Method for detecting local corrosion of material by electrochemical noise technology, noise probe and manufacturing method of the noise probe

A technology of electrochemical noise and technical measurement, applied in the direction of material magnetic variables, etc., can solve problems such as deviation of results, achieve the effect of real data, avoid gaps and internal holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples describe the present invention in more detail.

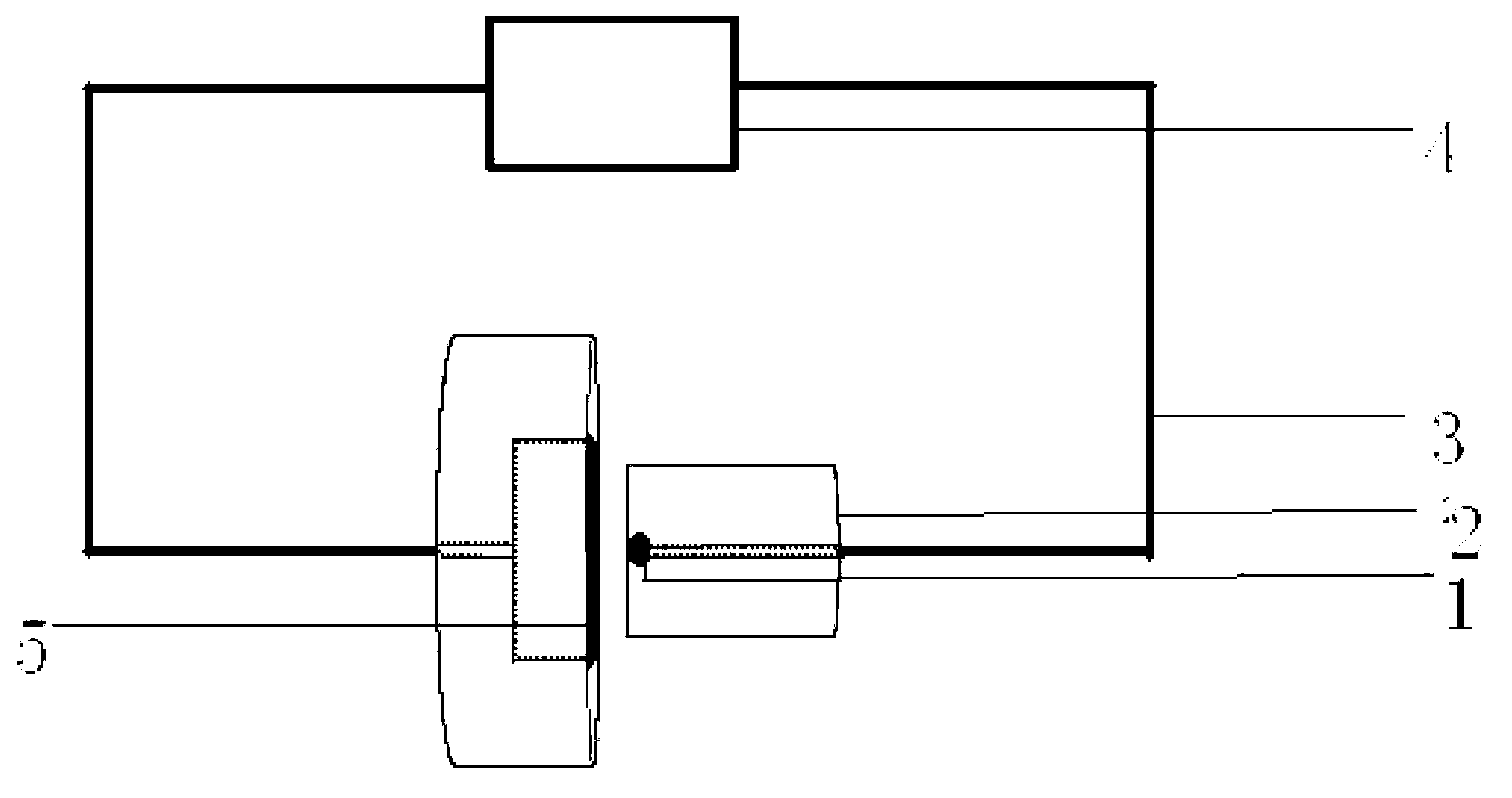

[0027] to combine figure 1 , the method for measuring the localized corrosion of materials using the electrochemical noise technique of the present invention is as follows: the noise probe is arranged at a position 1 mm away from the material to be tested, the material to be tested is used as the working electrode 5, the material to be tested and the noise probe pass through the wire 3 and the electrode The chemical workstation 4 is connected; the noise probe includes a stem 1 identical to the material to be tested and a powder coating sealing layer 2, and the powder coating sealing layer is wrapped around other parts of the stem except the end.

[0028] The shape of the core column can be cube, cuboid or cylinder, and its two-dimensional area is not more than 1.44mm 2 . The thickness of the powder coating sealing layer is not less than 3.6mm.

[0029] The shape of the stem is preferably a cube,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com