Method for detecting anticorrosion performance of 304 stainless steel under high temperature condition

A technology of 304 stainless steel and detection methods, applied in the direction of material electrochemical variables, etc., can solve problems such as difficult production, and achieve the effects of convenient use, good sealing, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

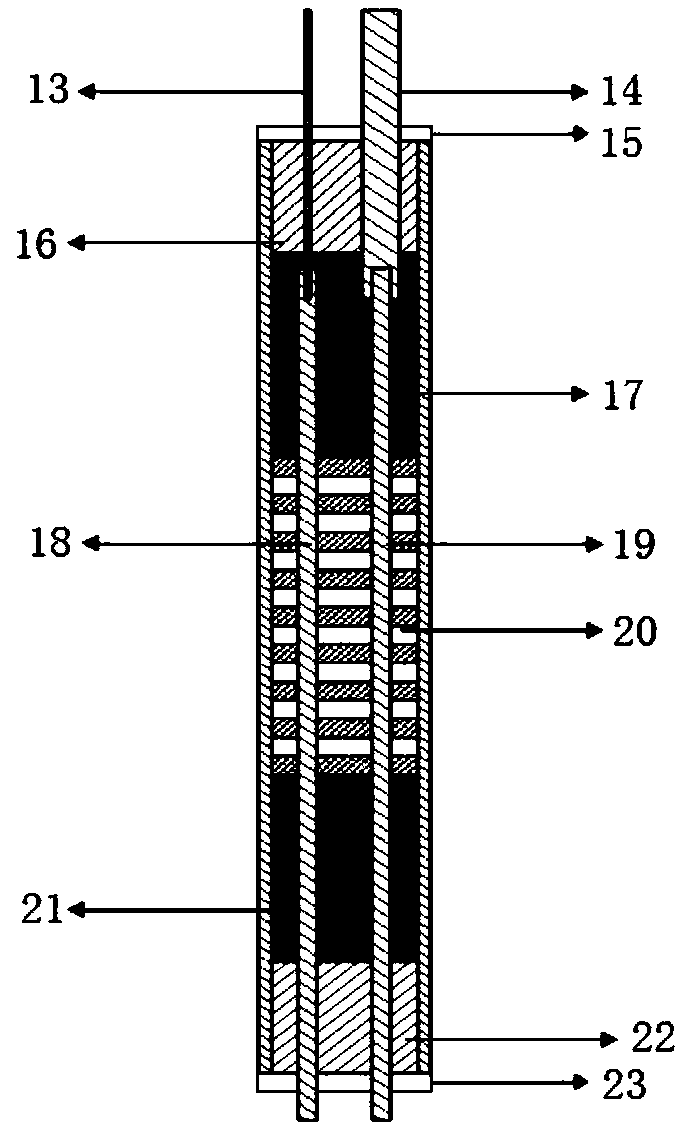

[0043] Reference-the preparation method of counter electrode device, during preparation, ceramic powder selects the Duropot809 series that U.S. Cotronics Company develops, and silver chloride wire and platinum sheet select the product of Tianjin Aida Hengsheng Technology Development Co., Ltd., carry out according to the following steps:

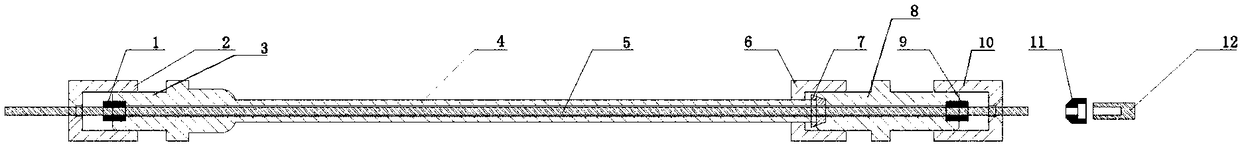

[0044] Step 1: Assemble the working electrode according to the structure of the working electrode device;

[0045]Step 2: Put the reference electrode and its connecting wires and the counter electrode and its connecting wires into the steel pipe to keep them out of contact with each other;

[0046] Step 3: Put 8-15 double-hole ceramic sheets on the reference electrode and the counter electrode, and clamp them on the inner wall of the steel pipe, so that the double-hole ceramic sheets are located in the middle of the steel pipe body;

[0047] Step 4: Mix ceramic powder and water according to the ratio of mass ratio (3-5): 1, pour into the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com