Analysis method for localized corroding based on electrochemistry noise

A technology of electrochemical noise and local corrosion, which is used in electrochemical variables of materials, analytical materials, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

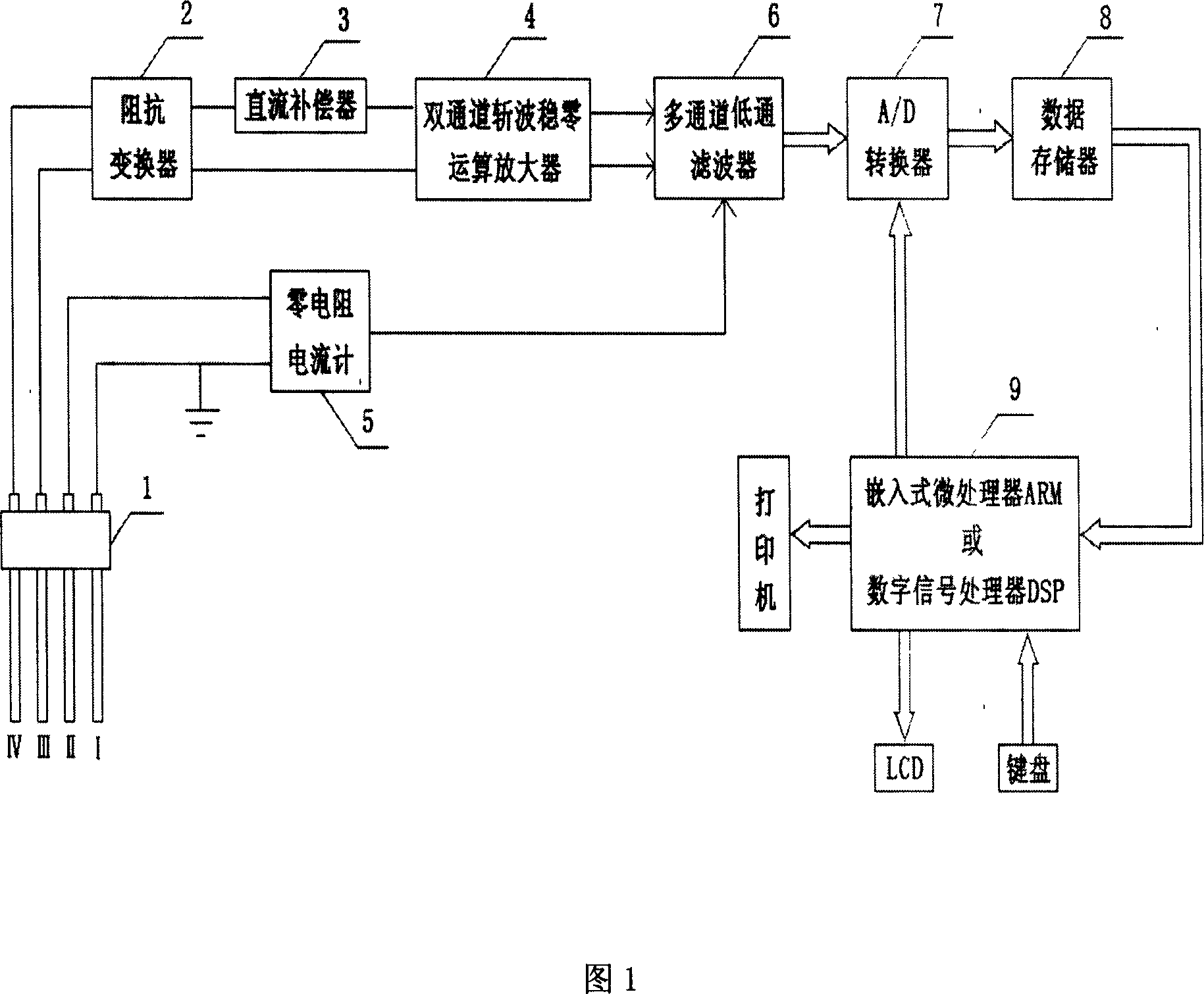

[0037] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples. The schematic diagram of the structure of the localized corrosion evaluation device based on electrochemical noise is shown in Figure 1, four-electrode probe 1, impedance converter 2, DC compensator 3, dual-channel chopper-stabilized zero operational data amplifier 4, zero-resistance ammeter 5 , multi-channel low-pass filter 6 and A / D converter 7 constitute an electrochemical noise monitoring system, and data memory 8 is used to store the original noise data collected, embedded microprocessor (ARM) or digital signal processor (DSP) 9 is the noise data analysis system, which forms a man-machine dialogue system with the keyboard and LCD, and can adjust and correct relevant parameters when necessary.

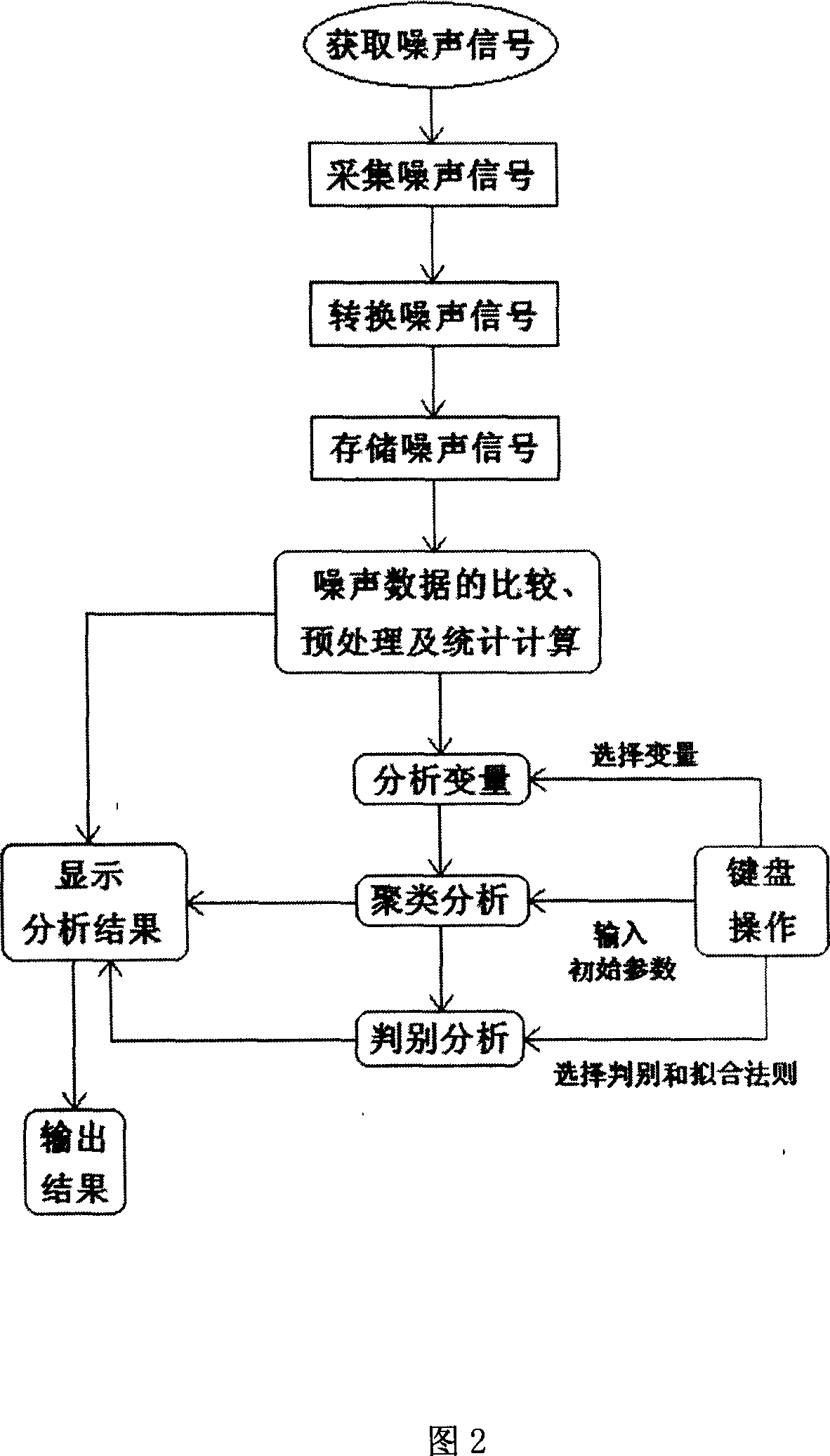

[0038] The analysis method of the present invention will be described below in conjunction with accompanying drawing 2, which is a flow chart of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com