Device for measuring corrosion products film dynamic performance

A technology for corrosion products and properties, applied in the field of measuring devices for in-situ measurement of corrosion product film fracture strain and fracture stress

Inactive Publication Date: 2008-10-15

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem that the in-situ measurement of the mechanical properties of the corrosion product film in the actual corrosion environment cannot be carried out in the past, and to provide a measuring device for in-situ measurement of the mechanical properties of the corrosion product film by using the electrochemical noise method, which is used for measuring high-temperature and high-pressure media The fracture stress and fracture strain of the corrosion product film formed under the condition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

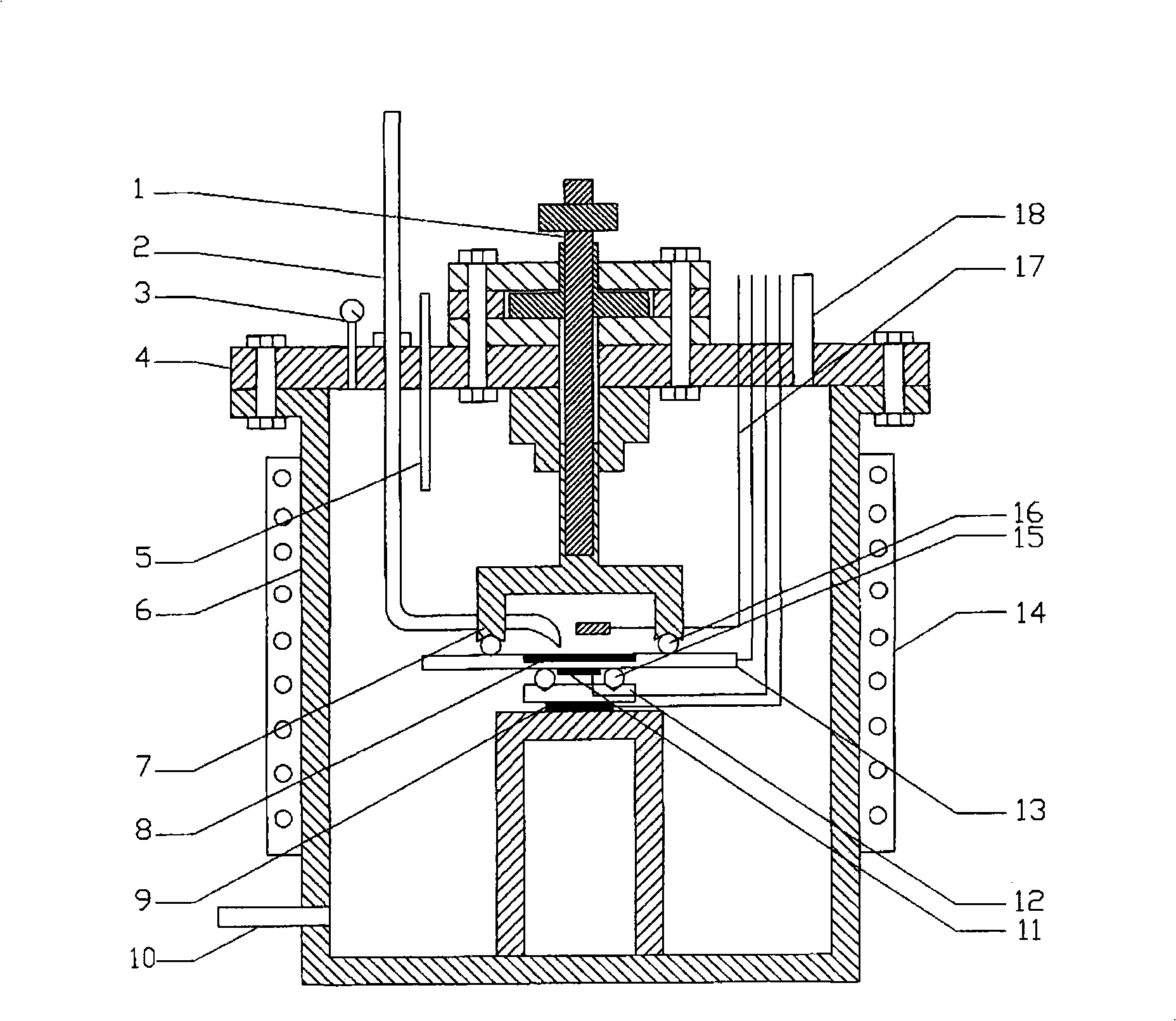

The invention provides a device using the electrochemical noise method to measure mechanical property of a corrosion product film in situ, belonging to the corrosion product film measurement field. The device simulates corrosion of a sample in high-temperature high-pressure CO2 environment through a four-point bending loading and load mechanism and a high temperature high pressure autoclave, and records deformation and received load of the sample when a signal changes suddenly through an electrochemical noise signal of the corrosion product film under an external force, which is generated when an electrode system measures the sample, thereby realizing in situ measurement of the mechanical property of a corrosion product in the high-temperature high-pressure CO2 corrosion environment, solving the problem that the measurement of the mechanical property of the corrosion product film can not be performed in the corrosion environment. The device also can obtain corresponding relations between environmental parameters and the mechanical property of the corrosion product film formed at different medium temperatures, gas pressures, periods and other environmental parameters.

Description

Device for measuring mechanical properties of corrosion product film Technical field The invention belongs to the measurement of corrosion product film, and particularly provides a measuring device for in-situ measurement of the fracture strain and fracture stress of the corrosion product film using the electrochemical noise method, and is particularly suitable for the fracture of the CO2 corrosion product film formed by steel under high temperature and high pressure. In-situ measurement of stress and fracture strain. Background technique During oil and natural gas collection and transportation, steel pipelines are exposed to high temperature and high pressure CO2 corrosive multiphase media environment. After the CO2 corrosion of steel in a high temperature and high pressure environment, a corrosion product film will be formed on the surface. The local damage of the corrosion product film under the action of external force leads to the occurrence of local corrosion of the steel....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/00

Inventor 柳伟路民旭孙建波张伟

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com