Method for preparing high-temperature electrochemical working electrode

A working electrode and electrochemical technology, which is applied in the field of high-temperature working electrodes and the preparation of working electrodes in high-temperature electrochemical systems, can solve the problem of less electrochemical systems and working electrodes, less preparation methods, difficulty in melt processing and forming, hydrophobicity and adhesion of bubbles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

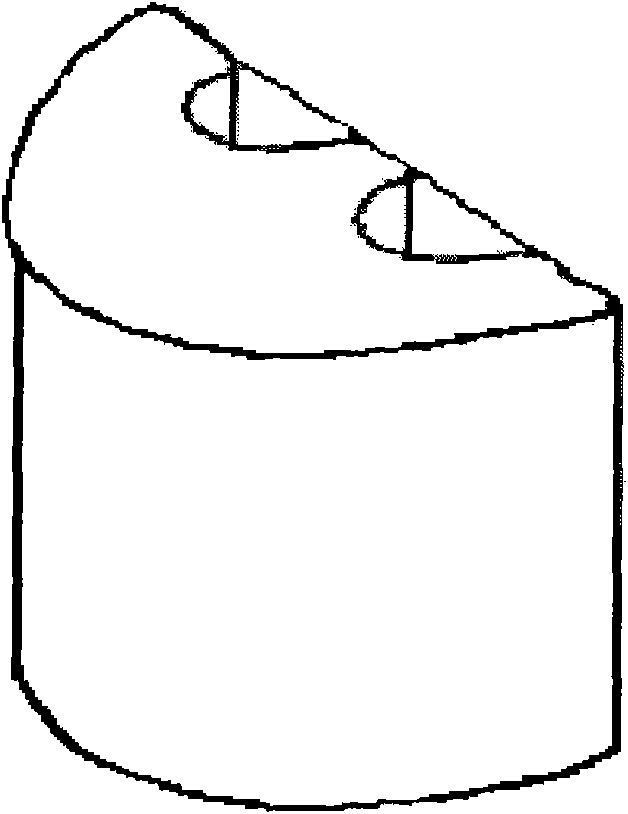

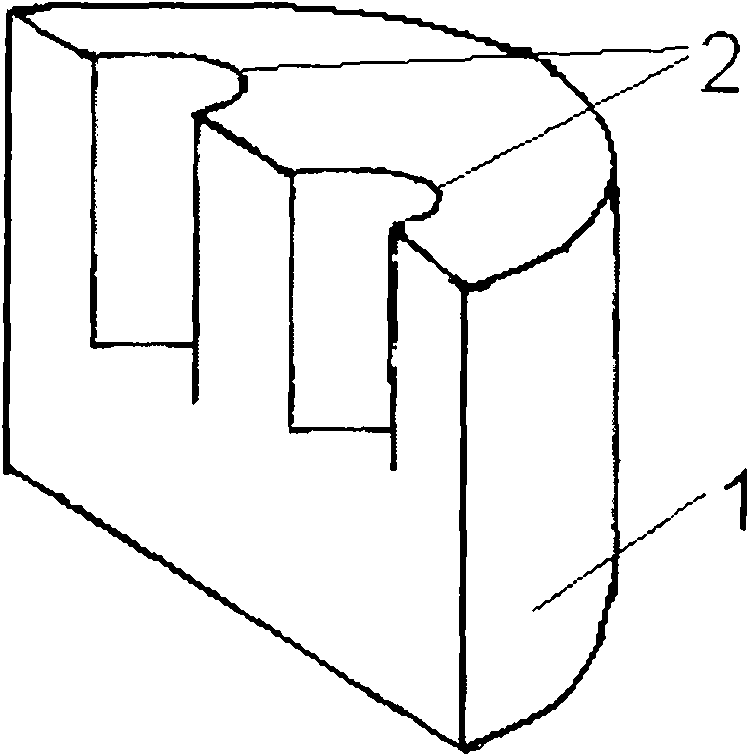

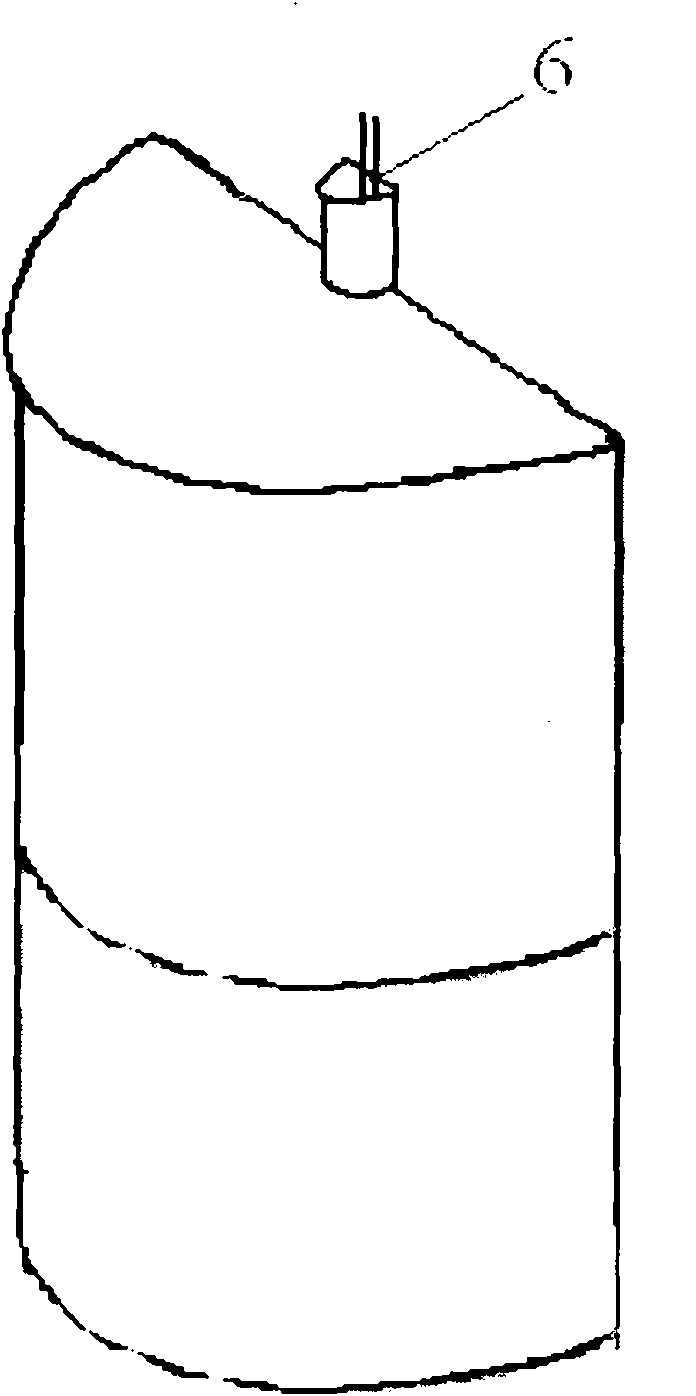

[0020] Select two φ4mm×20mm SUS304 stainless steel columns and connect them with φ1mm constantan wires by spot welding. Choose 20mm×20mm×15mm high-density insulation board as the base material, and fix two welded metal working electrode columns in the middle of the base. Choose a 30mm long φ20mm×2mm PVC pipe to fit on the base from the top of the electrode, and put the PVC pipe into the bottom of the base. Remove the excess base outside the PVC pipe, and wrap the base and the connection between the base and the PVC pipe with aluminum foil to avoid leakage of the filling material. Then pour the evenly mixed Portland cement into the grinding tool, and place it in a constant temperature system at 30°C for 24 hours. Afterwards, the temperature of the system was raised to 180°C to soften the PVC pipe and peel off the electrode body. After the aluminum foil and the base are removed, the surface of the electrode is mechanically ground and polished to obtain a high temperature resis...

Embodiment 2

[0022] Select two φ4mm×20mm carbon steel columns and connect them with φ1mm copper wires by spot welding. Choose 20mm×20mm×15mm high-density insulation board as the base material, fix 2 welded metal working electrode columns on the base and put a 30mm long φ20mm×2mm PVC pipe on the base from the top of the electrode. Use aluminum foil to wrap the base and the connection between the base and the PVC pipe to avoid leakage of filling materials. Then pour the evenly mixed Portland cement into the grinding tool, and place it in a constant temperature system at 30°C for 24 hours. Afterwards, the temperature of the system was raised to 180°C to soften the PVC pipe and peel off the electrode body. After the aluminum foil and the base are removed, the surface of the electrode is mechanically ground and polished to obtain a high temperature resistant carbon steel double working electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com