Automatic arranging conveying system facilitating product stacking or packing

An automatic arrangement and conveying system technology, applied in the direction of packaging, conveyor objects, transportation and packaging, etc., can solve the problems of prone to leaking products or multiple products, high labor intensity of workers, high labor cost, etc., and achieve general efficiency and low labor cost High, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

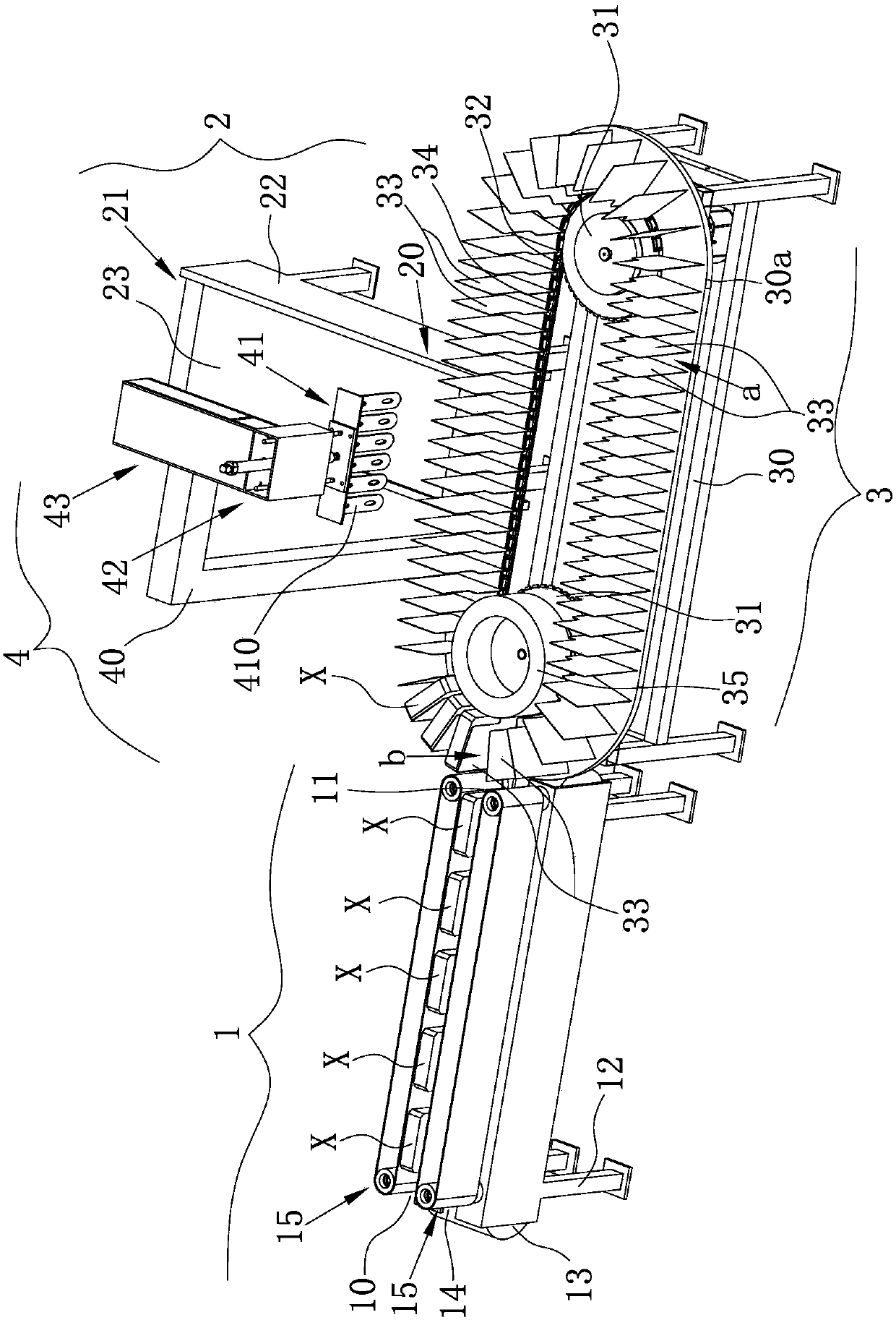

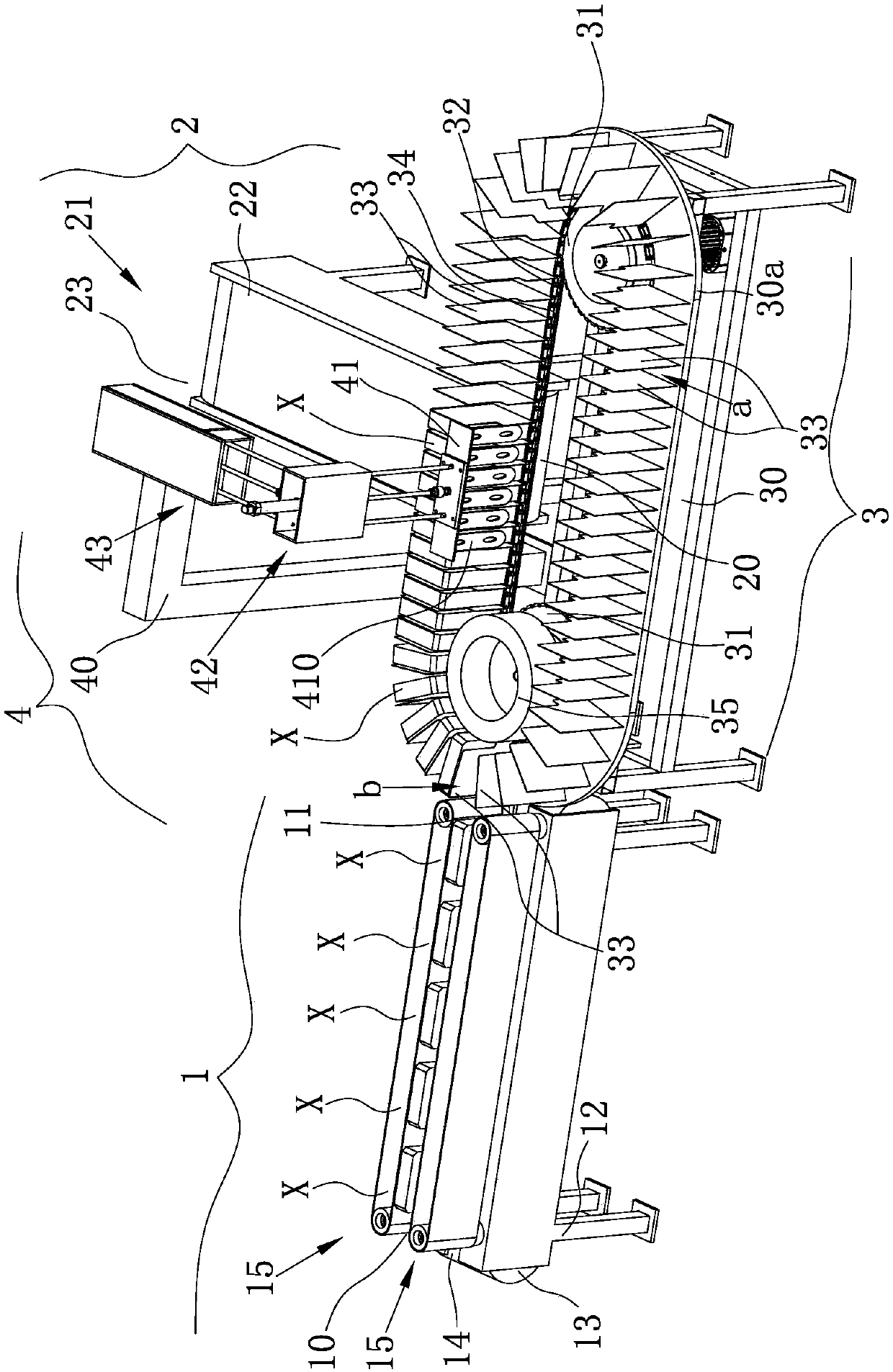

[0032] see figure 1 and figure 2 As shown, this embodiment provides an automatic arrangement and conveying system that is convenient for product stacking or packaging, which includes a feeding conveying unit 1 , a discharging conveying unit 2 , a connecting unit 3 , and a mechanical retrieving unit 4 .

[0033] The material feeding conveying unit 1 has a material inlet 10 and a material outlet 11, and the products are located between the material inlet 10 and the material outlet 11 at intervals, and the products are passed out from the material outlet 11 one by one.

[0034] Specifically, the feed conveying unit 1 includes a material rack 12, a conveying roller 13 positioned on the material rack 12 and the axis line is horizontally arranged, an endless conveyor belt 14, and a material inlet 10 and a material outlet 11 formed above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com