Real-time quantitative prediction method of three-dimensional cellular automaton of reinforced concrete steel bar pitting corrosion

A technology of three-dimensional cell and prediction method, which is applied in the direction of instruments, calculation models, biological models, etc., and can solve problems such as unpredictability and quantitative prediction of pit growth evolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Specifically, the invention adopts real-time wavelet energy spectrum monitoring information of electrochemical noise as a driving force to establish a three-dimensional cellular automaton method for quantitatively predicting the maximum pitting corrosion depth of steel bars.

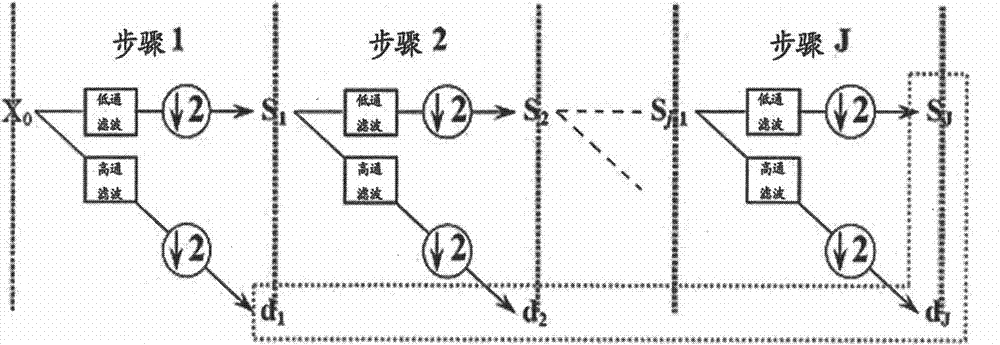

[0049] 1. Wavelet decomposition of EN signal

[0050] EN discrete signal x(kT), k=0, 1, 2,...N undergo binary wavelet decomposition, subspace The energy on can be calculated as follows,

[0051] E j n = Σ k ( d j , k n ) 2 - - - ( 1 )

[0052] E j n = Σ ...

Embodiment 2

[0081] Using Maltab language to write the wavelet energy spectrum algorithm of electrochemical noise, figure 1 The binary decomposition process using Sym4 orthogonal wavelet is given. Among them, the 8th-order decomposition of Sym4 wavelet has been able to accurately characterize the characteristics of electrochemical noise, the low-frequency signal in the 8th-order decomposition is removed as a trend, and the ratio of the signal energy of the 5th-8th order to the total energy in the remaining detail signals is The lysis probability p of M cells d .

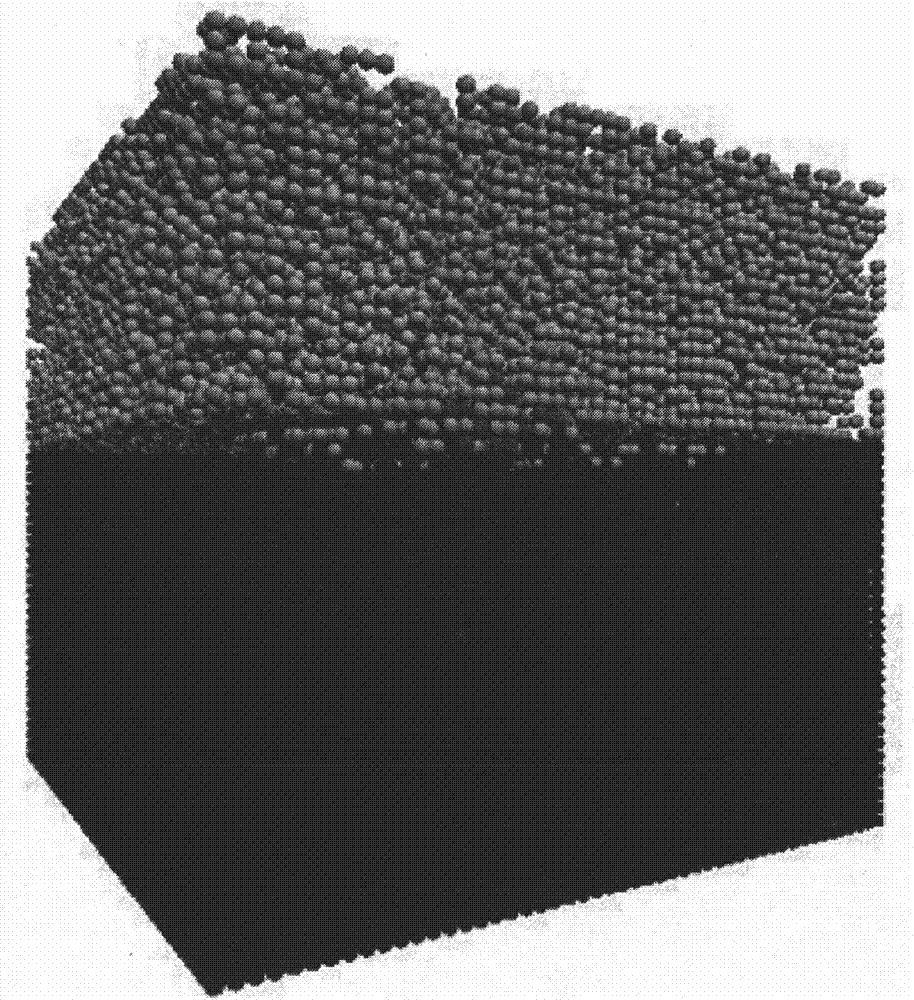

[0082] According to the above-mentioned CA modeling method, the software system of the three-element cellular automata for localized pitting corrosion was written through the Microsoft Visual Studio2008 software system, in which: the dark blue cell represents the unpassivated metal Fe; the green cell represents the acid The cells are occupied by the acidic solution; the brown cells refer to the metal iron after being passivated; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com