Distillation apparatus tower top system dew point corrosion test method

A dew point corrosion and distillation device technology, which is applied in the field of dew point corrosion test of the tower top system of the distillation device, can solve the problems that the reliability of the data cannot be verified, and the corrosion weight loss experiment cannot be carried out at the same time, so as to achieve high safety, no pollution, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

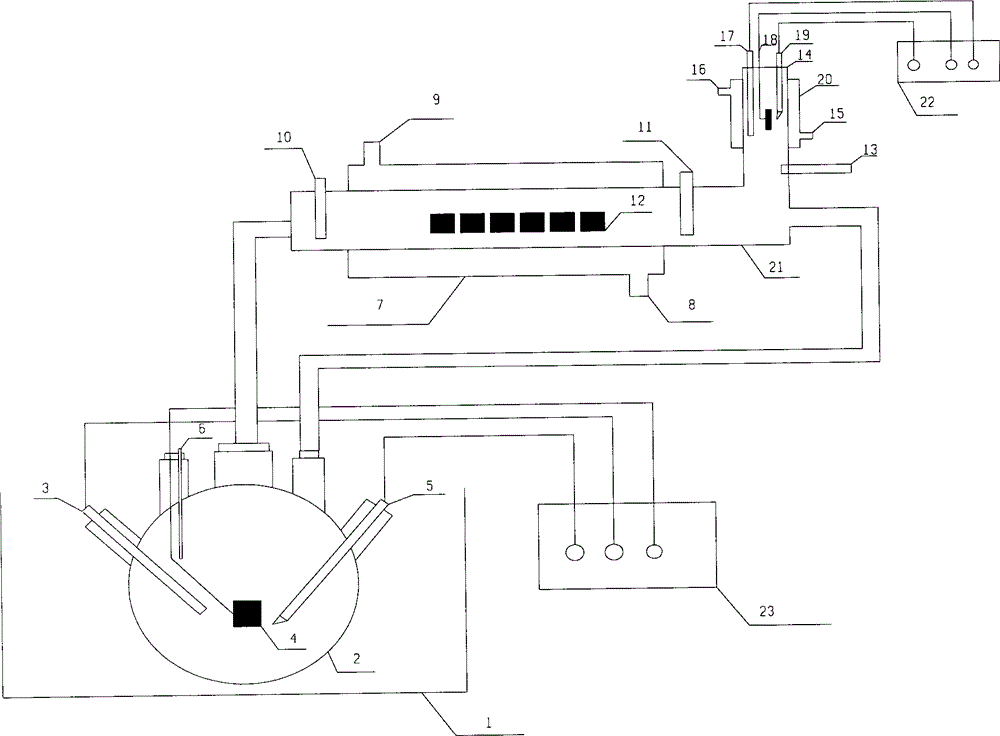

[0027] Such as figure 1 Shown is a test method for dew point corrosion of the overhead system of a distillation unit. The steps are:

[0028](1) Preparation of working electrodes for electrochemical testing: the working electrodes for electrochemical testing, i.e., the first working electrode and the second working electrode, are processed into cylinders with a diameter of 10-12 mm, welded with electrodes, and then welded with rings. Oxygen resin coating, after solidification, metallographic sandpaper is polished step by step to 800~1200#, then polished, degreased with acetone, wiped with anhydrous alcohol cotton ball, blown dry with a hair dryer, and put it in a drying box for later use;

[0029] Preparation of corrosion weight loss coupons: Process the corrosion coupons for the corrosion weight loss test into cuboids of required size, grind them step by step to 800~1200# with sandpaper, then degrease with acetone, and then soak in absolute ethanol for 2~5 Minutes, take it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com