Sensor suitable for high-temperature high-pressure water environment electrochemical noise measurement of nuclear power environment

A technology of high temperature and high pressure water and electrochemical noise, applied in the direction of electrochemical variables of materials, can solve problems that have not been reported in the research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

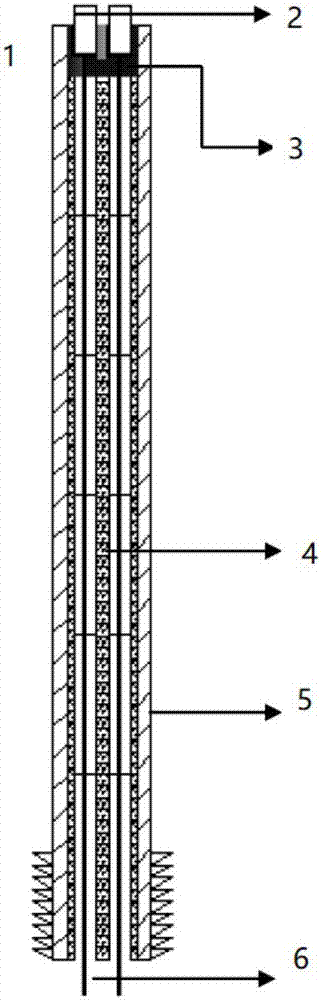

[0010] The reference electrode used in the present invention is a high-purity antimony electrode with a diameter of 3mm, and its potential is stable in a high-temperature and high-pressure water environment. The counter electrode is plasma sprayed 92% ZrO 2 +8%Y 2 o 3 (mass ratio) 304NG stainless steel electrode with a diameter of 3mm. Spray ZrO 2 +8%Y 2 o 3 The purpose is to reduce the exposed area of 304NG stainless steel, which has achieved the purpose of reducing the polarization of the working electrode. The thickness of the sprayed coating is about 50 μm, and the coating is stable in the high temperature and high pressure water environment, which can meet the test requirements. The manufactured high temperature and high pressure water electrochemical noise detection sensor has a working temperature range of about 160°C to 310°C and a pressure range of 6Mpa to 15Mpa. The two electrodes were put into a 316L stainless steel tube (inner diameter 10mm, outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com