Couple electrochemical noise corrosion monitoring probe

An electrochemical noise and corrosion monitoring technology, applied in the field of electrochemistry, can solve problems such as electrode short circuit and probe failure, and achieve the effect of prolonging life and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

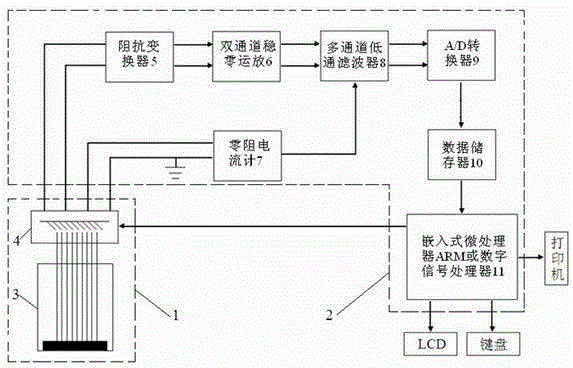

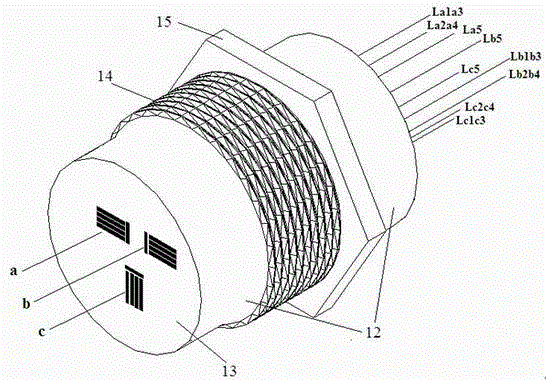

[0021] figure 1 Schematic diagram of the connection between the corrosion monitoring probe (1) for galvanic electrochemical noise and the CST500 galvanic electrochemical noise corrosion monitor (2); the planar multi-electrode galvanic electrochemical noise test assembly (3) and the control switch (4 ) to form a corrosion monitoring probe (1).

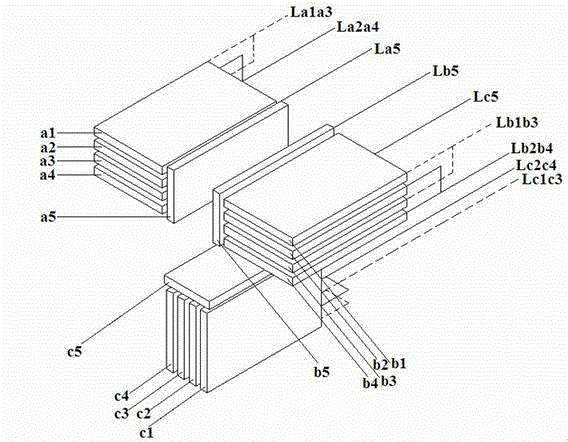

[0022] The probe wall (12) is made of 316L stainless steel with an outer diameter of 18 mm, the electrode piece is made of X52 carbon steel, and polysiloxane resin is filled between the electrode piece and the probe wall. a In the electrode group, the electrode sheets a1, a2, a3 and a4 are stacked at equal intervals, each electrode sheet is 3.0 mm long, 0.5 mm wide, and the distance between adjacent electrode sheets is 0.1 mm. The electrode sheet a5 is 2.3mm long and 0.5mm wide, and it is placed vertically with a1, a2, a3 and a4 with a distance of 0.1mm. The size and placement of the electrode sheets in the b and c electrode groups ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com