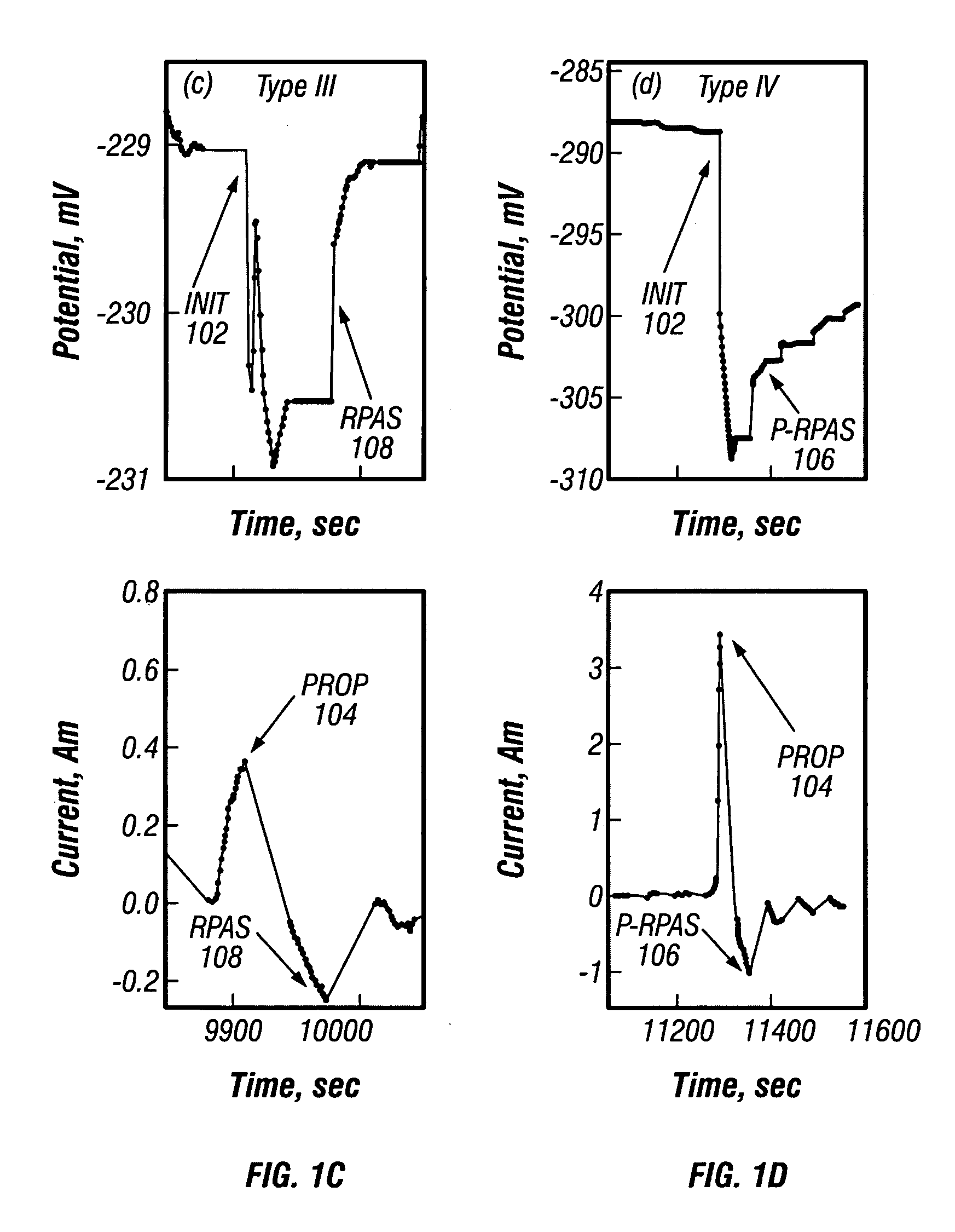

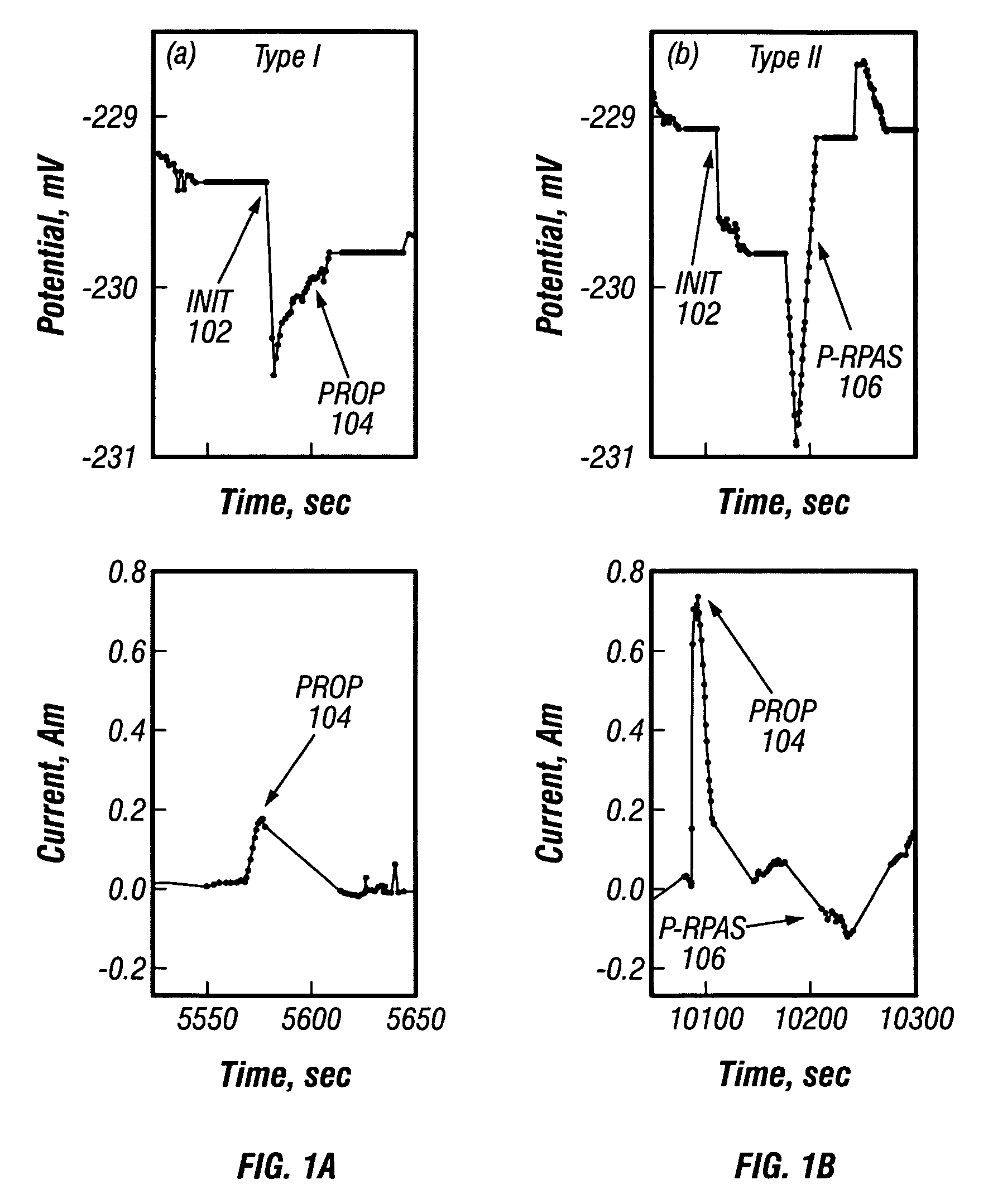

Quantitative transient analysis of localized corrosion

InactiveUS20050211570A1Weather/light/corrosion resistanceVolume/mass flow measurementElectricityTransient analysis

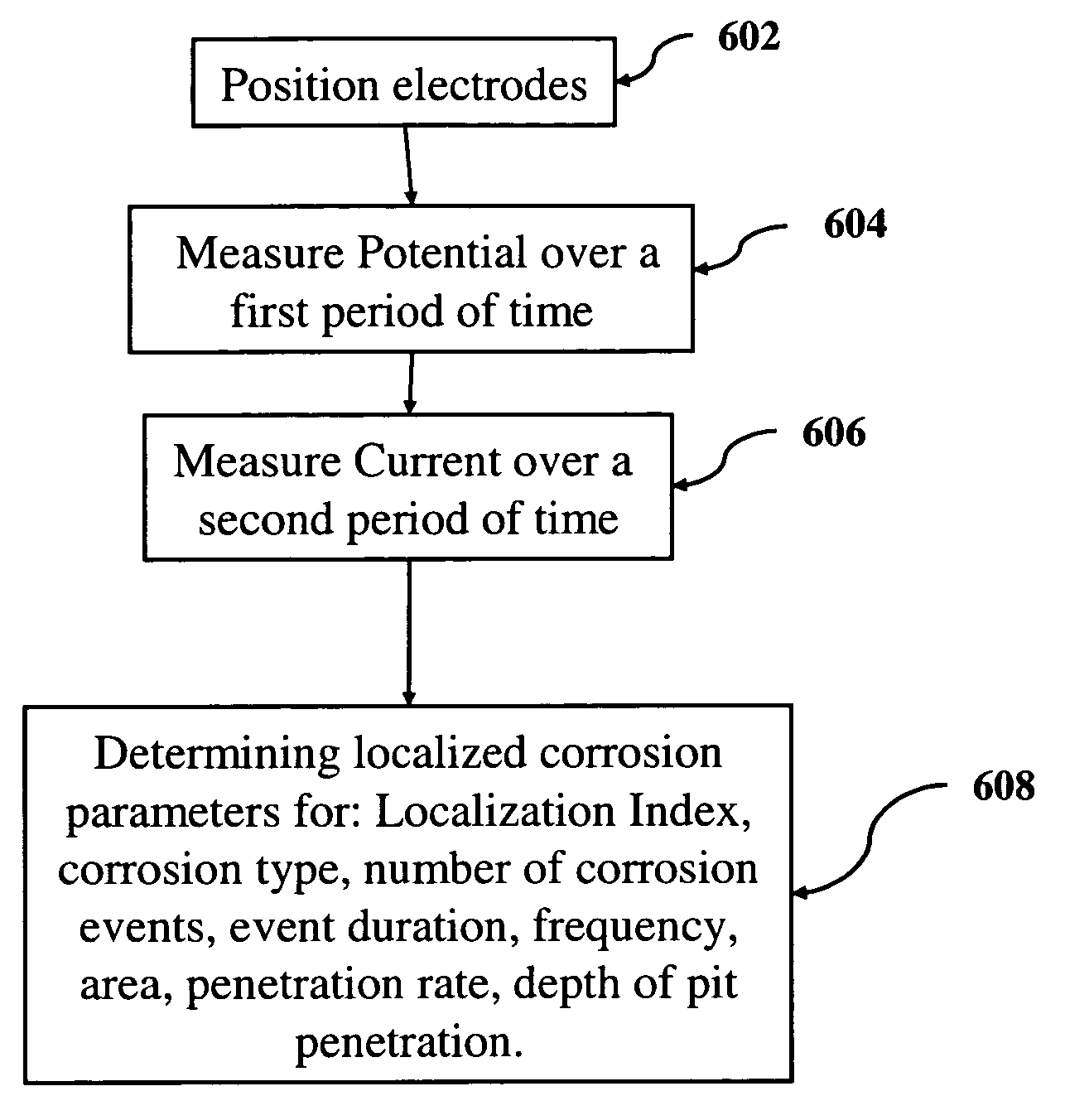

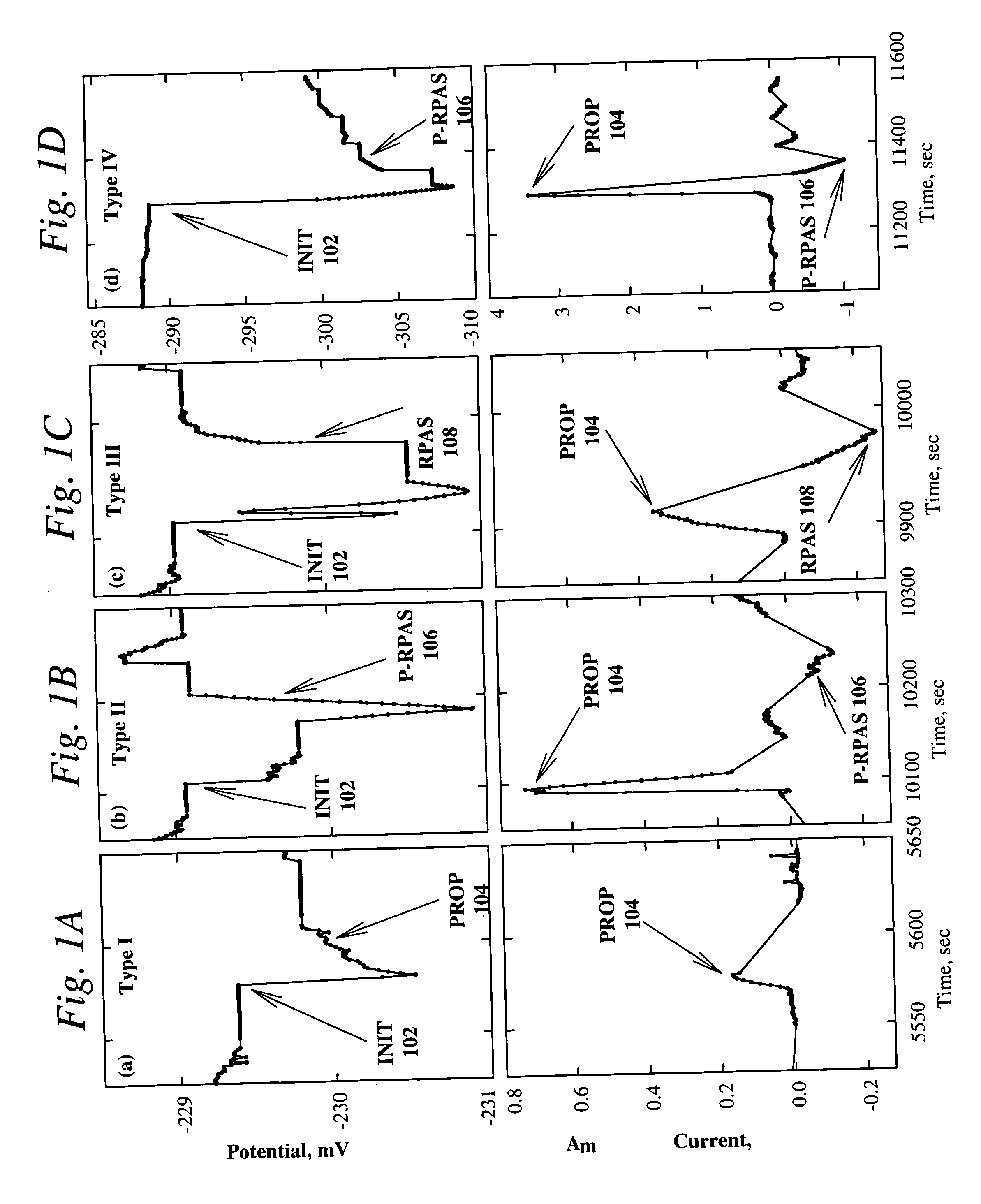

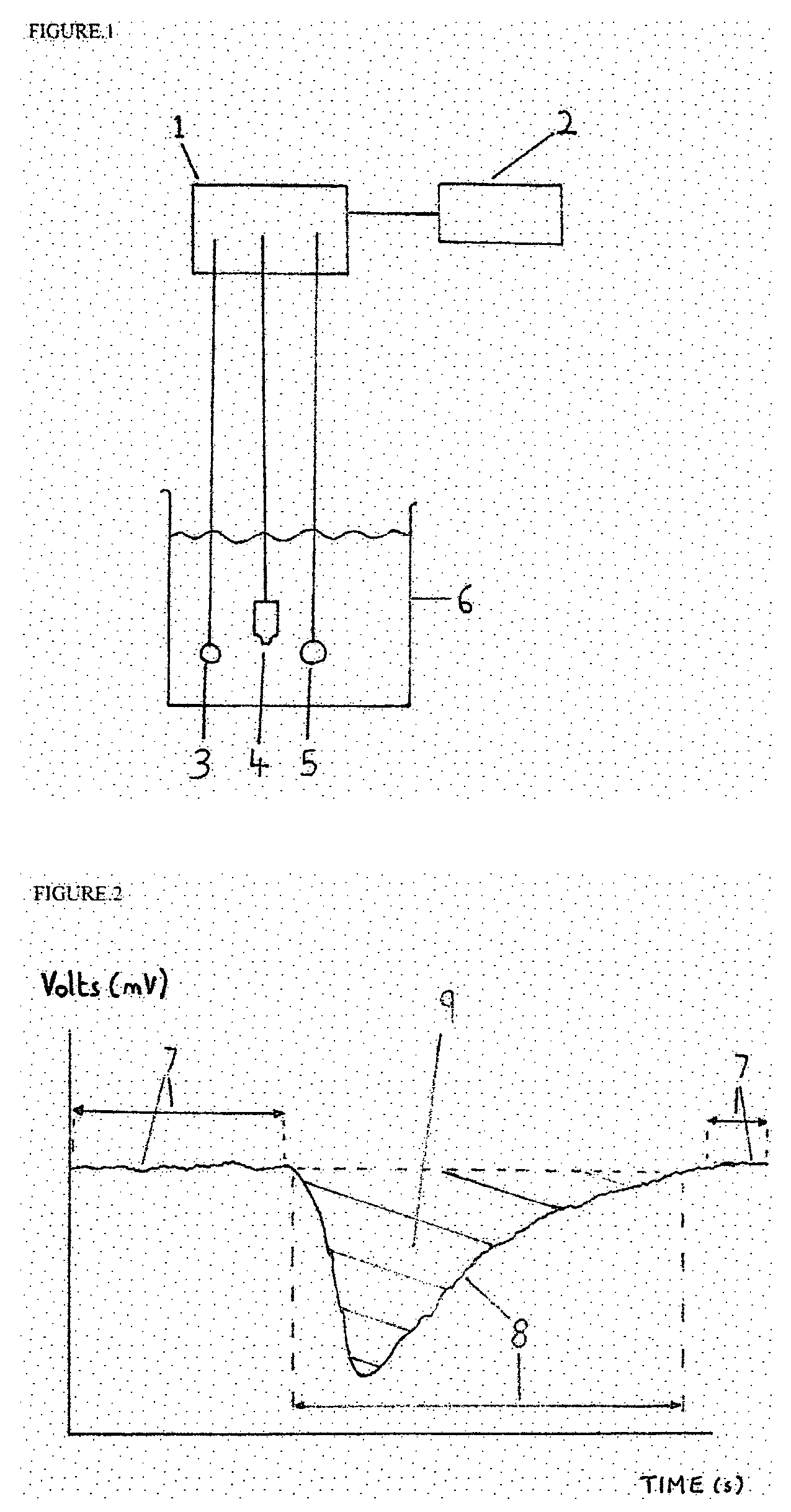

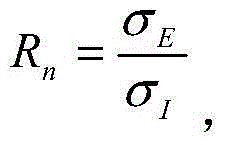

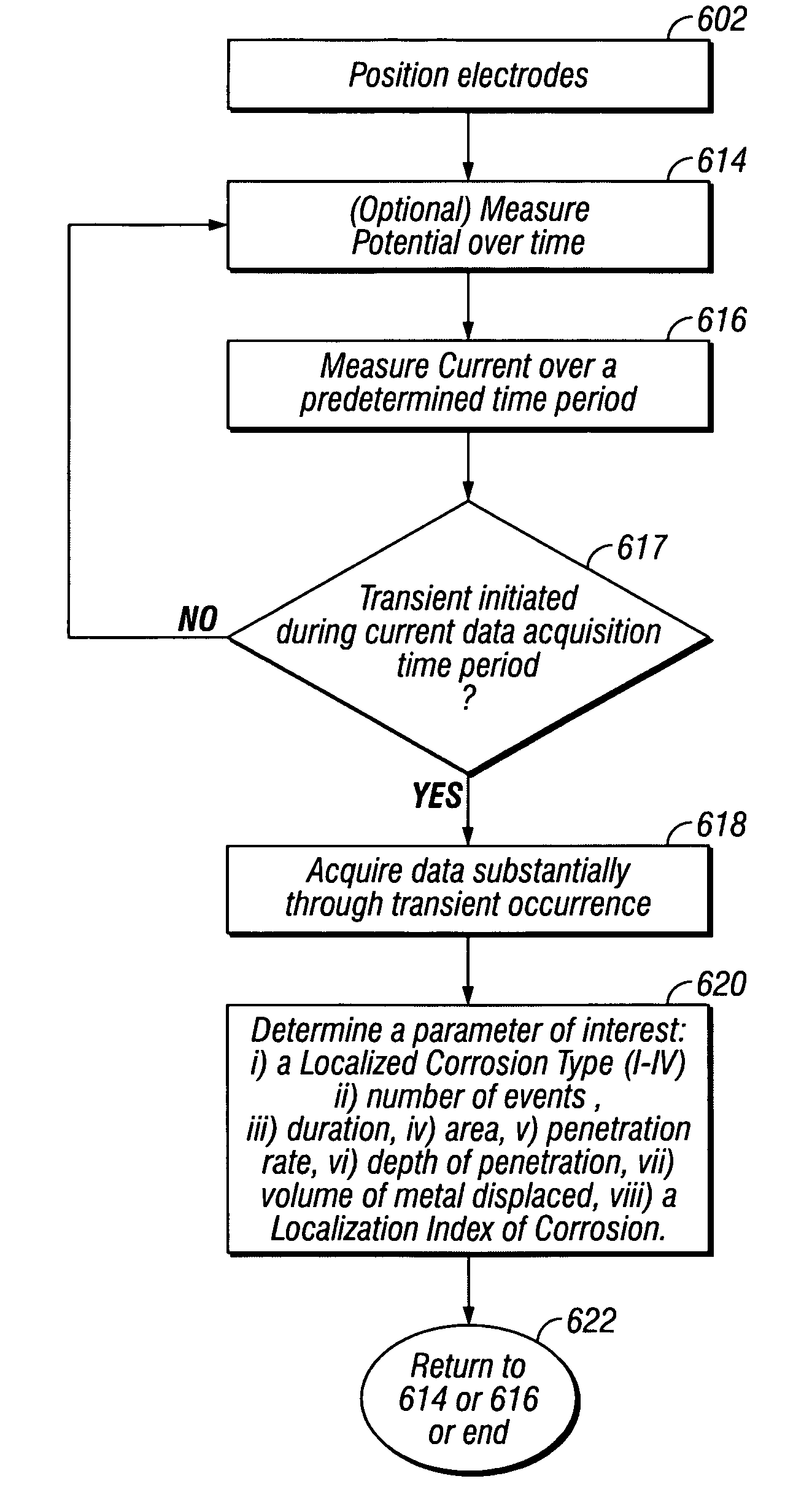

The invention provides an electrochemical noise method, apparatus and system for estimating parameters of interest related to corrosion rates of an electrically conductive article, the method comprising: placing a working electrode, a reference electrode, and a counter electrode in an environment of interest; measuring potential at open circuit between the working electrode and the reference electrode over time; placing the working electrode under a potentiostatic control; measuring current between the working electrode and the counter electrode for a predetermined period of time, the period of time of measurements may be extended to include a transient event; and estimating the corrosion rate.

Owner:BAKER HUGHES INC

Quantitative, real time measurements of localized corrosion events

InactiveUS20060144719A1Weather/light/corrosion resistanceVolume/mass flow measurementElectrical resistance and conductanceAuxiliary electrode

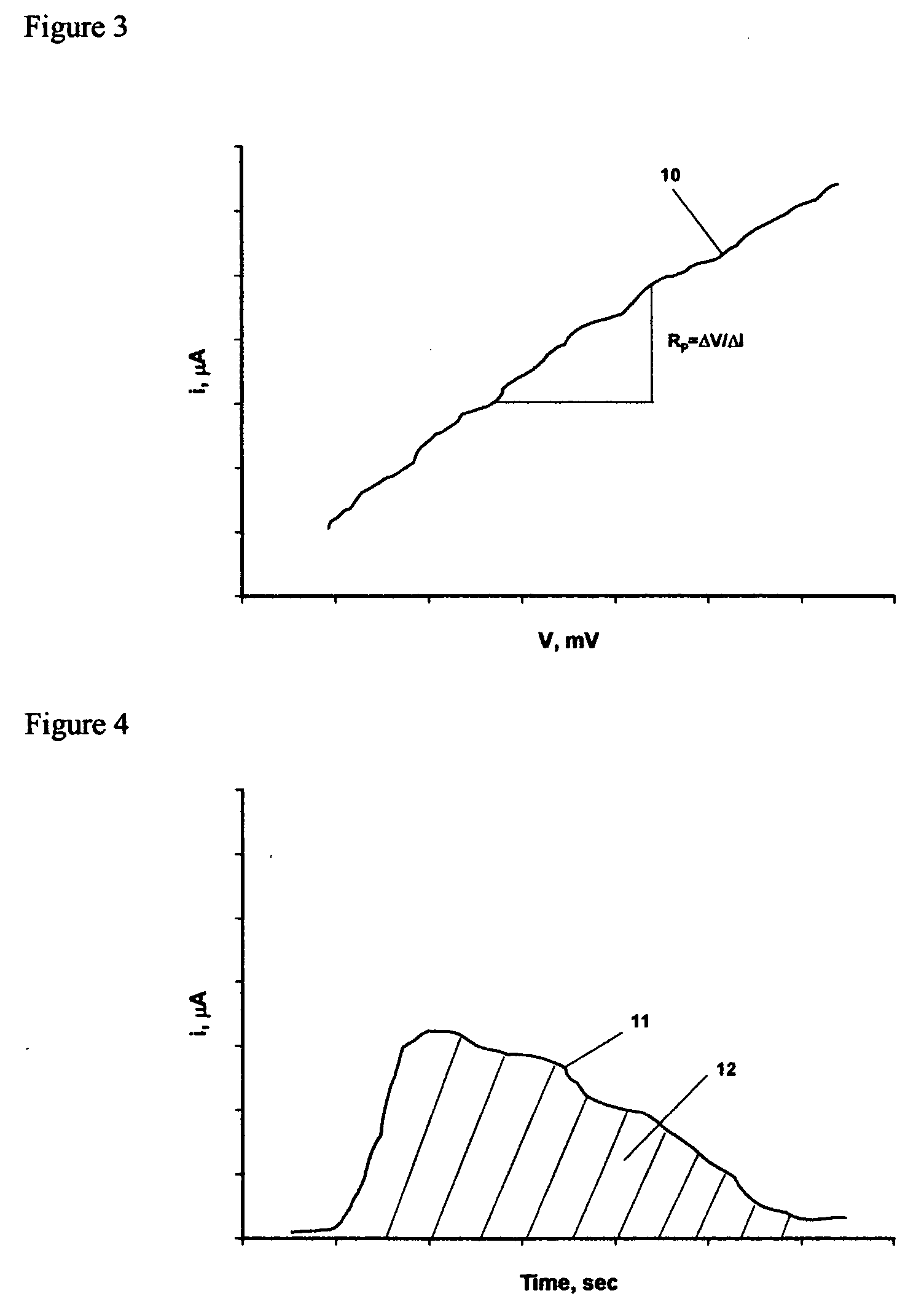

An electrochemical noise method, apparatus and system calculates parameters of interest related to corrosion rates of an electrically conductive article. The method involves placing a test electrode, a reference electrode, and an auxiliary electrode in an environment of interest; placing the test electrode under potentiostatic control regime for a potential scan; measuring the relationship of current v. potential (polarization resistance, Rp) of the test electrode relative to the reference electrode during a first period; switching from potentiostatic control to the open circuit potential (OCP) of the test electrode; monitoring the OCP of the test electrode during a second period; determining ΔI from the relationship Rp=ΔV / ΔI, where ΔV is measured over a second period of time; and calculating the localized corrosion from the measured potential and current data.

Owner:BAKER HUGHES INC

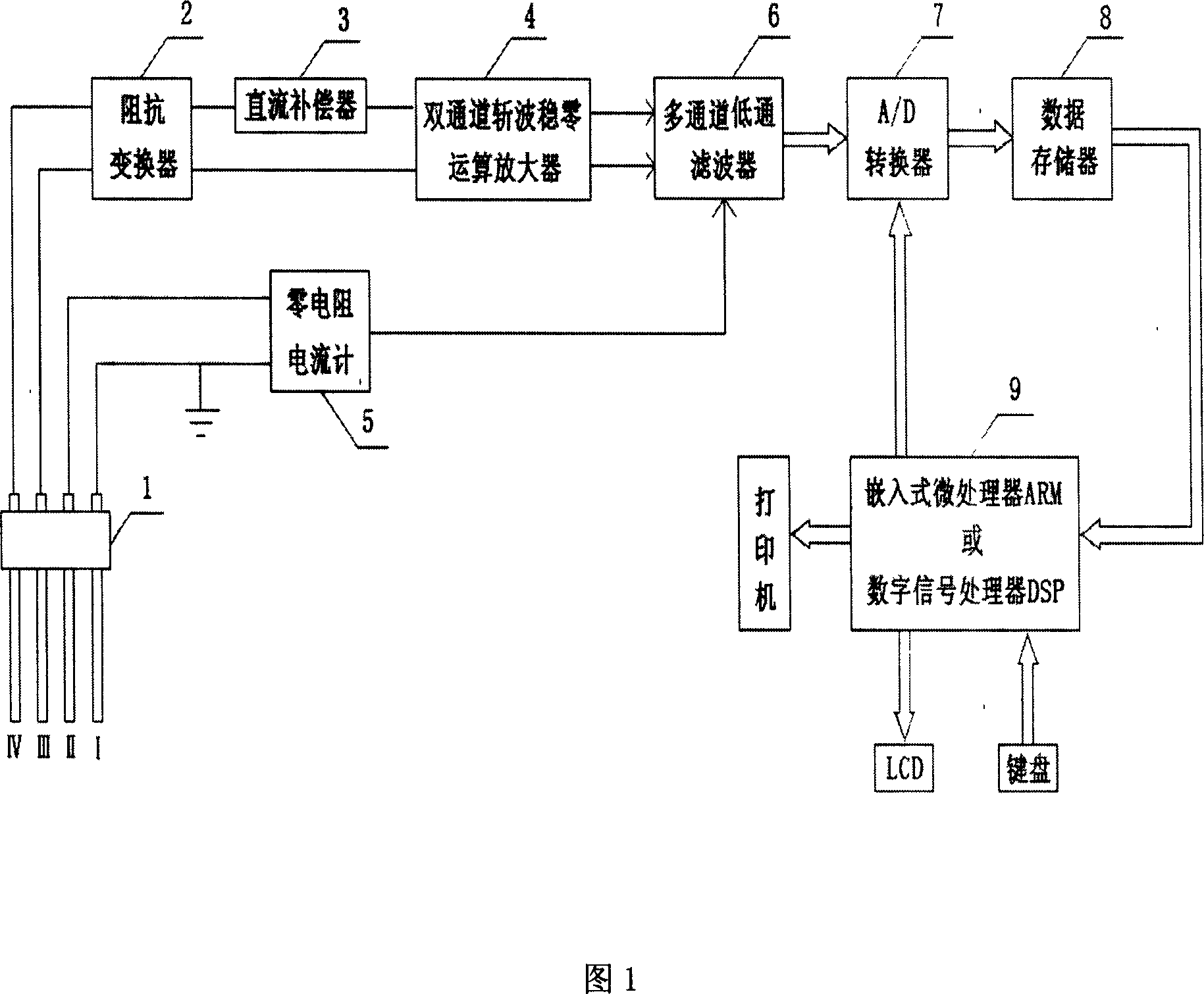

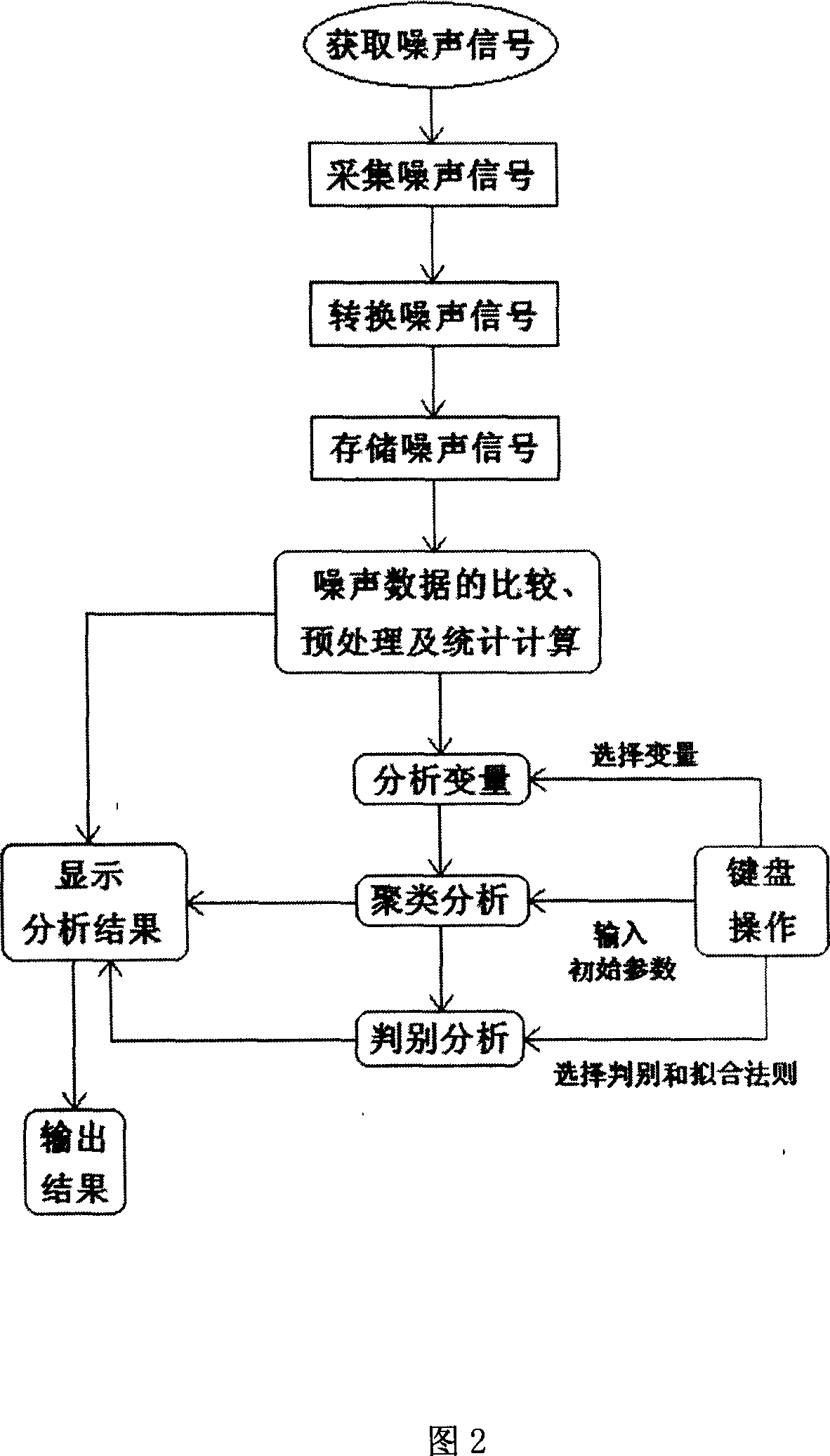

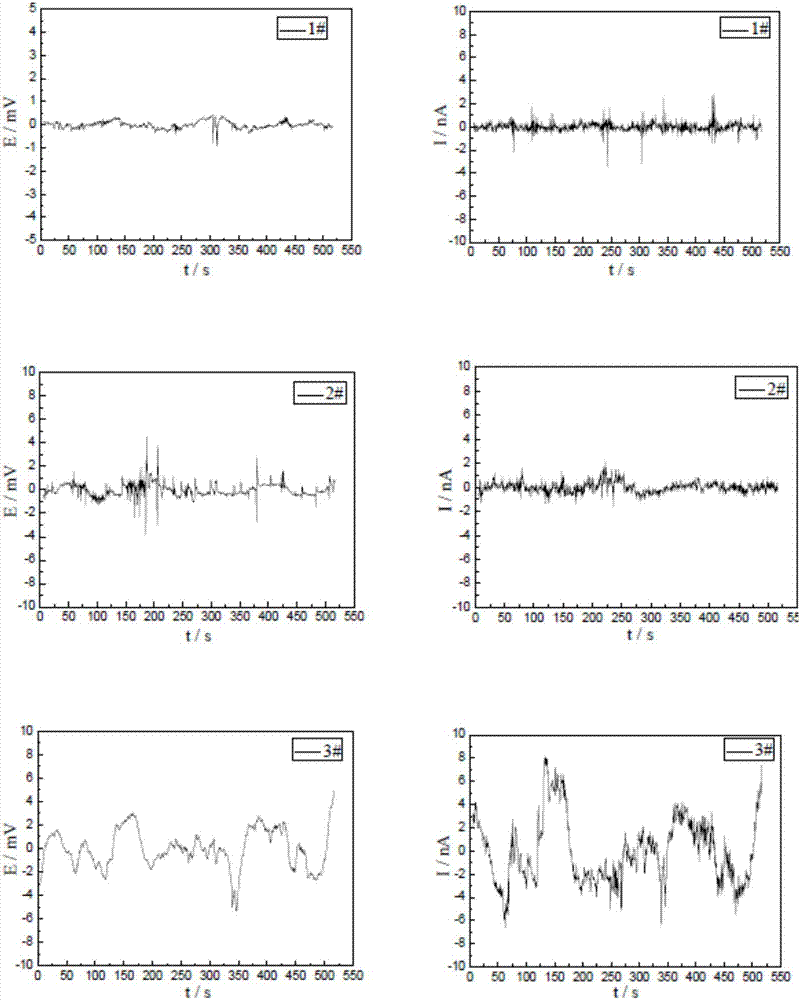

Analysis method for localized corroding based on electrochemistry noise

ActiveCN101017128AEasy to operateEfficient use ofWeather/light/corrosion resistanceSpecial data processing applicationsEngineeringSeverity/Intensity

This invention provides one local erosion analysis method and device based on electrical and chemical noise, wherein, the device adopts four electrode detector to overcome three electrode for one measurement and generates two level signals and one current signal; the stored original noise data are computing each section through software; then integrating all analysis functions to sort all parameters; according judgment equation to analyze and give out the erosion status results.

Owner:HUAZHONG UNIV OF SCI & TECH

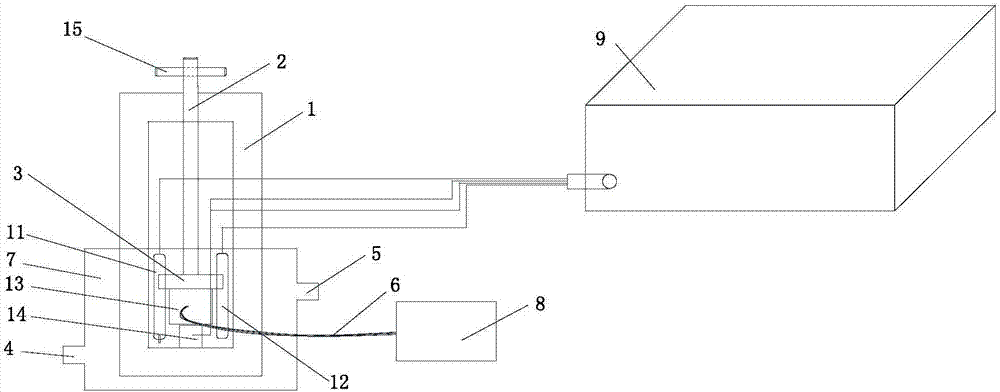

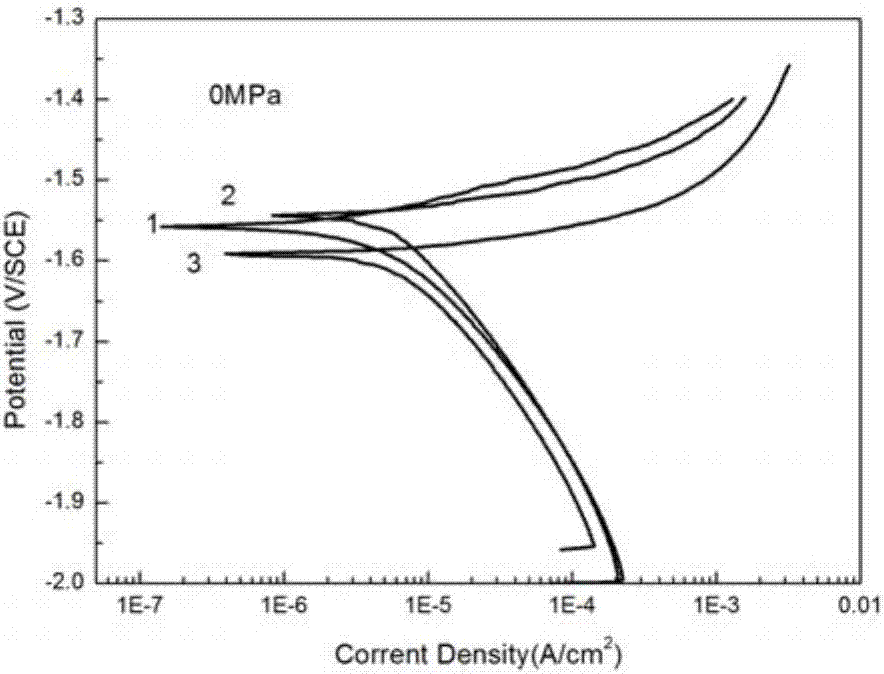

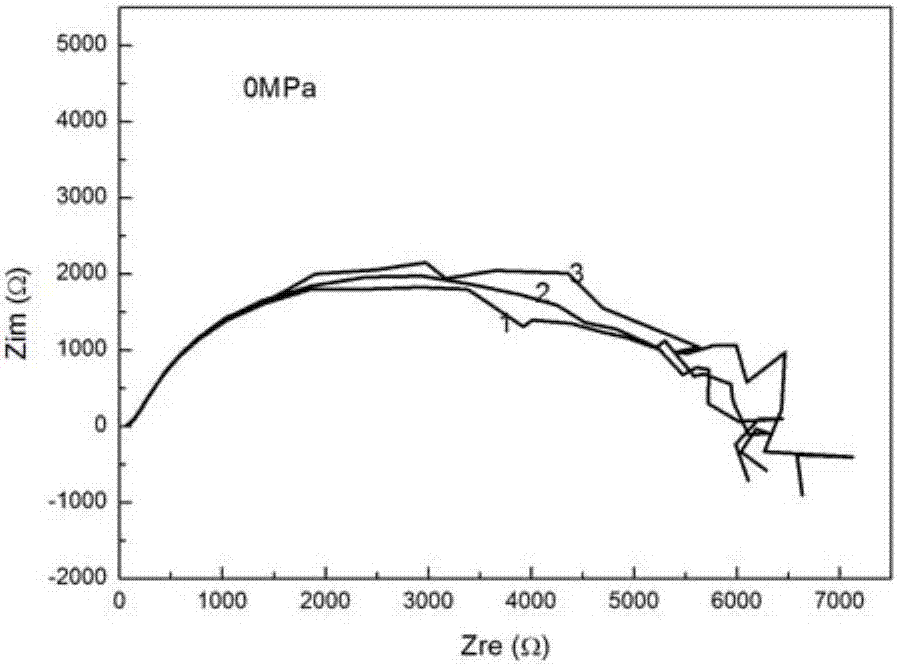

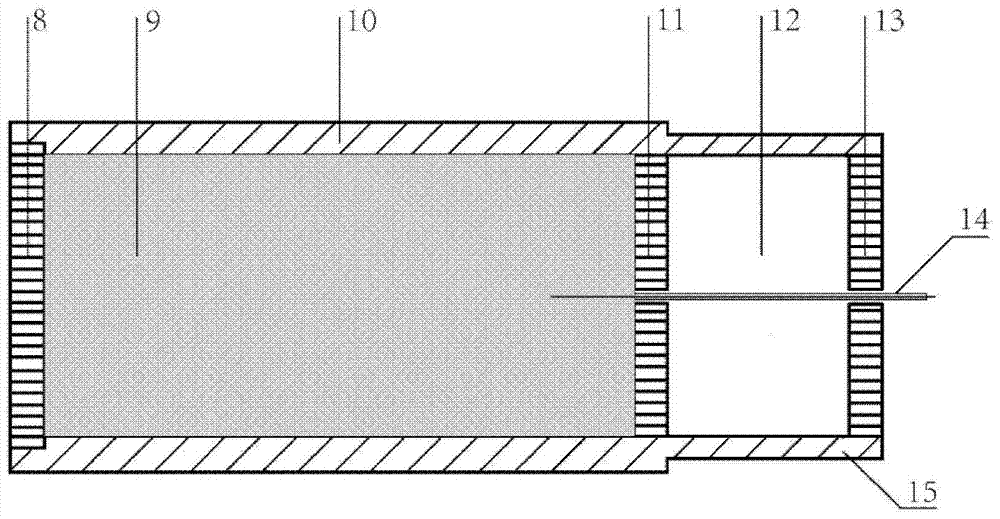

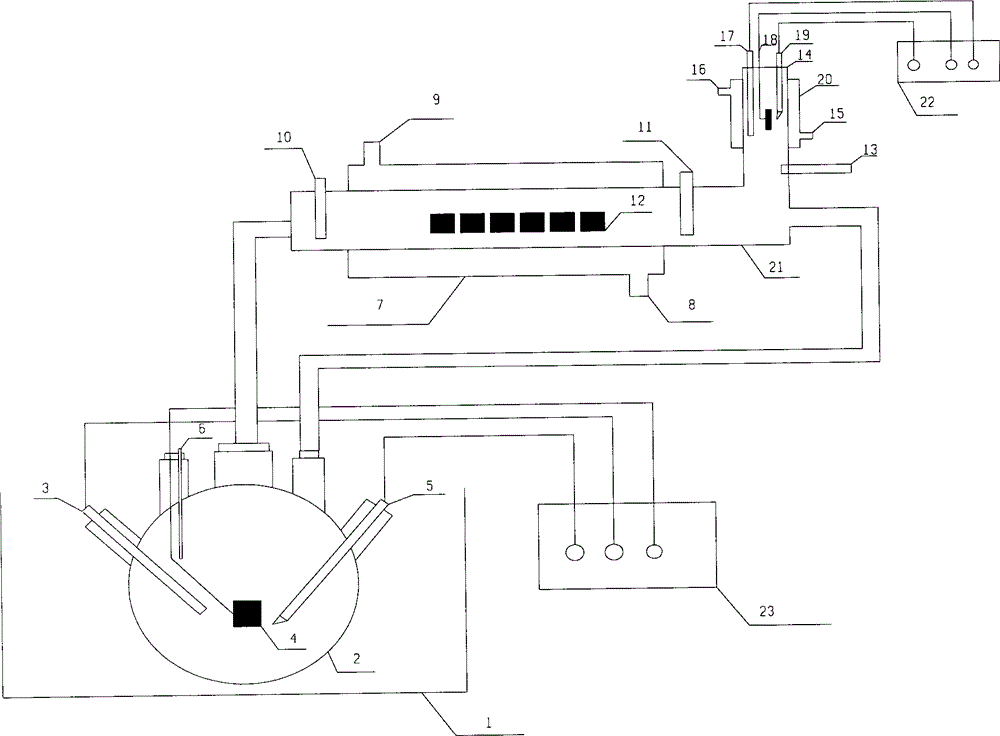

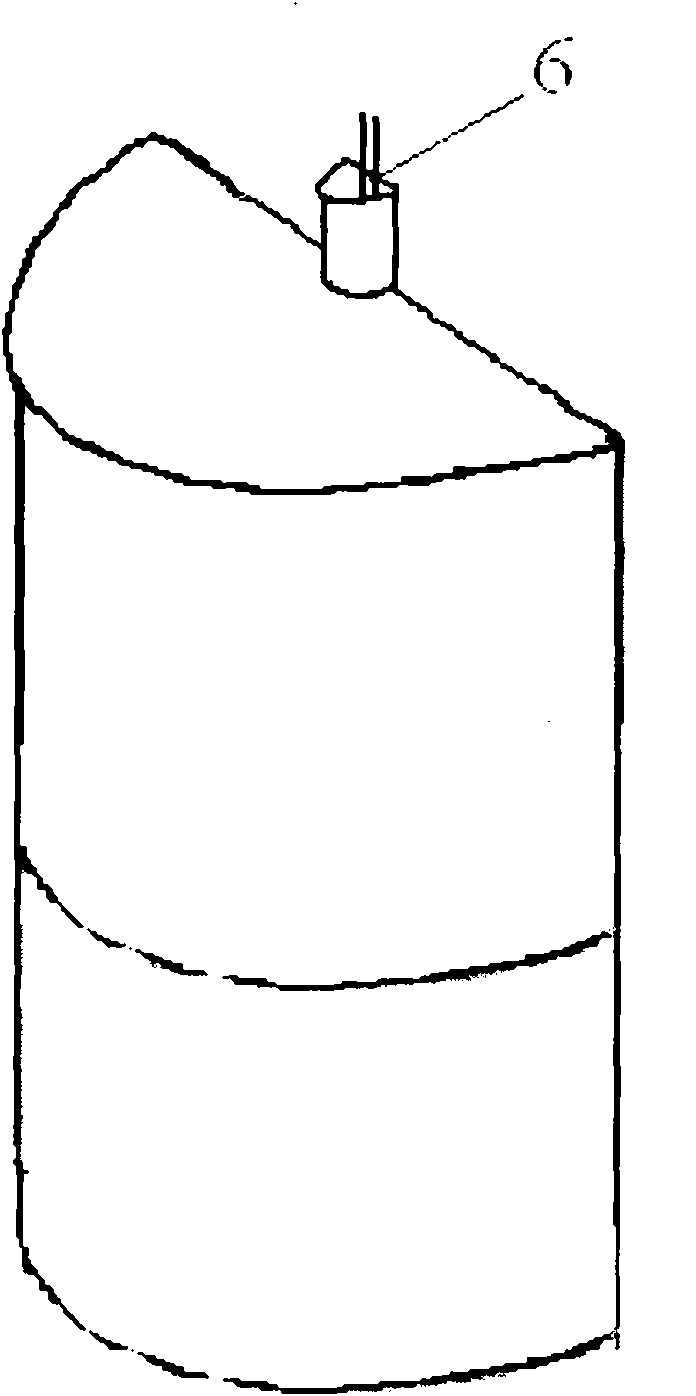

Simulation experiment device for hydrostatic stress corrosion electrochemical action of magnesium alloy and experiment method of simulation experiment device

ActiveCN106872349ASimple structureEasy to adjustWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesPeristaltic pumpTest fixture

The invention discloses a simulation experiment device for hydrostatic stress corrosion electrochemical action of a magnesium alloy and an experiment method of the simulation experiment device. The simulation experiment device comprises an electrolyte tank, a test device, a computer terminal and an electrochemical workstation, wherein the test device is placed in the electrolyte tank; electrolyte in the electrolyte tank is forced by a high-precision peristaltic pump to cyclically crawl. The simulation experiment device is simple in overall structure, and static pressure can be continuously adjusted. The experiment method is to adjust a screw rod of the test device to apply different sizes of hydrostatic stress on a magnesium alloy test sample, and then adjust the flow rate of the electrolyte through the peristaltic pump to really simulate a living body microenvironment in vitro, so as to carry out a series of electrochemical test operations on open circuit potential, a polarization curve, an alternating current impedance spectrum and electrochemical noise; test results are real and stable, and the reappearance and the reproducibility are high. The simulation experiment device and the simulation method can fully meet the requirement of the magnesium alloy for relevant research use on bearing of the hydrostatic stress in a human bone microenvironment.

Owner:SHANDONG UNIV OF SCI & TECH

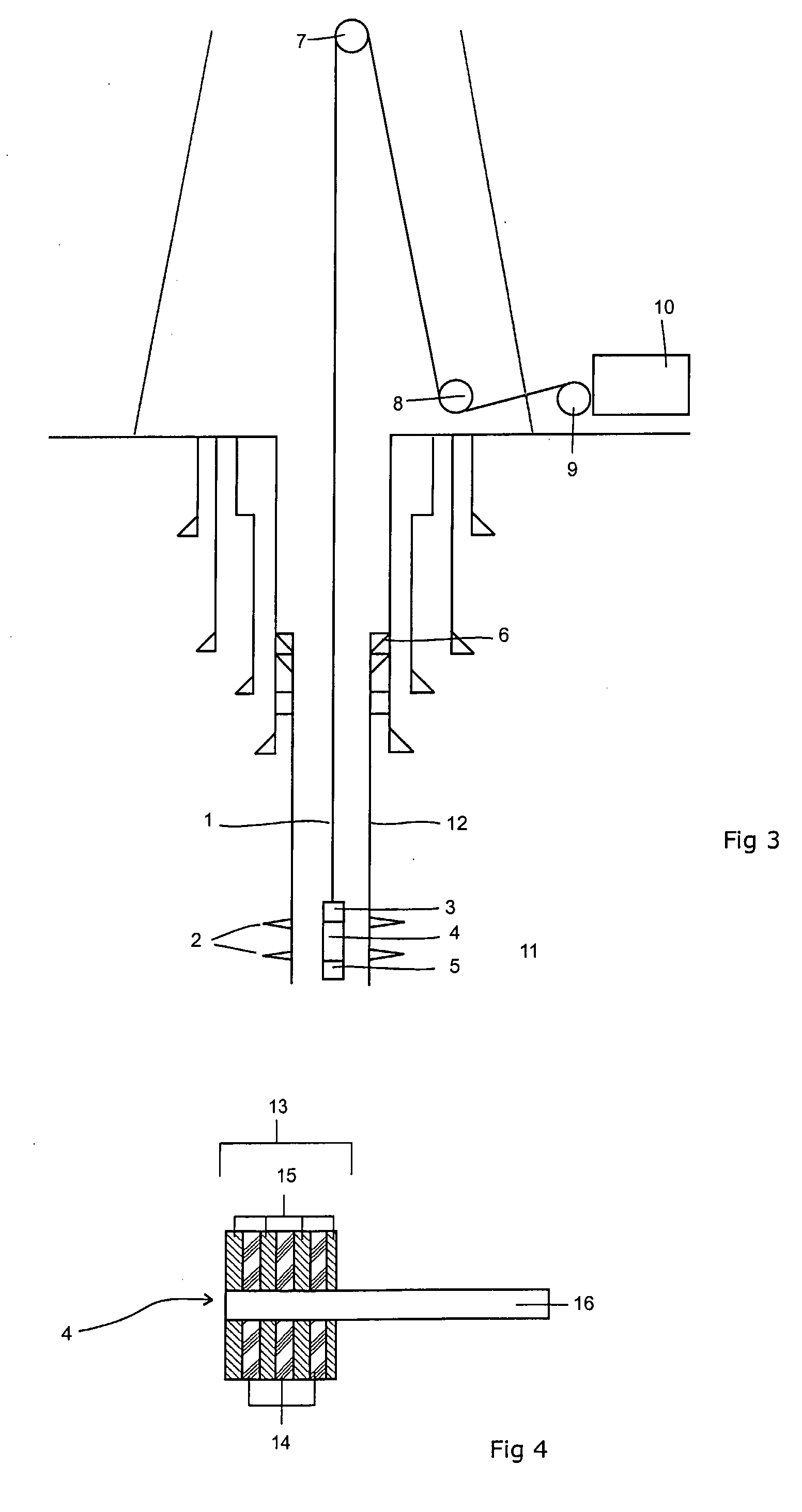

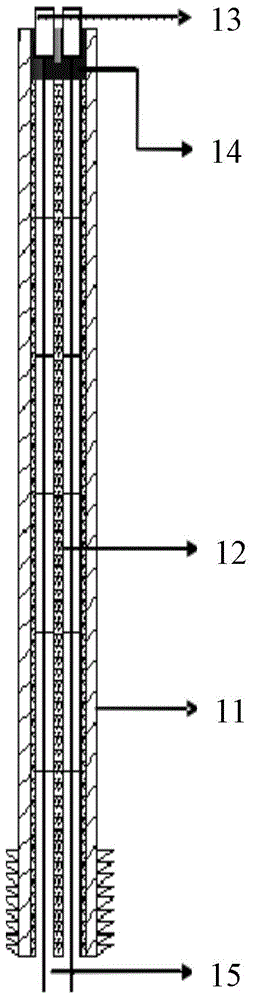

Measurement Of Corrosivity

A downhole corrosion monitor comprises a sensor head suspended on a cable, the cable being extensible so as to raise and / or lower the sensor head downhole and having a signal conductor to return data from the sensor head to the surface, the sensor head comprising a plurality of mutually insulated electrical sensors and means for detecting the voltages and / or currents existing therebetween. The electrical sensors can detect corrosion rate by one or both of linear polarisation rate and electrochemical noise and thus there will usually be at least three. The sensor head can further comprise sensors for at least one of temperature, pressure, vibrations, acceleration, flow sand rate and water cut. A corresponding method of obtaining data is also disclosed, together with a method of designing an item of downhole equipment and the item of downhole equipment thus designed.

Owner:CAPCIS

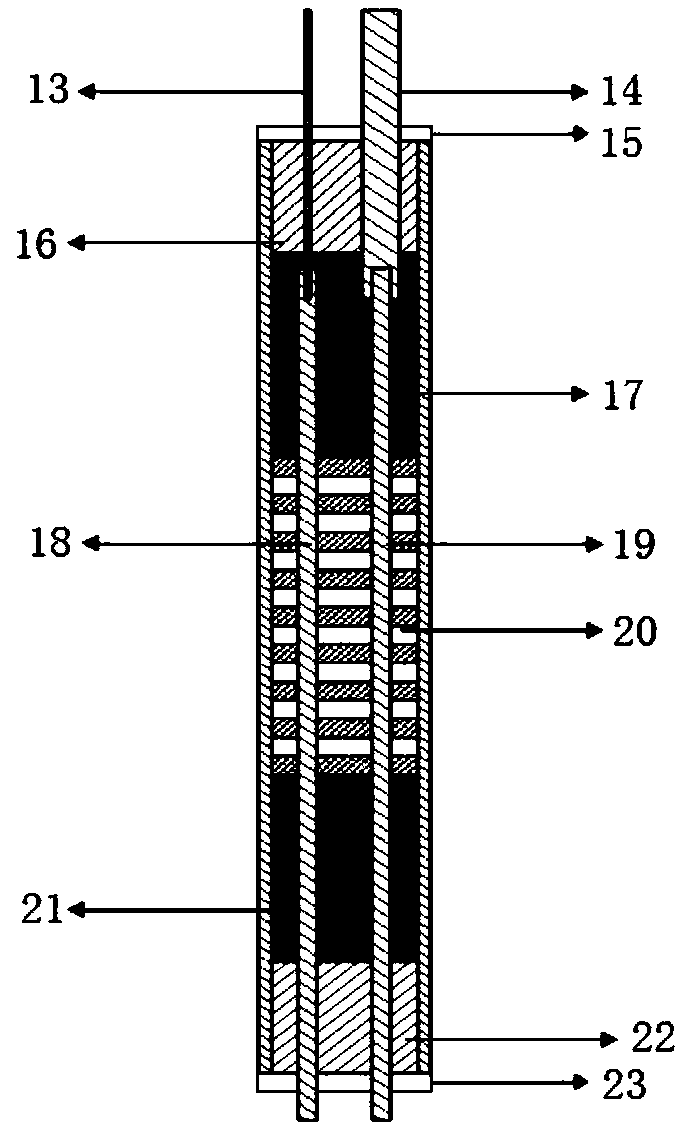

Oceanic capacitive electrode

ActiveCN104502981ASelf noise reductionSolution to short lifeElectric/magnetic detectionAcoustic wave reradiationCapacitanceLow noise

The invention discloses an oceanic capacitive electrode and is applied to ocean electric field measurement in the field of geophysical exploration. The oceanic capacitive electrode mainly comprises a capacitive electrode body made of metal materials and a protecting structure, and an insulating layer is arranged on the surface of the capacitive electrode body and is high in insulating property and corrosion resistance. The oceanic capacitive electrode has the advantages that direct contact between the capacitive electrode body and external environment media is avoided by the insulating layer, the electrode body and external electrolyte form a capacitor, and an external electric field is measured by means of capacitive coupling; in the presence of the insulating layer, chemical reaction between the electrode and ions in seawater is avoided, electrochemical noise generated during the chemical reaction is further avoided, and the electrode can achieve lower noise level; meanwhile, stabilization time for the electrode to establish balance is shortened, and continuous consumption during electrode use is avoided.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Quantitative Transient Analysis of Localized Corrosion

InactiveUS20080283418A1Weather/light/corrosion resistanceVolume/mass flow measurementTransient analysisEngineering

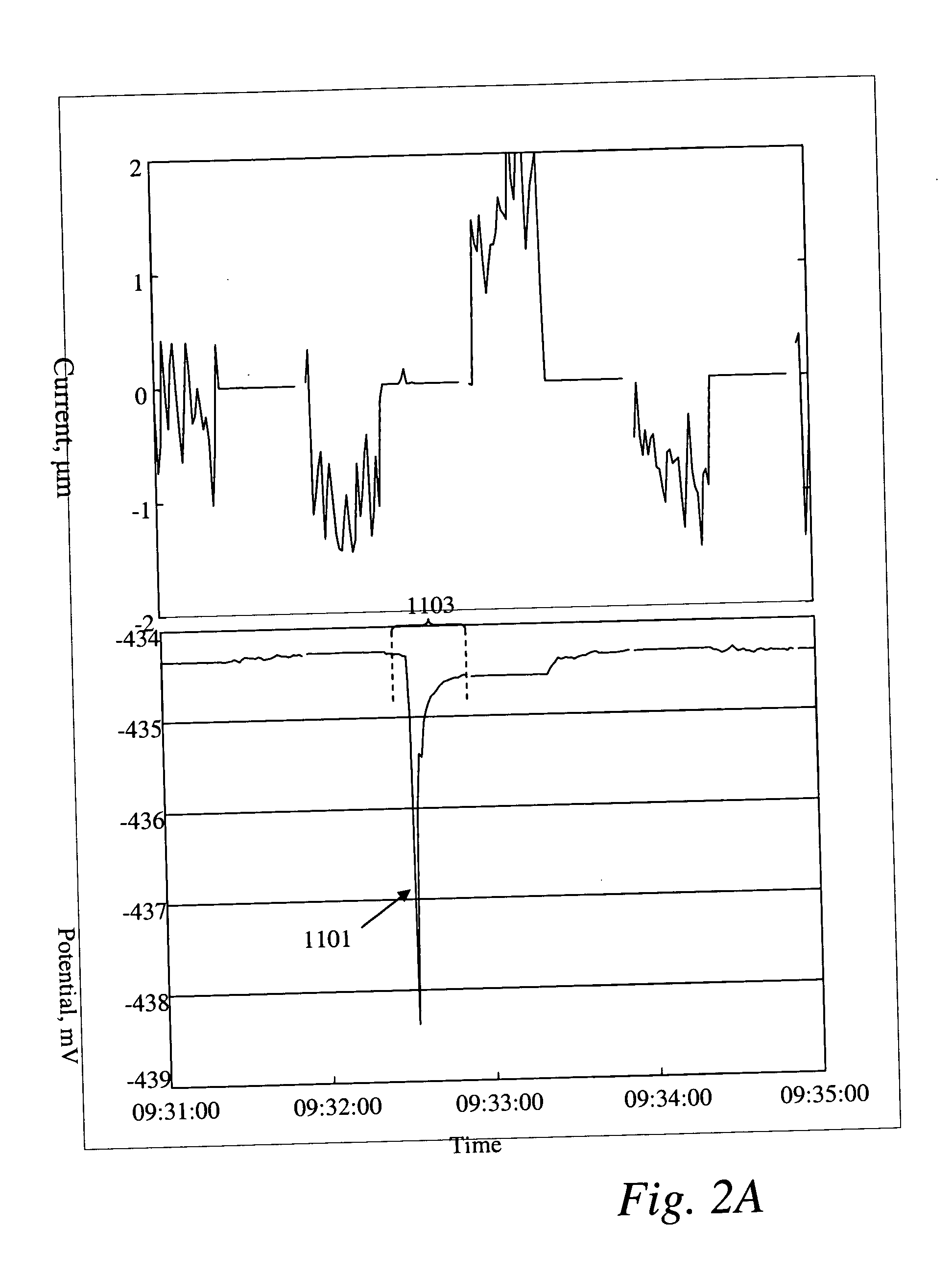

An electrochemical noise method, apparatus and system may be used to estimate and / or calculate parameters of interest related to corrosion rates of an electrically conductive article. The apparatus involves a working electrode (having substantially the same composition of the electrically conductive article), a reference electrode, and a counter electrode in an environment of interest. The working electrode is placed under potentiostatic control. A current transient between the working electrode and the counter electrode is measured. The working electrode is switched to open potential. A potential transient is measured over the duration of a localized corrosion event. The localized corrosion may then be calculated based on the measured potential transient and the current transient.

Owner:BAKER HUGHES INC

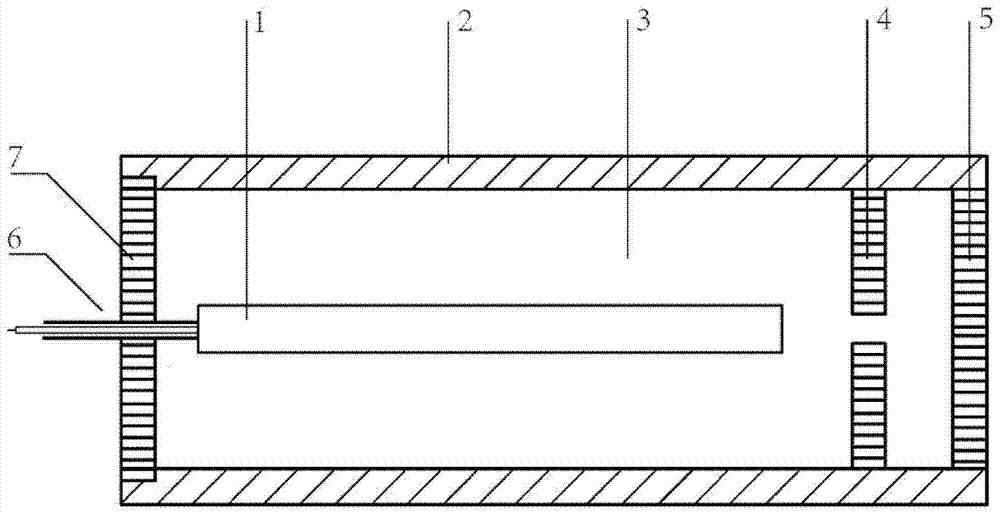

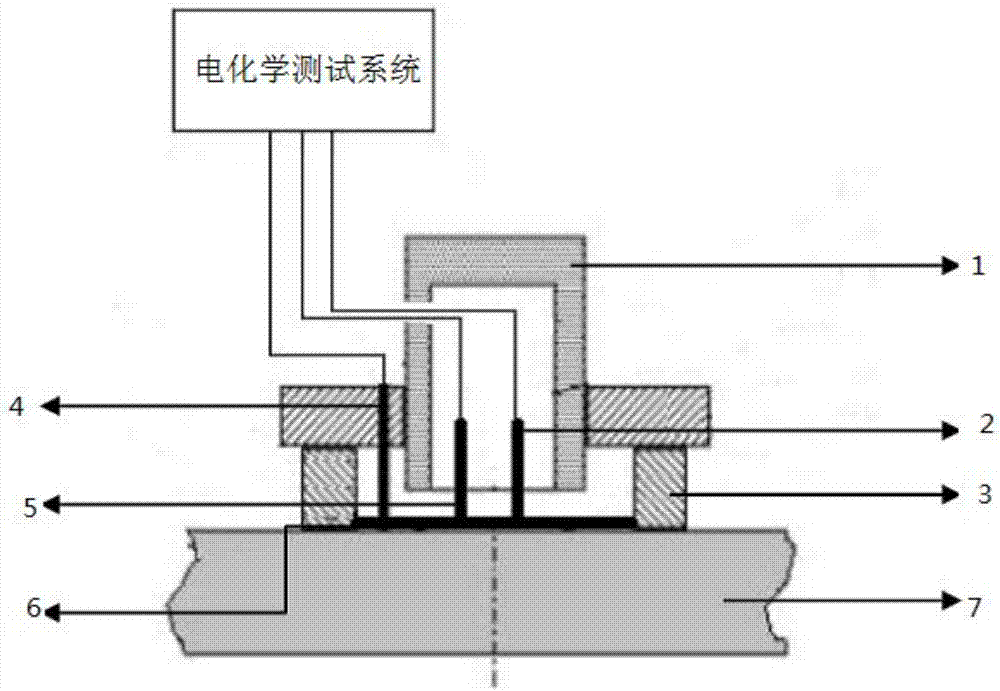

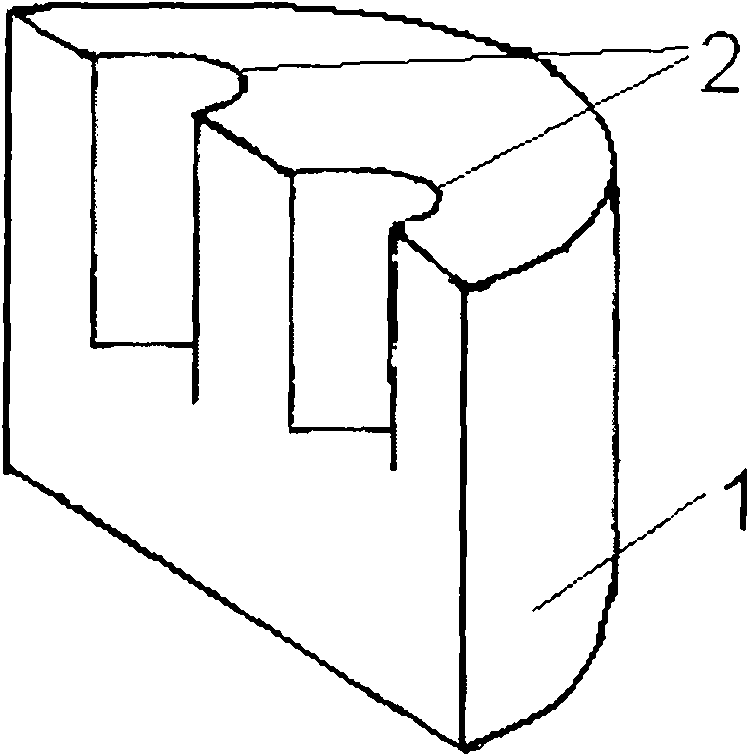

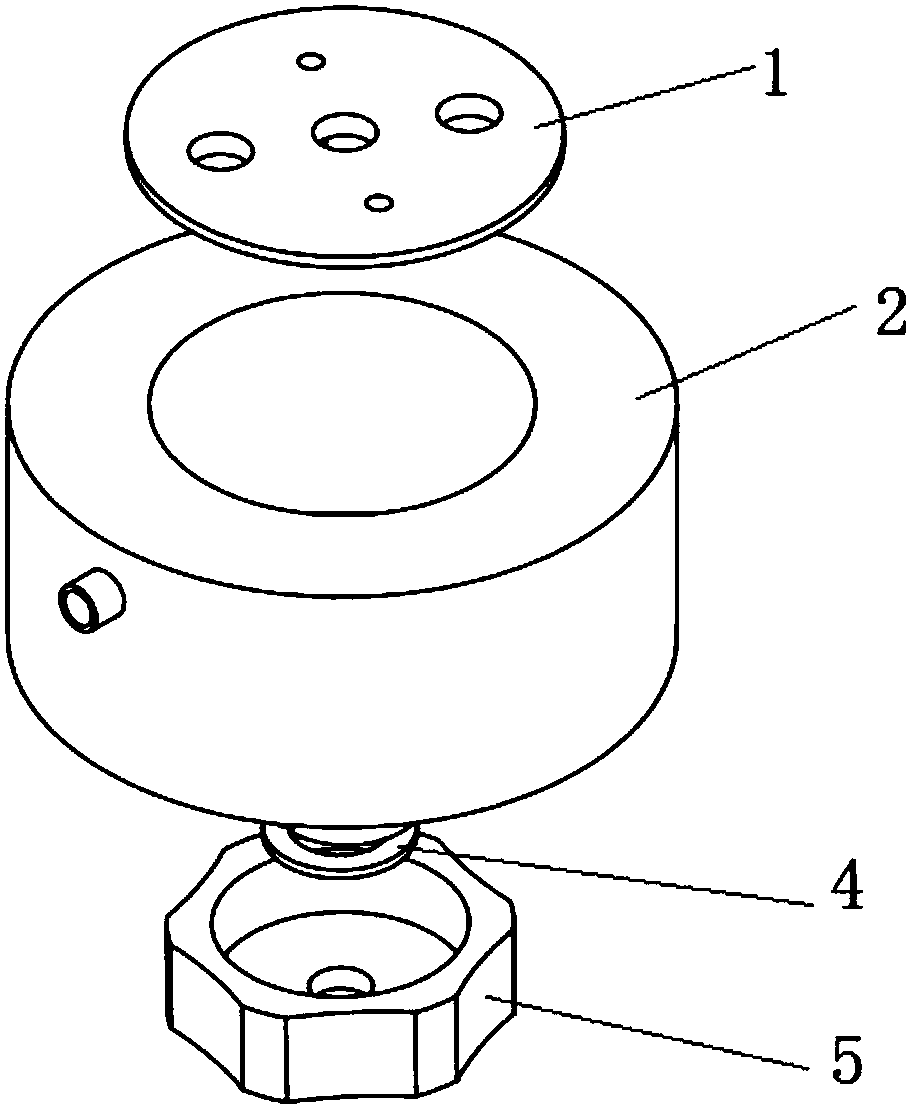

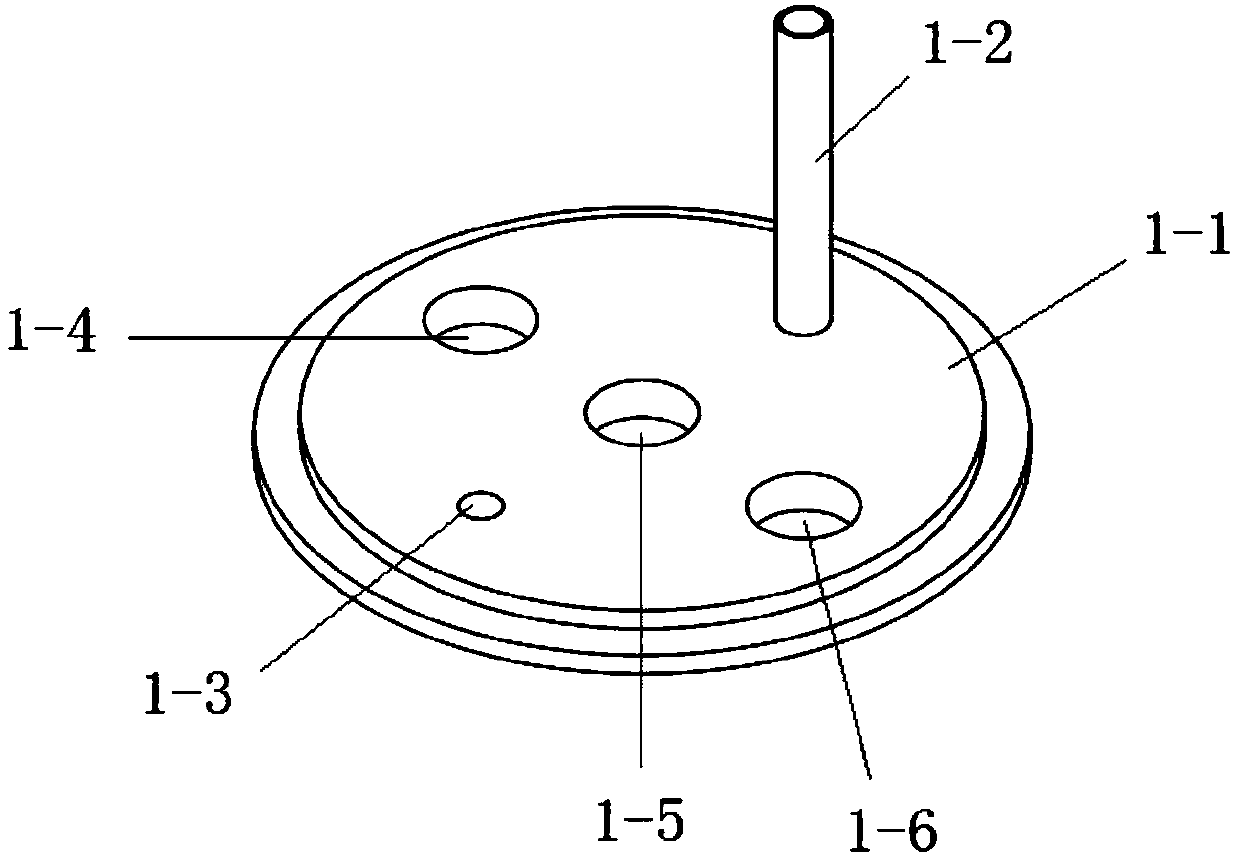

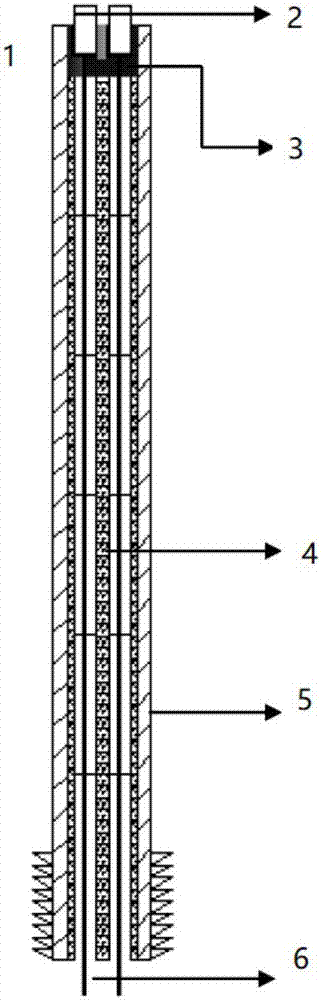

Electrochemical noise sensor for metal pipeline outer surface corrosion detection

InactiveCN107202755AEnables remote corrosion detectionNo distractionWeather/light/corrosion resistanceEngineeringFilter paper

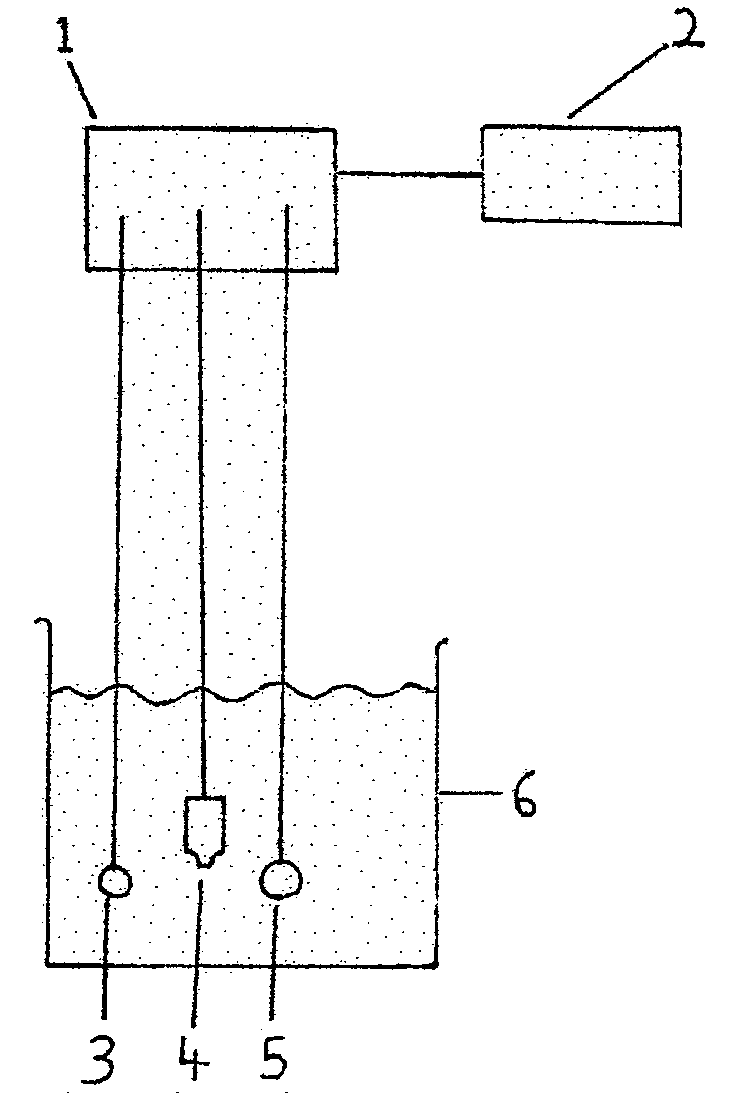

The invention relates to an electrochemical noise sensor for metal pipeline outer surface corrosion detection. The electrochemical noise sensor comprises a shell (1), a reference electrode (2), a counter electrode (5), an electric contact (4) directly contacted with the surface of a pipeline to be detected, and an adjustable support pillar (3). The reference electrode (2) and the counter electrode (5) are fixedly connected with the lower part of the shell (1); the adjustable support pillar (3) and the shell (1) are fixedly connected; the lower ends of the reference electrode (2) and the counter electrode (5) are isolated from a steel pipeline to be detected through wetting filter paper; the upper part of the support pillar (3) is connected with the shell; the distances from the reference electrode (2) and the counter electrode (5) to the metal surface to be detected is adjusted through adjusting the length of the adjustable support pillar.

Owner:TIANJIN UNIV

Distillation apparatus tower top system dew point corrosion test method

ActiveCN105277482AEasy to operateImprove securityWeather/light/corrosion resistanceDistillationSpectroscopy

The present invention discloses a distillation apparatus tower top system dew point corrosion test method. The method is as follows: 1) processing a working electrode and a corrosion coupon; 2) an etching solution is poured into a five-necked flask, a second (II) three-electrode system is fixed in three mouths of the five-necked flask, the five-necked flask is fixed in a numeric display oil bath pot; 3) other two ports of the five-necked flask are respectively connected with an inlet and an outlet of a condenser horizontal inner tube, the corrosion coupon is fixed in the condenser horizontal inner tube, a first (I)three-electrode system is fixed in the upper portion of a condenser inclined tube; and 4) the five-necked flask is heated by the numeric display oil bath pot, a first-section condenser outer tube cooling water inlet and a second-section condenser outer tube cooling water outer are opened, the cooling water flow is adjusted, then acidic aqueous electrochemical tests, corrosion weight loss experiments under dew formation environment and electrochemical test experiments under dew formation environment can be performed. The electrochemical test and corrosion weight loss dew point corrosion test are can be performed by the method, tests of electrochemical impedance spectroscopy, electrochemical noise and the like under dew point environment can be realized, and data reliability can be verified by weight loss experiments.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

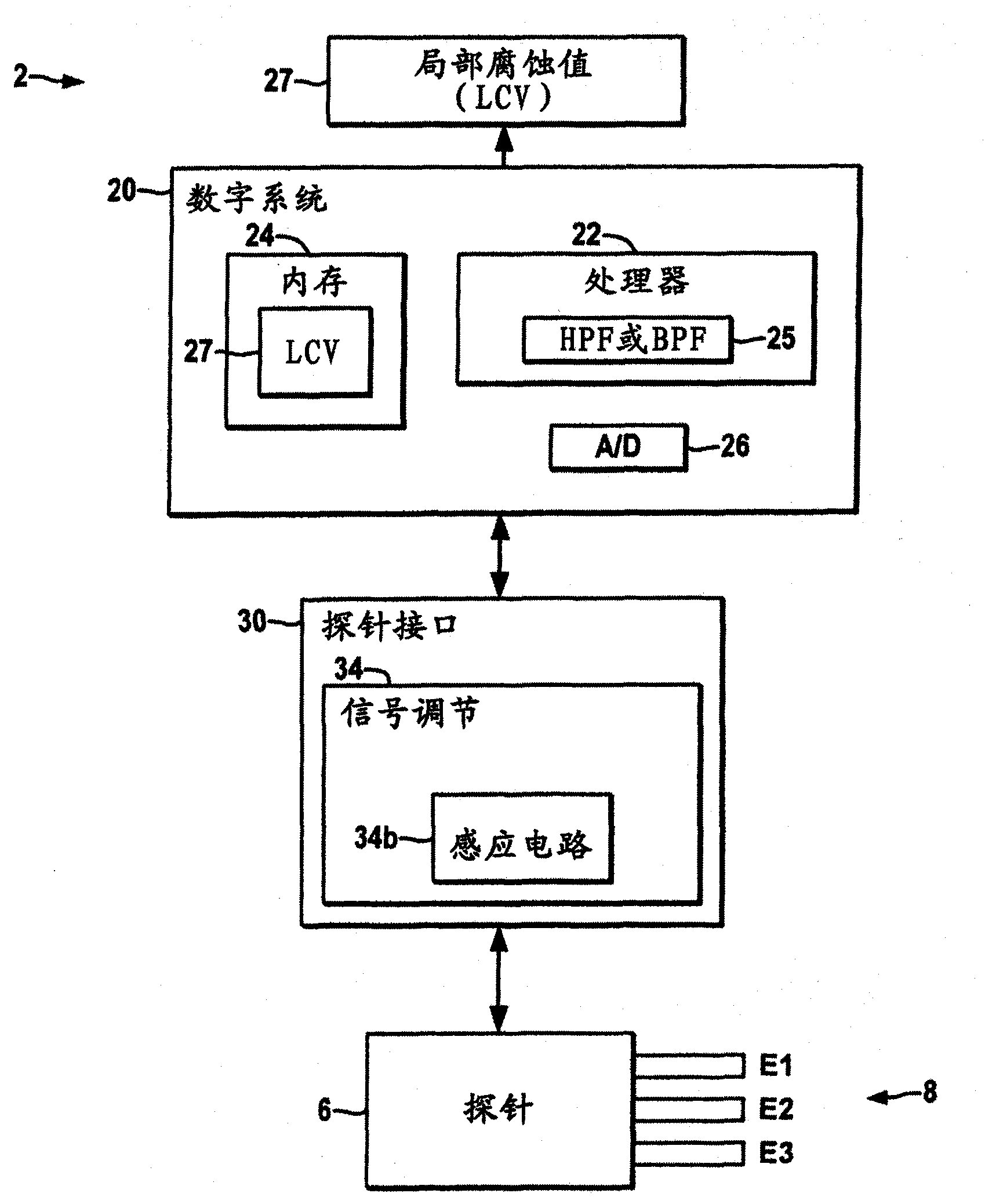

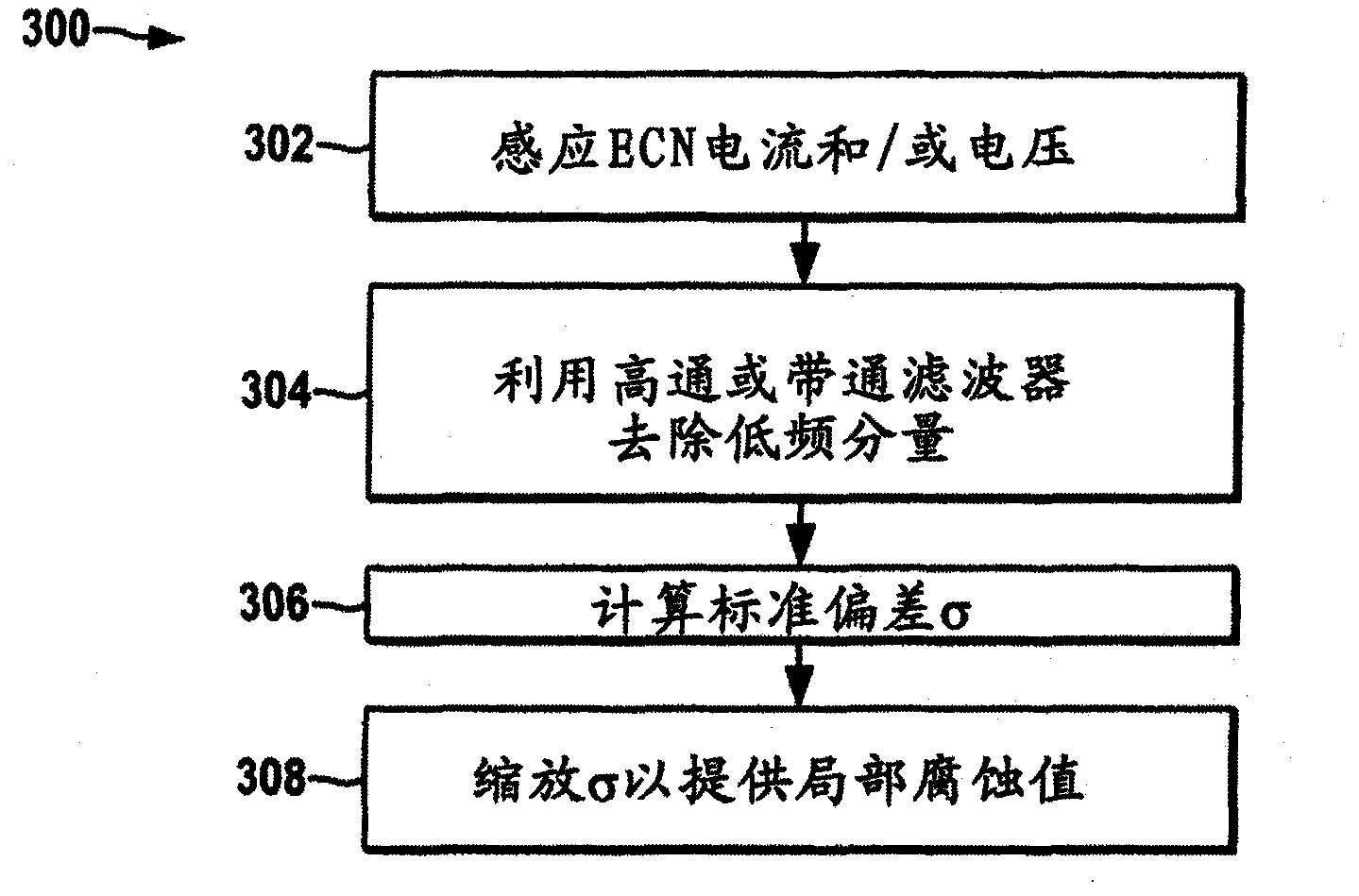

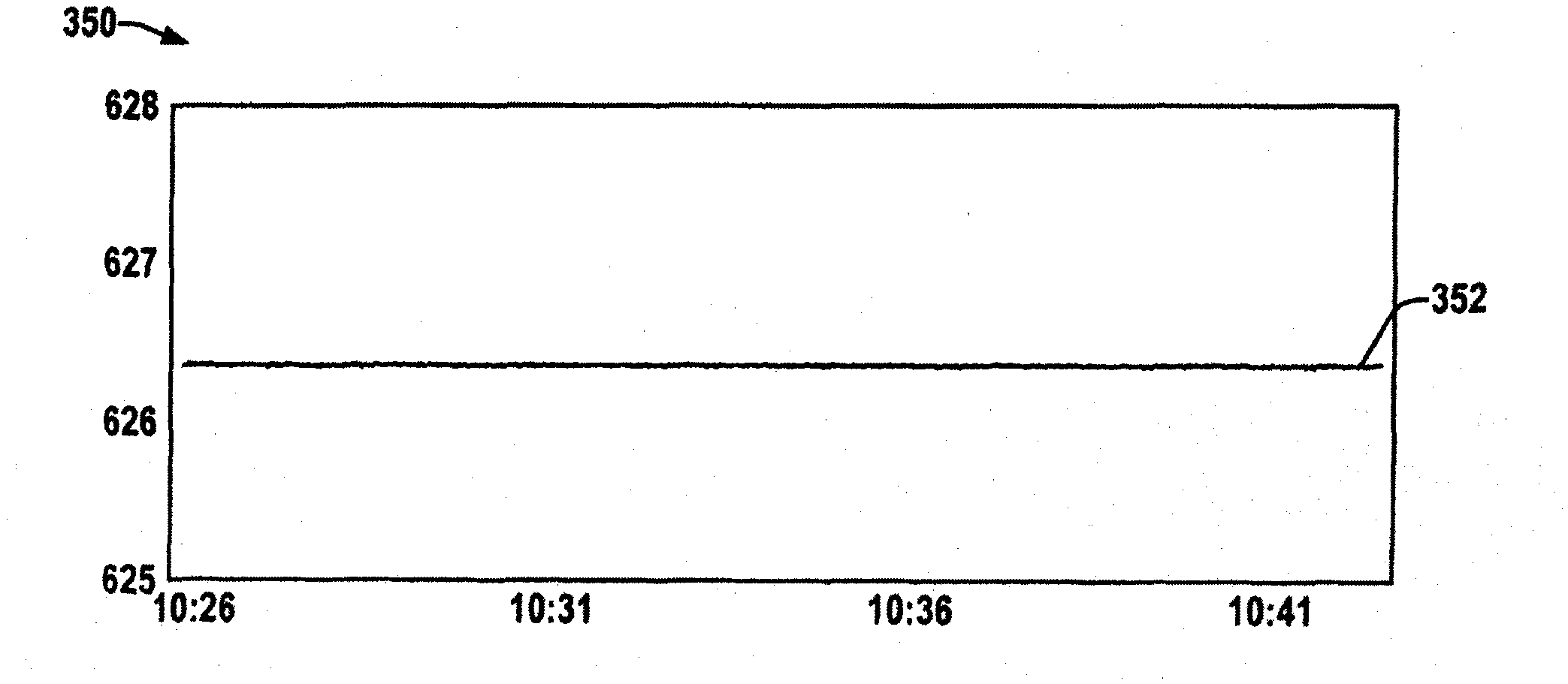

Electrochemical noise as a localized corrosion indicator

InactiveCN102132162AWeather/light/corrosion resistanceResistance/reactance/impedenceLow-pass filterBand-pass filter

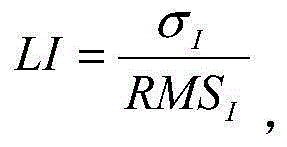

Systems and methods are presented for a method for measuring or monitoring localized corrosion in which an electrochemical noise (ECN) signal is sensed and filtered by a high-pass or band-pass filter to remove low frequency components not related to localized corrosion and a standard deviation of the filtered signal is computed and scaled to provide a localized corrosion value.

Owner:PEPPERL FUCHS GMBH

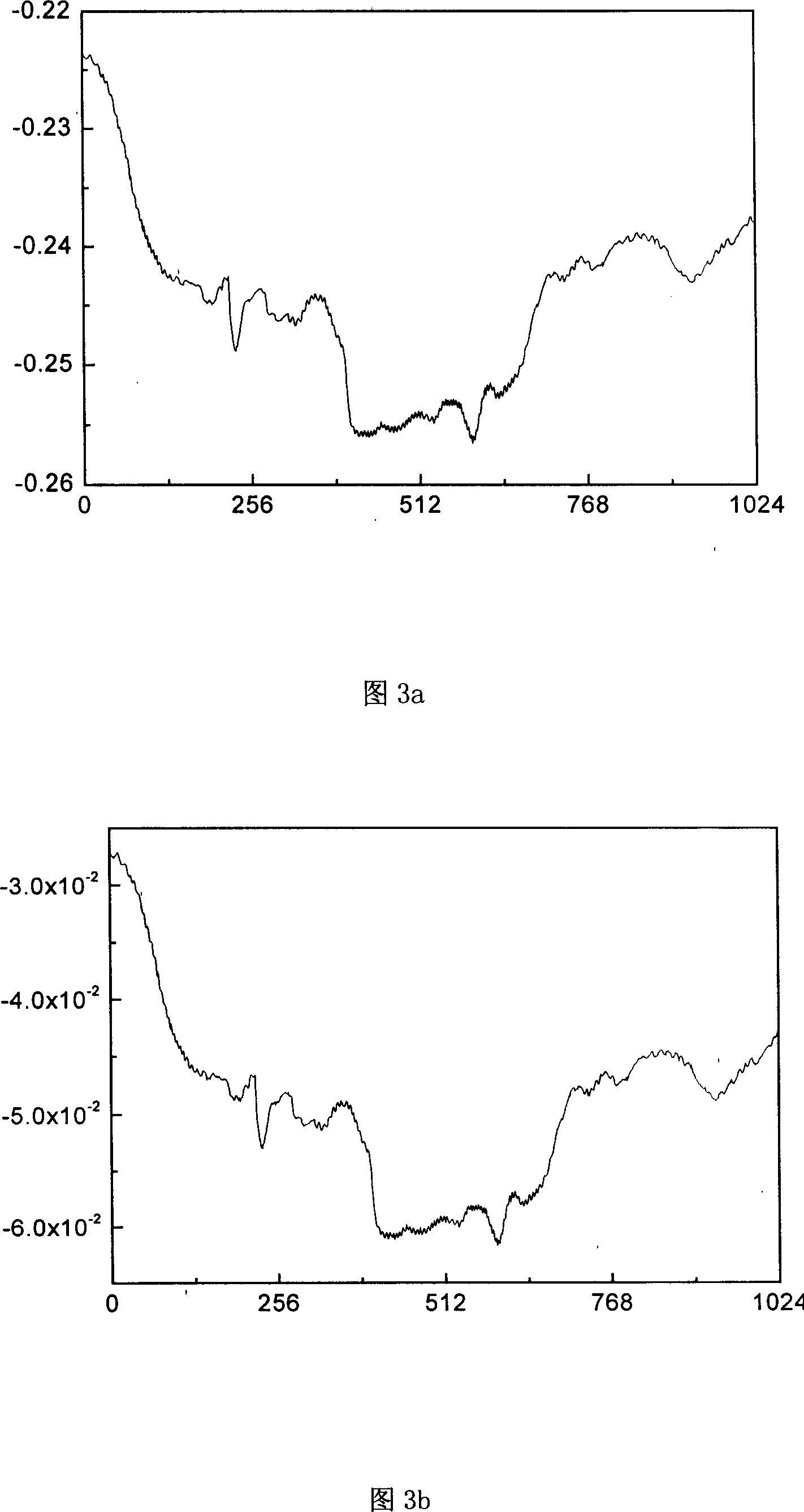

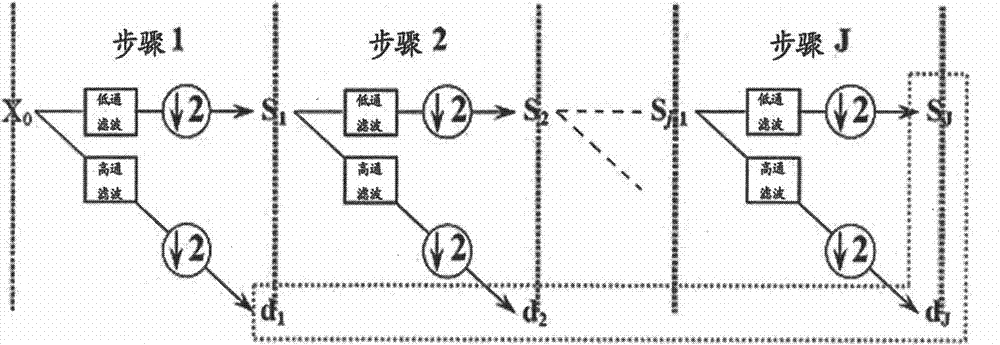

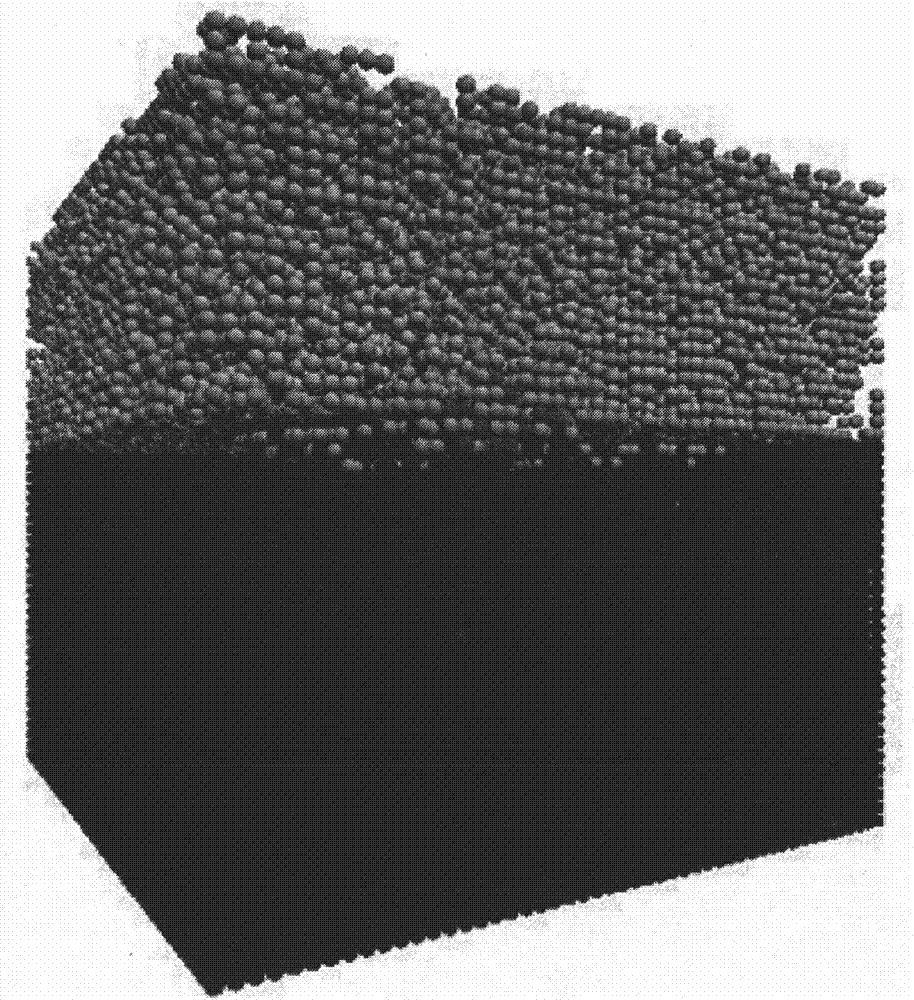

Real-time quantitative prediction method of three-dimensional cellular automaton of reinforced concrete steel bar pitting corrosion

The invention provides a real-time quantitative prediction method of a three-dimensional cellular automaton of reinforced concrete steel bar pitting corrosion. The method comprises the steps that a wavelet energy spectrum algorithm of local pitting corrosion electrochemical noise is established by a rapid wavelet transform method; a three-dimensional cellular automaton model of local pitting corrosion is established based on an elementary reaction of local steel bar pitting corrosion; and the quantitative prediction method of the three-dimensional cellular automaton based on real-time electrochemical noise monitoring information is established by taking a wavelet energy ratio of the electrochemical noise in different scales as a driving force. The established prediction method adopts local corrosion electrochemical noise intrinsic information which can be monitored directly as the driving force of the three-dimensional cellular automaton, so that the corrosion action capacity of an erosion environment and a metal system can be reflected directly and accurately; and in addition, the in-situ, on-line and real-time monitoring information can timely correct a prediction model, so that the prediction accuracy is ensured.

Owner:HARBIN INST OF TECH

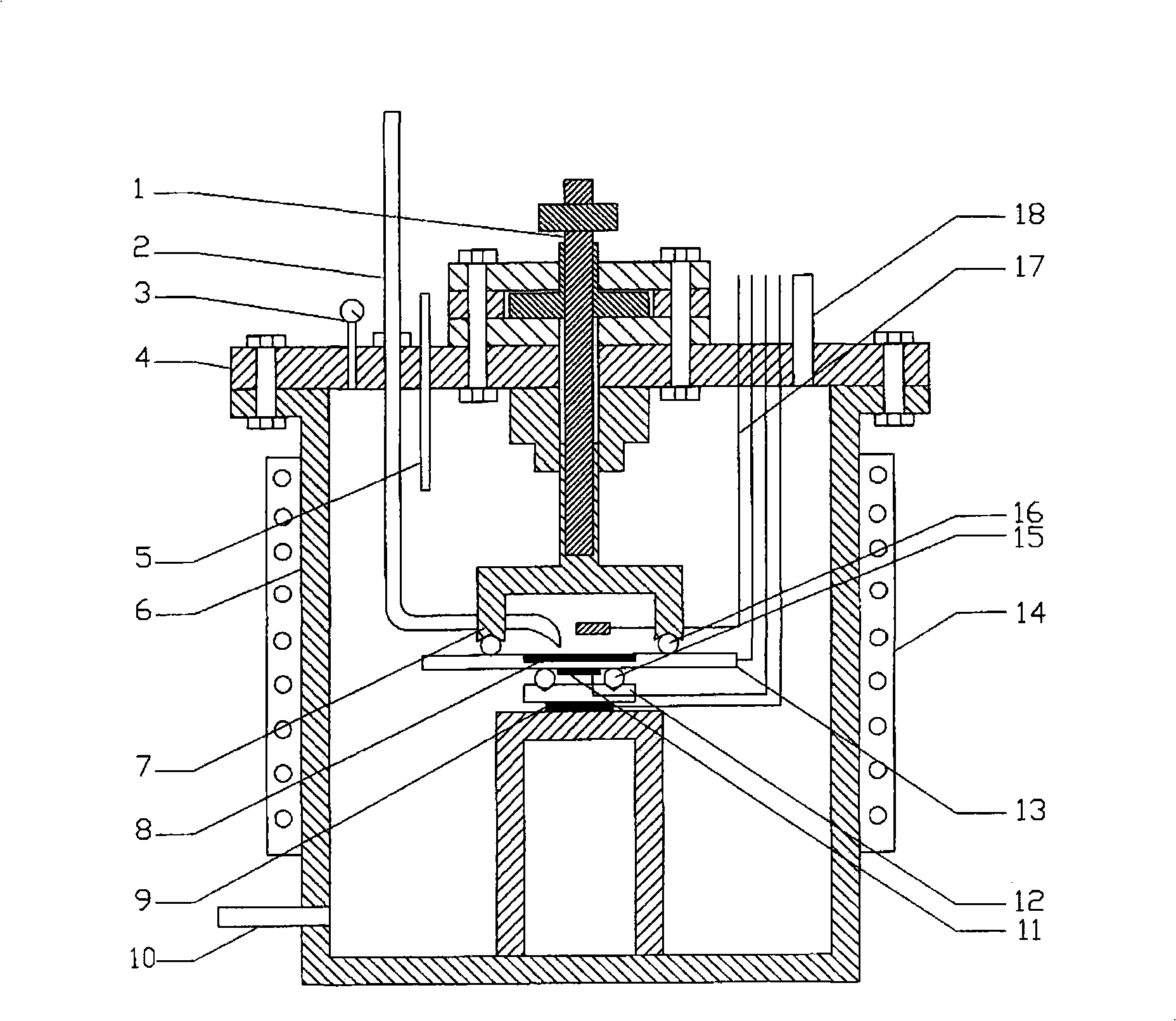

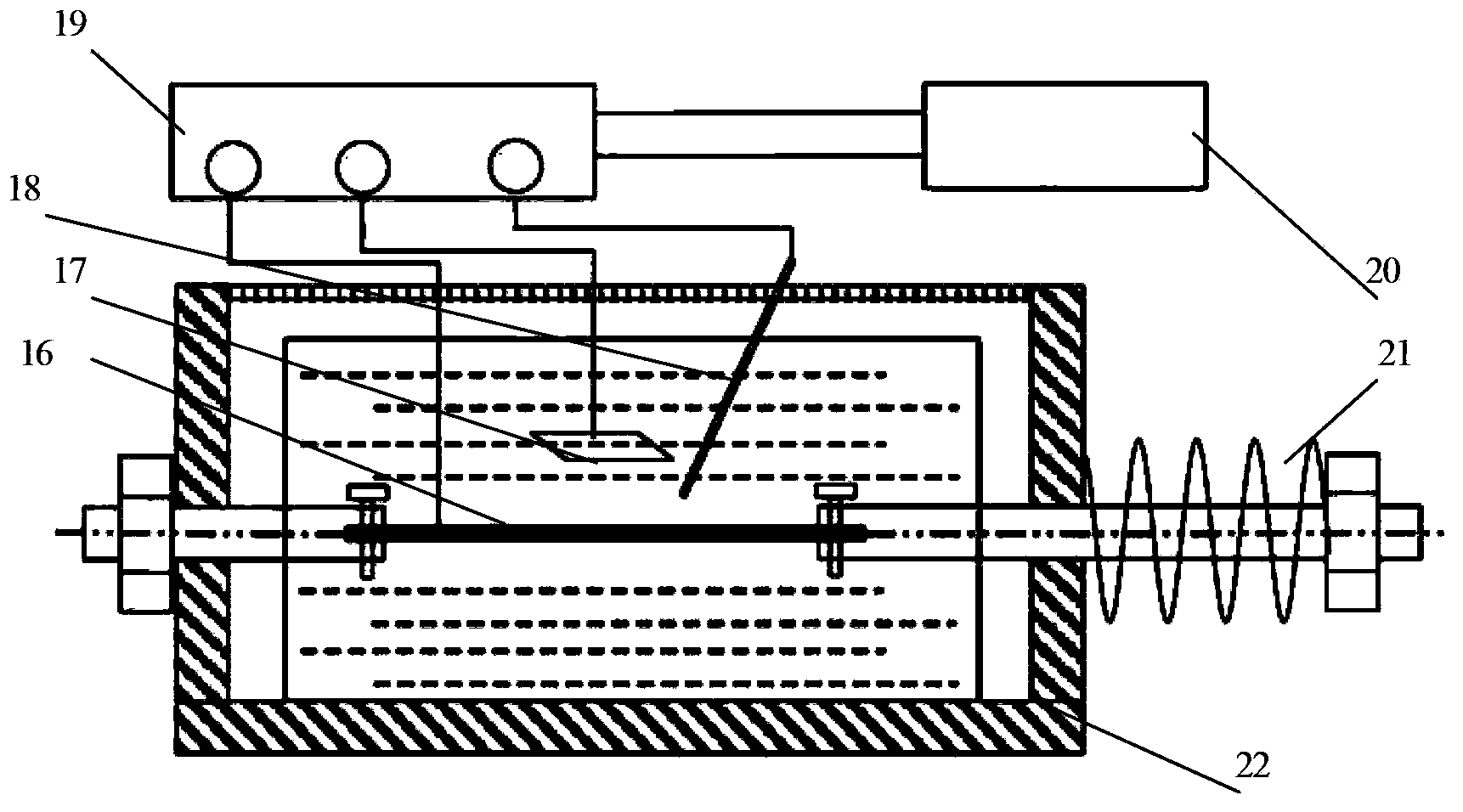

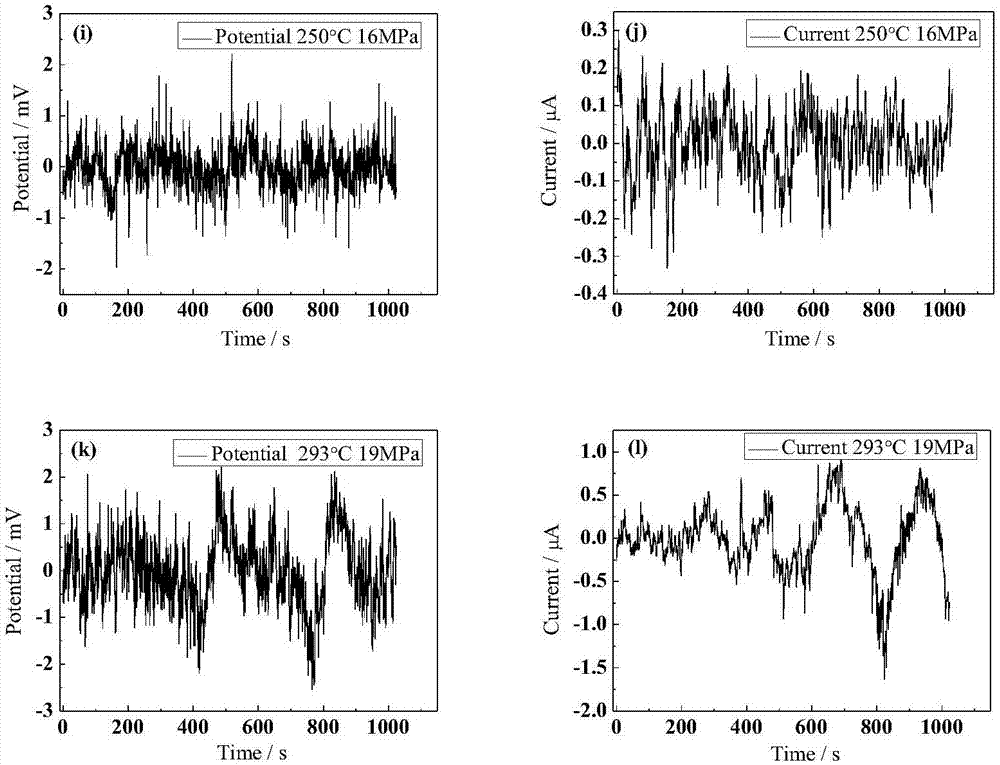

Device for measuring corrosion products film dynamic performance

InactiveCN101285746ASolve the problem of in-situ measurement of mechanical propertiesStrength propertiesHigh pressureMechanical property

The invention provides a device using the electrochemical noise method to measure mechanical property of a corrosion product film in situ, belonging to the corrosion product film measurement field. The device simulates corrosion of a sample in high-temperature high-pressure CO2 environment through a four-point bending loading and load mechanism and a high temperature high pressure autoclave, and records deformation and received load of the sample when a signal changes suddenly through an electrochemical noise signal of the corrosion product film under an external force, which is generated when an electrode system measures the sample, thereby realizing in situ measurement of the mechanical property of a corrosion product in the high-temperature high-pressure CO2 corrosion environment, solving the problem that the measurement of the mechanical property of the corrosion product film can not be performed in the corrosion environment. The device also can obtain corresponding relations between environmental parameters and the mechanical property of the corrosion product film formed at different medium temperatures, gas pressures, periods and other environmental parameters.

Owner:UNIV OF SCI & TECH BEIJING

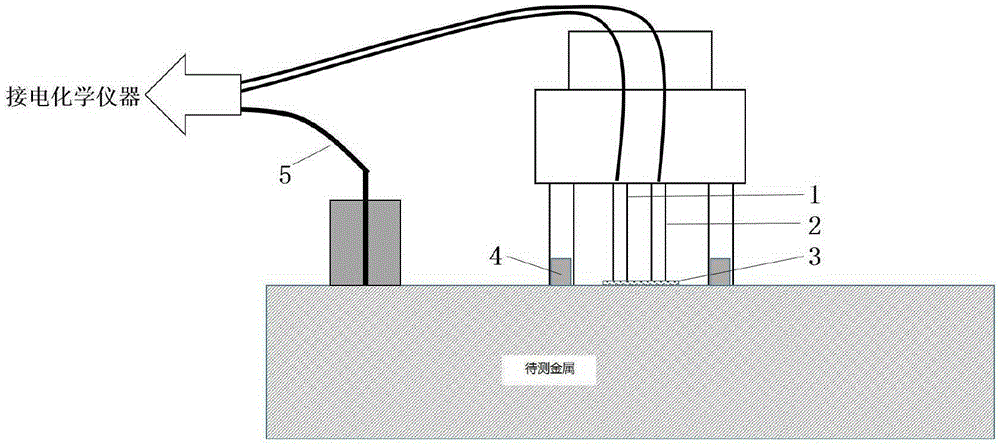

Sensor and detection method for atmosphere corrosion detection of steel member or test piece

InactiveCN105424590ARealize on-site real-time corrosion monitoring and detectionWeather/light/corrosion resistanceElectricityLarge size

The invention relates to a sensor for atmosphere corrosion detection of a steel member or a test piece. The sensor comprises a supporting column for supporting the sensor, a reference electrode (2), a counter electrode (1), a working electrode electric contact lead wire (5) which is in direct contact with the surface of the steel member or test piece to be detected, a plastic net (3) and a magnet (4), and is characterized in that the magnet (4) is fixed at the lower end of the supporting column; and the lower ends of the reference electrode (2) and the reference electrode (2) are separated from the surface of the steel member or test piece to be detected through the plastic net (3). The invention also provides a method for detecting the atmosphere corrosion detection of the steel member or the test piece by adopting the sensor. With the adoption of the sensor and the method, the on-site corrosion detection of the large-size steel member or test piece can be realized in real time; and an adopted electrochemical noise technology has no interferences on a detected system and belongs to nondestructive testing.

Owner:TIANJIN UNIV

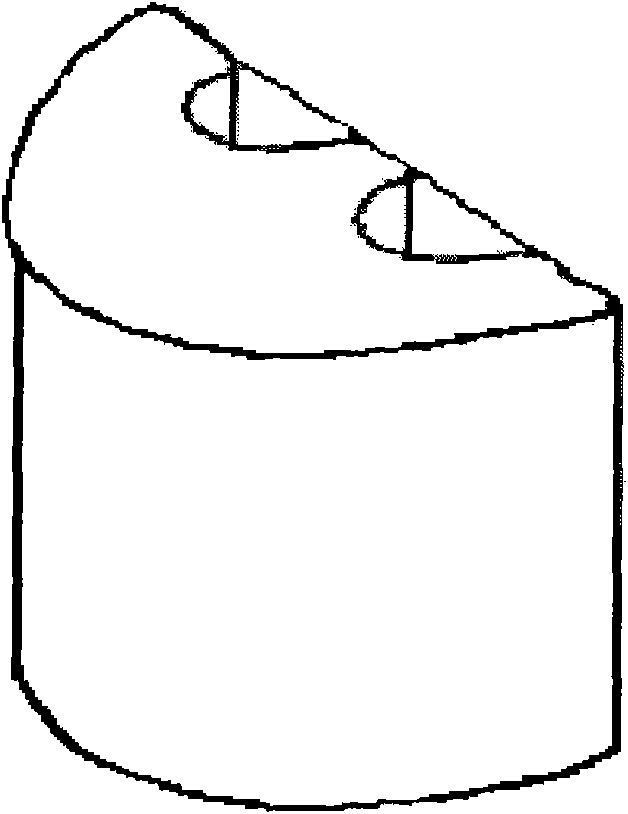

Method for preparing high-temperature electrochemical working electrode

InactiveCN101825600ASolve the packaging problemResolve connectivityMaterial electrochemical variablesPortland cementTemperature resistance

The invention relates to a method for preparing a high-temperature electrochemical working electrode, and belongs to the technical field of electrochemical corrosion measurement and material characterization. The method is characterized in that: a welded double electrode is fixed in a base; a PVC pipe at a proper size is connected with the base and is sealed by an aluminum foil; commonly used Portland cement is used as a packaging material; the ordinary PVC pipe is used for packaging an infusion grinding tool; and finally, the PVC pipe is softened and stripped at a high temperature to prepare the high-temperature working electrode with high corrosion resistance and high temperature resistance. The whole working electrode is divided into two work testing parts and is convenient to monitor electrochemical noise under a high-temperature corrosion condition. The method has the advantages of low cost, simple process and easy operation, and is favorable for accurately monitoring the material corrosion performance in real time in the corrosion process under the high-temperature corrosion condition. The method is suitable for all metal matrixes for electrochemical detection, such as stainless steel, carbon steel and the like, and can be used in law measurement, mechanism inspection and characterization of material performance in a corrosive environment.

Owner:DALIAN UNIV OF TECH

Portable variable load digital stress corrosion measurement device

InactiveCN103674817APrecise control of load sizeLoad size can be adjusted at any timeWeather/light/corrosion resistanceMeasurement deviceSpectroscopy

The invention relates to the field of stress corrosion measurement and in particular relates to a portable variable load digital stress corrosion measurement device. The problems that the precision is insufficient by taking a spring as a load application source, the spring is difficult to replace and the like in the prior art are solved. According to the measurement device, a tensile test piece is arranged between a movable tensile head and a stationary tensile head; one end of the tensile test piece stretches into the stationary tensile head, and the other end of the tensile test piece and the movable tensile head stretch into one end of a liquid pool to be connected with each other; the other end of the movable tensile head is connected with a worm gear reducer through a transmission shaft; a loading force measurement sensor is arranged on the transmission shaft. The tensile test piece, a reference electrode and an auxiliary electrode form a three-electrode system, and the three-electrode system is connected with an electrochemical workstation and a computer to perform electrochemical testing. The device can be used for conventional constant stress and constant strain experiments and also can be combined with the electrochemical workstation for performing electrochemical polarization, electrochemical impedance spectroscopy and electrochemical noise measurements under the actions of constant stress and variable load.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Dew point corrosion monitoring method based on electrochemical noise

ActiveCN103822872AReal-time online monitoringDiversification of monitoring meansWeather/light/corrosion resistanceHigh resistanceVoltmeter

The invention relates to a dew point corrosion monitoring method based on electrochemical noise, and mainly solves the problem that a dew point corrosion condition cannot be reflected in a real-time manner in the prior art. The method adopts the technical scheme that main components comprising a three-electrode-assembly probe, a zero-resistance ammeter, a high-resistance voltmeter, an A / D convertor and a computer are adopted; the three-electrode-assembly probe comprises a reference electrode assembly and two working electrode assemblies, and the reference electrode assembly is connected with the high-resistance voltmeter; the first working electrode assembly is connected with the zero-resistance ammeter and the high-resistance voltmeter respectively, and the second working electrode assembly is connected with the zero-resistance ammeter; potential noise generated by the high-resistance voltmeter and current noises generated by the zero-resistance ammeter enter the A / D convertor, and the A / D convertor is connected with the computer; the reference electrode assembly comprises at least one reference electrode, the first working electrode assembly comprises at least one working electrode, and the second working electrode assembly comprises at least one working electrode. The technical scheme well solves the problem. The dew point corrosion monitoring method can be used in dew point corrosion monitoring of oil refineries.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

Quantitative transient analysis of localized corrosion

InactiveUS7713405B2Weather/light/corrosion resistanceVolume/mass flow measurementTransient analysisEngineering

An electrochemical noise method, apparatus and system may be used to estimate and / or calculate parameters of interest related to corrosion rates of an electrically conductive article. The apparatus involves a working electrode (having substantially the same composition of the electrically conductive article), a reference electrode, and a counter electrode in an environment of interest. The working electrode is placed under potentiostatic control. A current transient between the working electrode and the counter electrode is measured. The working electrode is switched to open potential. A potential transient is measured over the duration of a localized corrosion event. The localized corrosion may then be calculated based on the measured potential transient and the current transient.

Owner:BAKER HUGHES INC

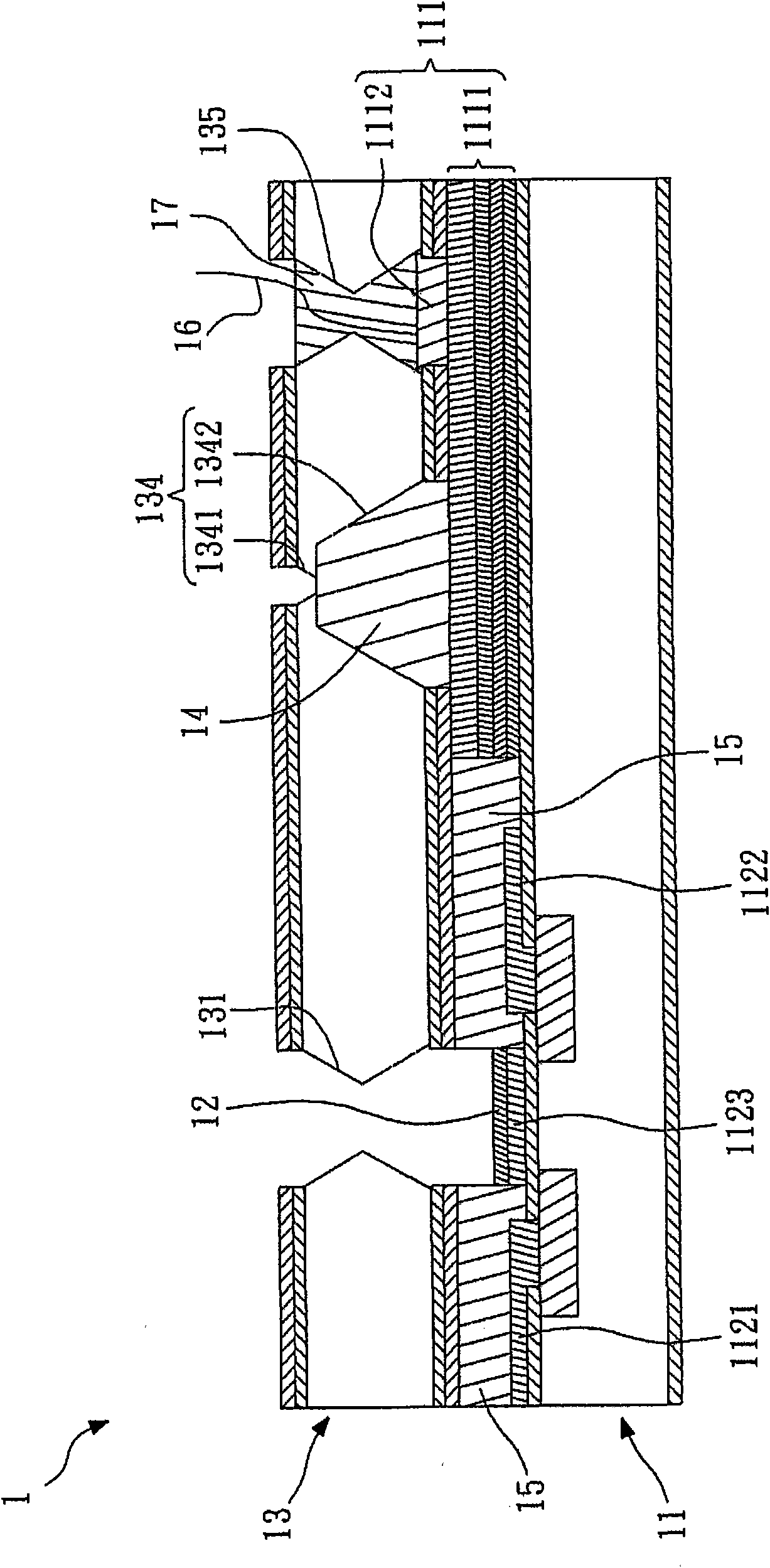

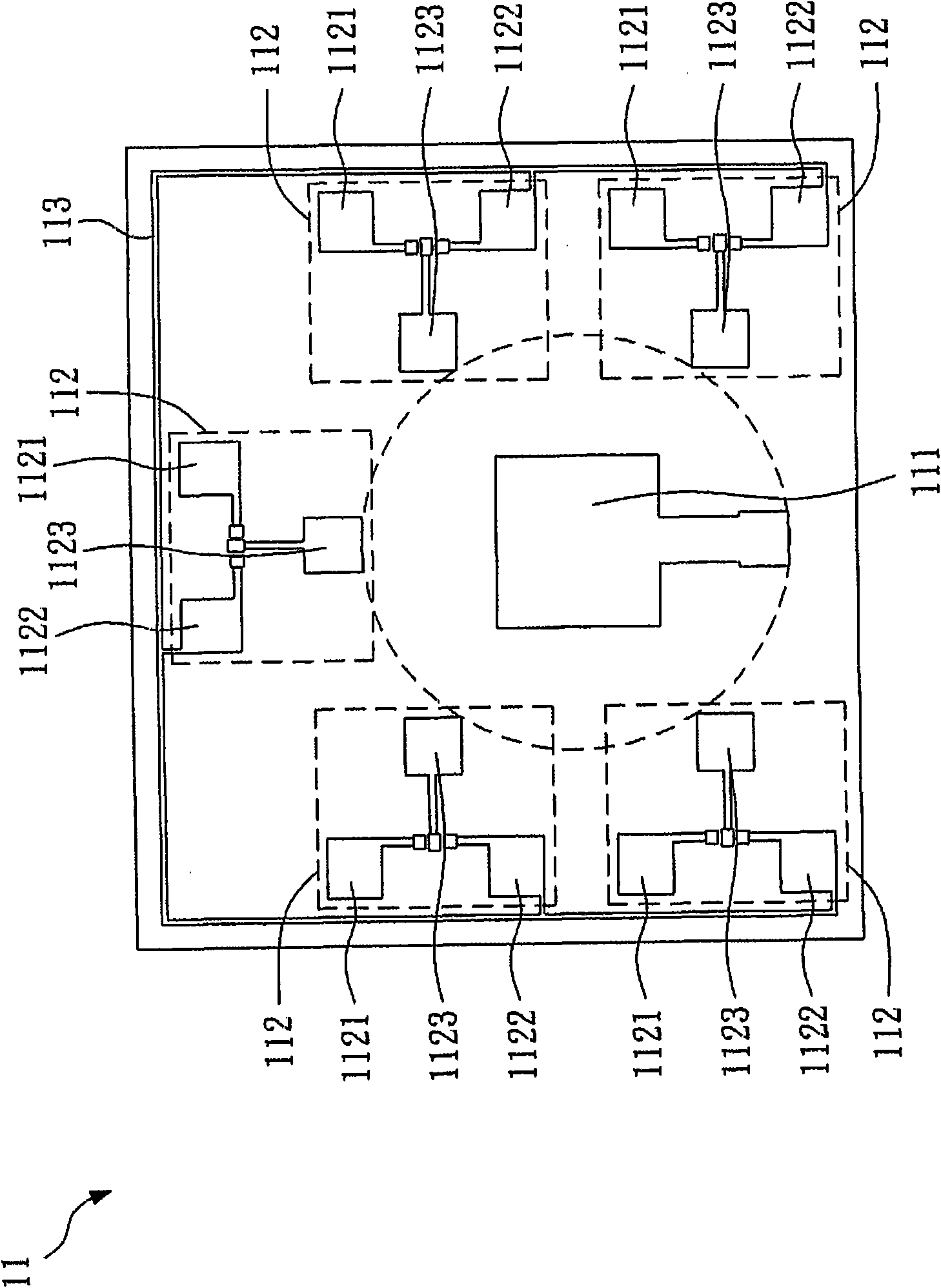

Blood analysis micro system

InactiveCN102466652AQuick responseHigh precisionMaterial electrochemical variablesMicroelectromechanical systemsLow offset

A blood analysis micro system with multiple ion sensing functions is manufactured by using a micro electro mechanical system (MEMS) process and a packaging technology. The blood analysis micro system is provided with an integrated miniature reference electrode, thus the size of a chip is miniaturized. The blood analysis micro system is provided with a grid sensing region larger than a planar ion selection electrode (Planar ISE) or an ion sensing filed effect transistor (ISFET), thus unnecessary signal interference can be effectively avoided, and possibility of packaging difficulty and liquid leakage is reduced. Therefore, the blood analysis micro system has the advantages of light weight, thinness, short size, high reaction speed, high precision, lower cost and high compatibility with an IC process, and has excellent electrochemical properties such as extremely high long-term potential stability, extremely low offset-compensating potential, small alternating current impedance, stable dynamic reference potential, low electrochemical noise, high electrode reproducibility and the like.

Owner:IND TECH RES INST

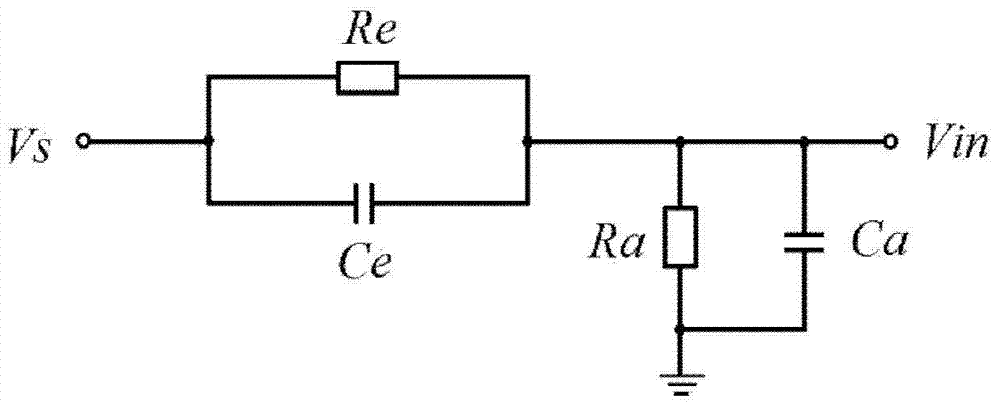

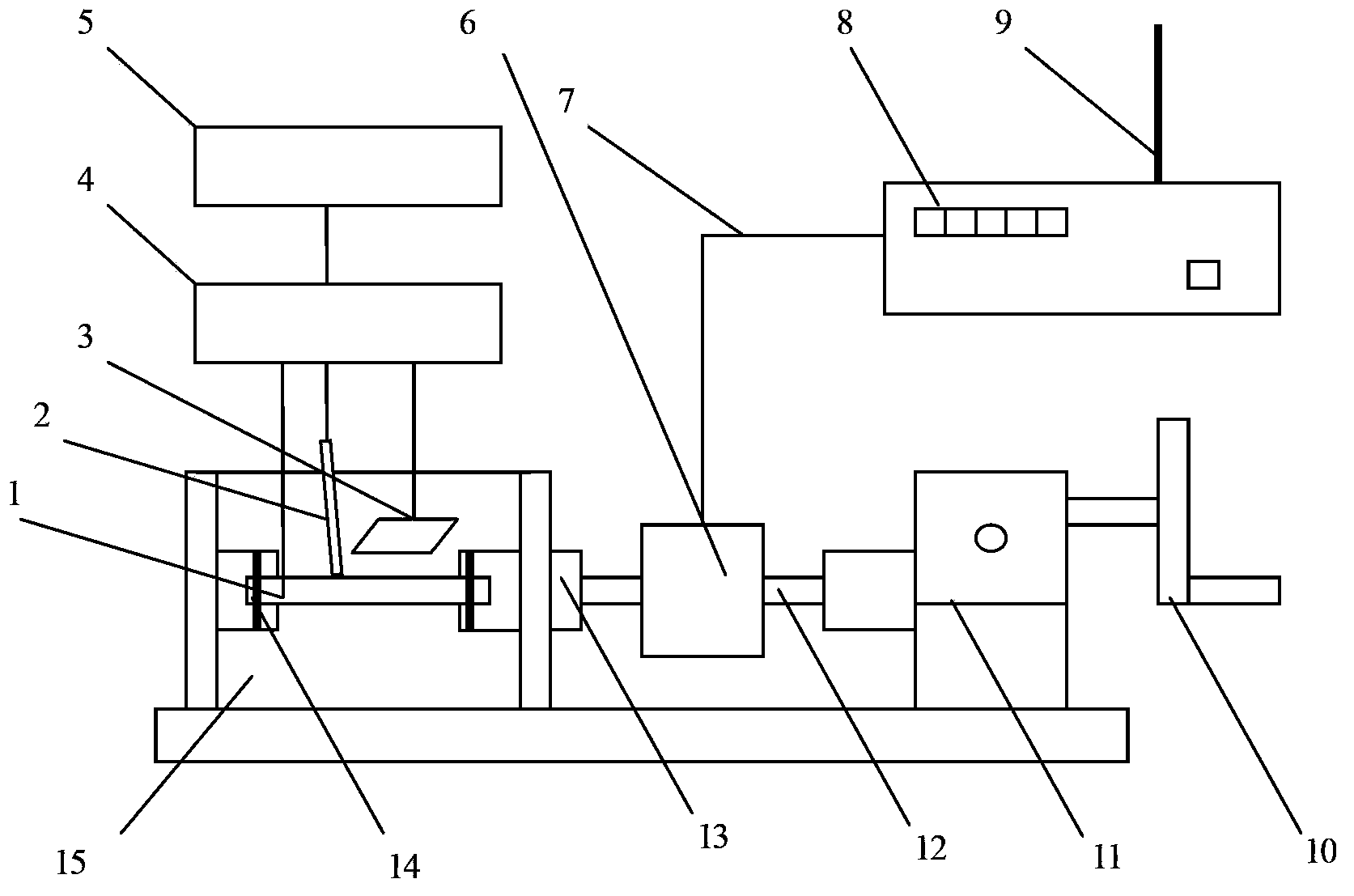

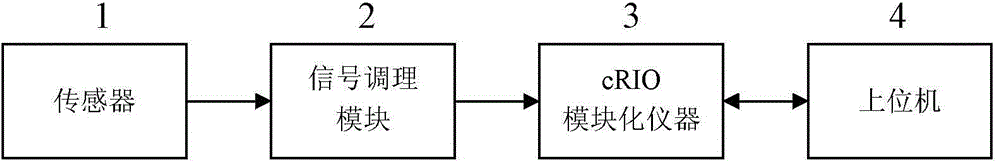

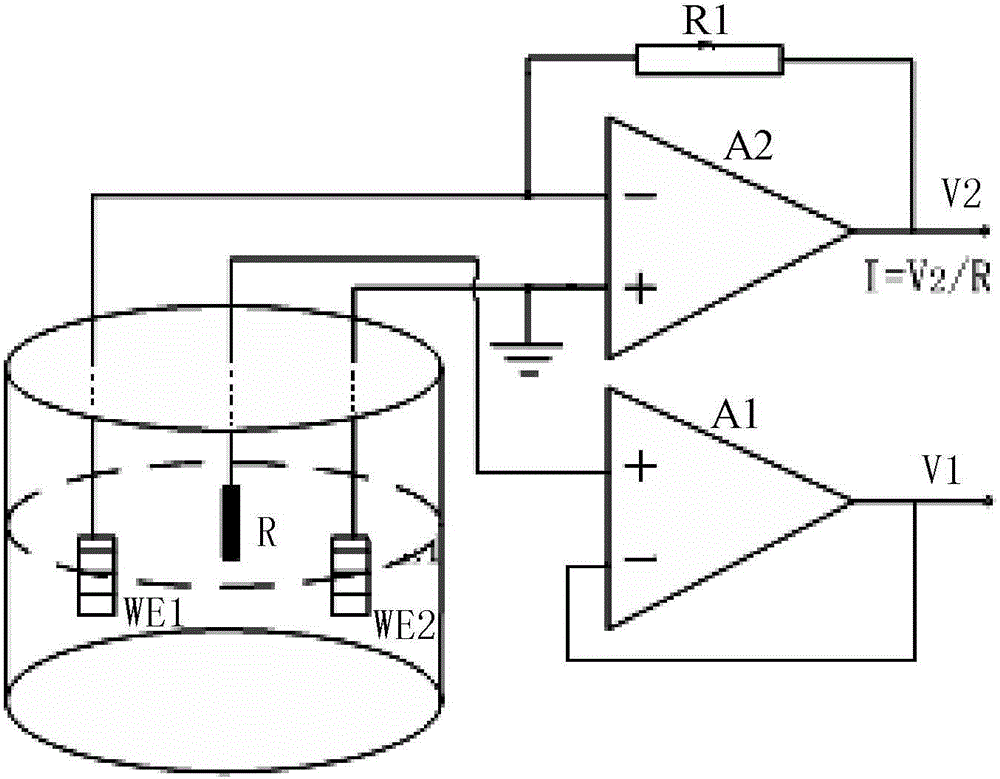

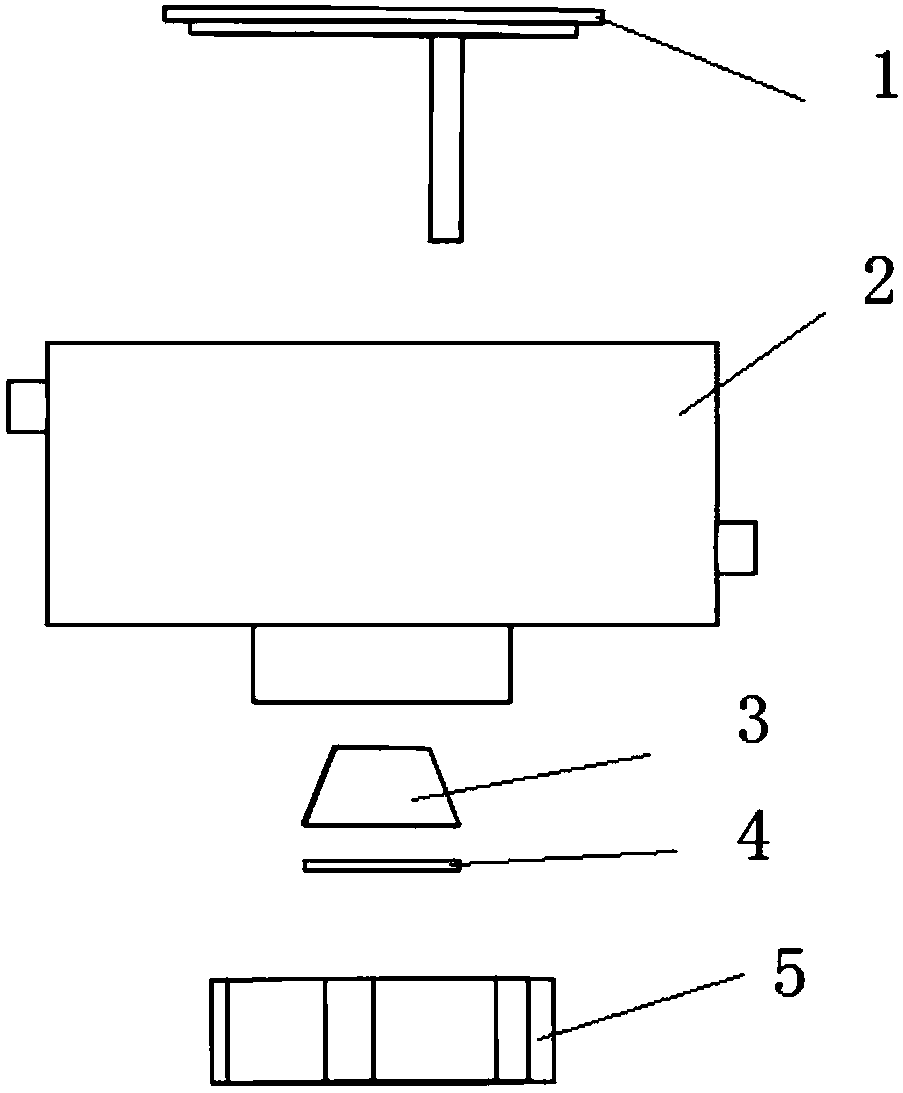

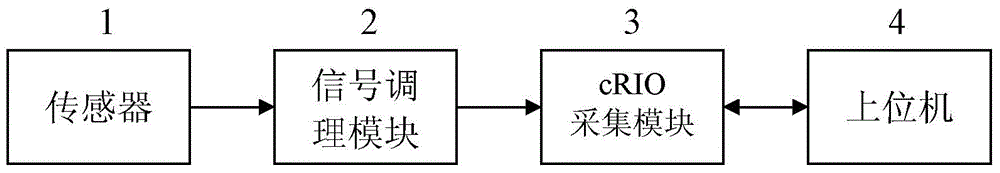

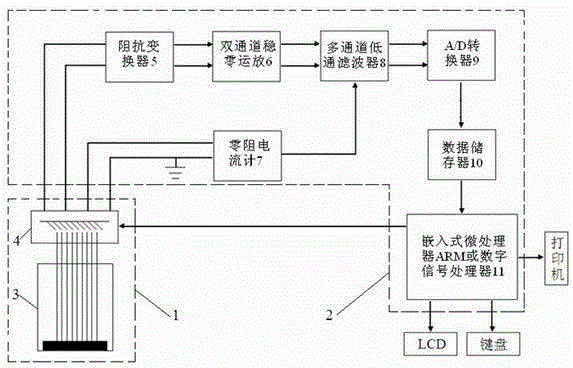

Noise acquisition system based on electrochemical noise corrosion signal

InactiveCN104568728ARealize acquisitionImplement storageWeather/light/corrosion resistanceSignal conditioning circuitsData treatment

The invention relates to a noise acquisition system based on an electrochemical noise corrosion signal. The noise acquisition system comprises a sensor, a signal conditioning module, a cRIO acquisition module and an upper computer, wherein the sensor is an electrochemical noise sensor and is connected with the cRIO acquisition module through the signal conditioning module; the cRIO acquisition module is an acquisition controller of the system and is connected with the upper computer through an Ethernet interface; the upper computer is a computer for running electrochemical noise system software; the signal conditioning module is an acquisition signal conditioning circuit. The noise acquisition system based on the electrochemical noise corrosion signal, provided by the invention is a multi-channel electrochemical noise test instrument and can realize the acquisition, the storage and the display of electrochemical noise data, process the data through electrochemical noise data processing software in the upper computer, extract characteristic parameters and characterize the corrosion property.

Owner:TIANJIN UNIV

Temperature controllable electrolytic cell device simultaneously used for electrochemical experiments and slow strain rate tensile tests and using method thereof

PendingCN110609066AAnalyzing CorrosionMaterial strength using tensile/compressive forcesMaterial electrochemical variablesTemperature controlStress conditions

The invention discloses a temperature controllable electrolytic cell device simultaneously used for electrochemical experiments and slow strain rate tensile tests and a using method thereof. Accordingto the device, an electrolytic cell is formed in a reaction tank, and a circulating water tank is formed along the outer ring of the electrolytic cell, so that the temperature control of an experimental environment in the electrolytic cell is completed while a tensile test is carried out, and the fixing and sealing of a tensile sample are completed through the combination of a sealing plug, a sealing gasket and a rotary cover. The device can perform electrochemical tests, such as polarization curve measurement, electrochemical alternating current impedance spectrum, electrochemical noise tests and M-S curve measurement, on samples at different temperatures and under different stress conditions, and is used for analyzing the corrosion condition of the material.

Owner:TIANJIN UNIV

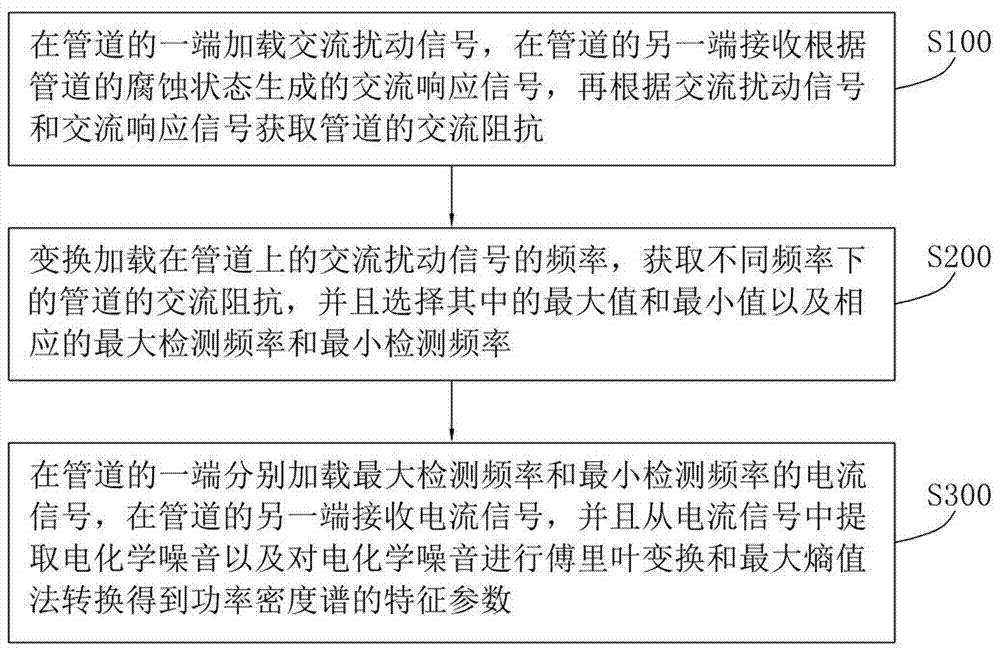

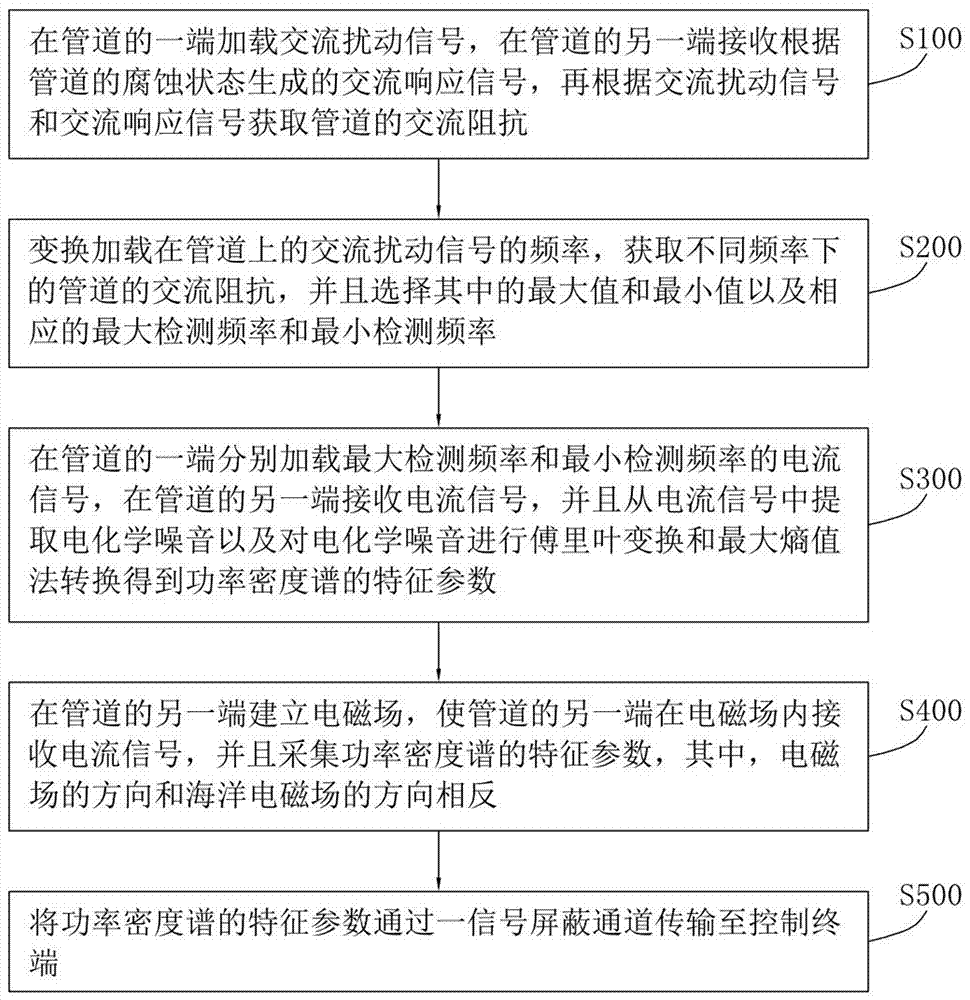

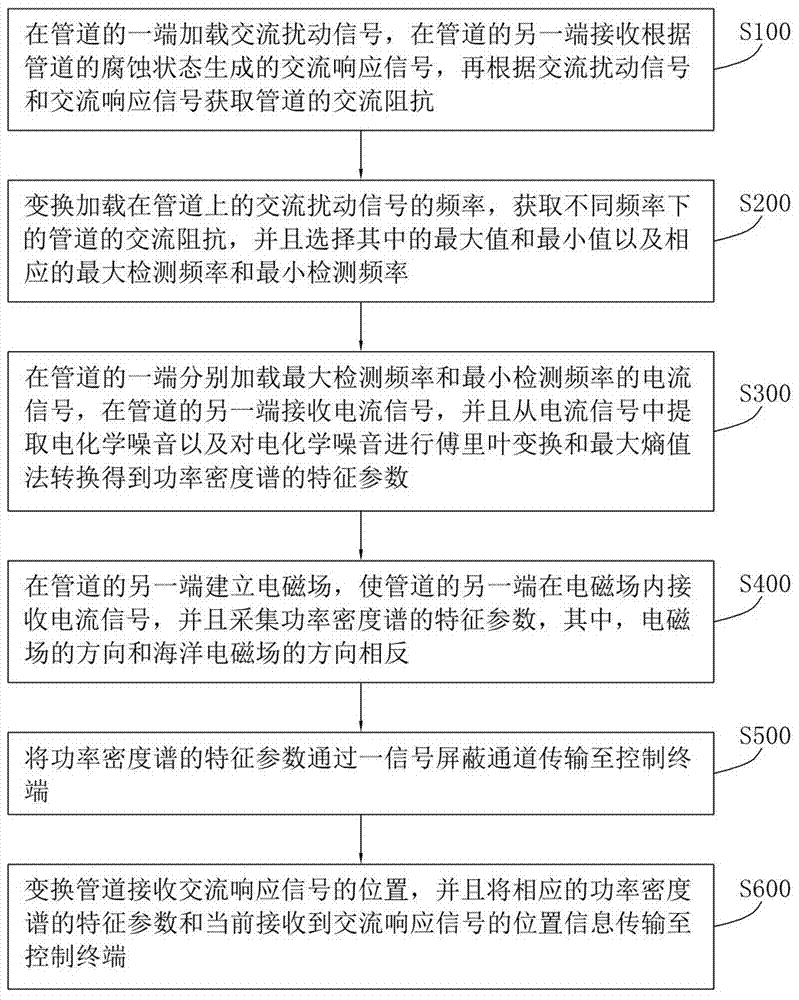

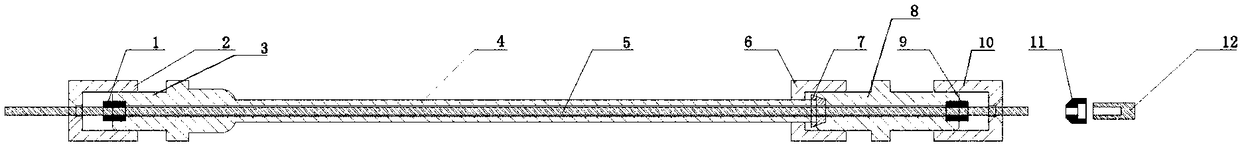

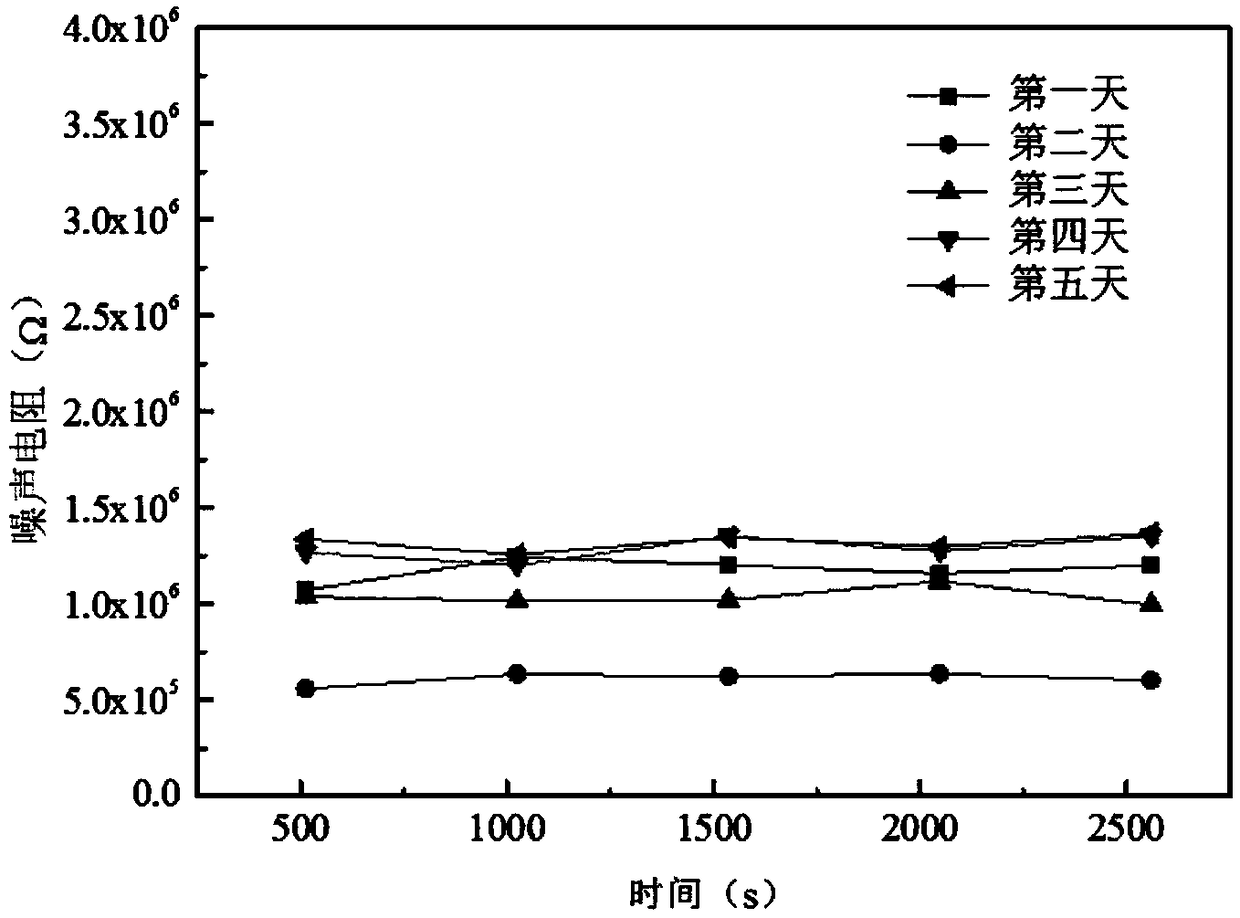

Method for detecting corrosion of submarine pipelines

InactiveCN107328819AWeather/light/corrosion resistanceMaterial impedancePower flowAlternating current

The invention discloses a method for detecting corrosion of submarine pipelines. The method comprises the following steps of: acquiring alternating-current impedance, acquiring detection frequency and determining pipeline conditions. The detailed steps are as follows: loading alternating-current disturbance signals to one end of a pipeline, receiving alternating-current response signal generated according to the corrosion state of the pipeline at the other end of the pipeline, and acquiring alternating-current impedance according to the alternating-current disturbance signals and the alternating-current response signals; changing the frequency of the alternating-current disturbance signals loaded on the pipeline, acquiring the alternating-current impedance of the pipeline under different frequencies and selecting maximum value and minimum value and corresponding maximum detection frequency and minimum detection frequency; and respectively loading current signals with maximum detection frequency and minimum detection frequency to one end of the pipeline, receiving the current signals at the other end of the pipeline, extracting electrochemical noise from the current signals and carrying out fourier transformation and maximum-entropy-method transformation on the electrochemical noise to obtain characteristic parameters of a power density spectrum.

Owner:WENZHOU POLYTECHNIC

Method for detecting anticorrosion performance of 304 stainless steel under high temperature condition

ActiveCN108226245AImprove sealingImprove stabilityMaterial electrochemical variablesInsulation layerMetallurgy

Owner:TIANJIN UNIV

Dew point corrosion monitoring method based on electrochemical noise

ActiveCN103822872BReal-time online monitoringDiversification of monitoring meansWeather/light/corrosion resistanceHigh resistanceVoltmeter

The invention relates to a dew point corrosion monitoring method based on electrochemical noise, and mainly solves the problem that a dew point corrosion condition cannot be reflected in a real-time manner in the prior art. The method adopts the technical scheme that main components comprising a three-electrode-assembly probe, a zero-resistance ammeter, a high-resistance voltmeter, an A / D convertor and a computer are adopted; the three-electrode-assembly probe comprises a reference electrode assembly and two working electrode assemblies, and the reference electrode assembly is connected with the high-resistance voltmeter; the first working electrode assembly is connected with the zero-resistance ammeter and the high-resistance voltmeter respectively, and the second working electrode assembly is connected with the zero-resistance ammeter; potential noise generated by the high-resistance voltmeter and current noises generated by the zero-resistance ammeter enter the A / D convertor, and the A / D convertor is connected with the computer; the reference electrode assembly comprises at least one reference electrode, the first working electrode assembly comprises at least one working electrode, and the second working electrode assembly comprises at least one working electrode. The technical scheme well solves the problem. The dew point corrosion monitoring method can be used in dew point corrosion monitoring of oil refineries.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

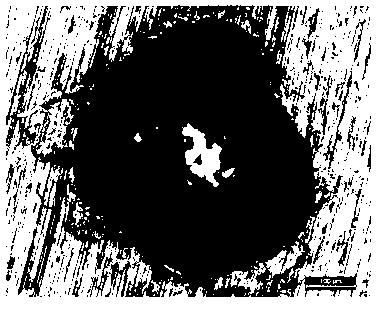

Sensor suitable for high-temperature high-pressure water environment electrochemical noise measurement of nuclear power environment

The invention relates to a sensor suitable for high-temperature high-pressure water environment electrochemical noise measurement of nuclear power environment. The sensor comprises a high-purity antimony electrode as a reference electrode, stainless steel as a counter electrode of which the surface is sprayed with ZrO<2+>Y2O3 and a stainless steel housing. A porcelain tube with double holes is fixedly installed in the stainless steel housing. Two electrodes are fixed in the porcelain tube, and the front end is stretched out from the front end of the porcelain tube. A copper guide wire guided from the rear ends of two electrodes passes through the double holes of the rear end of the porcelain tube, and is sealed by a ceramic powder sealant. The copper guide wire guided from the rear ends of the counter electrode and the reference electrode passes through the porcelain tube, so that the electric insulation and heat insulation of the copper guide wire and the main stainless steel housing can be guaranteed.

Owner:TIANJIN UNIV

Method for detecting local corrosion of material by electrochemical noise technology, noise probe and manufacturing method of the noise probe

InactiveCN103323520AAvoid polarizationMeet the requirements of electrochemical noise testing technologyMaterial magnetic variablesNatural stateWorkstation

The invention relates to a method for detecting local corrosion of a material by an electrochemical noise technology, a noise probe and a manufacturing method of the noise probe. The noise probe is arranged at a position 1mm away from a material needing to be detected; the material needing to be detected is used as a working electrode; the material needing to be detected and the noise probe are connected to an electrochemical workstation by leads; the noise probe comprises a core column prepared from a material the same as the material needing to be detected, and also comprises a powder paint seal layer which is coated on outer parts of the core column but ends. The method can realize a local corrosion test of a measurable material in a polarization-free natural state, is based on a traditional electrochemical noise test technology and a scanning electrochemical microscope test principle, can detect local corrosion of the material in a natural state, does not introduce any additional signals or polarization, is an electrochemical test method for real-time, on-line, in-situ and lossless reflection of local corrosion of the material, and can guarantee real material test data in a natural corrosion state.

Owner:HARBIN ENG UNIV

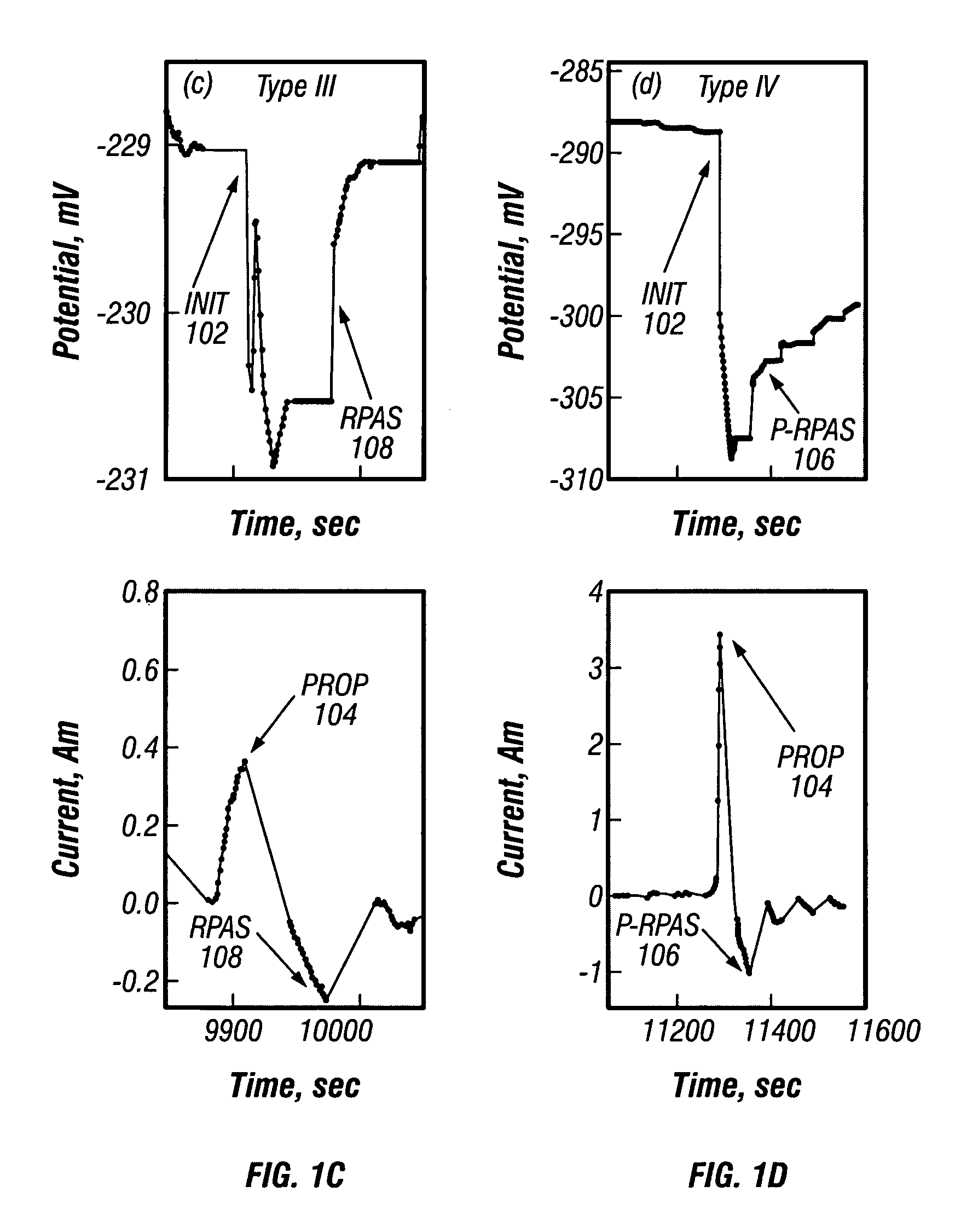

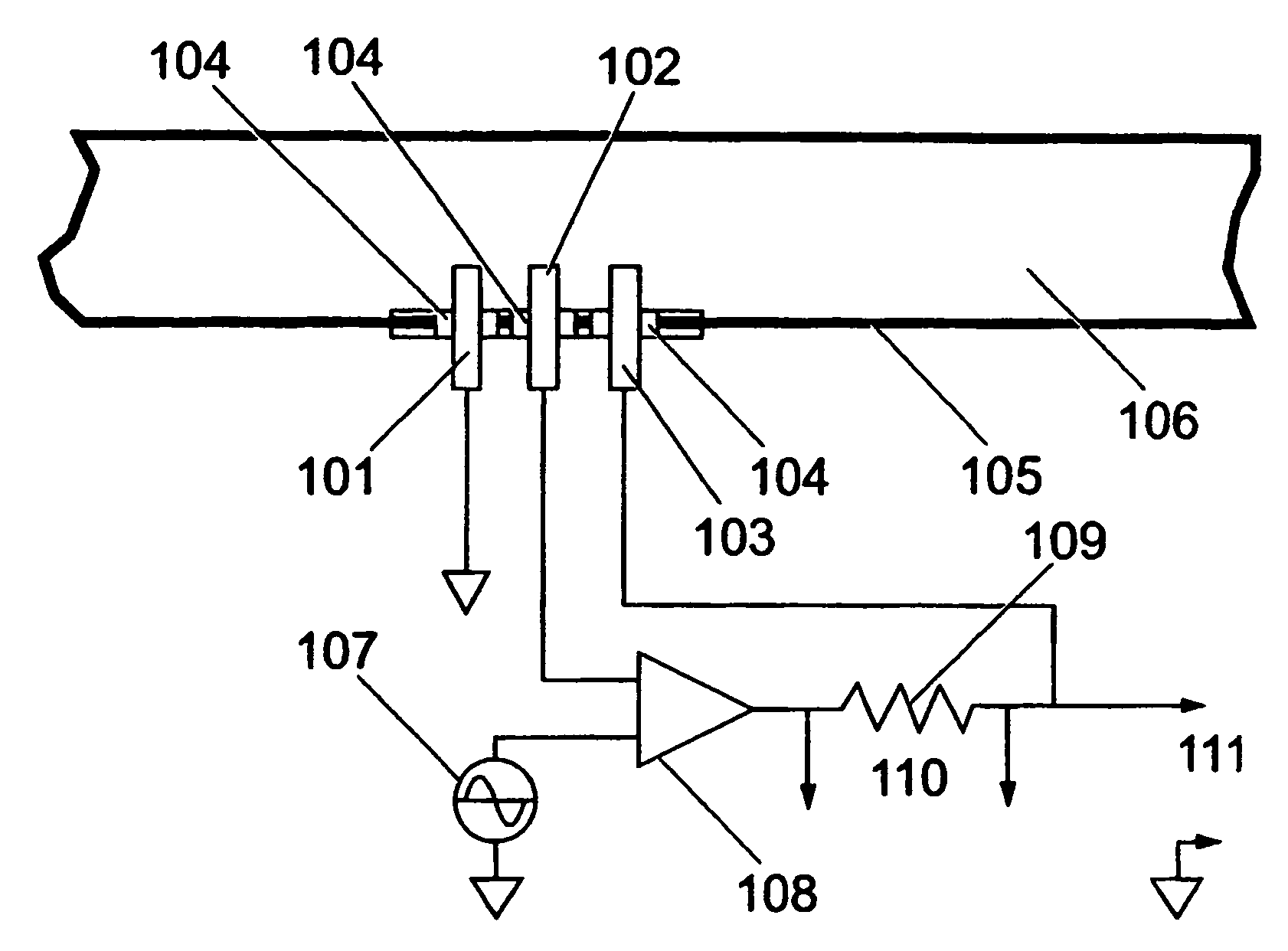

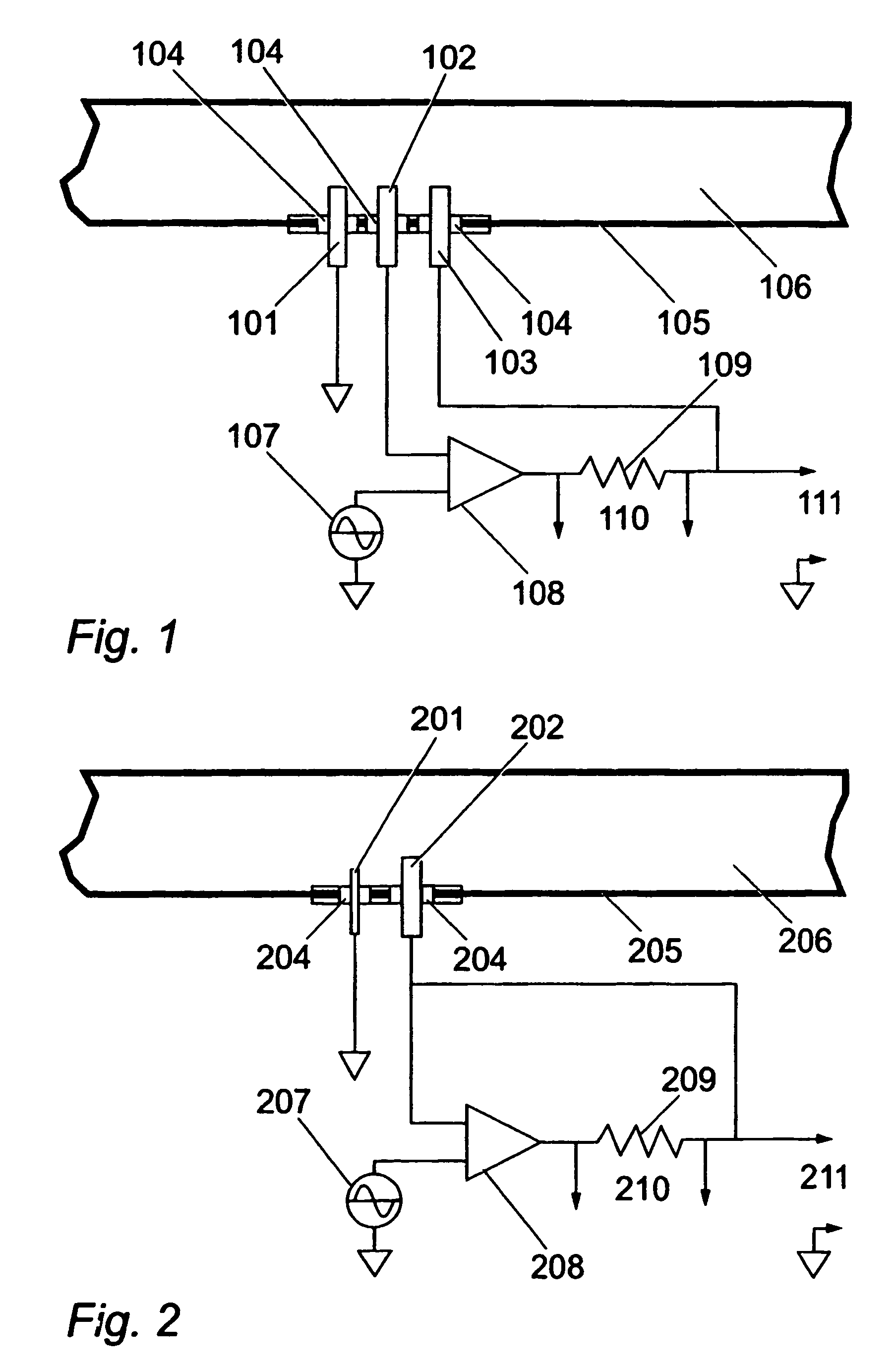

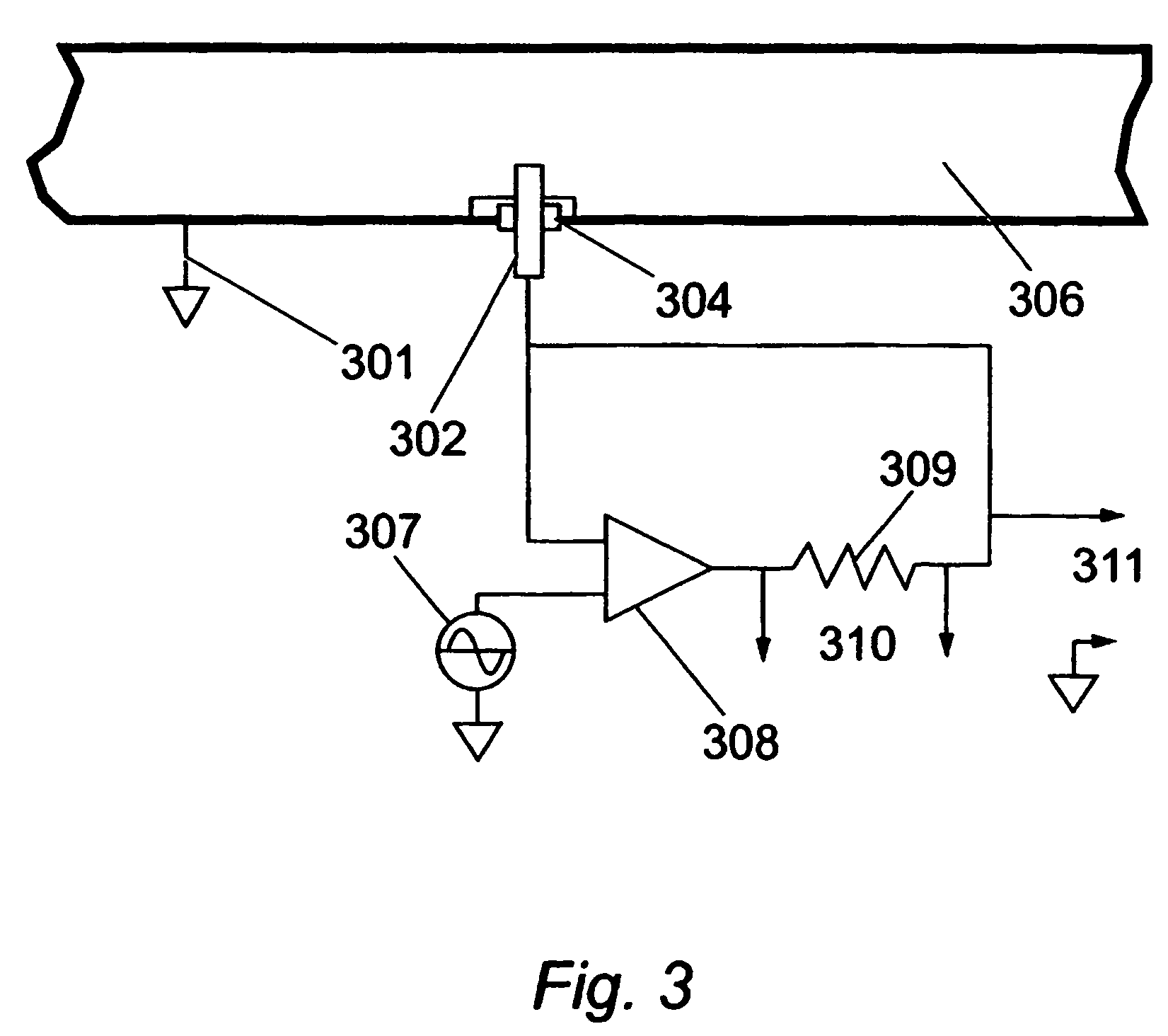

Estimation of localised corrosion penetration

ActiveUS7520975B2Simple methodGood estimateWeather/light/corrosion resistanceVolume/mass flow measurementHarmonic analysisMetallic materials

The present invention provides a method and apparatus for estimation of general and localized corrosion penetration rates of metallic materials and objects. The invention can also be used to discriminate between general and localized corrosion. A one, two or three electrode probe having electrodes (101, 102, 103) made of the same material as the material being monitored is located in the same corrosive environment as the material being monitored. An electrochemical harmonic analysis is performed and electrochemical noise signals are monitored, and the resulting responses are analyzed and compared to discriminate between general and localized corrosion attack and to determine a localized corrosion penetration rate. A law frequency sine wave is applied to the working electrode. Harmonic analysis of the electrode response provides information regarding the general corrosion rate and the stern-geary constant. Electrochemical noise analysis of the electrode response and comparison with harmonic data provides a means of determination of localized corrosion penetration rate.

Owner:INTERCORR HLDG +1

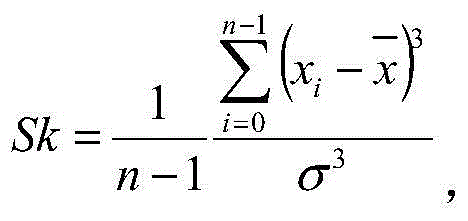

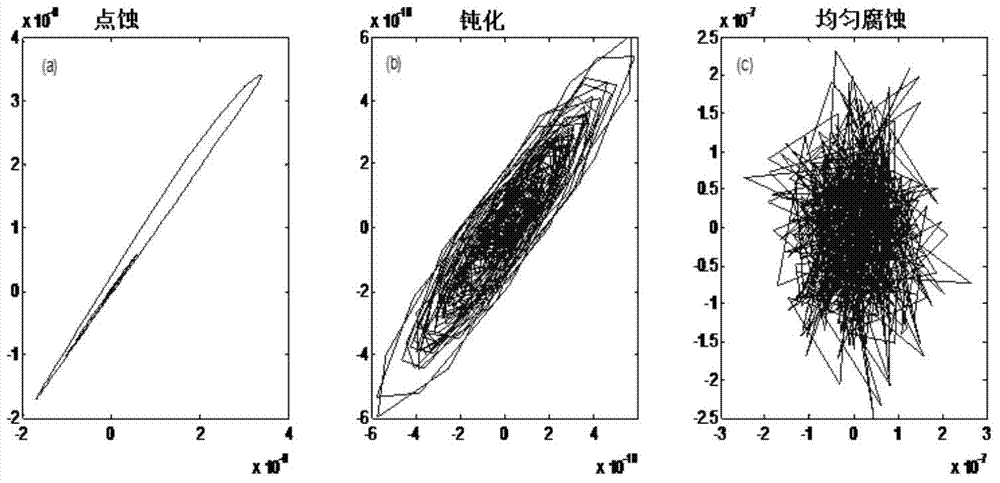

Electrochemical noise corrosion type distinguishing method based on support vector machine

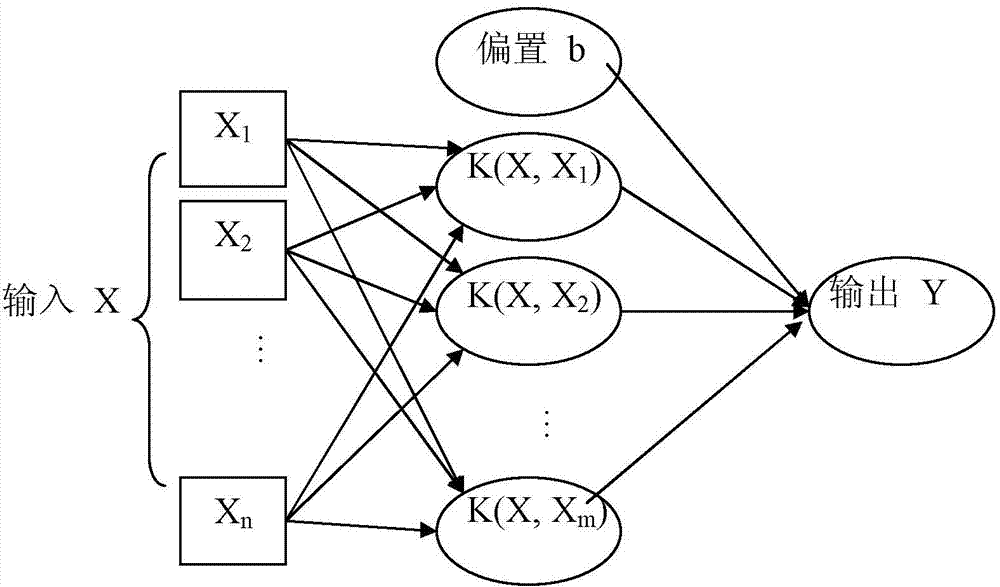

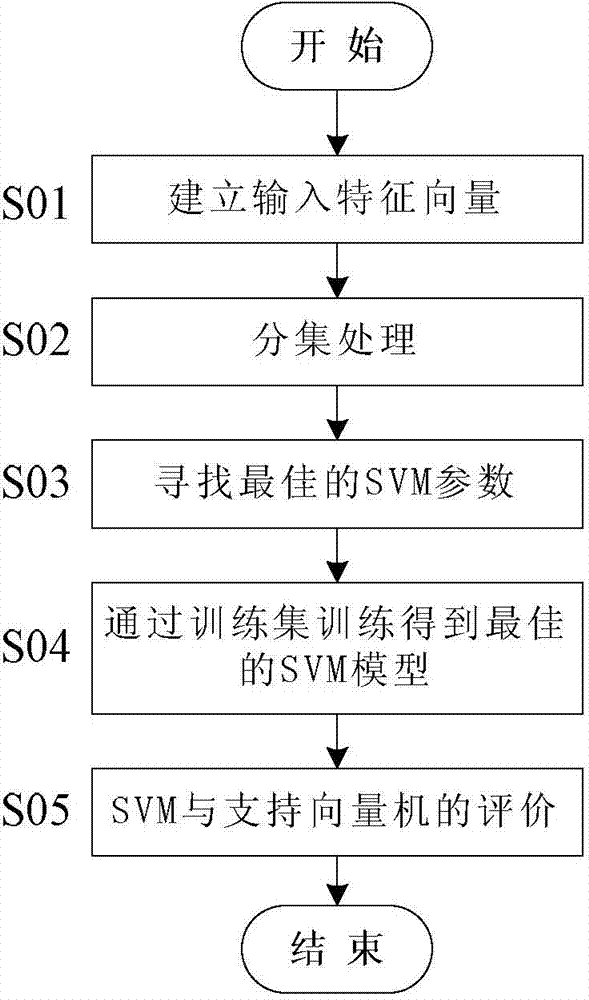

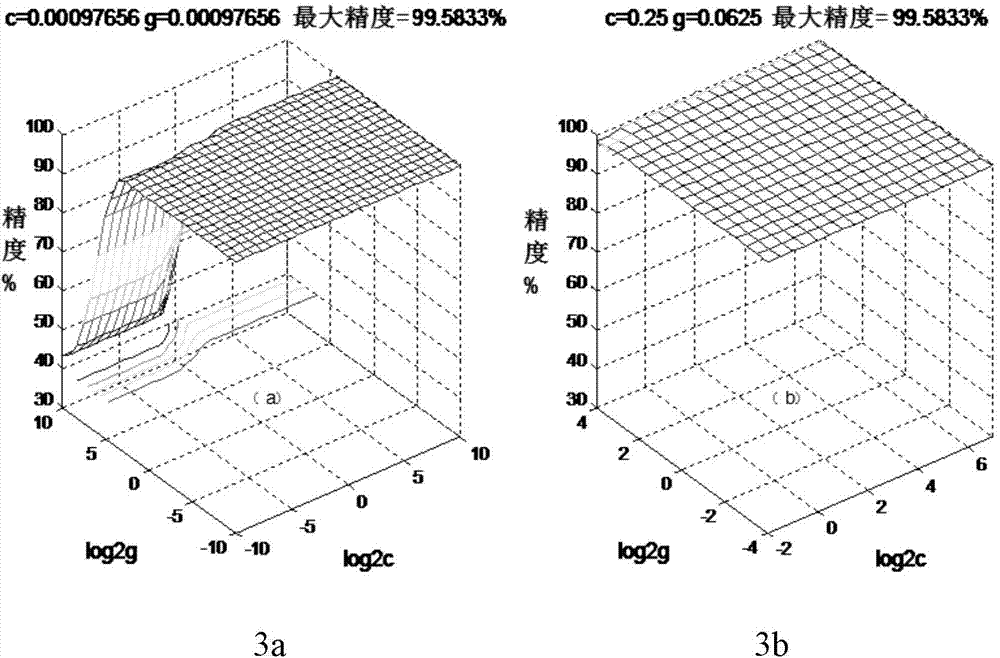

InactiveCN104502267AHigh test set accuracyImprove forecast accuracyWeather/light/corrosion resistanceFeature vectorAlgorithm

Owner:TIANJIN UNIV

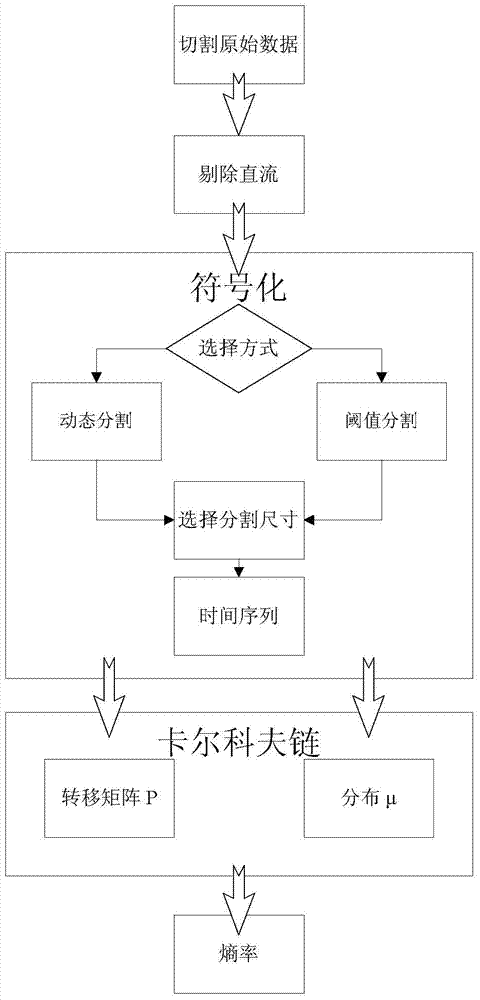

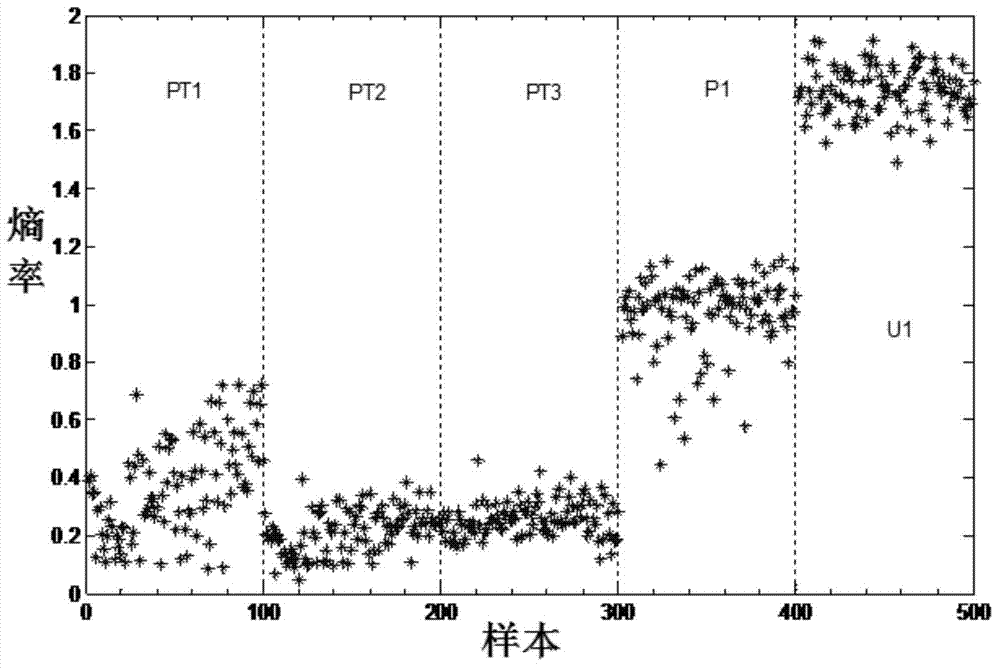

Entropy rate-based electrochemical noise corrosion signal processing method

The invention relates to an entropy rate-based electrochemical noise corrosion signal processing method, which comprises the following steps: cleansing original data; performing direct current removal on data of each small file by using a wavelet removal method to obtain time data; signifying the time data; calculating probability distribution and a transfer matrix; calculating to obtain an entropy rate value; analyzing the size relation among entropy rates of three corrosion systems; according to a sample, verifying the entropy rate value; and evaluating the entropy rate processing results. In the entropy rate-based electrochemical noise Corrosion signal processing method provided by the invention, each entropy rate is used as a new characteristic value for characterizing an electrochemical corrosion system to represent the degree of chaos of the corrosion system; the data processing results show that each entropy rate can well distinguish among different corrosion systems, and cannot be affected by the concentration of a solution; and finally, an entropy rate parameter and a noise resistance performance parameter are compared to obtain the advantages and the disadvantages of the use of the entropy rate.

Owner:TIANJIN UNIV

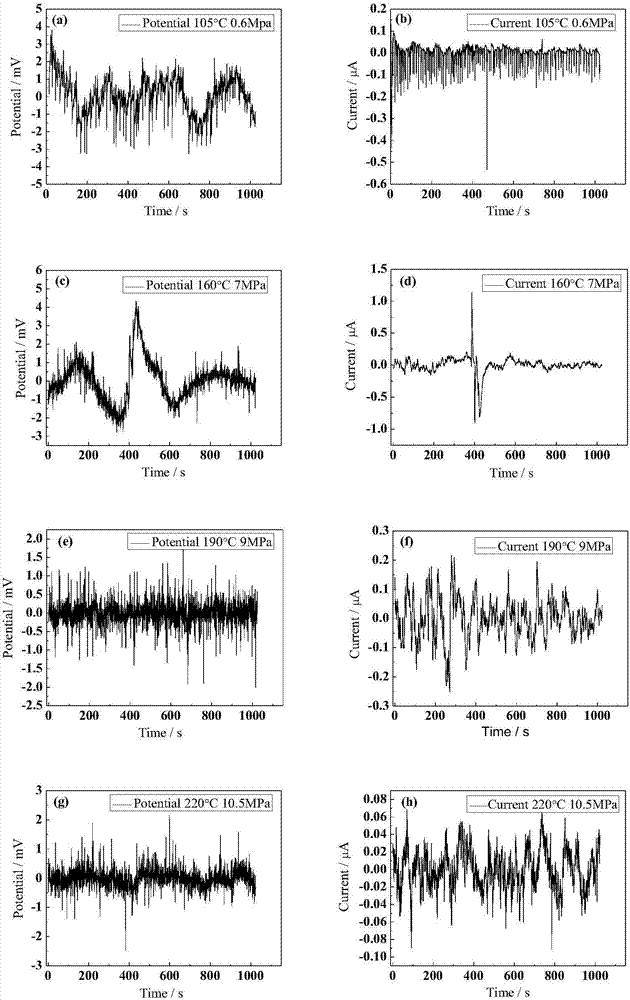

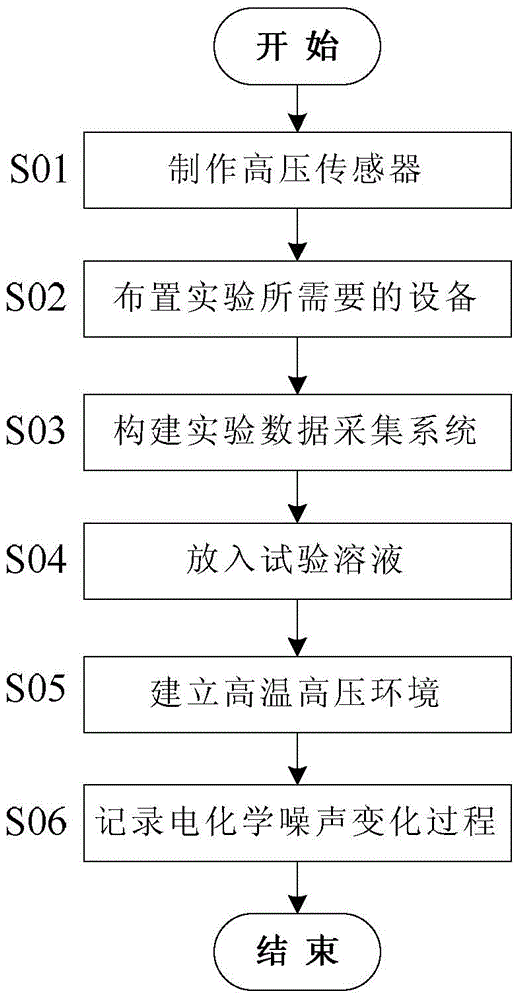

Electrochemical noise experimental method at high temperature and high pressure

The invention relates to an electrochemical noise experimental method at a high temperature and a high pressure. The method comprises the following steps: manufacturing an electrochemical noise sensor; arranging equipment required by experiments; constructing an experimental data collecting system; putting into a test solution; establishing a high-temperature and high-pressure environment; recording an electrochemical noise changing process and the like. Aiming at the condition that electrochemical noise in a high temperature and high pressure environment is the blind point and difficulty all the way in the field of electrochemical noise, the electrochemical noise experimental method at the high temperature and the high pressure is a direction of development in the future. The mechanism of corrosion at a constant temperature is basically known by people while researches on the corrosion mechanism under the high temperature and high pressure water environment are few. The primary cause is shortage of researching paths and backwardness of instruments as well as huge difficulty on researches in the high temperature and high pressure water environment. However, emergence of electrochemical noise makes researches on corrosion mechanism at the high temperature and high pressure possible.

Owner:TIANJIN UNIV

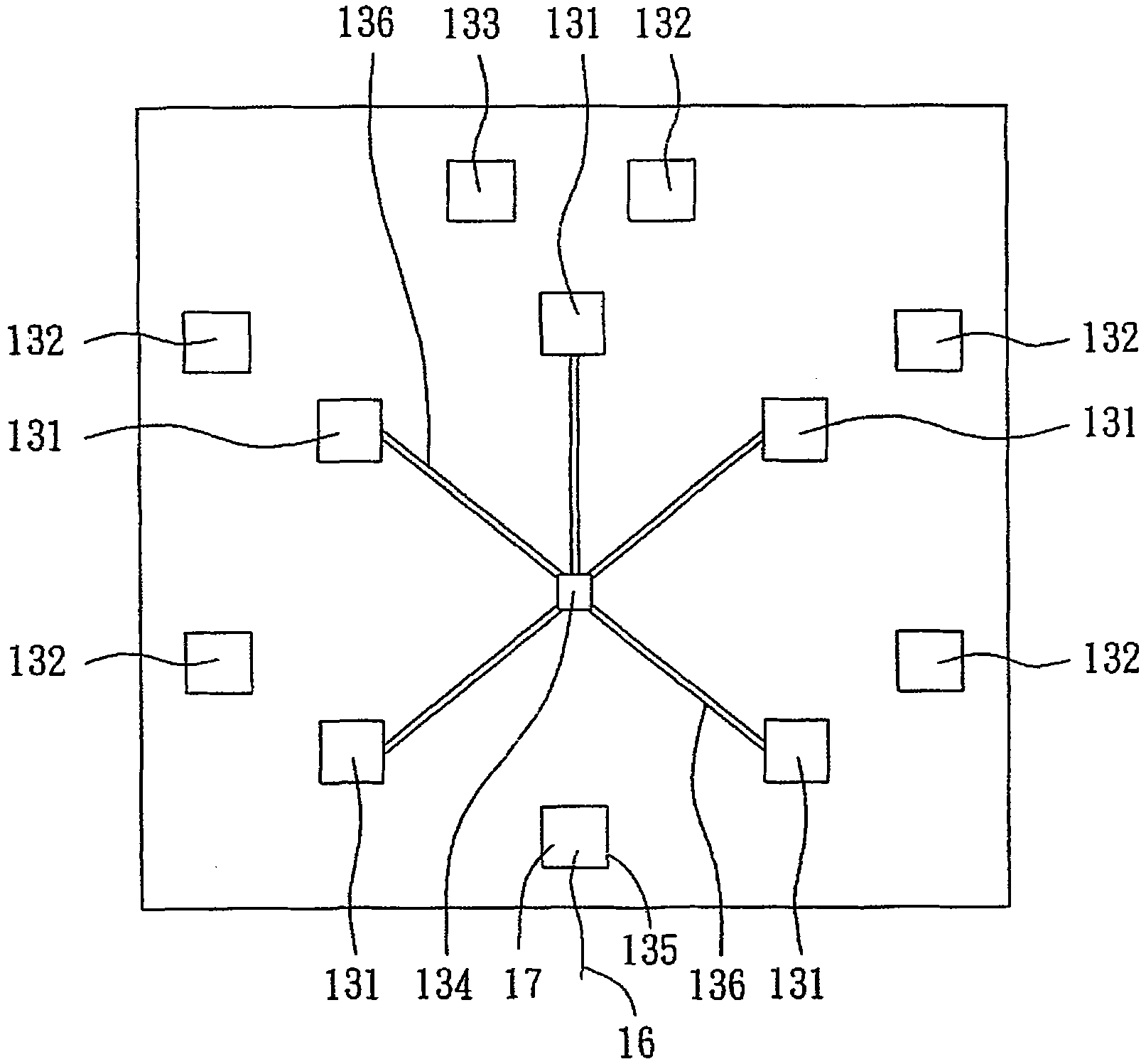

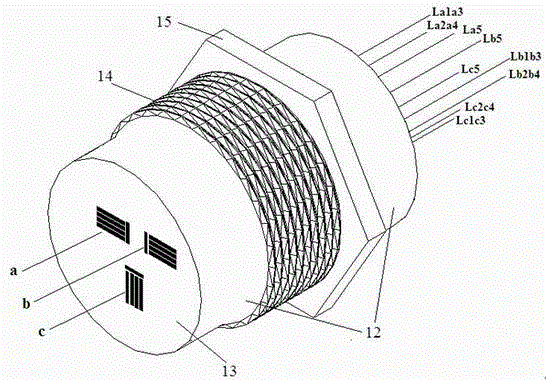

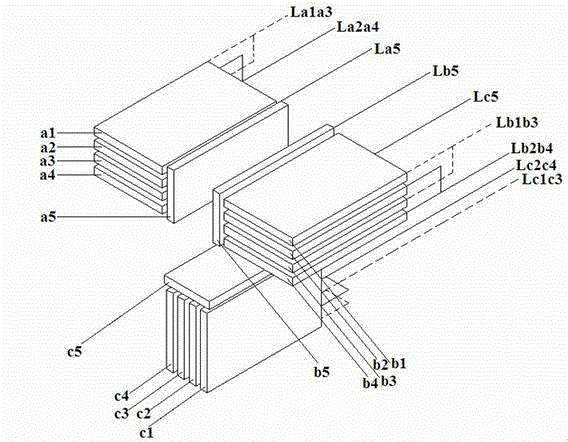

Couple electrochemical noise corrosion monitoring probe

ActiveCN102128784BIncreased sensitivityExtend your lifeWeather/light/corrosion resistancePower flowGas phase

The invention provides a couple electrochemical noise corrosion monitoring probe, which comprises a planar multi-electrode couple electrochemical noise testing component for generating a couple electrochemical noise potential and a current signal and a control switch for controlling a short-circuit mode of each electrode sheet. The monitoring probe is a probe for monitoring local corrosion of a metal material in a multi-phase corrosive environment, particularly a corrosive gas-phase environment by using couple electrochemical noise, can be used for monitoring solution phase and gas phase corrosion and has high sensitivity; moreover, local corrosion information of metal corrosion can be provided by using a couple electrochemical noise signal. The monitoring probe is provided with the control switch, the short-circuit mode of each electrode sheet can be changed according to the change of a monitoring signal, and a small-interval electrode group on the probe is switched into a large-interval electrode group, so that initial high sensitivity during monitoring is ensured and the service life of the probe in the corrosive environment can be prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com